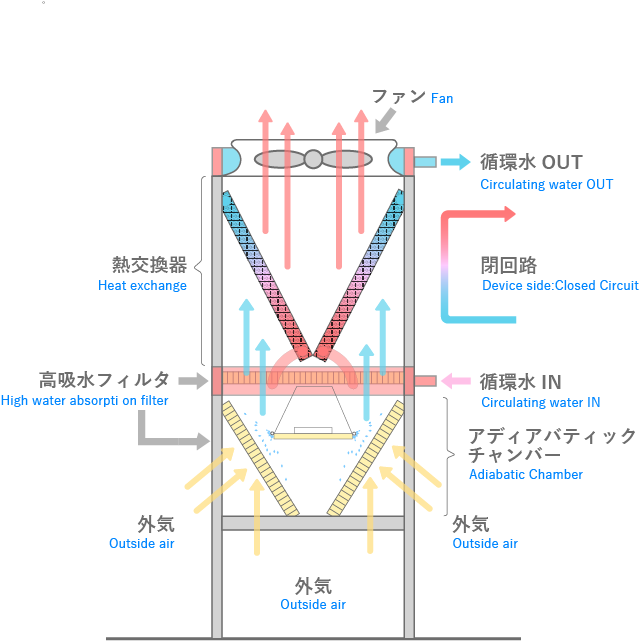

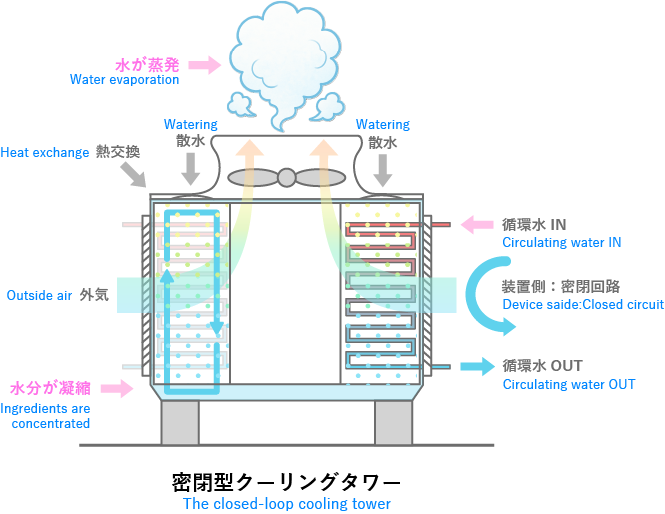

How ecobrid works

The ecobrid dry cooler is a next-generation closed-loop air-cooled cooling tower that eliminates water evaporation and component condensation.

With its low water consumption, it offers water-saving benefits, as well as effective maintenance of the circulating water quality.

ecobrid cooling method

STEP 1

Outside air passes through a heat exchanger and is cooled.

STEP 2

Cooling is achieved by varying the amount of outside air passing through using the cooling fan (0 to 100%).

STEP 3

Water is sprayed into the Adia butting chamber to cool the air passing through it.

💡No watering of the heat exchanger!

💡No water consumption except in summer!

Features

1. Leverages the advantages of a closed-loop air-cooling system to solve all the challenges of conventional primary cooling water systems

💡There is no evaporation or scattering of circulating water, so minimal water is sufficient◎

Unlike traditional cooling towers, ecobrid eliminates concerns about water evaporation or dispersion.

While it does require water for spraying into the adiabatic chamber, this is only necessary when outdoor temperatures exceed 30°C during the summer. This allows for efficient heat exchange with minimal water costs.

*For more details on water-saving benefits, please refer to the "Water Saving Effect Simulation" below.

