物理発泡成形を知る

物理発泡成形とは

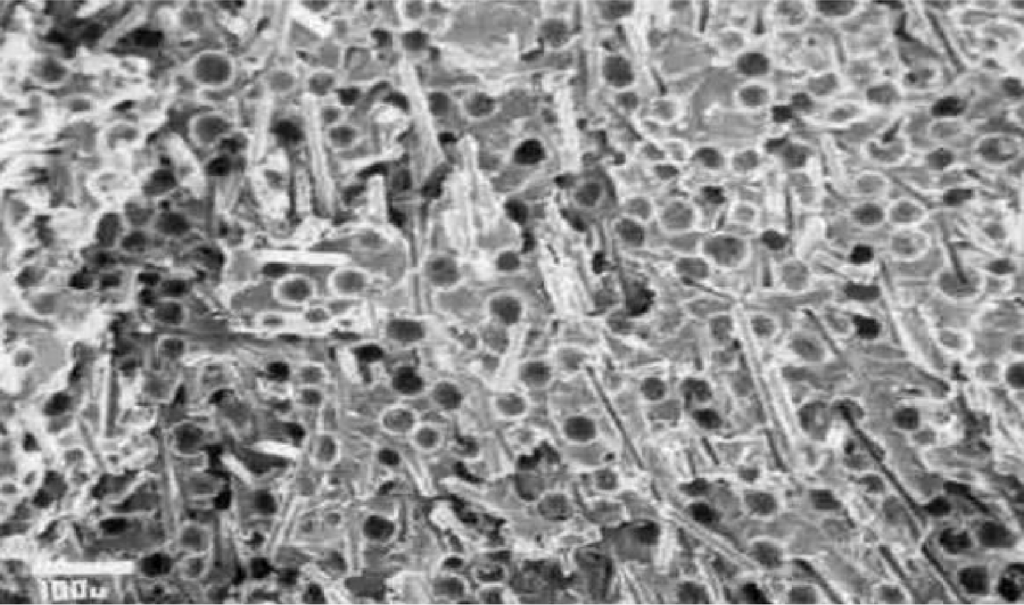

物理発泡成形とは、超臨界状態まで高圧にした窒素または二酸化炭素をシリンダー内の溶融樹脂に直接注入・混合し、射出時の圧力の低下によって発泡する成形技術です。これにより、樹脂内部に微細な気泡(セル構造)が形成されます。成形プロセスの制約にとらわれず、機能性の最適化を図ることができ、低密度化と柔軟な設計によって20%以上の材料削減や重量軽減も可能です。

さらに、化学発泡剤と異なり加工温度の制限がなく、ポリマー中に化学残留物が残らないため、粉砕材はバージン材と同等の物性を保持し、再利用が可能です。このため、リサイクル性が求められるコンシューマ製品の生産に適しています。自動車、家電製品、医療機器、包装資材、一般消費財などの幅広い分野で採用されています。

使用するガスが高圧なほど樹脂へのガス溶解量が増え、より強力で均一な発泡が可能になります。

超臨界状態(SCF)とは、物質を臨界温度以上・臨界圧力以上にした状態で、液体と気体の性質をあわせ持つ流体のことです。樹脂発泡成形では主に超臨界窒素や超臨界二酸化炭素が使用されます。流体並みの溶解性と気体並みの拡散性があるため、容器樹脂に混ざりやすく、微細発泡を実現します。

