The molding problem may be caused by water quality.

Although good molded products were produced at the start of production, as operation continued, the number of defective products with sink marks and warpage increased... You managed to deal with the problem by changing the conditions, but the cycle became longer and productivity decreased. Have you ever had such an experience?

Furthermore, if the water quality continues to deteriorate, the cooling effect will decrease due to corrosion and scale buildup inside the pipes, which may not only result in molding defects but also equipment failure and sudden shutdowns.

In fact, one of the fundamental causes of these problems is the quality of the cooling water. The condition of the water, which is often overlooked, has a major impact on the stability of the molding site.

The preCLEAR water quality management method eliminates water quality problems

Water quality problems can occur at molding sites. The solution is the preCLEAR ion exchange water softener with filter.

By removing components that cause corrosion on the inner walls of pipes and softening the cooling water, the quality of the water is stabilized, significantly reducing the risk of molding defects such as sink marks and warpage, as well as sudden shutdowns due to equipment failure.

preCLEAR is a device developed not only to improve water quality, but also to maintain a continuously stable molding environment.

The role of three filters in regulating water quality

preCLEAR consists of two microfilters and one ion exchange filter. When cooling water is supplied, it is first filtered through the primary filter (50 μm), followed by the secondary microfilter (25 μm), which removes suspended matter according to particle size. Finally, the ion filter performs ion exchange to soften the cooling water.

Features

1. Two-stage filtration improves water quality and prevents plumbing problems

The primary filter (50 μm) and secondary filter (25 μm) efficiently collect suspended solids in the circulating water. By reducing impurities in the water, the corrosion rate inside the pipes is slowed, preventing problems that can lead to reduced productivity.

The two-stage filter structure allows for longer filter replacement intervals and improves maintainability.

2. Soft water maintains cooling efficiency and stabilizes molding quality.

The ion exchange filter absorbs calcium and magnesium, softening the water. By suppressing the formation of scale, it reduces the decline in cooling efficiency of Mold Temperature Controller and the occurrence of dimensional defects. This ensures stable molding and long-term equipment protection.

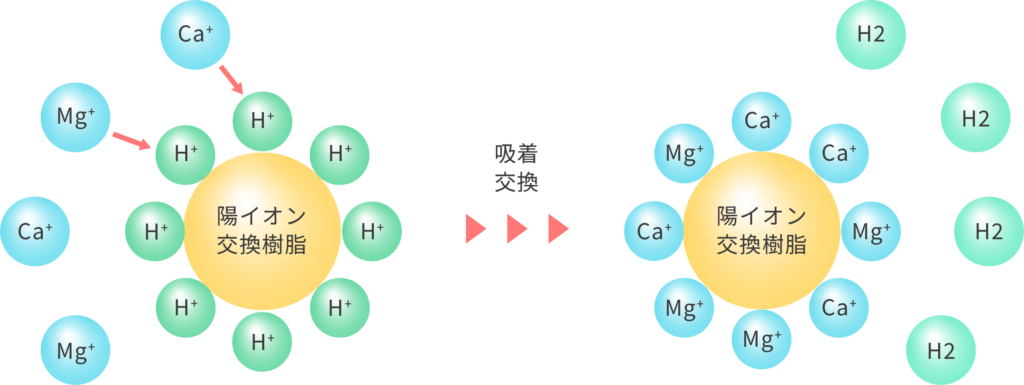

How ion exchange removes hardness components

Ion exchange is a process in which specific ions contained in water are replaced with other ions contained in ion exchange resin.

With preCLEAR, the hydrogen ions (H⁺) attached to the resin are exchanged for calcium ions (Ca²⁺) and magnesium ions (Mg²⁺), which are the main hardness components in water.

This process removes harsh components and softens the cooling water.

3. Easy installation and maintenance

It is easy to install as it can be installed directly in the existing circulation line without requiring large-scale piping changeover work. In addition, the filter and ion exchange resin are cartridge type, which can be easily replaced by anyone, reducing the burden of daily maintenance.

4. No power source or chemicals required

No chemicals or salt are used, and no power source is required. After installation, operating costs can be significantly reduced by simply replacing the filter and ion exchange resin.

