Drying performance that supports ultra-precision molding

Why our solutions are trusted for Engineering plastics

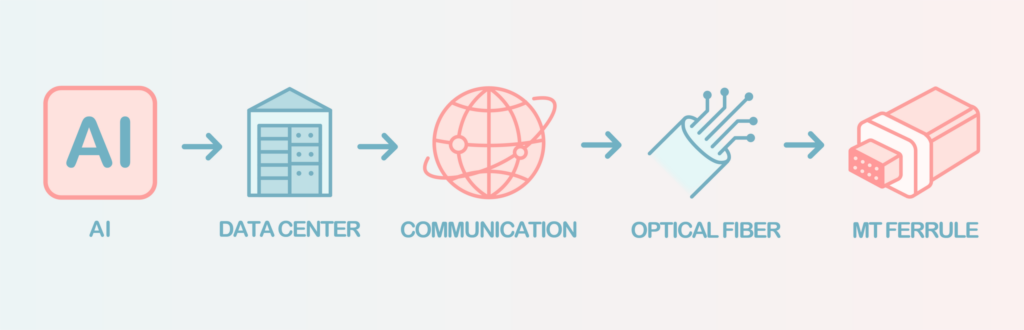

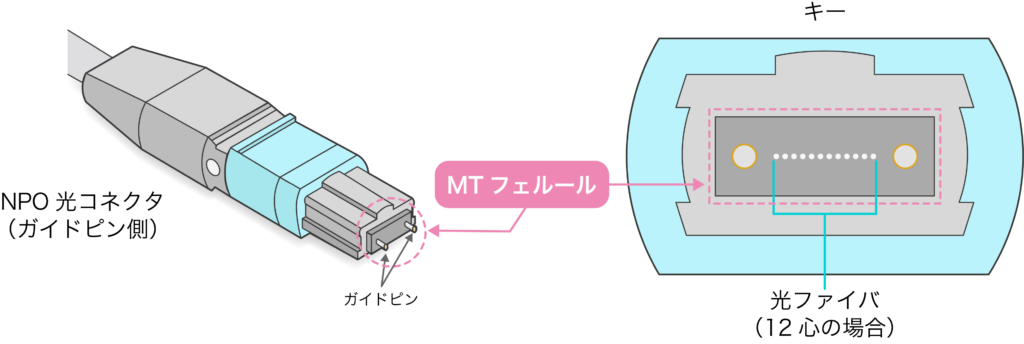

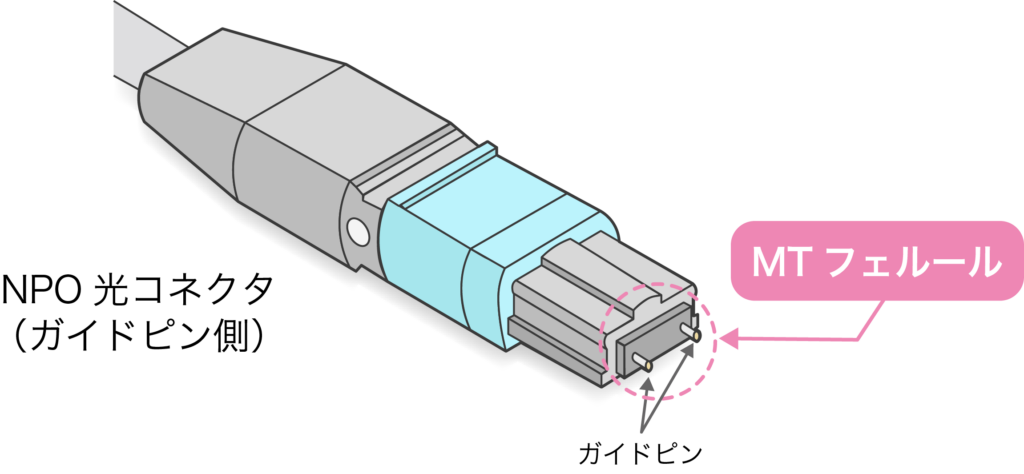

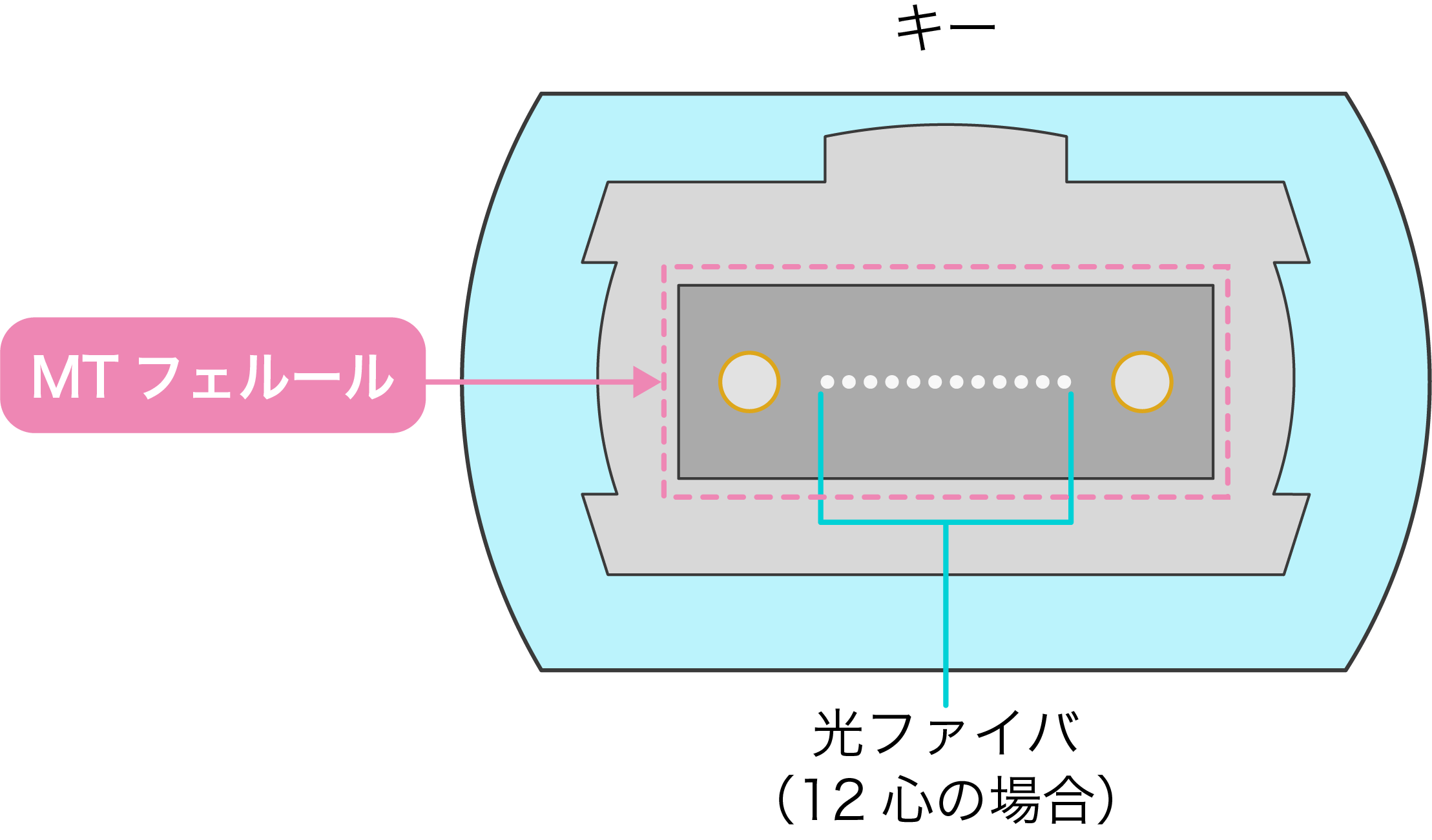

In recent years, the spread of AI and IoT, the evolution of cloud computing, and the expansion of data centers have progressed rapidly. Accordingly, the development of optical communication infrastructure to transmit and receive huge amounts of data at high speed and with stability is accelerating. At the core of this is optical fiber communication, and the optical fiber connection component known as the MT ferrule (a ferrule for multi-core optical fiber), which can be said to be the heart of that communication and ensures accurate connections, is attracting attention.

MT ferrules are precision components that house multiple optical fibers in a single connector and achieve extremely high-precision positioning. This requires ultra-precision molding with dimensional tolerances of less than ±1 μm, and super engineering plastics such as PPS (polyphenylene sulfide), which has excellent durability, dimensional stability, and low warpage, are used for manufacturing them.