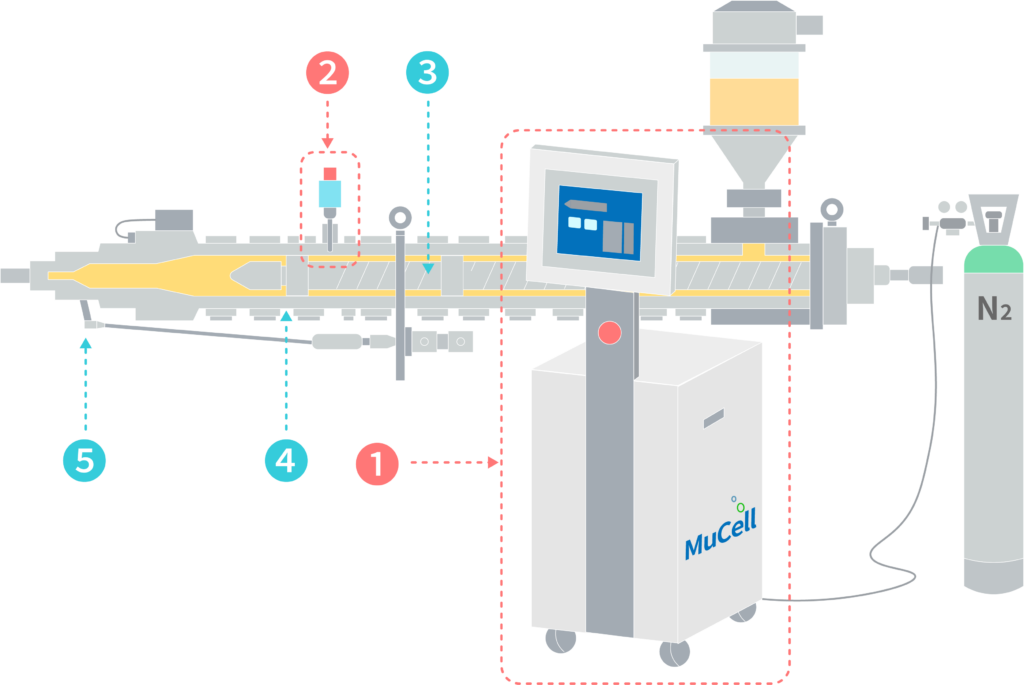

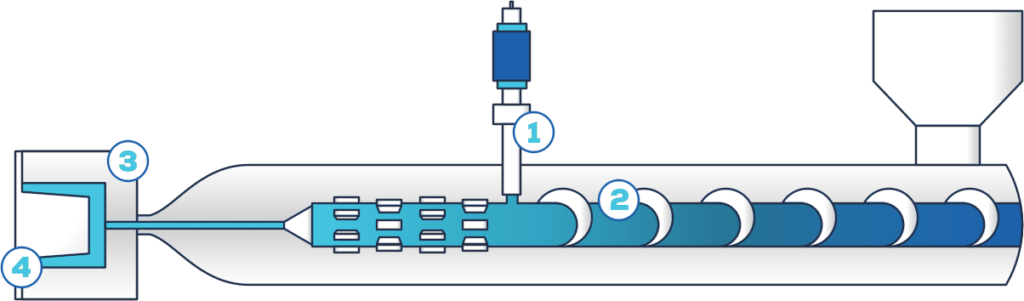

SCF供給装置の構成

物理発泡成形には、成形機の専用可塑化装置(最適化されたスクリューとシリンダー)に加え、超臨界流体装置であるMuCell本体とインジェクターが必要です。また、弊社MuCellに対応する成形機ライセンスメーカーでは、対応成形機の見積もりにも対応しています。

