特長

1. 均一な熱風制御を実現するホッパードライヤー

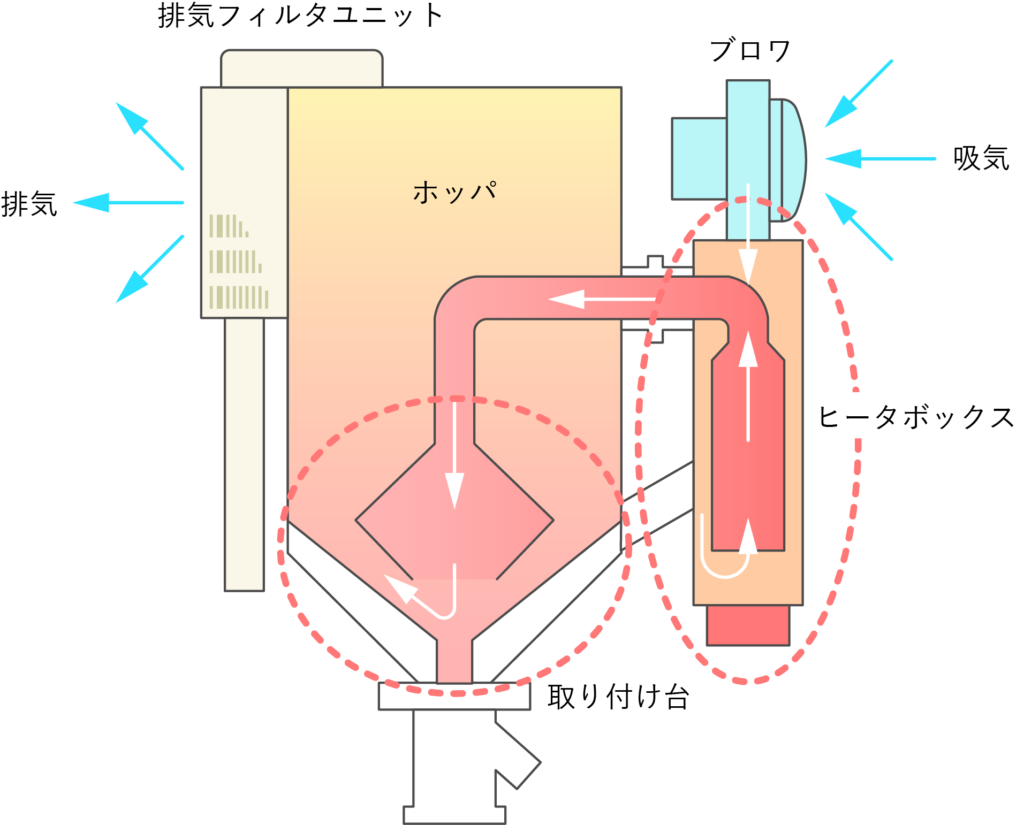

ブロワーにより取り込まれた外気は、整流対策を施したヒーター部を通過し、吐出口から均一に分散されます。熱風の流れを最適化することで、ホッパー内部全体にムラなく供給され、設定温度と樹脂温度との差を最小限に抑えます。

また、ホッパー内部にはマツイ独自のディフューザーコーンを採用しています。コーンとホッパー壁面に隙間を設けることでマスフローを促進し、ブリッジの発生を防ぎながら、材料を均一に排出します。

大型部品や高強度部品に使う長繊維材を扱うと、ホッパー内で材料が詰まりやすくて困っています。

ガラス繊維や炭素繊維を熱可塑性樹脂に複合化した長繊維材料は、繊維同士が絡みやすく、ブリッジが発生しやすい特性があります。

その影響で材料不足が起こり、材料の焦げ付きや成形機の計量異常、スクリュの過温といったトラブルが出てしまいます。

弊社独自のディフューザーコーンは、ホッパー内の材料流動を改善し、ブリッジを防止します。これにより、材料を安定して供給することでき、成形トラブルの抑制につながります。

2. 二重安全機構による、ヒーター過温防止設計

ヒーター過温警報は発生した場合には、電圧引き外し式(SHI式)ブレーカーが作動し、電源を遮断します。異常時に速やかに装置を停止させることで、ヒーターや周辺機器へのダメージを防止します。さらに、温度調節計とは独立した安全装置として、外部過温防止装置を標準装備しています。

このように、二重の安全機構により、万一の異常時にも高い安全性を確保しています。

3. 放熱を抑え、省エネルギー運転を実現

ヒーターボックスは、熱交換性能と断熱性能を両立した二重構造を採用しています。さらに、装置内で最も高温となるホッパー下部についても二重構造とすることで、外部への放熱を大幅に抑制しています。

これにより、加熱した熱風のエネルギーを効率よく乾燥に活用でき、ヒーターのムダな出力を抑えることが可能です。熱ロスを低減することで、安定した乾燥性能を維持しながら、省エネルギー運転に貢献します。

4. ホッパー内部を素早く清掃できるメンテナンス構造

小型ホッパーでは、直胴部がヒンジを中心に開く構造を採用し、内部へのアクセス性を向上させています。中大型ホッパーには大口径の清掃窓を設け、扉を開けるだけでホッパー内部の清掃が可能です。

ホッパーサイズに応じた清掃方式とすることで、ワンタッチでメンテナンス作業を行えます。これにより、清掃時間の短縮や負担軽減につながり、日常点検や段取りを効率化します。

5. 工場環境を守る、長寿命シートフィルター

工場内環境をクリーンに保つため、脱着が容易で長寿表なシート状フィルターを標準装備しています。日常点検や交換作業を簡単に行える構造とすることで、メンテナンス作業の負担を軽減します。設備周辺の清潔性を保つことで、安定稼働と品質維持を支えます。