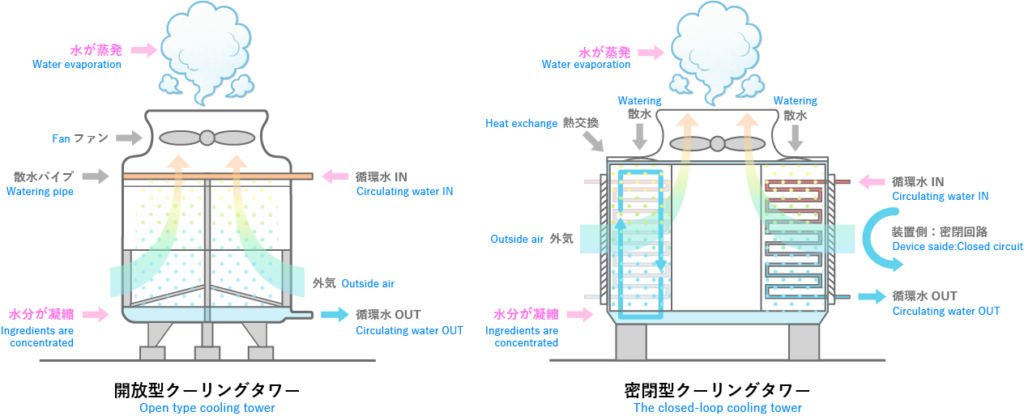

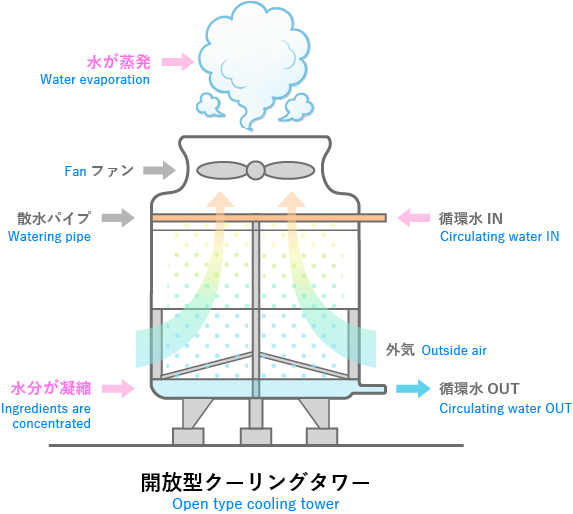

The image below shows the structure of a conventional cooling tower.

*The size ratio of the image shown may differ from the actual product.

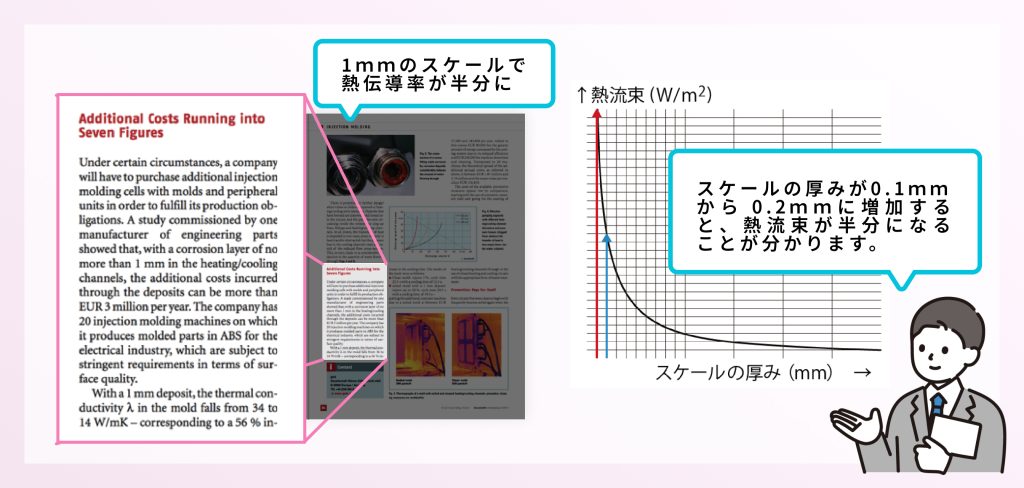

💡No concentration of water means no scale risk

When water evaporates, it becomes concentrated, and minerals such as calcium and magnesium solidify, leading to the formation of scale. This scale can clog pipes, hindering heat exchange and making it difficult to maintain proper cooling and temperature control. Such heat exchange issues can lead to variations in mold temperature, causing molding defects such as warping and deformation, increased cooling times, as well as maintenance and downtime due to equipment malfunctions.

Ecobrid is an air-cooled sealed type, so there is no water concentration and the risk of scaling is reduced, resulting in improved productivity and reduced costs.

💡With closed-loop air cooling, no need for traditional water quality management or maintenance

Thanks to the closed-loop air cooling system, ecobrid eliminates the need for typical water quality management, blowdowns, and maintenance related to scale buildup on cooling towers. Additionally, there is no need for chemicals, so there’s no concern about handling or disposal.

Since ecobrid requires minimal maintenance and no time-consuming management, it enables significant cost reductions, including maintenance costs.

