Aiming for factor4 of molding factories

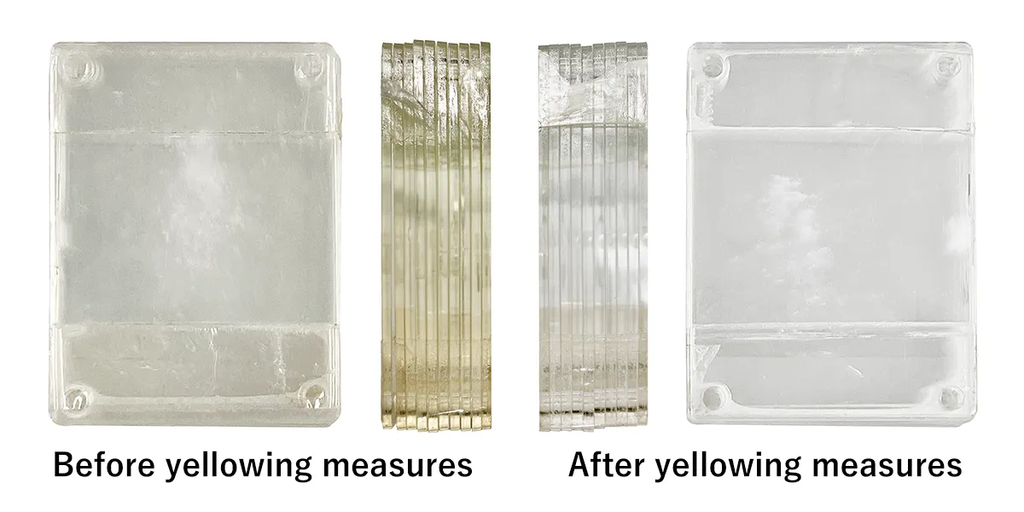

How to prevent yellowing of plastic molded products.

2022.12.26

What is yellowing of plastic molded products?

Yellowing of plastics literally means that plastic moldings turn yellow.

Have you ever seen plastic covers such as car headlights and smartphone cases yellowing over time? This yellowing is a familiar example of yellowing.

By what mechanism does this yellowing occur?

First, plastic undergoes changes in its molecular structure under the influence of heat, oxygen, moisture, and ultraviolet rays, resulting in changes in material properties and discoloration. This is called "degradation of plastic", and the degradation caused by heat and oxygen is called "thermal degradation".

When plastic molecules are affected by heat due to thermal degradation, they react with oxygen in the air to form peroxides, and chromophores (molecular structures that cause discoloration) are produced in this reaction. This causes discoloration such as yellowing to the plastic.

Heat and oxygen, which cause yellowing, are present everywhere around us. In other words, all plastic products can be affected by thermal degradation, and yellowing has become an inseparable issue with plastic molding.

Why does yellowing occur during the molding process?

Yellowing is also a phenomenon that can occur in the molding process.

Antioxidants are usually added to plastic materials to prevent deterioration due to high temperatures during molding. However, since antioxidants cannot completely prevent discoloration, transparent precision molded products (lenses, etc.) that have strict discoloration criteria may be considered defective in some cases.

In addition, the risk of yellowing increases depending on the environment during drying. Excessive drying, such as drying the material at too high a temperature or for too long, can cause yellowing.

How to prevent plastic from yellowing?

Now, let's take a look at some effective yellowing solutions from drying to just before molding.

Achieving proper drying

In molding factory, molding machines and dryers are always in operation, and it is very difficult and time-consuming to manually manage and control the drying conditions of all materials.

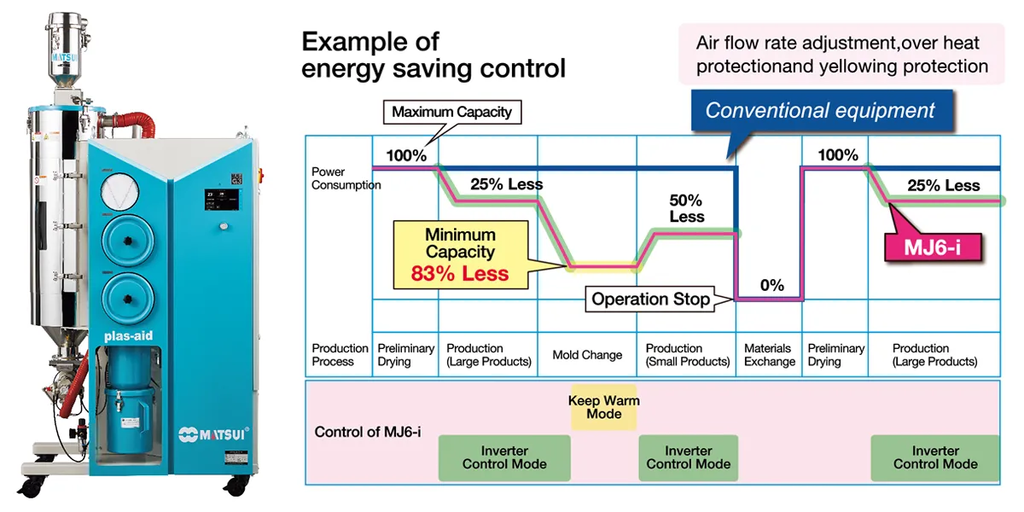

With the MJ6-i Dehumidifying dryer equipped with the iplas function, Drying air flow rate is controlled to the optimum state according to the amount of resin used in the molding machine, so proper drying in Automatic operation is possible, leading to energy saving. increase.

By supplying resin raw materials in the optimum dry state to the molding machine, we can expect the effect of preventing yellowing of molded products.

