Features

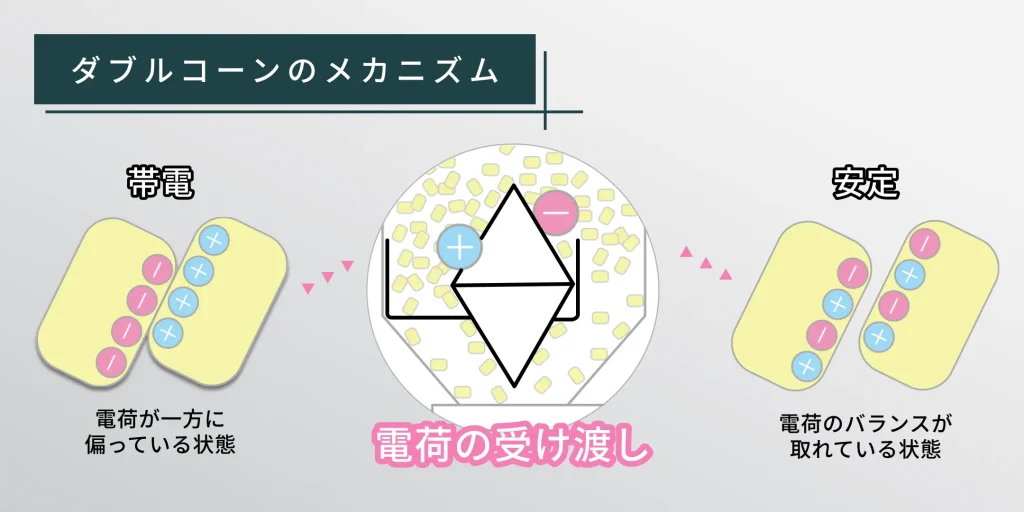

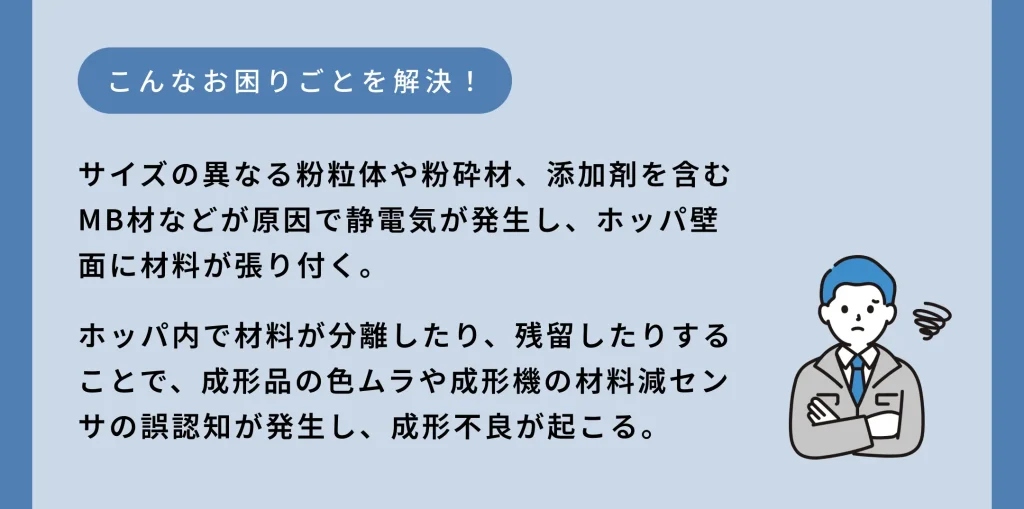

1. Reduces collisions and peeling between resins, reducing static electricity generation!

Static electricity occurs when two substances collide, transferring charges and separating them into one with more positive and one with more negative charges. By installing a double cone, not only are collisions and separation between resins reduced, but when charged resin comes into contact with the double cone, the charge is transferred and the resin becomes stable. This makes it possible to suppress the generation of static electricity, increase the fluidity of the resin in the hopper, and achieve smooth material supply.