弊社取り扱い装置

弊社までお問い合わせください。

❶ SCF供給装置

❷ インジェクター

お客様にて対応をお願いいたします

成形機メーカーにお問い合わせください。

❸ 専用スクリュー

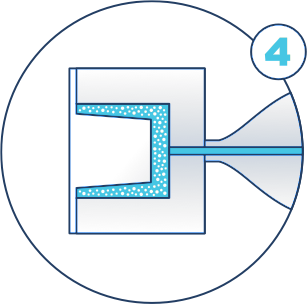

❹ 専用シリンダー

❺ シャットオフノズル

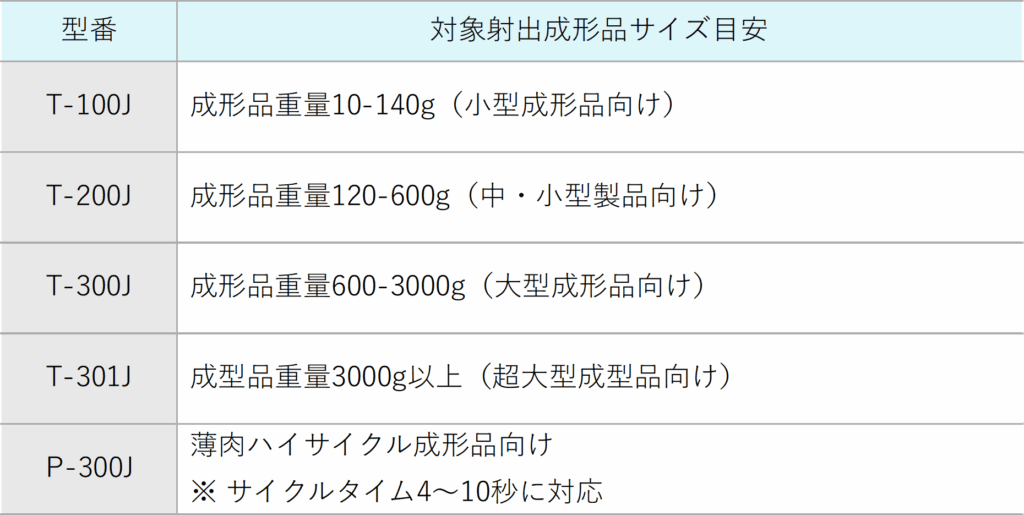

MuCellラインナップ

射出成形機向けには、成形品のサイズやサイクル時間に応じた5種類の製品を、ブロー成形向けには、成形品のサイズや成形方法に応じた4種類の製品をラインナップしています。

特長

1. 射出性の向上で、設計の自由度を広げます

SCF(超臨界流体)を溶融ポリマーに均一に溶解させることで、樹脂の粘度を下げ、射出圧力を低下することが可能です。たとえば、ガラス繊維強化結晶性エンプラでは約10〜15%、非結晶性ポリマーでは約15〜25%の粘度低下が見られます。

粘度が下がることで、同じ温度・射出速度条件でも射出圧力を低く抑えることが可能になります。結果として、薄肉部や複雑形状でもすみずみまで樹脂が行き渡り、長い流動長の確保が容易になります。特に二酸化炭素ガスを用いた場合には、流動性改善効果がより明確に表れ、薄肉化や複雑リブなど、これまで困難だった設計領域が実現可能となります。