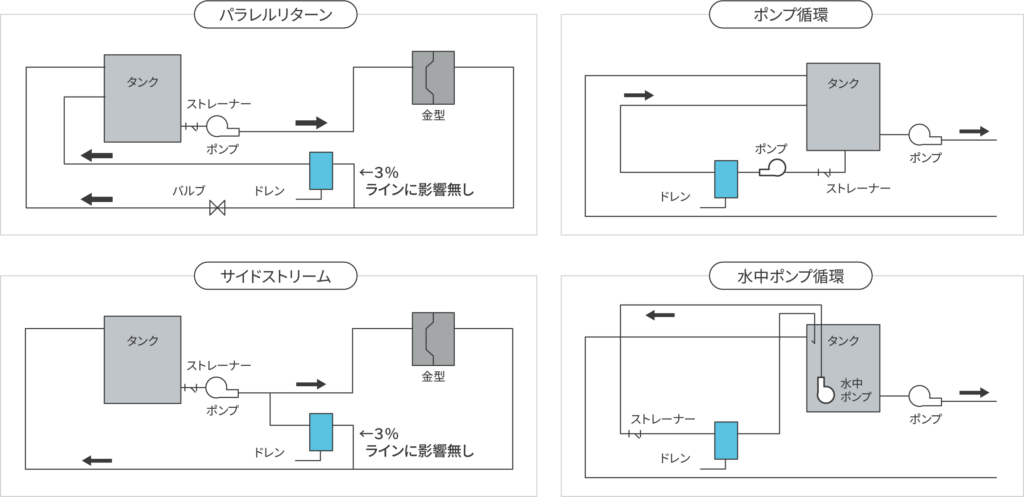

Connection example

This is connected to the connection system (chiller, sealed cooling tower) line.

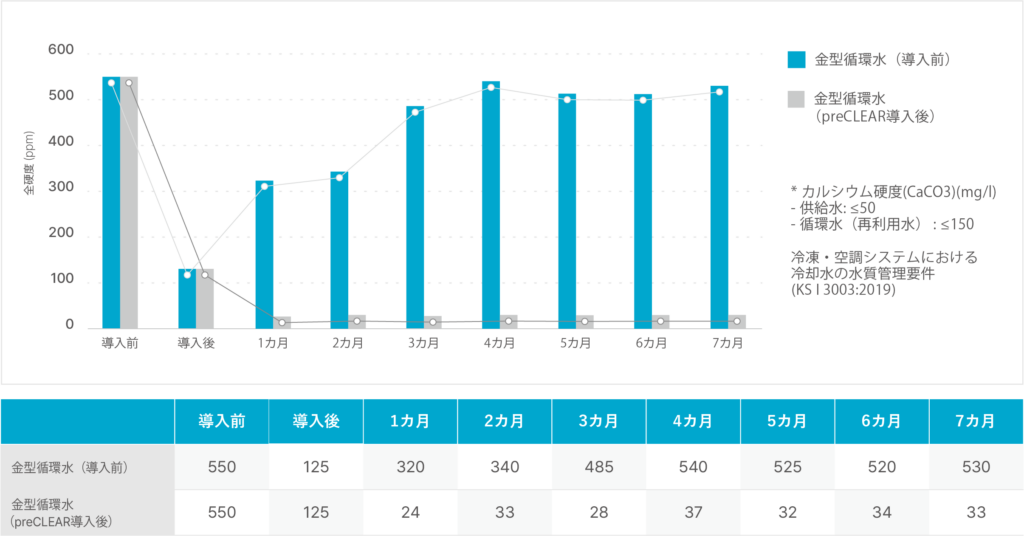

Performance Example

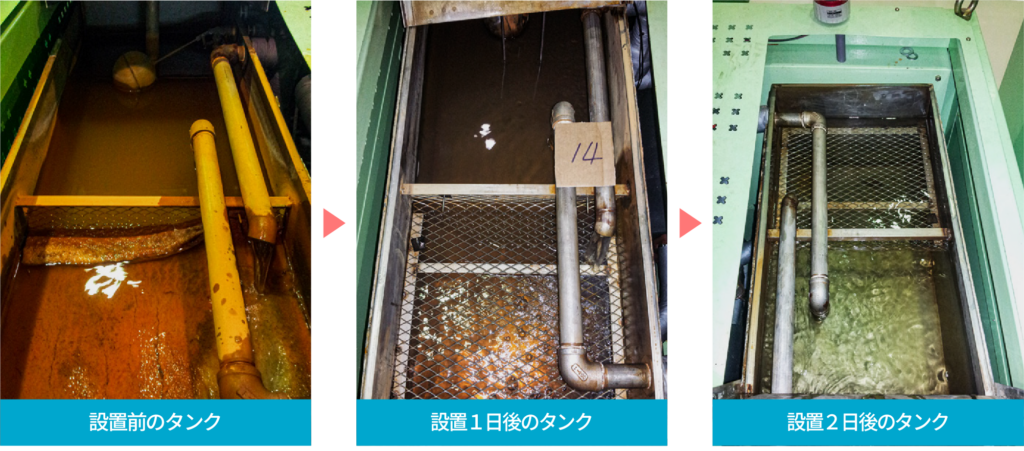

We introduced preCLEAR and monitored the progress of water quality.

Before installation: Turbidity and discoloration were evident, and the water quality was unstable.

One day later: The water quality has changed significantly, and the transparency has improved.

Two days later: The image becomes even clearer.

As you can see in the photos, you can see the effects of introducing the equipment in a short period of time.

Combination with solution items

"Kalfa SEP x preCLEAR" is a two-tiered water quality solution

Calfa SEP uses a high-speed separation method to efficiently remove solids in water up to 7 μm in diameter. When combined with preCLEAR, it can also recover even finer suspended solids, maximizing the water quality improvement effect.