However, these materials are hygroscopic, and if moisture control before molding is insufficient, it will have a negative impact on dimensional accuracy, appearance, and strength.

In other words, the quality of the dehumidifying and drying process is one of the processes that greatly affects the precision of the product.

Our Dehumidifying Dryer are:

- Stable drying at low dew points

- Reliable drying quality even for super engineering plastics

- Extensive track record in precision molding

This has earned us a high level of trust in the field of high-performance resin molding, including the manufacture of MT ferrules.

What is an MT ferrule?

This is a precision part that bundles multi-core optical fibers into one and connects them in the correct position. Unlike regular ferrules (single core), this requires dimensional accuracy in the μm range in order to simultaneously hold multiple fibers, such as 12 or 24 cores. It is primarily used in data centers and optical communication equipment, and is a part that supports high-speed communication companies.

Appropriate drying management for highly functional resin molding with diverse applications

High-performance resins are used in a wide variety of fields, including MT ferrules, medical devices, drones, precision gears, and small motor parts. To adapt to each environment, they must have high heat-resistant resistance, chemical resistance, and mechanical properties.

For example, in medical devices, resins such as PPS (polyphenylene sulfide), LCP (liquid crystal polymer), and PEEK (polyether ether ketone) are used in the moving parts of endoscopes, gears in blood analyzers, wiring holders, etc. These resins are characterized by heat-resistant and chemical resistance, which allows them to withstand sterilization processes and contact with chemicals, but even small amounts of moisture can cause dimensional changes and a decrease in strength, so the accuracy of drying before molding greatly affects the reliability of the product.

Additionally, high-performance resins such as LCP and PEEK are used in drones for high-precision propeller transmission gears, sensor fixing parts, camera mount parts, etc. These applications require molding that is lightweight and has excellent dimensional stability, and insufficient drying can cause problems such as warping, burrs, and dimensional defects.

In particular, materials such as PA (nylon), which is highly hygroscopic, and LCP and PEEK, which maintain their performance even at high temperatures, often experience a decrease in fluidity due to moisture absorption, or the generation of gas or burns, and insufficient drying often leads directly to product defects. It is extremely important to understand the characteristics of these materials and then select and operate a dryer that can manage the optimum temperature and dew point for each resin.

Changes in physical properties due to moisture absorption have a significant impact on parts that require strict precision.

It is important to determine the appropriate drying conditions according to the material properties.

Next, we will introduce the features of our dryers in detail.