💡No risk of bacteria spreading from the fan, ensuring excellent consideration for human health and the environment

Legionella is a bacterium that is widely distributed in natural environments such as soil and rivers in the temperature range of 20℃ to 50℃.

A typical cooling tower provides a habitat for bacteria, so there is a risk that bacteria may grow if splashed from the fan via water droplets.

The ecobrid is sealed and does not scatter, so there is no impact on the human body or the environment due to the spread of bacteria.

In 1999, Legionnaires' disease was designated as a Class 4 infectious disease. If a doctor diagnoses a person with Legionnaires' disease, a notification must be submitted.

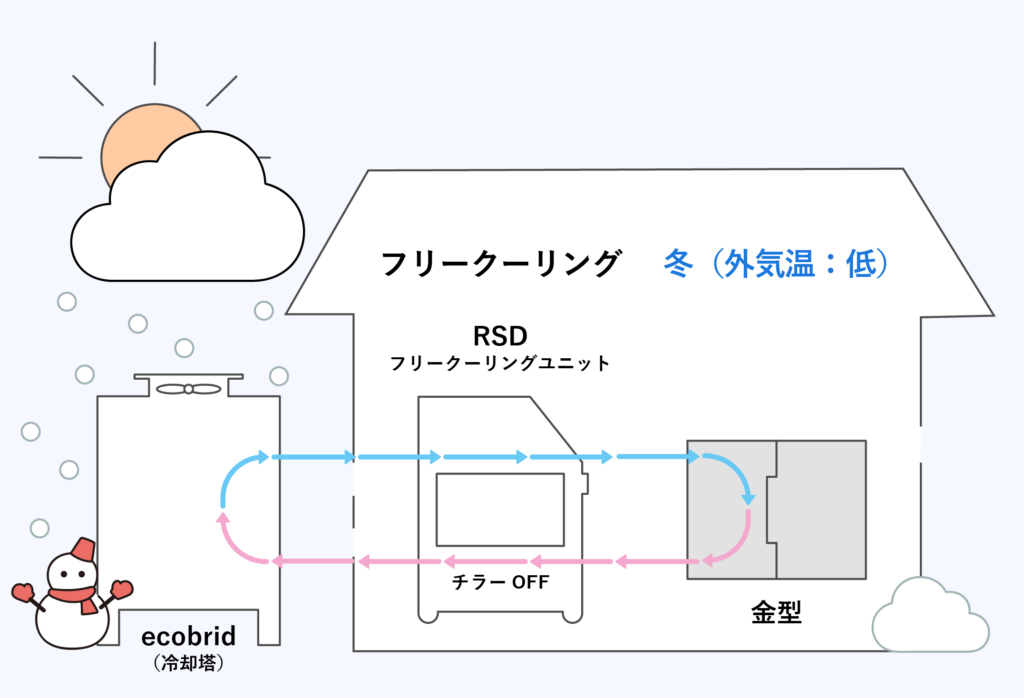

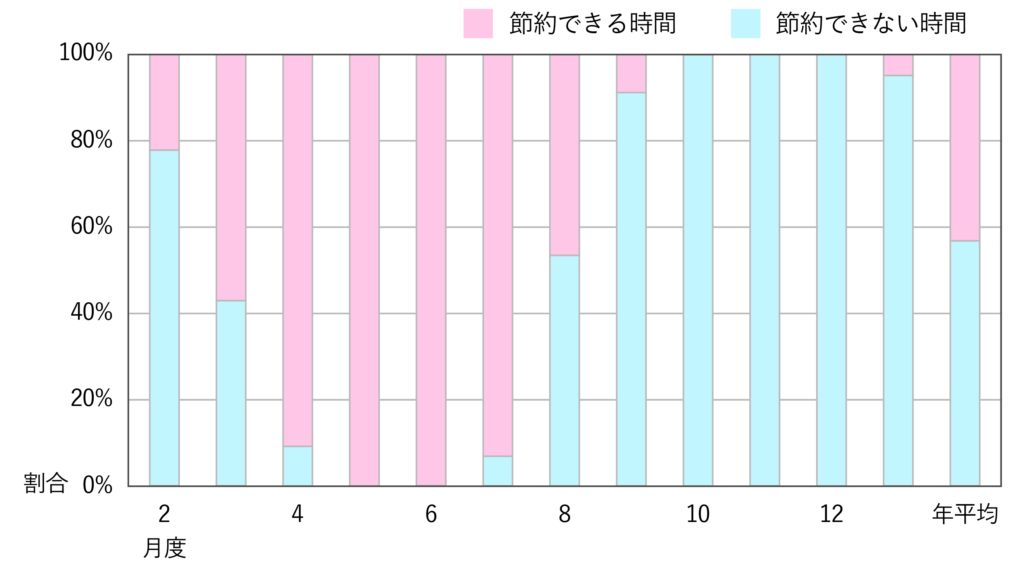

2. Free-Cooling System Reduces Chiller Operating Hours and Cuts Electricity Costs by Up to 54%

Free cooling is a system that stops the chiller during cooler periods, such as winter or when the required cooling water temperature isn’t very low, and uses the water supplied by the cooling tower directly as cooling water. By controlling the chiller's operating hours, unnecessary energy consumption can be reduced.

The energy saving effects of introducing Free-cooling System are as follows:

3. Maximized space-saving with modular components

By integrating control panels, tanks, valves, and other unit components, ecobrid achieves a highly compact design.

The integration of the components allows for faster on-site installation.

Additionally, the pump unit and cooling water tank are made of stainless steel, ensuring excellent durability.

Performance Impact Simulation

Water saving effect simulation

This simulation analyzes the water savings and reduction in water utility costs when operating a cooling system at 100 cooling tons with a circulation water flow rate of 1,300 L/min for 20 days (24 hours per day).

[Simulation Environmental conditions]

◆General cooling tower

Condition 1: 0.8% of the factory circulating water evaporates.

Condition 2: 0.05% of the factory circulating water is lost due to carryover.

Condition 3: 0.4% of the water is used for blowdown to dilute the concentrated water.

◆ Factory water rates

Condition 4: The basic fee is 39.1 yen per cubic meter.

Condition 5: The usage fee is 5.6 yen per cubic meter。

