特長

1. 「水」と「空気」の力で薬品洗浄と同レベルの洗浄力を実現!

水と空気を使用した独自のキャビテーション発生システムで、薬品洗浄と同レベルの洗浄力を発揮します。薬品不要のため、度重なる洗浄による素材へのダメージを心配することがなく、鋳物・銅・アルミ・ゴムなどの耐薬品性能の低い素材も定期的に洗浄が可能です。

密度の高い酸化被膜を薄く残す洗浄方法のため、洗浄後のコーティングは不要です。

汚れの再付着も予防します。

2. 対象物の分解組立は不要で手間いらず!

現状の接続方法で洗浄機と金型を接続するため、洗浄作業を生産工程に簡単に組み込むことが可能です。金型の分解作業がないことに加え自動運転で洗浄するため、人手を割く必要がありません。

3. 廃液処理不要!洗浄水のリサイクルで環境負荷軽減へ。

薬品は不使用のため、廃液は水の成分とスラッジの成分のみの構成になります。汚染物質がない場合は、そのまま廃棄することも可能ですが、汚れをフィルタでキャッチすることで、洗浄水をリサイクルすることができます。

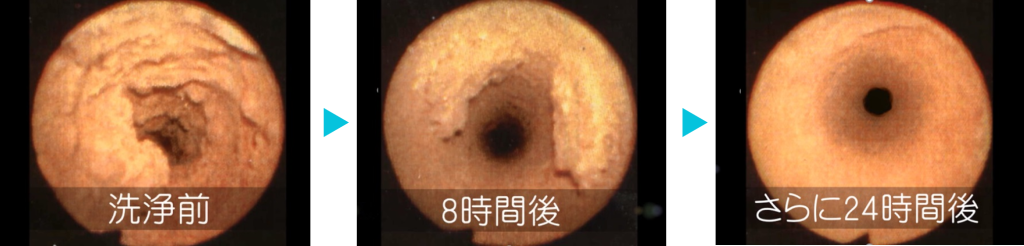

4. 定期的な洗浄で高い予防保全効果を発揮!

3Dプランターで出力した複雑な配管やダイカスト金型などで使用される微細径の配管などは、詰まりのトラブルが頻発します。本洗浄機は複雑細管の洗浄にも対応しているため、定期的な洗浄による洗浄時間の短縮とスラッジの硬化前の除去によって、トラブルに対する予防保全が可能です。

5. 豊富なラインナップで対象物に合わせた洗浄機の選択が可能!

精密部品などの成形で使用する小型機から、自動車の大型部品などの成形で使用する超大型機まで、豊富なランナップで最適なサイズの洗浄機をご提案します。

製品紹介ムービー

効果事例

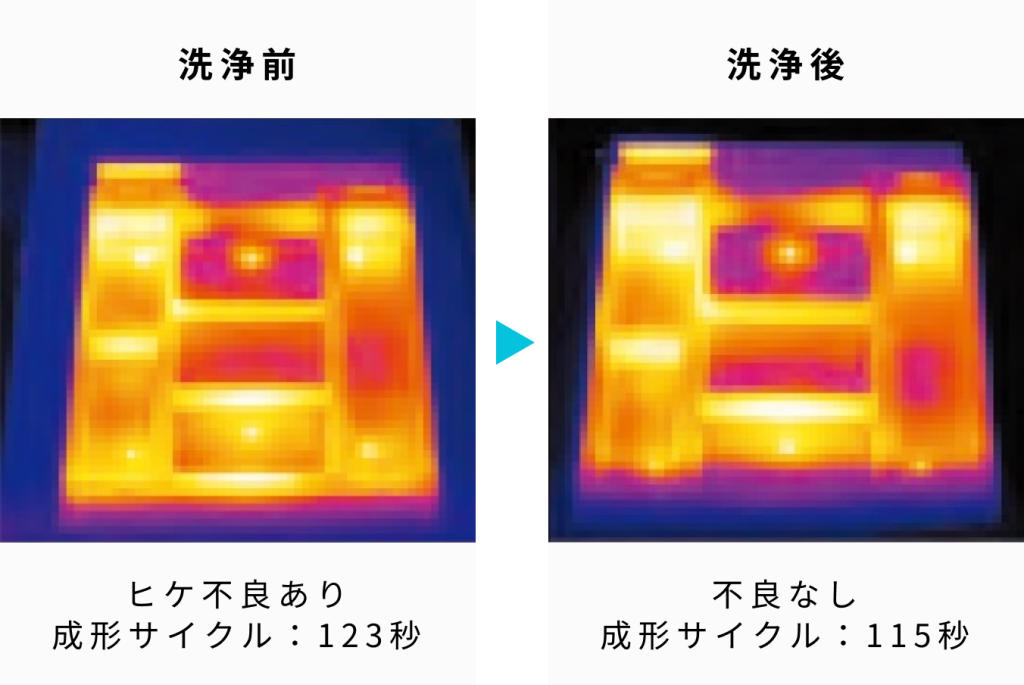

水質の悪化によって起因するトラブルの解消例

課題:冷却不良

➡ ①ヒケの発生

➡ ②サイクルタイムが初期条件(113秒)から10秒延滞

洗浄対象物:7年間使用した金型

対応:NRシリーズによる金型洗浄

結果:成形不良の発生をリサイクルタイムを8秒短縮