Keep the drying temperature low

Thermal degradation of resin raw materials progresses faster the longer they are exposed to high temperatures. In that respect, it is good to be able to dry the resin in a short time without raising the temperature as much as possible.

Since the boiling point of water is lowered in a vacuum, water can be evaporated at low temperatures.

Vacuum heat transfer drying DPD3.1 was developed based on this idea. This vacuum heat transfer method dries the resin at a low temperature, suppressing the effects of heat and preventing yellowing of the molded product.

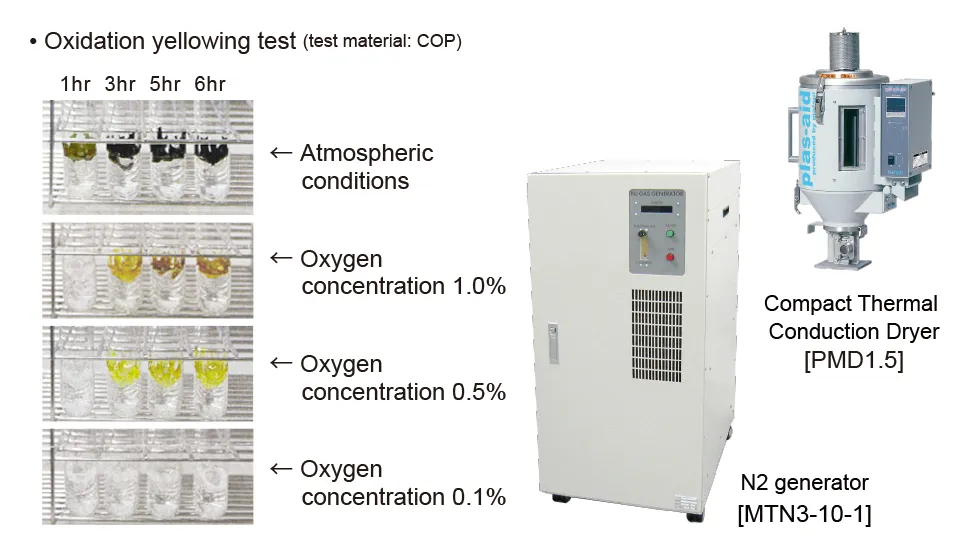

Reduce oxygen (nitrogen replacement)

Thermal degradation of resin is caused not only by heat, but also by the interaction of heat and oxygen in the air.

Nitrogen dryers are effective for this purpose. In this dryer, oxygen (O2) in the drying environment and resin is replaced with nitrogen (N2) to prevent oxidation of the resin during drying.

There is also a method of using a small Thermal Conduction Dryer and a nitrogen generator together. A small dryer is installed on the molding machine, and by directly injecting nitrogen into the interior immediately before molding, oxygen is blocked, preventing the resin molecules from reacting with oxygen and suppressing yellowing of the molded product.

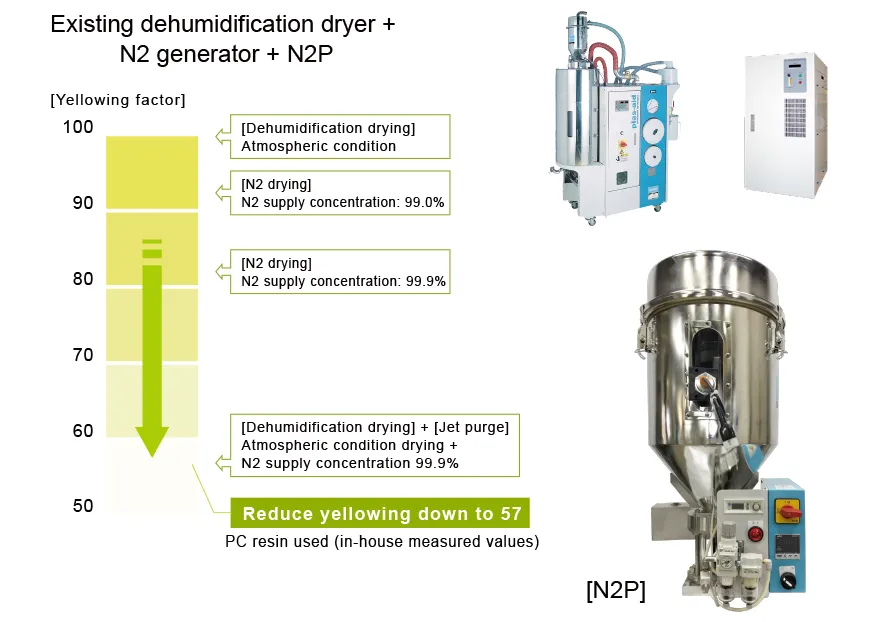

Utilize existing equipment to dry with nitrogen displacement

I think that there are many molding factory who have problems such as "Even if they want to introduce a new dryer, it is costly, the existing machine is wasted, and there is no place to put it." In such cases, it is possible to introduce a nitrogen Feeder can be used in combination with the existing Dehumidifying Dryer and an N2P collector that can be installed on the molding machine. Temperature-controlled high-concentration nitrogen is supplied at the material Loading port on the molding machine to prevent temperature changes and oxidation of the resin. This makes it possible to suppress yellowing of molded products.

Summary

In order to prevent yellowing of plastic molded products, it is important to know the mechanism of thermal degradation and oxidation and to take appropriate approaches. In this column, we introduced proper drying of resin raw materials, which is the entrance to molding. Supplying the resin to the molding machine in an appropriate dry state is effective not only for yellowing, but also for preventing molding defects such as black spots and burns.

The key to solving the problem is to implement countermeasures that match the type of resin raw material, the level of quality required for the molded product, and the conditions of each molding factory. MATSUI offers various solutions. Please feel free to contact us.

CX Design Department Yasuhiko Iijima