射出圧力の低減により金型への負荷が軽減されることで、金型寿命の延長にもつながります。

2. 低圧成形で、精度の高い美しい仕上がりを実現

SCF(超臨界流体)を利用した発泡成形では、セル(微細気泡)の成長が充填や保圧の役割を担うため、従来のように高い射出圧力や長時間の保圧をかける必要がありません。

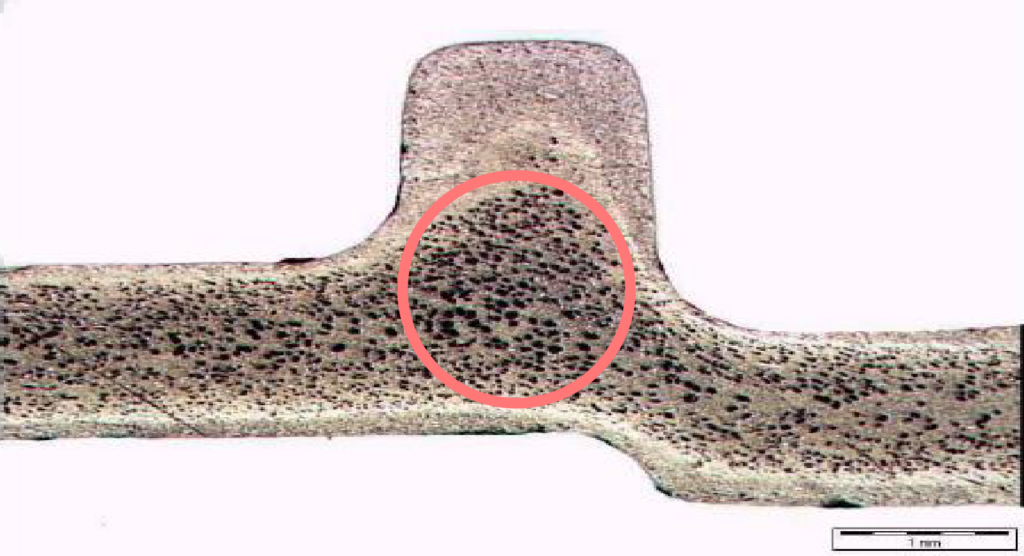

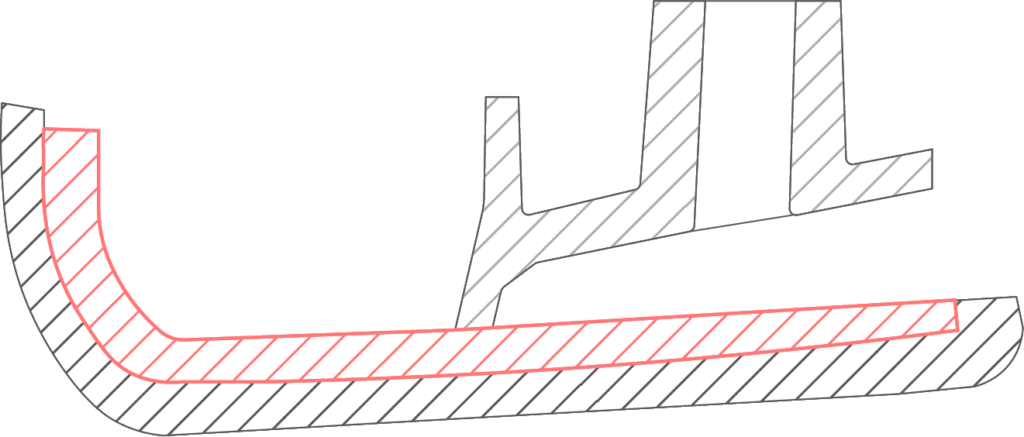