Features

1. Honeycomb dehumidifying and drying technology that achieves a low dew point of up to -60°C

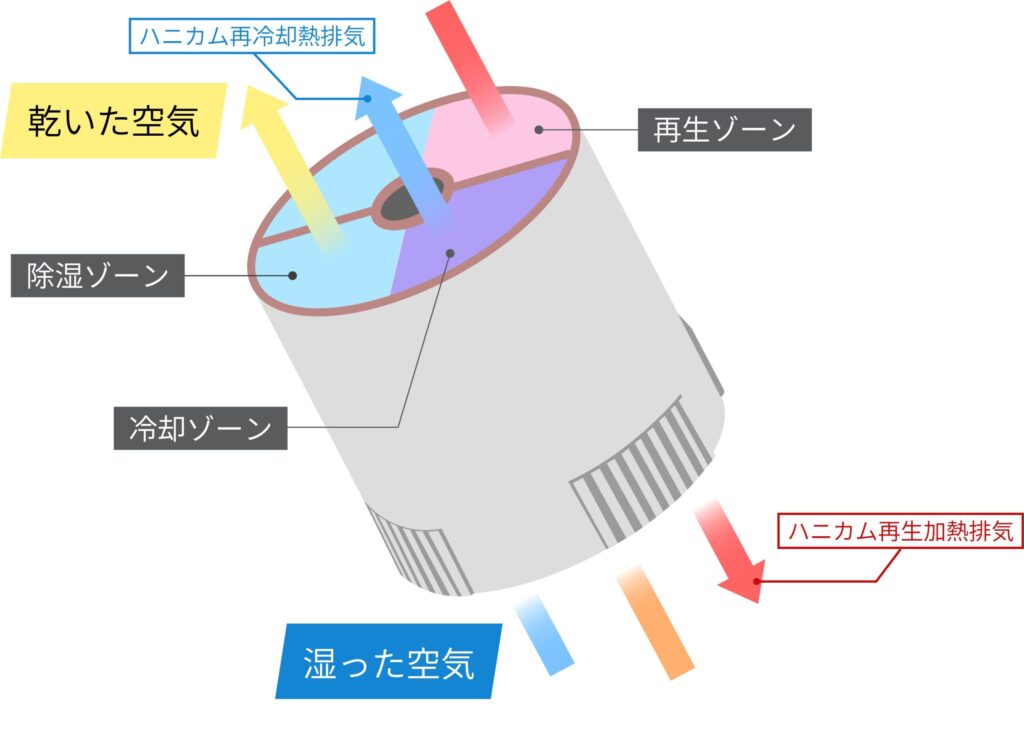

The MJ6-i uses a honeycomb rotor to provide a three-zone continuous cycle of "dehumidification, regeneration, and cooling," stably supplying dry air with an ultra-low dew point of -40°C under normal use and up to -60°C under certain conditions.

As the rotor slowly rotates, it absorbs moisture from the air sent to the drying hopper in the "dehumidification zone," and then in the following "regeneration zone," the absorbed moisture is evaporated by superheating with high-temperature air to restore its absorption power.Furthermore, in the "cooling zone," the rotor, which has become hot after regeneration, is cooled to an appropriate temperature to prepare for the next dehumidification.

By continuously performing this cycle without stopping, the dew point of the dried air can be maintained stably.The complete regeneration cycle prevents deterioration of the adsorbent's performance, maintaining drying quality close to its initial performance for a long period of time.

2. The introduction of a heat exchanger reduces power consumption

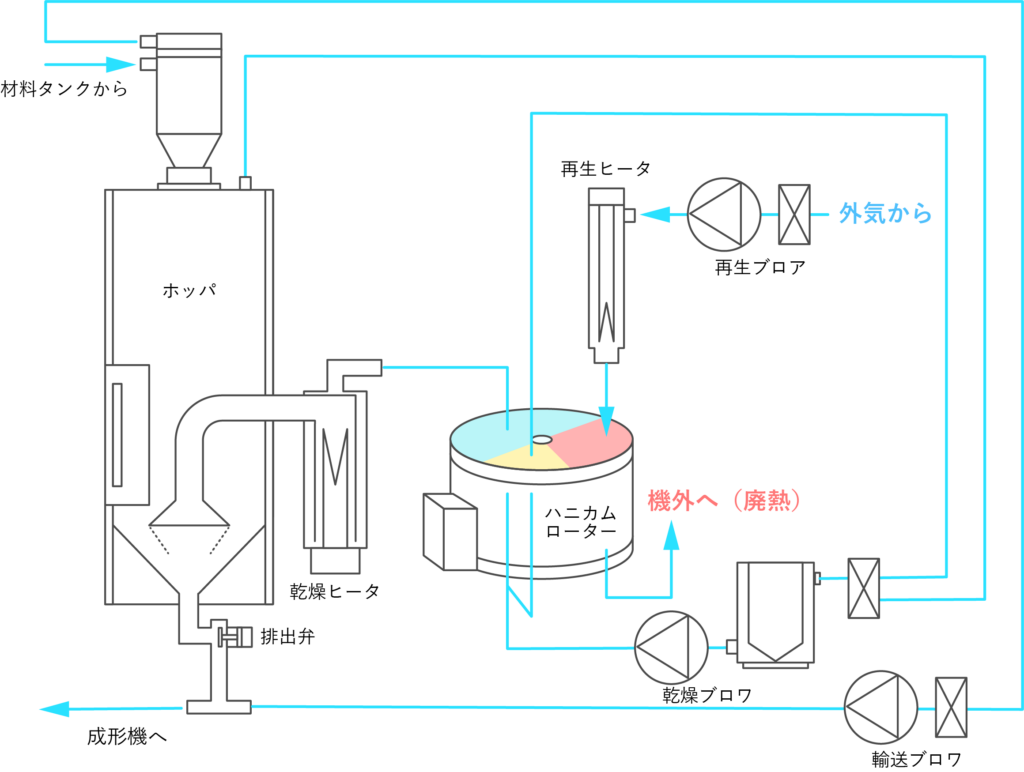

Conventional Dehumidifying Dryer take Air supply outside air directly and heat it in a regenerative heater to create high-temperature air. However, this method requires the outside air at room temperature to be heated from scratch, which requires a large amount of energy for the regenerative heater, resulting in increased power consumption.