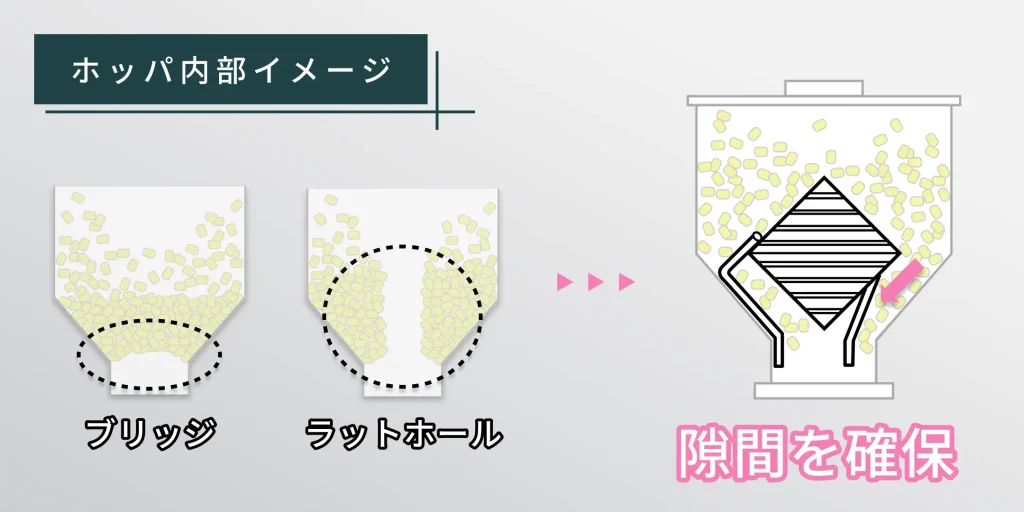

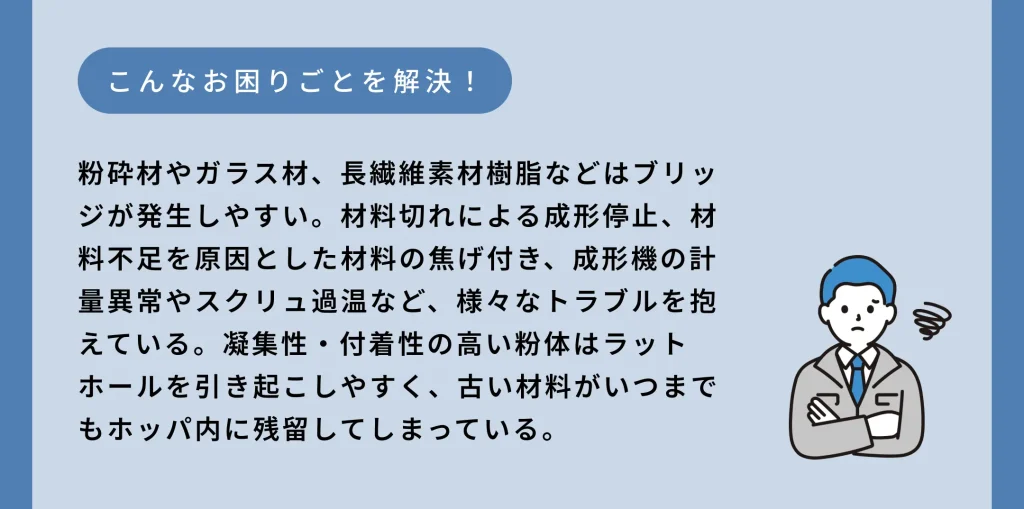

2. Bridge occurrence is suppressed, and short path control and first-in, first-out resin are possible!

By securing a gap between the cone and the hopper wall with a conductive support member, the cone promotes mass flow and discharges materials uniformly while preventing bridging. Since it is fixed with a support member, it can be easily installed without welding work.