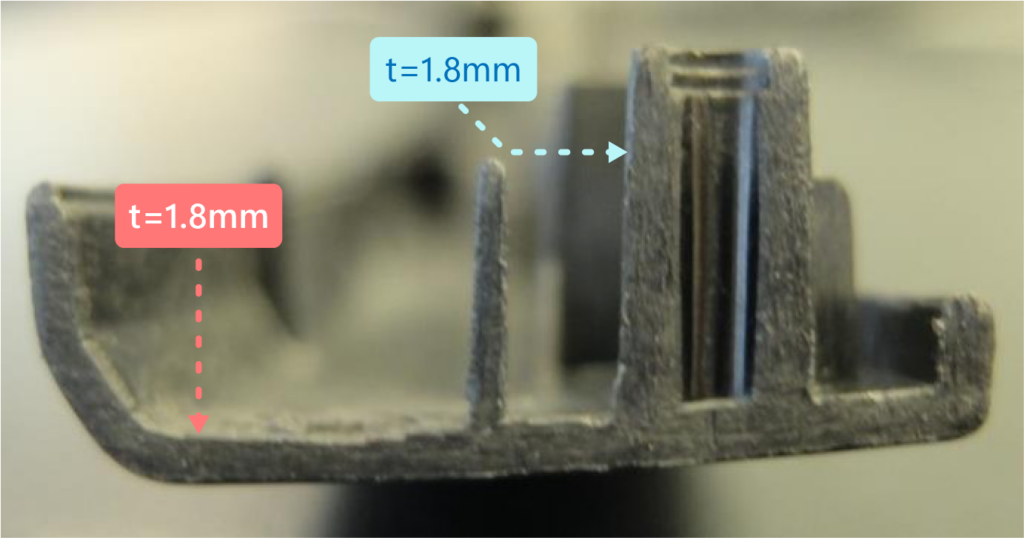

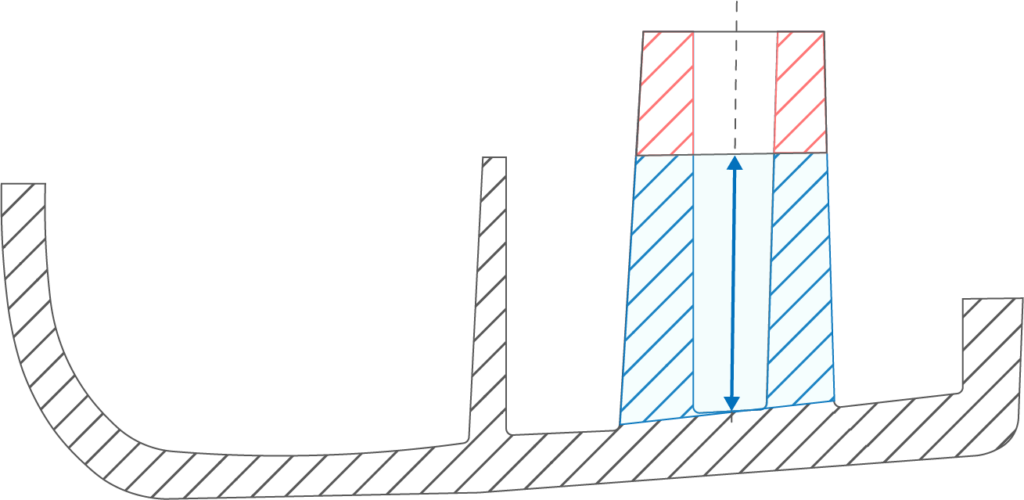

その結果、樹脂内部の残留応力を減らし、ヒケやソリ、真空ボイドなどの成形不良が大幅に減少し、寸法精度の高い成形品を安定して成形することができます。特にリブや肉厚部がある構造では、セル成長の効果でヒケを効果的に抑制することができ、リブの厚みを基本肉厚と同等に設定しても外観品質を損なうことはありません。