Furthermore, because the hot honeycomb regenerated heated exhaust air was directly released outside the machine, there were concerns that the waste heat would affect the air conditioning environment and increase the burden on the air conditioning equipment.

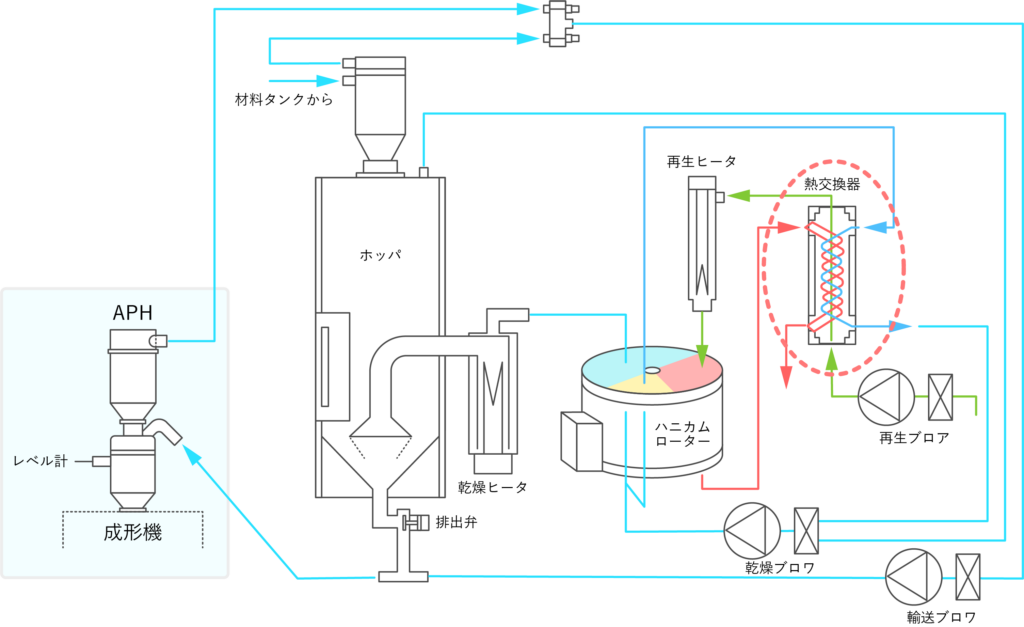

To solve these problems, the MJ6-i comes standard with a heat exchanger. By crossing the honeycomb regenerative heating exhaust and honeycomb cooling exhaust in the heat exchanger, the regenerative air is pre-heated, reducing the burden on the regenerative heater. This results in a significant reduction in the power consumption of the regenerative heater and a reduction in the air conditioning load due to a drop in exhaust temperature, resulting in an energy-saving design that takes into consideration both energy loss and environmental impact.

