環境にやさしく、設備にやさしく。ー ドライアイス洗浄の基本

1. ドライアイスブラストとは?

ドライアイスペレットやブロックドライアイスをシェービングしてマクロ粒子化したパウダースノーペレットを、圧縮空気で高圧噴射。金型や成形設備に付着した樹脂カス・スケール・油分などの汚れを、高い洗浄力で除去します。

ドライアイスは非常に柔らかく、接触しても摩擦を起こしにくい非摩擦性の洗浄メディアです。また、ドライアイスは、個体から直接気体へと昇華する性質を持つため、洗浄後に二次廃棄物を一切残さず、洗浄対象に残渣が付着することもありません。

さらに、薬剤を使用せず毒性がないため、作業者にも安心してご利用いただけます。電気を通さない非伝導性を備えていることから、電子部品や制御系統など、精密な装置の洗浄にも適しています。

手作業やサンドブラストのような接触・摩擦を伴う洗浄とは異なり、対象物を傷つけることなく、環境にも設備にもやさしい洗浄方法です。

従来の洗浄方法と比べると、ドライアイスブラストにはご覧のとおり多くの強みがあります。さらに非接触で行えるため、金型などを分解せず、そのまま洗浄できるのも大きな利点です。

| 洗浄方法 | 二次廃棄物なし | 非導電性 | 非毒性 | 非研磨 |

|---|---|---|---|---|

| ドライアイスブラスト洗浄 | 〇 | 〇 | 〇 | 〇 |

| サンドブラスティング | 〇 | 〇 | ||

| ソーダブラスティング | 〇 | 〇 | ||

| ウォーターブラスティング | 〇 | 〇 | ||

| 工具 | 〇 | 〇 | ||

| 溶剤/化学薬品 | 〇 |

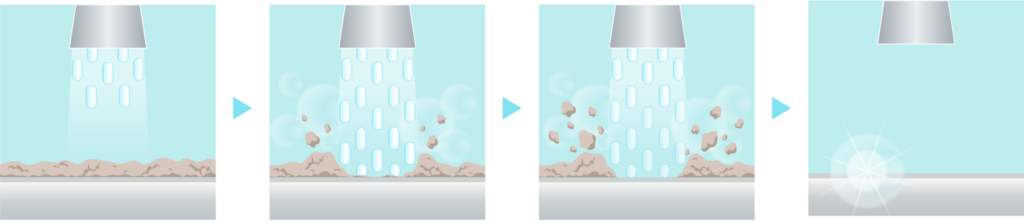

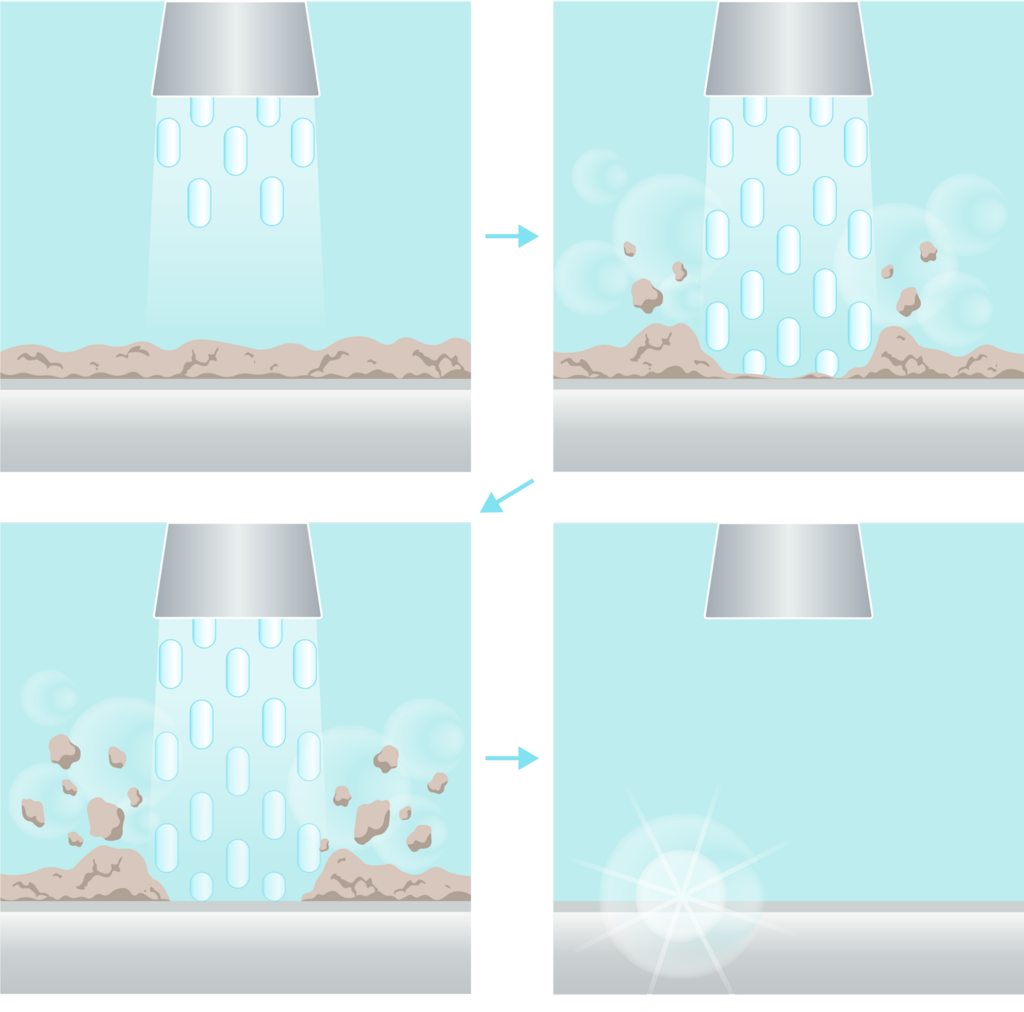

2. どう洗う?ドライアイス洗浄のしくみ

ドライアイス洗浄は、超音速で噴射したドライアイス粒子が対象物に衝突すると、運動エネルギーによって付着物が削られます。それと同時に-78.5℃のドライアイスの冷却効果により、付着物が脆化します。その直後、ドライアイスは接触と同時に個体から気体へと急激に昇華し、体積が約800倍に膨張。この瞬間に生じる小さな爆発のような衝撃が、汚れを洗浄対象から弾き飛ばします。そのため、対象物には一切のダメージを与えず、表面に残留物を残すことなく、きれいな状態へと回復させることができます。

ドライアイスの「衝撃」「冷却」「昇華」という3つの効果が組み合わさることで、傷つけずに汚れを除去することができます。

下の映像では、実際の洗浄の様子をご紹介します。

特長

1. マイクロ粒子と低圧動作でかなえる精密洗浄

特許技術「シェーブドライアイス」を搭載し、従来のペレット型に比べてドライアイスをはるかに微細なマイクロ粒子へと加工。これにより、精密成形の電子部品や医療向け成形品の繊細な金型表面や複雑形状、微細な隙間まで、傷つけることなく的確に洗浄することができます。