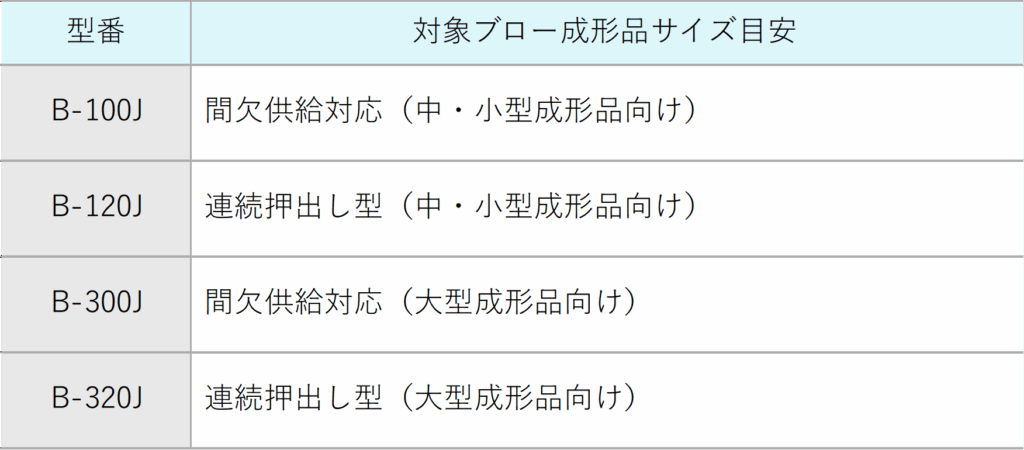

ヒケ状態の比較

ソリッド成形品(左) 重量:36g

MuCell成形品(右) 重量:29g

20%の重量低減を達成

短辺ソリ状態の比較

ソリッド成形品(下) ソリ:1㎜

MuCell成形品(上) ソリ:0.2㎜

0.8㎜のソリの軽減を達成

3. 発泡とデザイン最適化で、軽量化と材料削減

樹脂内部に微細な気泡(セル)を形成することで、製品の密度を低下させ、一般的には約10%前後の軽量化効果を発揮します。

さらに、発泡によりヒケの発生を抑えられるため、構造上必要な部分だけ肉厚を確保し、不要な部分は薄肉化する設計が可能なため、薄肉設計により約20%の材料削減が可能です。両者を組み合わせることで、最大で30%程度の軽量化と材料コスト削減を実現します。

例えば、自動車使用される車内ドアの装飾パネルでは、MuCellによる発泡成形とデザインの最適化により、樹脂使用料を大幅に削減することが可能です。

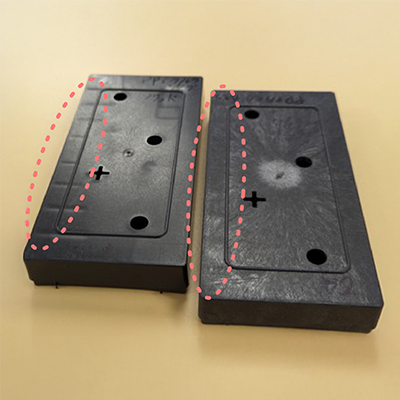

ソリッドデザイン

MuCellデザイン(肉厚比 1:1)

デザイン変更により、肉厚が2.8㎜から1.8㎜へ薄肉化を実現。合計40%の樹脂使用料の削減に成功しました。

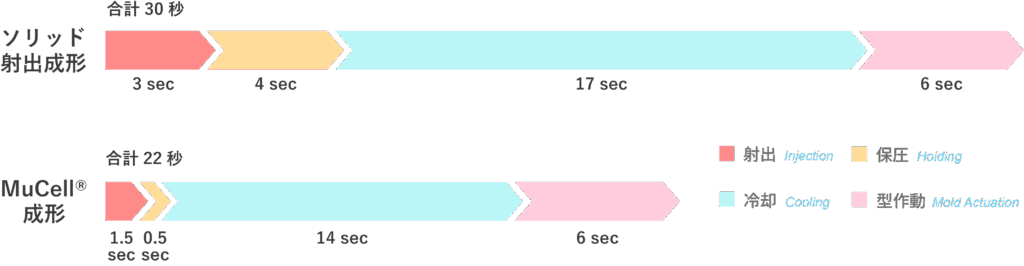

4. 保圧時間の削減で、生産性の最大化に貢献

セルの成長が保圧工程を補うため、保圧時間を大幅に短縮することが可能です。これにより、サイクルタイム全体が短縮され、生産効率が向上。大量生産ラインでは、年間生産数の増加に直結します。

また、保圧時間の削減は残留応力の低減にも貢献し、寸法安定性や外観品質の安定化にもつながります。

5. 幅広い樹脂対応で、未来のリサイクルにも安心です

SCF発泡は、ほとんどの熱可塑性ポリマーに適用可能で、均一かつ微細なセル構造を形成します。化学発泡剤を使用しないためポリマー中に化学残留物が残らず、リサイクル時にも物性低下がほぼ見られません。ランナーや不良品を粉砕して再利用する際も、バージン材に近い品質を維持できます。