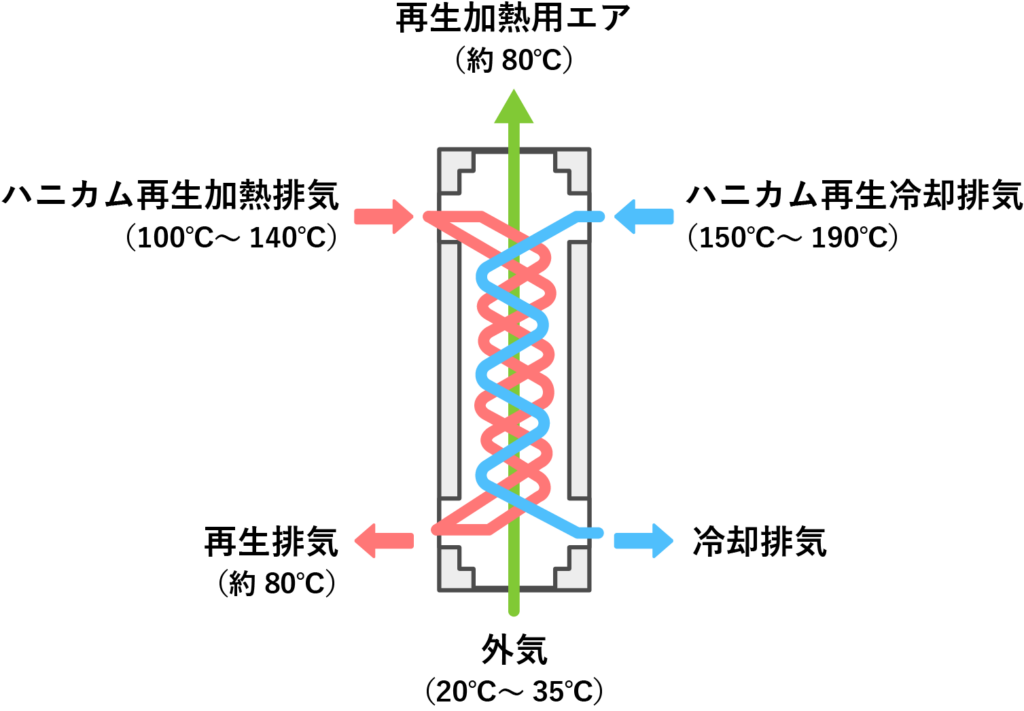

How a heat exchanger works

Thermal energy has the property of naturally transferring from a high temperature to a low temperature. A heat exchanger is a device that utilizes this property to transfer heat efficiently by taking advantage of temperature differences.

In the MJ6-i, the high-temperature "honeycomb regeneration heated exhaust" generated in the process of superheating and evaporating the moisture adsorbed in the regeneration zone, and the "honeycomb regeneration cooled exhaust" whose temperature has risen due to the heat absorbed when cooling the rotor in the cooling zone, are both passed through a heat exchanger. This system preheats outside air at 20-30°C to approximately 80°C, reducing the load on the regeneration heater.

In addition, the regenerated heated exhaust air, which is between 100 and 140°C, is cooled to approximately 80°C through heat exchange before being discharged outside the unit, minimizing the impact on air conditioning. The regenerated cooled exhaust air, which is between 150 and 190°C, is also cooled by heat exchange with outside air for the dehumidification process.

3. Conveying pipe are also kept at a low dew point to prevent re-absorption of moisture.

Even if the material is properly dried, if it absorbs moisture again during transport to the secondary collector, there is an unavoidable risk of molding defects.

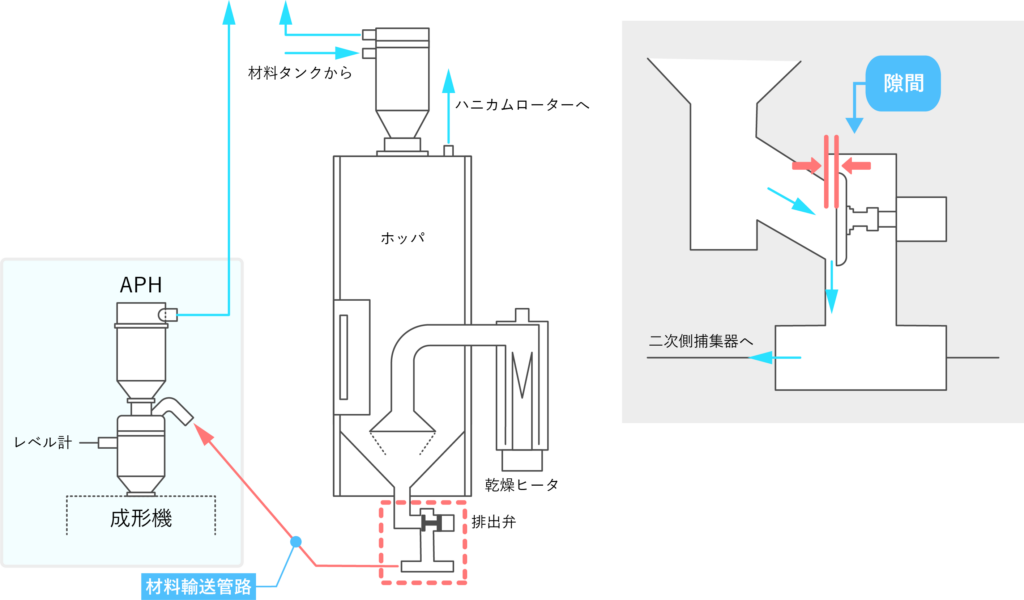

To address this issue, the MJ6-i is equipped with our proprietary material discharge unit, the "PD (Push Damper)," which is installed in the drying hopper. By filling the material Conveying pipe with dehumidified dry air before transport begins, the risk of re-absorption of moisture and temperature drop after drying is significantly reduced.

