特長

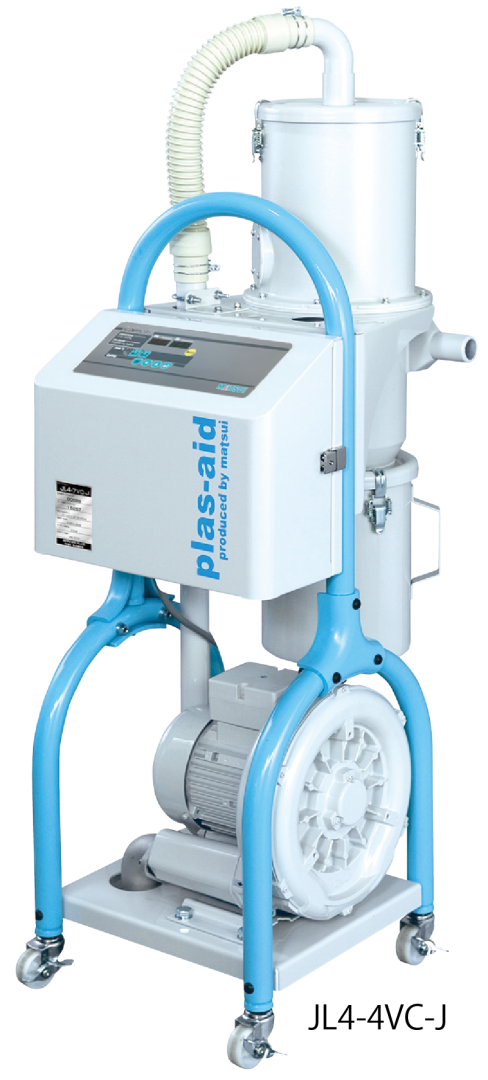

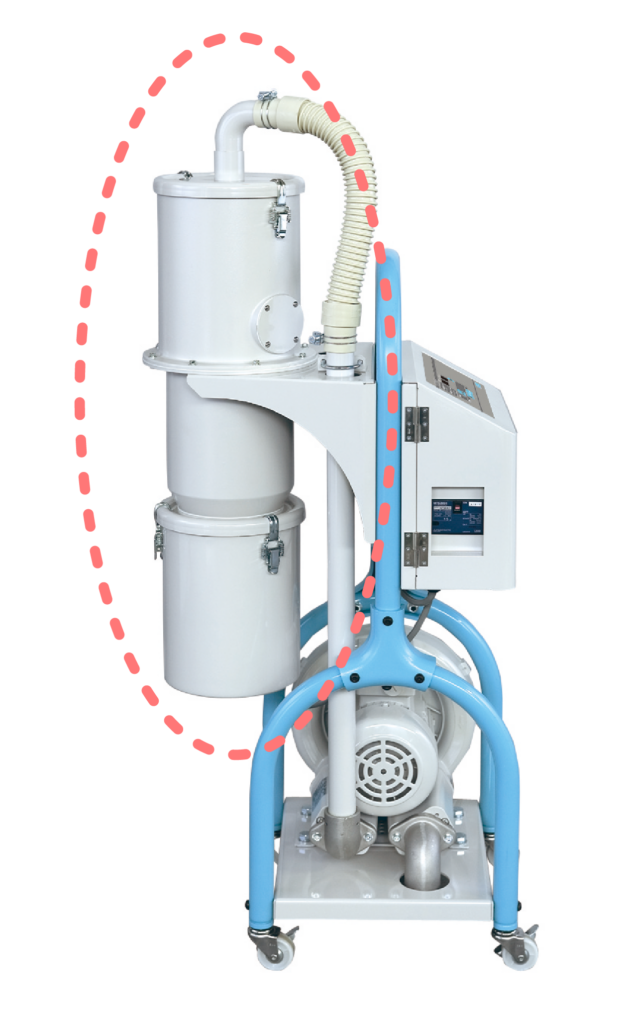

1. フィルタの清掃頻度を抑えるサイクロンセパレータ

フィルタ前にサイクロン式集塵セパレータを設置することで、輸送中に発生する粉塵を集中的に捕集します。これにより、フィルタへの粉塵付着を抑え、フィルタへの負荷軽減と清掃頻度の低減に貢献します。

