Features of ecobrid

1. Energy saving

By optimizing the operation of the system, no wasted energy is consumed.

Uses an aluminum die-cast axial flow fan Drive by a DC brushless motor. Compared to conventional cooling devices, the average Power consumption has been reduced by more than 30%. Since it is an aluminum fan, it has excellent durability and does not require maintenance. In addition, the noise during operation has been suppressed to 57 dB or less.

2. Maintenance

When the outside temperature rises above 30 degrees Celsius, in addition to the full-speed operation of the cooling fan, external water is sprayed onto the adiabatic chamber to cool the passing air. Therefore, water does not come into contact with the heat Replacement. If the outside temperature drops below 0 degrees Celsius and there is a possibility of freezing, the water inside the device will be automatically collected without using a valve to prevent freezing and cracking. No need to add antifreeze Medium such as ethylene glycol. You can use it with confidence even on lines where ethylene glycol cannot be used.

3. Safety

Equipped with the latest microprocessor. It is possible to constantly monitor the operating status of the device with a backlit Indication. When a trouble occurs, the cause of the problem and the remedy are Indication as an alarm message. Smooth response is possible. In addition, since the temperature and pressure sensors required for data collection are connected, it is possible to manage the production line.

4. Unitization of components

Unit components such as control panel, tank, and valve are integrated. Realized space saving. Since the components are integrated, on-site construction can be done quickly. In addition, the pump unit and cooling water tank are made of stainless steel, so they have excellent durability.

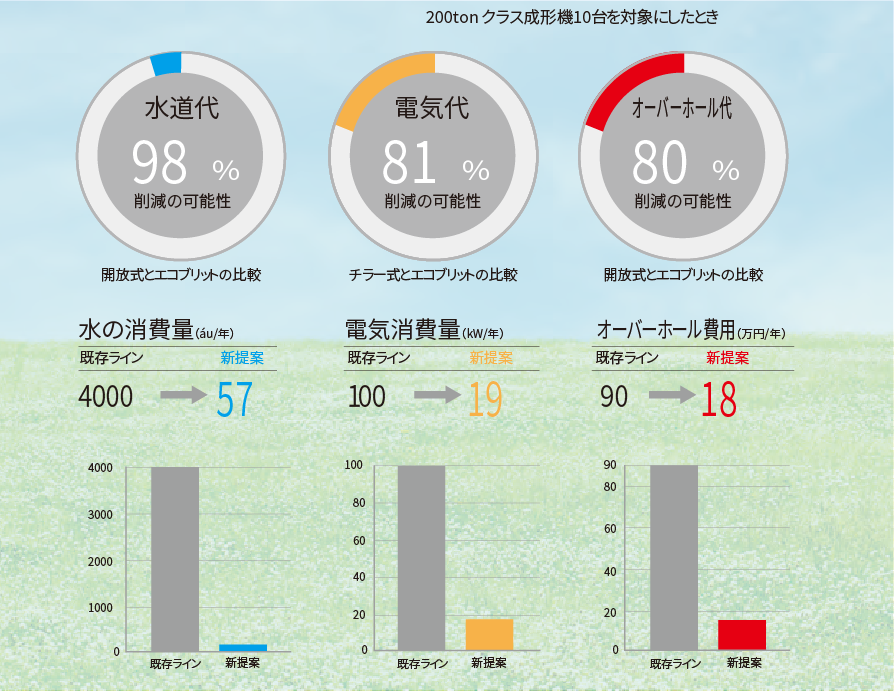

ecobrid also leads to cost reduction.

Compared to open and Closed cooling towers, ecobrid has a water saving rate of about 95%, a power saving rate of about 25%, no scale, algae, bacteria, etc., and there is almost no need for long-term maintenance. .. The investment can be recovered in 1 to 3 years.