Specifically, a small gap is provided between the discharge port of the drying hopper and the closed discharge valve, just enough to prevent the material from falling, and some of the dry air is allowed to flow into Conveying pipe through this gap.This makes it possible to maintain a low dew point in the material transport route before transport, preventing the resin material from absorbing moisture again.

We have implemented drying care that begins before transportation, which contributes to stabilizing molding quality.

The PD employs a diagonal structure, which has the effect of preventing material from getting stuck. This allows for smooth discharge of material. In addition, powder pressure is less likely to be applied directly to the valve disc, leading to smoother operation of the valve disc.

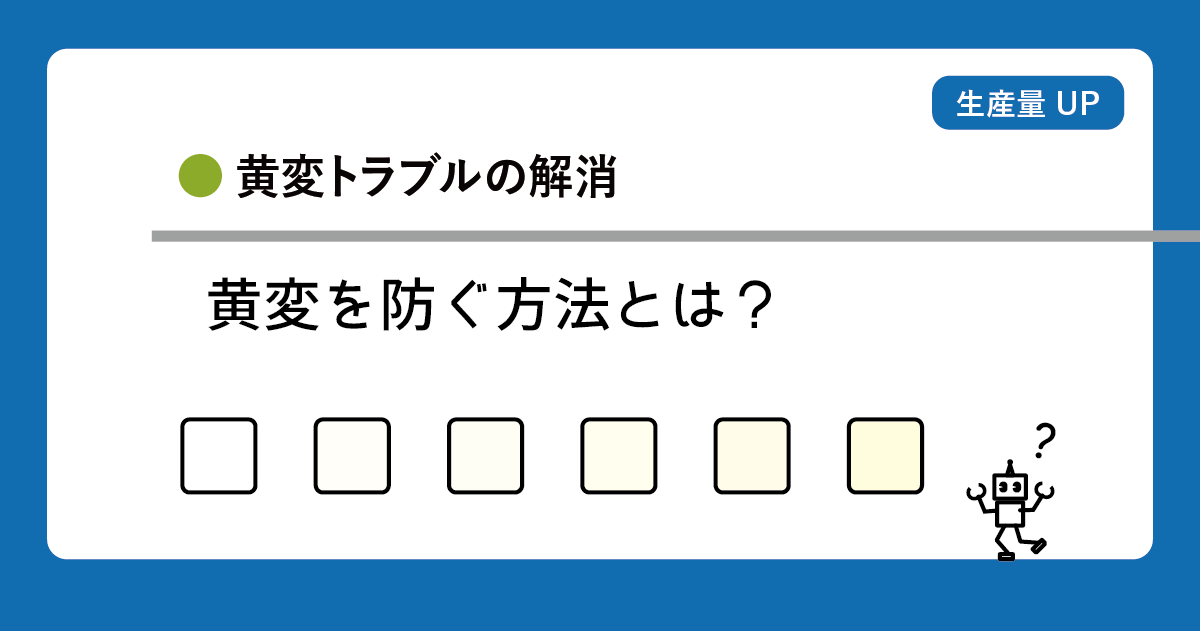

4. Self-control function prevents excessive drying and energy loss

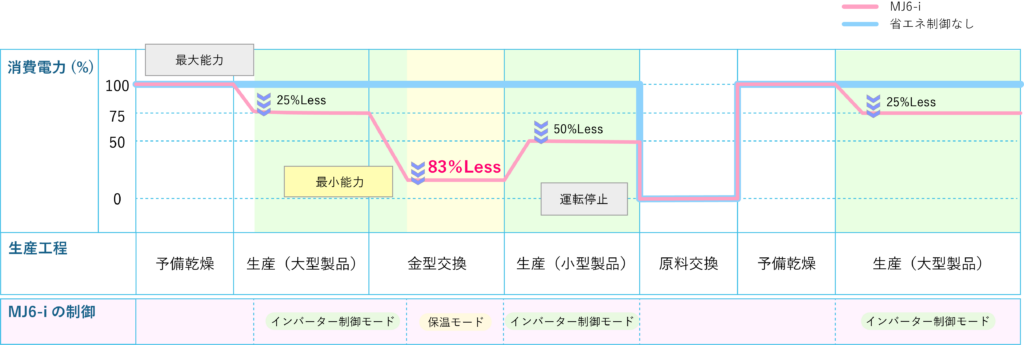

The MJ6-i is Dehumidifying Dryer equipped with a self-control function. It continuously monitors the device's usage status and autonomously determines the operating mode based on the data obtained. It automatically controls operation in the most energy-efficient mode while always maintaining the optimal drying condition, preventing over-drying. Because the control switches autonomously according to various operating conditions, such as full production, low-volume production, and temporary suspension, it is possible to significantly reduce running costs compared to conventional machines.