さらに、PEEK・PEI・PSUなどの高耐熱・高価格材料においても軽量化とサイクル短縮の効果が大きく、コスト削減と生産性向上を両立します。

リサイクル性や環境配慮が重視されるコンシューマ製品、自動車部品の分野などで高い評価をいただいており、持続可能な製造プロセスの構築に貢献します。

成形の流れ

4つの技術ステップをご紹介

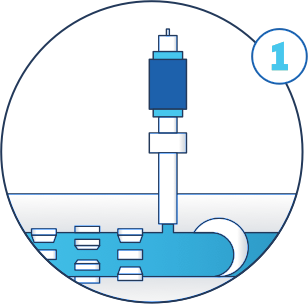

可塑化工程において、正確に計量された超臨界状態の窒素や二酸化炭素(SCF)が、バレルに取り付けられた専用インジェクターを通じて溶融樹脂に注入されます。

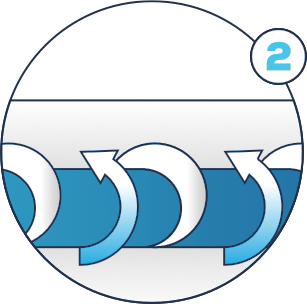

注入されたSCFは、可塑化バレル内にある特別設計の混合部を備えたスクリューによって均一に分散・混合されます。これにより、SCFが溶融樹脂中に安定的に溶解し、単一相の均質な溶融体が形成されます。

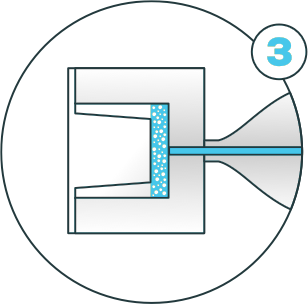

続いて、単一相溶融体が金型キャビティに射出されると、キャビティ内での急激な圧力降下によって発泡セルの核が生成されます。分子レベルで均一に分散したSCFにより、ソリッドスキン層を伴った均質で独立した発泡構造が形成されます。

その後、制御された発泡セルの成長が進むことで、従来の保圧工程が不要となり、金型キャビティ全体に均一で低圧な充填圧力がかかります。最終的にキャビティが充填されるとセルの成長は停止し、安定した成形品が得られます。

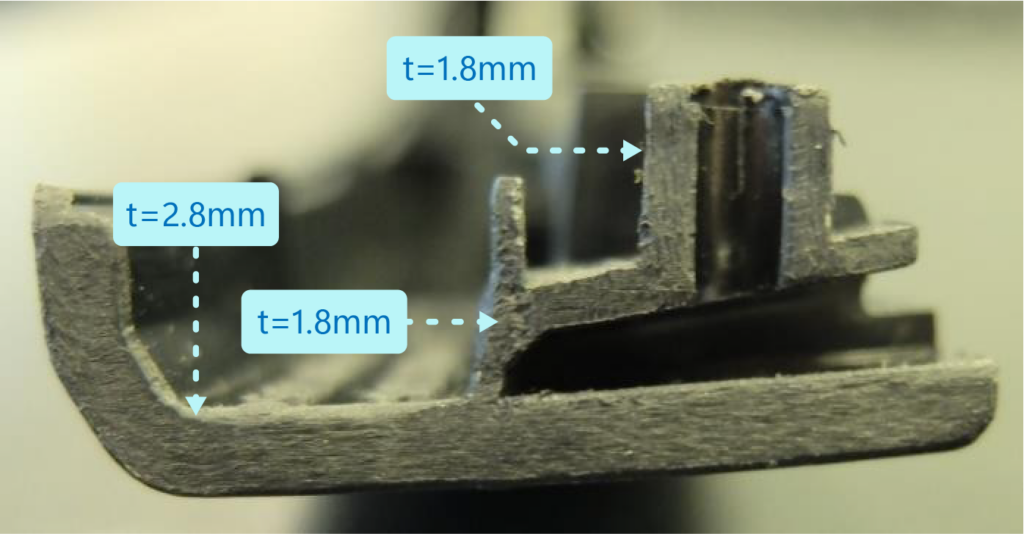

導入事例