Features

1. High maintenance efficiency due to closed circulation

The heat exchanger is maintenance-free as no Primary cooling water connection is required.

The closed circulation system prevents the accumulation of impurities, eliminating problems caused by water quality and the buildup of scale that is typical of Air cooled.

2. Stable cooling performance thanks to a high-flow, high-pressure pump

A large-flow, high-pressure pump is used to ensure a stable flow rate even for molds with complex structures.

Control Panel uses flat keys and the temperature is displayed in 0.1°C increments (steps), allowing for precise temperature control.

3. Energy-saving operation through inverter control

By using inverter control for the compressor, energy consumption during low load periods is reduced, achieving highly efficient energy-saving operation.

(MCCA3‐100/200)

4. Small and compact design

By using a sealed compressor and inverter control, we have achieved a compact design that saves space and is easy to install.

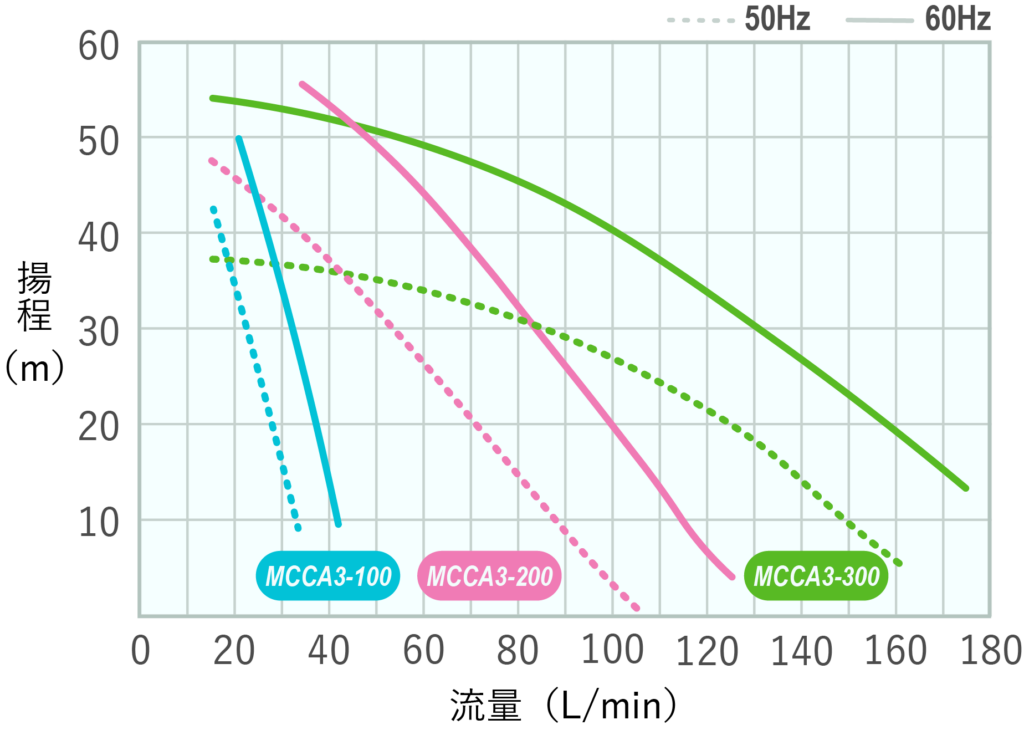

■ Pump performance curve

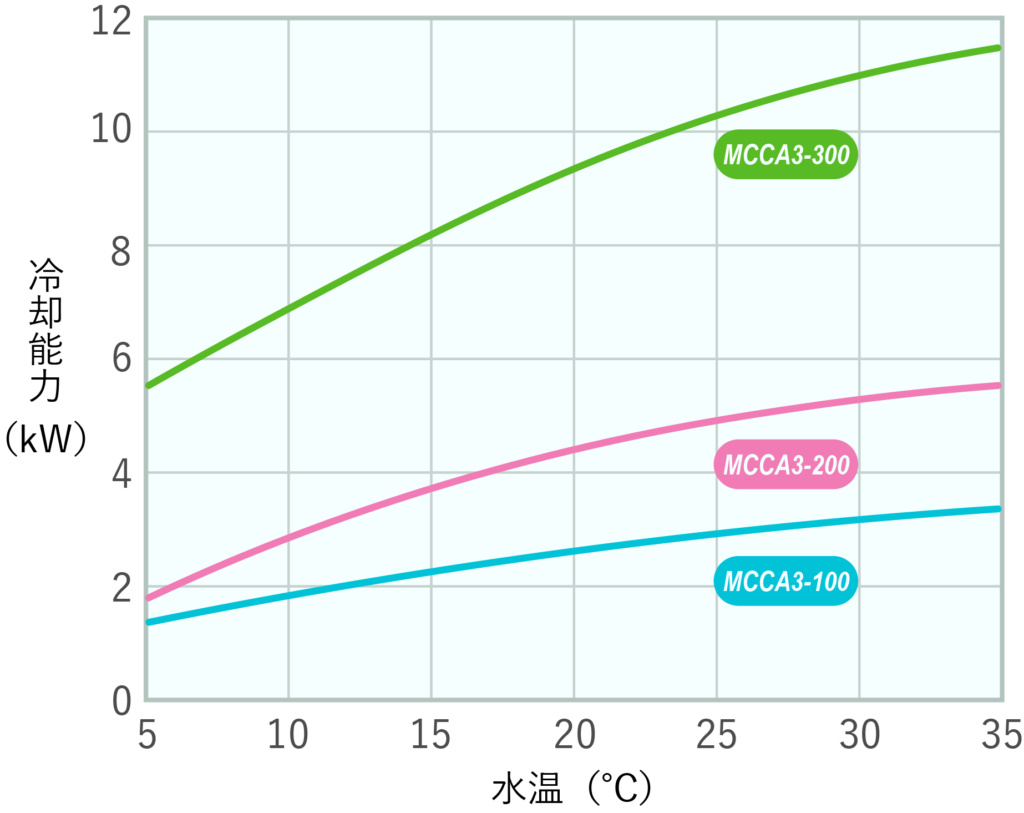

■ Cooling capacity diagram

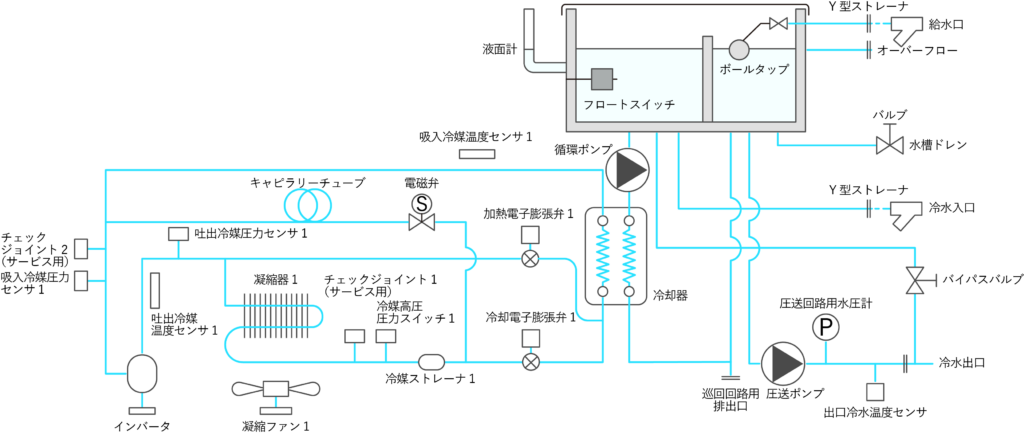

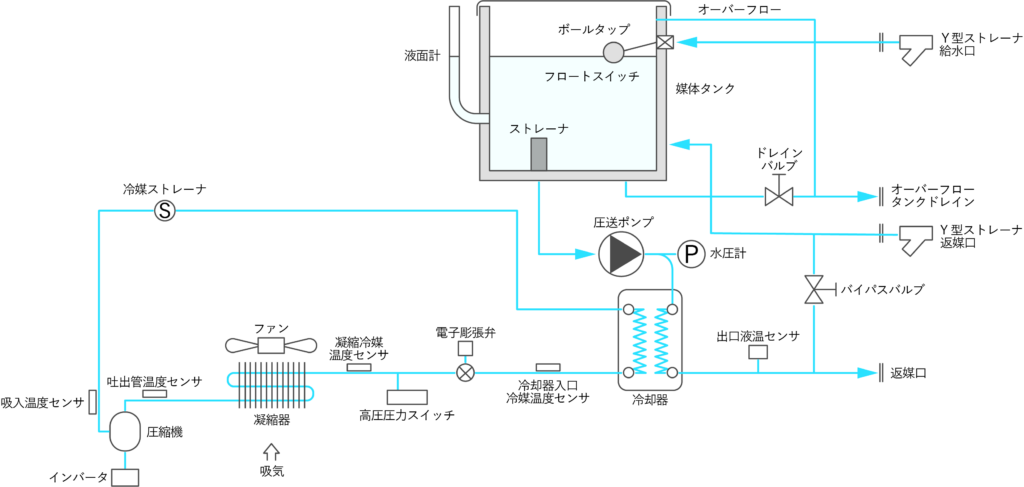

Flow Diagram

MCCA3-100

MCCA-300N