Furthermore, the device automatically adjusts and manages the drying conditions, reducing the operator's workload for operation and monitoring, and contributing to labor savings on site.

The graph below shows the power consumption under energy-saving control of the MJ6-i.

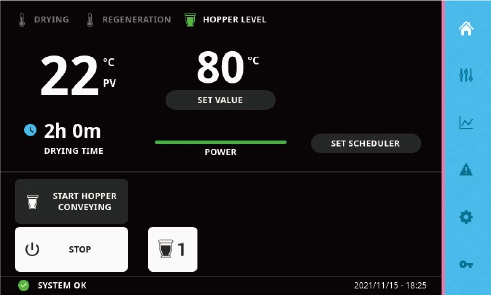

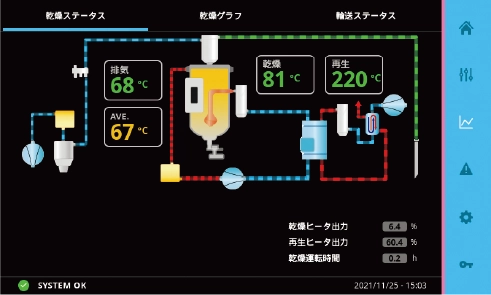

5. The touch panel features an intuitive UX design

The device features a large, highly visible 7-inch touch panel, achieving a user experience (UX) design that allows users to operate it intuitively. Various data such as drying status, temperature control, and operating results are visualized in graphs to help users understand the situation on-site. By displaying important information graphically, anyone can immediately check the current status.

Furthermore, operations such as changing the set temperature and registering and editing schedule timers can be easily performed by simply touching the screen.By enabling immediate responses and adjustments on-site without the need for complex operations, the system reduces the burden of daily work and leads to improved operational efficiency.

6. Flexible response to limited on-site space

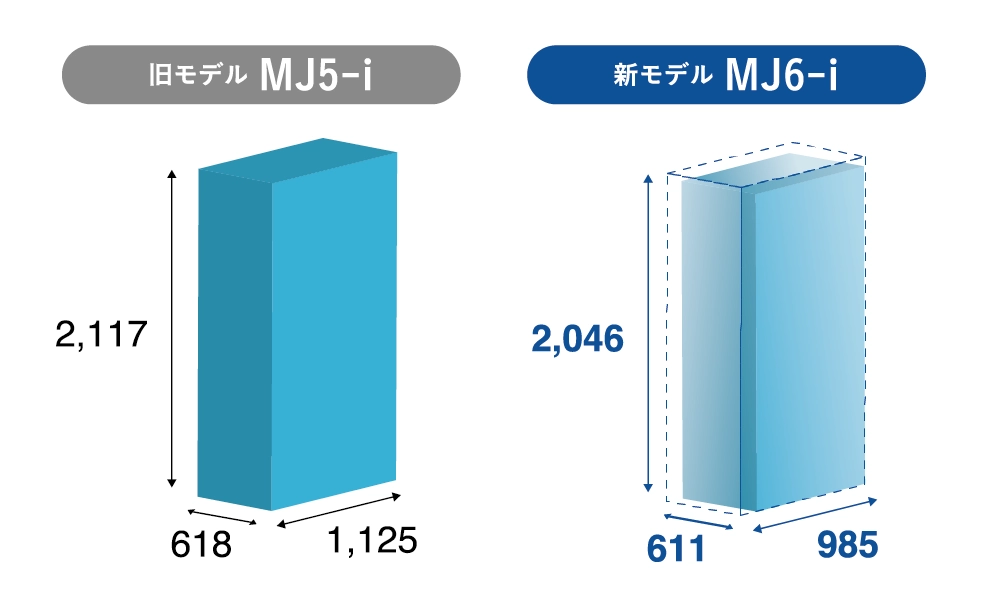

By optimizing the internal structure and revising the parts layout, we have achieved a smaller size without compromising basic performance or functionality. While maintaining the same processing power as previous models, the more compact housing allows for space savings. This allows for flexible installation even in limited work spaces, and also makes it easier to ensure work flow around the device and accommodate layout changes, which is expected to improve on-site space efficiency.