3. The magnetic type provides two benefits: anti-static measures and measures against metal powder!

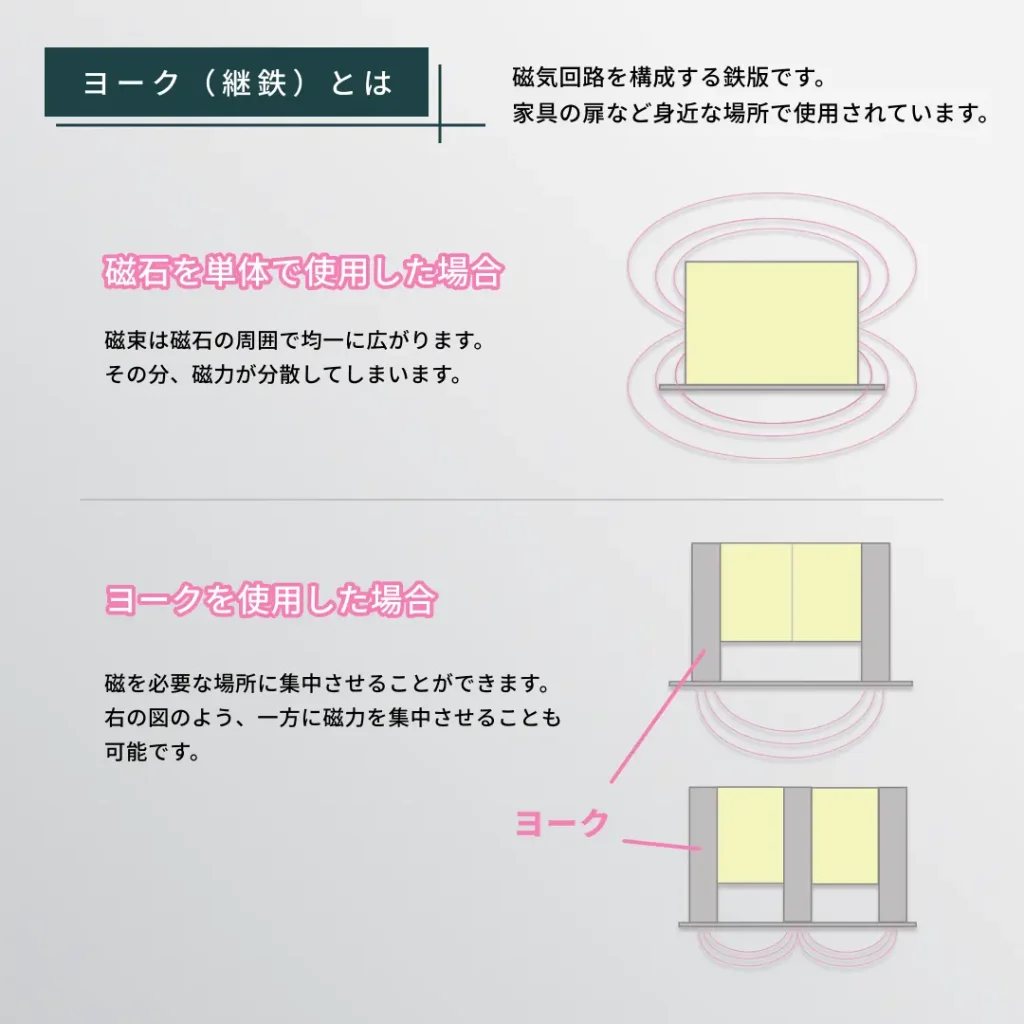

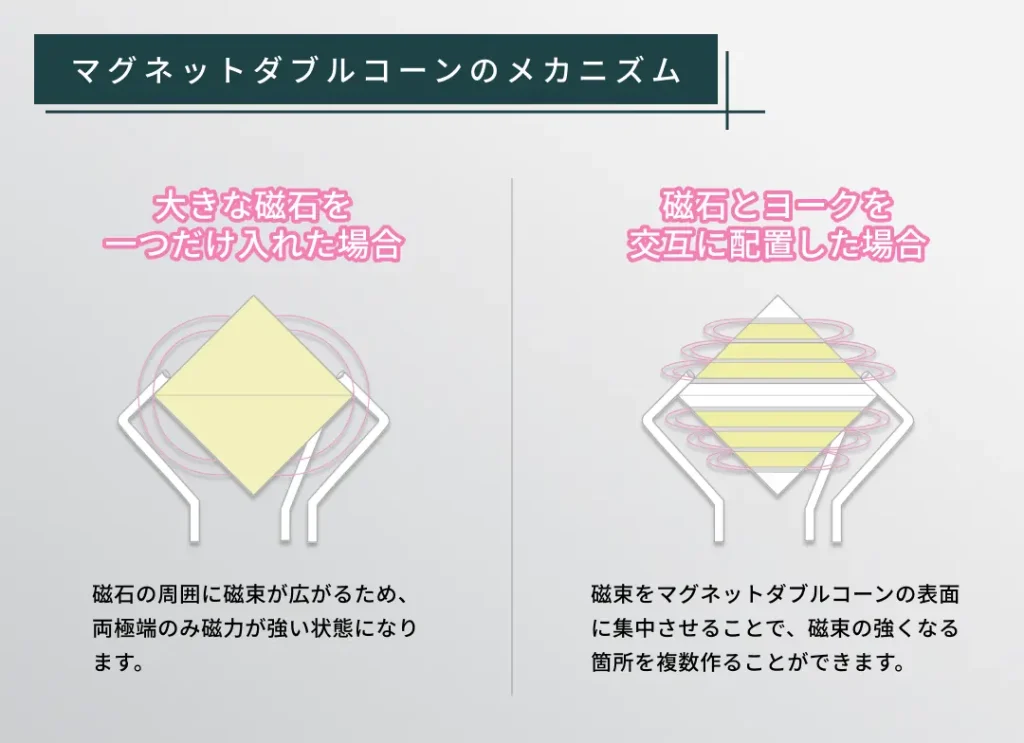

The double magnetic cone contains a magnet and a yoke, with two cone-shaped cones assembled on the top and bottom. The structure of placing a magnet inside the double cone is our proprietary patented technology. By arranging the magnets and yokes alternately, the surface magnetic force of the double cone is strengthened, improving the effectiveness of removing ferrous metal powder. In addition, because it is fixed inside the hopper by a support member, it can be easily removed and the metal powder cleaned off.