また、粉砕材など粉塵を含みやすい材料の輸送においても、輸送能力を大きく低下させることなく、長時間にわたり安定した材料輸送が可能です。

2. 清掃タイミングを可視化する掃除お知らせカウンター

掃除お知らせカウンターを標準搭載しています。あらかじめ輸送回数を設定することで、フィルタ清掃の目安となるタイミングをランプ表示でお知らせします。

これにより、掃除のタイミングが把握しやすくなり、清掃忘れや不要な頻繁清掃を防ぐことが可能です。適切なタイミングでメンテナンスを行うことは、フィルタの目詰まりを抑えた安定した輸送状態の維持に役立ちます。

3. メンテナンス性に配慮した大型ダストボックス

大型ダストボックスの採用により、集塵した粉塵をまとめて排出しやすい構造となりました。ダスト排出作業が簡単に行えるため、日常メンテナンス時の作業負担を軽減します。

Vタイプでは、キャップを外すだけでダストの排出が可能です。

メンテナンス回数の削減と作業性に配慮した構造により、樹脂輸送機の安定稼働と生産性向上をサポートします。

4. 省スペース化を実現するコンパクト構造

空気源、制御盤、集塵装置、ダストボックスを機能的に一体化した構造を採用しました。装置全体をコンパクトにまとめることで、工場内の限られたスペースにも設置しやすくなっています。

省スペース化に配慮した設計により、レイアウトの変更や装置導入時の負担を抑え、工場空間を有効的に活用することが可能です。スッキリとした構成で、高効率な材料輸送を実現します。

