We use a physical foaming method in which supercritical gas is directly dissolved into resin. This molding method has high foaming properties and a wide range of applications, enabling the production of lightweight injection molded and blow molded products with good dimensional stability.

What is MuCell® Microcellular Foam Molding?

About MuCell® Microcellular Foam Molding

This is a physical foaming molding method that uses nitrogen or carbon dioxide extracted from the atmosphere directly to dissolve the resin. It has stronger foaming power than chemical foaming and is more environmentally friendly.

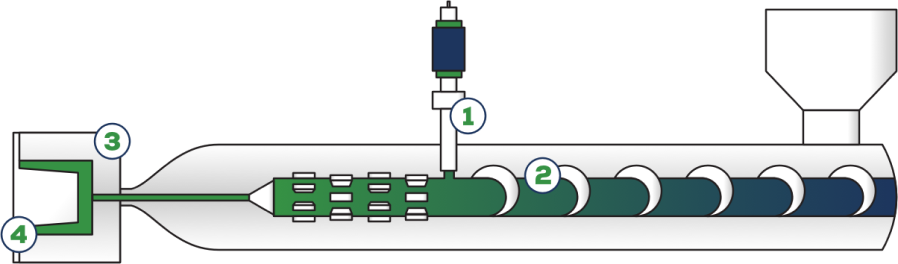

Molding process (mechanism)

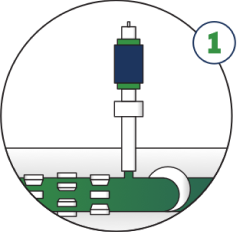

During plasticization, precisely metered amounts of supercritical nitrogen or carbon dioxide (SCF) are injected into the resin through a dedicated injector attached to the barrel.

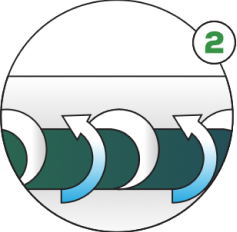

The specially designed mixing screw in the plasticizing barrel uniformly disperses, mixes and dissolves the SCF in the molten resin, forming a single-phase melt.

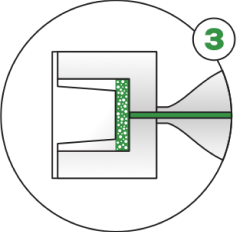

When the molten resin is injected into the mold cavity, the pressure drop in the mold cavity causes the nuclei of foam cells to form. The SCFs dispersed in the molecules form a homogeneous, closed-cell foam structure with a solid skin layer.

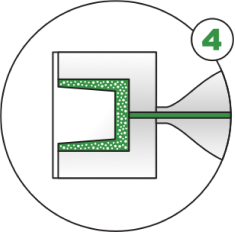

Controlled foam cell growth replaces the packing step and applies a uniform, low fill pressure to the entire mold cavity. Cell growth stops once the mold cavity is filled.

Features of MuCell®

Reduction of resin usage

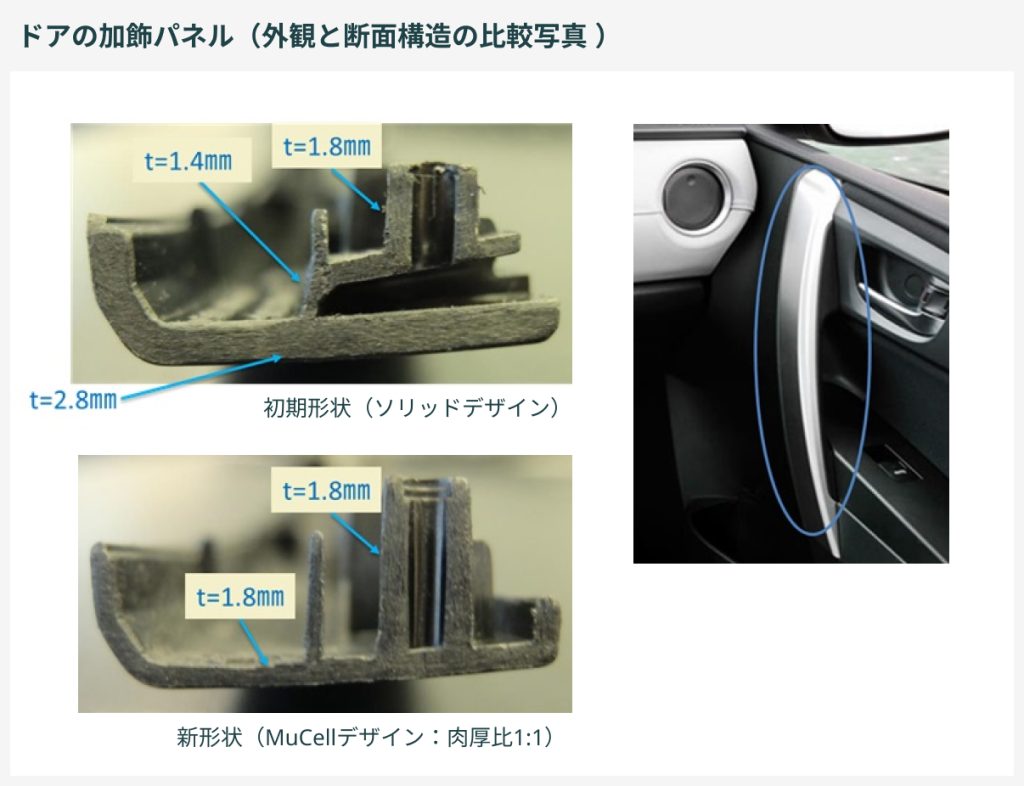

Foaming of resin can reduce weight and the amount of resin used. In addition, foaming can prevent sink marks, enabling unprecedented designs, and reducing the volume of molded products can further reduce the amount of resin used.

Improved warping and sink marks

Since the foaming of the resin replaces the pressure holding, it is possible to prevent sink marks. In most cases, setting a rib with the same thickness as the base wall thickness will prevent sink marks from occurring on the molded product.

In addition, since pressure holding is no longer necessary, warping caused by pressure holding can be improved.

Increased productivity

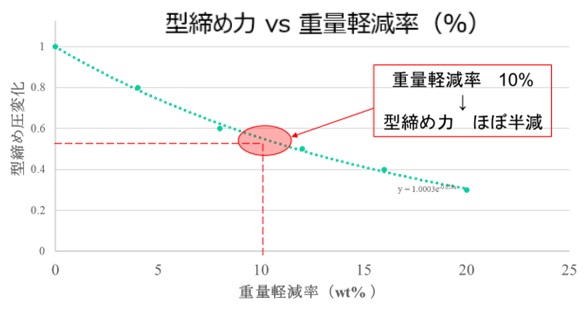

Since foaming prevents sink marks, this molding method does not require pressure holding. This allows the clamping force to be reduced by approximately 50% (when the weight reduction rate is 10%), which allows the clamping tonnage of the molding machine to be reduced.

Also, with the same molding machine, you can double the number of molded parts. In addition, you can shorten the cycle time by reducing the time required for the pressure holding process.

Examples