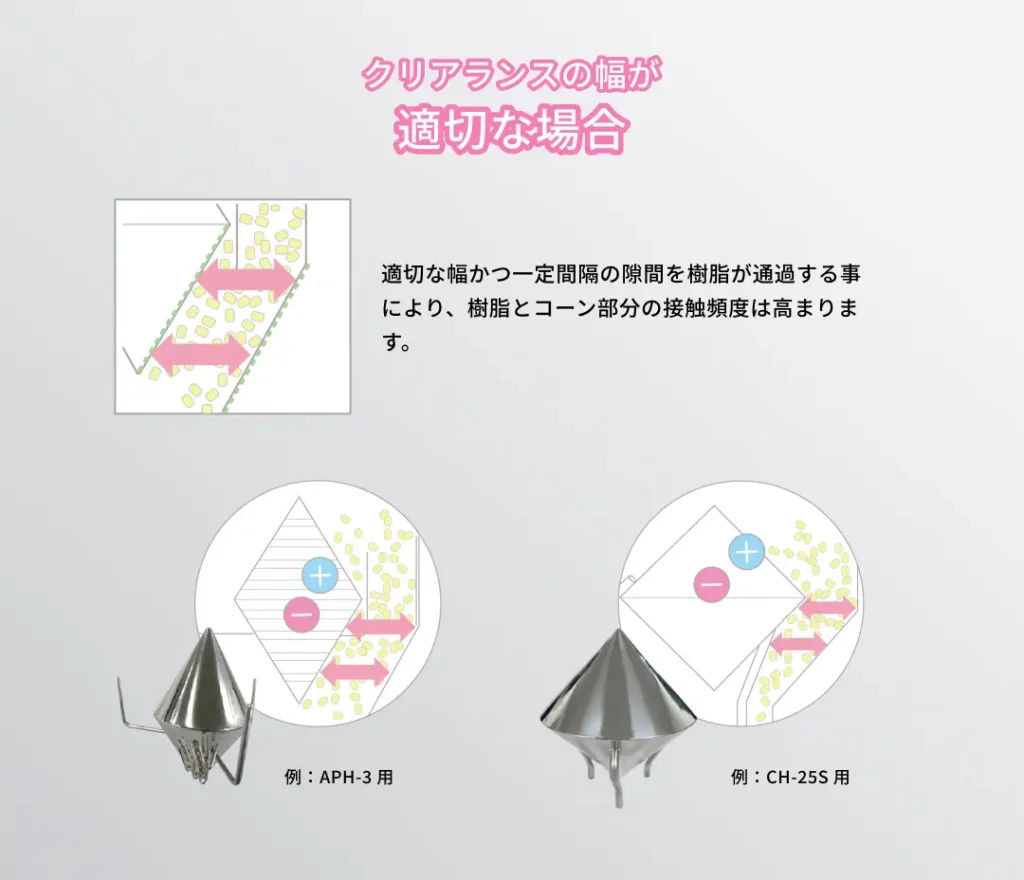

4. Cone shapes are available to suit each hopper diameter!

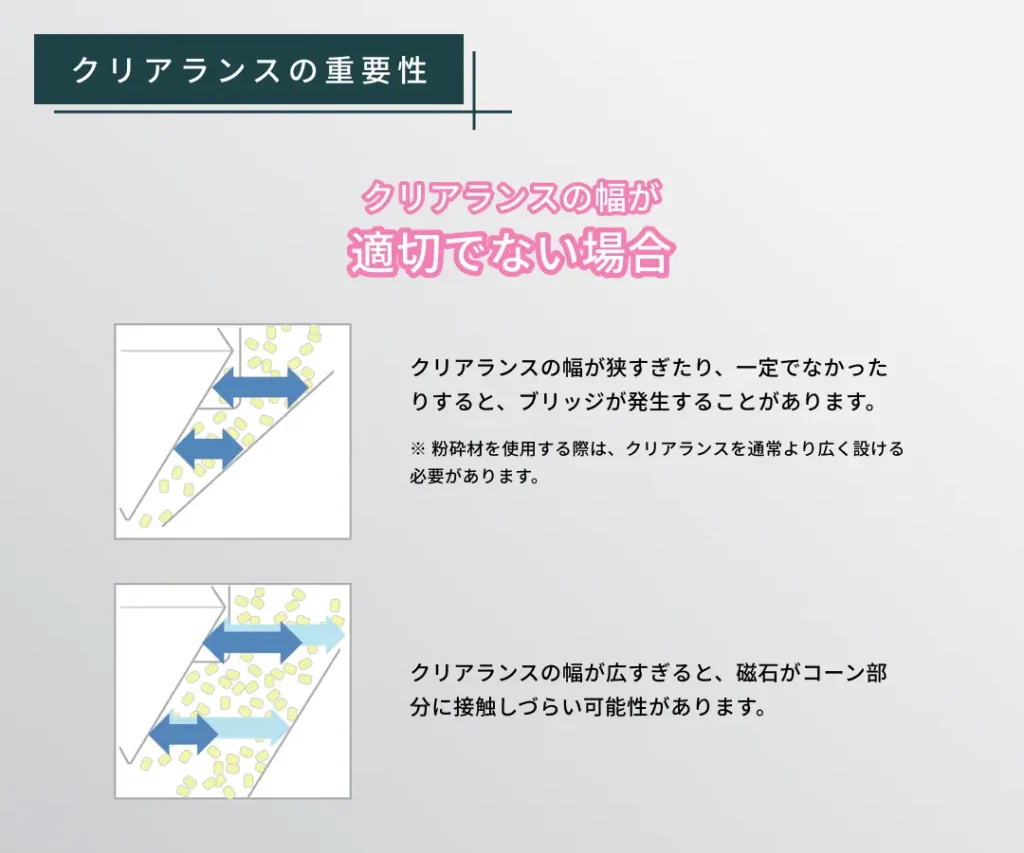

We have multiple double cones of different shapes. There are many different shapes of hoppers. If the clearance (gap) between the cone and the hopper wall is not set to an appropriate width, the effect of preventing bridging and static electricity and removing ferrous metal powder will be reduced. By using a cone that matches the hopper diameter, mass flow will be promoted and the frequency of contact between the resin and the cone will increase, which is expected to have a high effect on reducing static electricity and removing ferrous metal powder.