General cooling tower

Based on conditions 1–3, it is found that 1.25% of the circulating water is consumed or lost.

1300 (L/min) x 1.25 (%) x 60 (min ⇒ Hr) x 24 (Hr ⇒ day) x 20 (day ⇒ month) = 468㎥ evaporation/month

A total of 468 m³ of circulating water evaporates per month (wasted)

Basic water usage ▲ 468 (m³) x 39.1 (yen) + usage fee 468 (m³) x 5.6 (yen) = 20,919 yen

Annually, the water cost totals 5,616 m³ = 251,028 yen

Closed-loop Air-cooled Systeme cobrid

Unlike cooling towers, ecobrid eliminates circulating water evaporation and water loss, resulting in nearly no water fees.

Note: Only during the summer, when the outside temperature exceeds 30°C, will there be spraying on the filter.

Annual water costs for the cooling tower are 251,028 yen

The total amount of spray used by ecobrid in summer is 45 m³ annually (assuming a 22.5 m³ monthly contract).

5,616m³ - 45m³ = 5,571m³ water savings

The water cost is 251,028 yen - 10,809 yen = a cost reduction of 240,219 yen

ROI (Return On Investment) Effect simulation

Simulation with the closed-loop air-cooling system in the following conditions:

① Extension of recycling (cooling) time prevention: 22 sec ⇒ 20 sec

② Reduction in product defect rate: 11% ⇒ 10%, assuming 15 units in a UK-based factory

[Simulation Environmental conditions]

Condition 1: 180 tons

Condition 2: Material: PP, 1 shot of 95g (16 pieces)

Condition 3: Cycle time 22 sec

Condition 4: Monthly production of 100,000 units

Annual reduction: 168,485 (yen) x 15 units = 2,527,275

When calculated with the difference in cost between the new system and the open cooling tower:

ROI (return on investment) = 63.1% (payback period: 1.6 years)

Investment amount: 6,000,000 yen

When replacing an existing open cooling tower:

ROI (return on investment) = 25.2% (payback period: 4.0 years)

Investment amount: 10,000,000 yen

Note: The calculation above does not include reductions in water and electricity costs. Annual running cost reductions of approximately 500,000 yen are included, which further increases the ROI.

Case Study

The ecobrid has a proven track record across a wide range of industries, ensuring a reliable and effective solution for your needs.

Examples include: PET preforms and caps, automotive, home appliances, healthcare, daily goods, electrical components, pharmaceuticals, and more.