5. 作業環境に配慮した低騒音設計

輸送時に発生しやすい金属音や空気音を抑える設計とし、工場内での騒音低減に配慮しています。

運転時の騒音レベルは80dB以下に抑えています。

これにより、作業者への音による負担を軽減し、長時間稼働時でも比較的快適な作業環境づくりに貢献します。

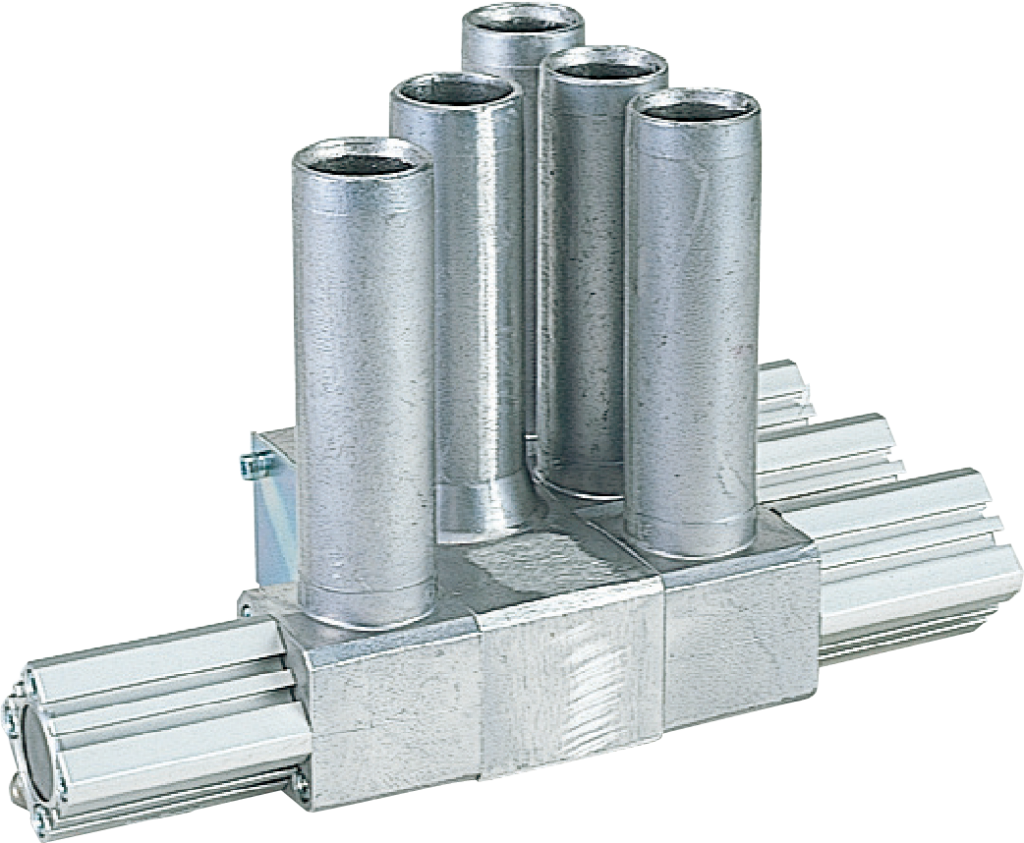

多方向ローダーバリエーション

2~6の方向分岐バルブをご用意しています。

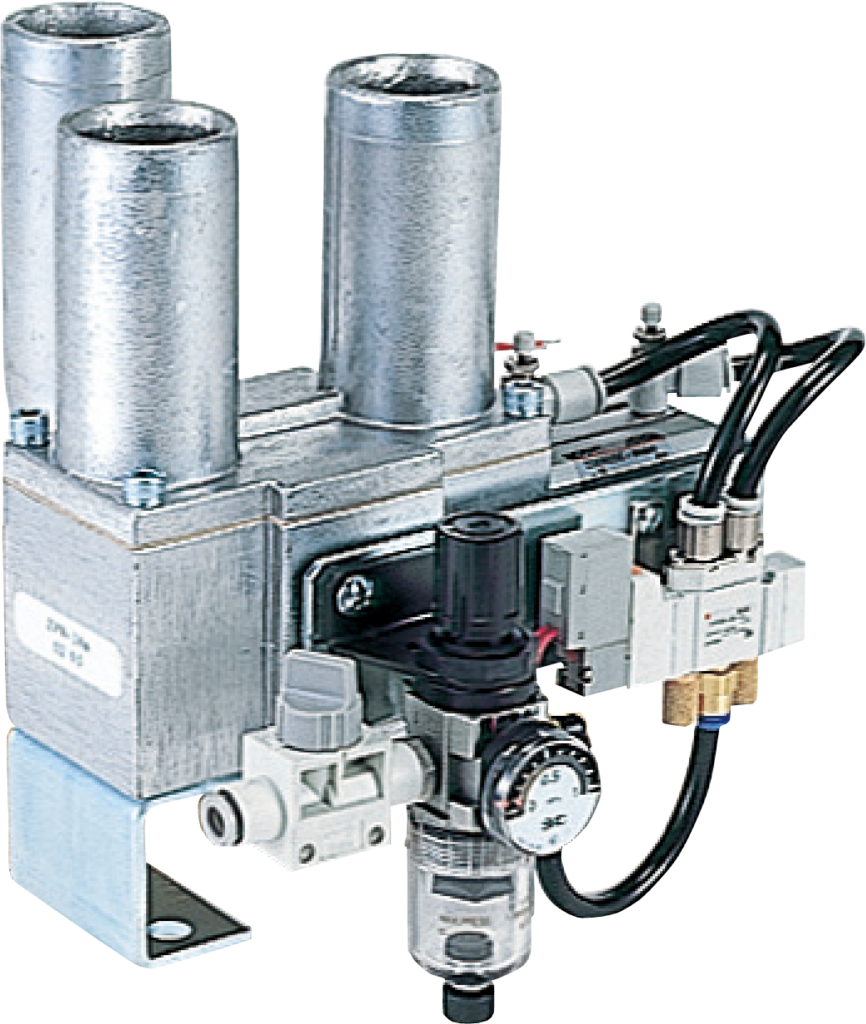

2方向分岐バルブ

3方向分岐バルブ

4方向分岐バルブ