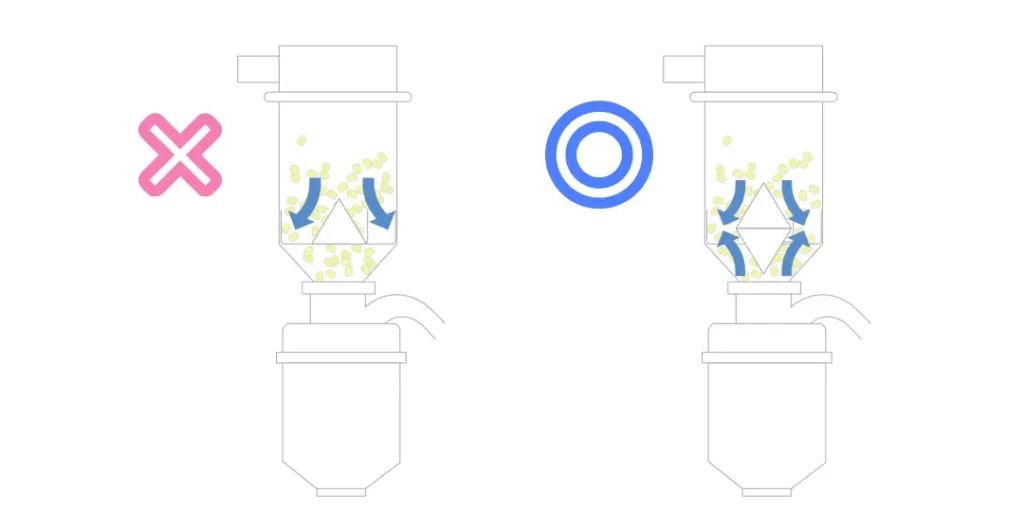

5. It is effective for products where the resin flows inside the hopper!

When the cone is shaped like Screen cone, resin falling from above will come into contact with the cone, but resin flowing from below will come into contact with the cone less frequently. However, our double cone combines two cone-shaped cones on the top and bottom, making it possible for the flowing resin to come into contact with the cone from above and below. Therefore, the installation of a double cone has great benefits, especially for products where the resin flows inside the hopper, such as our APH.

Introducing how to use the Double Cone Series x APH!

1. Combine the Double Cone Series for even greater effectiveness!

Top row: Double cone

Bottom: Double magnet cone

Using a double cone and a magnetic double cone in each of the upper and lower hoppers, and bridging and reducing static electricity in each hopper, is highly effective. Also, installing a magnetic double cone on one side can also be used to remove ferrous metal powder. Of course, it is possible to install magnetic cones on both the top and bottom, but if you do install a magnetic cone on one side, it is more effective to install it on the lower hopper, which is closer to the molding machine.

2. The magnetic separator can be replaced with a magnetic double cone!

Bottom: Magnetic separator ➡ Magnetic double cone

The double cone magnet is manufactured with the same surface magnetic flux density of 0.3T (=3,000G) as the magnetic separator, and has the same magnetic force. Therefore, it can be safely used as a measure to remove ferrous metal powder. It also has the effect of reducing static electricity, so it can solve multiple problems at once.

3. Double cone and magnetic separator can also be combined.

Top row: Double cone

Bottom: Magnetic separator

The magnetic force of the double cone magnet and the magnetic separator are the same, but the equipment shapes are different. Therefore, it is necessary to select the equipment that suits the facility environment, the resin used, and the customer's problem. If the use of a magnetic separator is desired, we recommend using it in combination with a double cone. Please feel free to contact us for details.

背景なし.png)