また、本装置は0.14~0.97MPaという低圧でも十分な洗浄力を発揮する低圧作動設計を実現。最小エア使用量0.3㎥/minからブラストが可能なため、圧縮エアの消費を抑えつつ、洗浄効果を最大化できます。これにより、高効率かつ低騒音な洗浄環境を実現し、作業者の負担や設備の消耗も軽減します。

電子部品向けの精密成形では、金型表面が非常に繊細で…。洗浄中に微細なキズが入らいか正直かなり気を使うんです。

その点はご安心ください。ドライアイスを特許技術でマイクロ粒子化しており、低圧でも高い洗浄力で繊細な金型でも傷つけずに、細部まできれいにできます。

それな安心して任せられそうですね!

2. 連続※最大45分の安定ブラストでかなえる段取時間の削減

i3 MICRO CLEAN2は、5kg(カート付きで6kg)のブロック状ドライアイスに対応し、

※最大45分間の連続ブラストが可能です。

さらに、ペレットやナゲットタイプのドライアイスにも対応可能です。より安定供給しやすく、ドライアイスの形状に左右されにくいため、運用の柔軟性が向上します。もちろん、これらもマイクロ粒子化されるため、繊細な洗浄対象にも高精度なブラストが行えます。

※ ブラスト時間は、参考値になります。

3. 見える・残せる・守れる操作性でかなえる安定洗浄

i3 MICRO CLEAN2は、7インチ液晶ディスプレイとデジタルコントロールを採用しています。ブラスト圧力やドライアイスの粒径、供給量といった主要パラメーターを細かく設定でき、洗浄対象に応じた最適条件をレシピとして保存可能です。作業者ごとのバラつきを抑え、いつでも安定した洗浄品質を維持できるようサポートします。

また、ドライアイスの残量はLEDインジケーターにより、リアルタイムで可視化され、補充のタイミングを事前に把握することが可能です。作業中の急な中断を防ぎ、ムダな手待ち時間を削減することで、稼働効率を大きく向上させます。

洗浄条件を毎回イチから合わせるのって、結構手間なんですよね…。

しかも、装置の操作に慣れていないと、設定ミスも心配で。

i3 Micro Clean2なら、一度決めた条件をレシピとして保存できますし、操作画面も直感的で扱いやすいんです。スクリーンロック機能もあるので、うっかり設定を変えてしまう心配もありません。

効果事例

ドライアイスブラスト洗浄の効果事例をご紹介!

i3 MICRO CLEAN2は、精密成形金型をはじめ、さまざまな種類の金型に対応可能な洗浄装置です。さらに、洗浄対象は金型にとどまらず、軟質材料や熱硬化性材料の成形品に付着したバリの除去、ミキサー羽根などの機械部品の洗浄など、多様な現場で活躍しています。

幅広い用途で実際に効果を発揮している、導入事例の一部をご覧ください。

効果事例 ①

効果事例 ②

導入前テスト・見学のご案内

導入の不安を解消する、事前テストと見学を受付中!

導入をご検討中のお客様には、事前テストや見学の機会をご用意しております。

弊社の大阪拠点「factor4 tech-studios」では、 i3 Micro Cleanの実機を常時展示しており、サンプル品を用いたデモや、実際の洗浄対象物をお持ち込みいただいての洗浄テストが可能です。

さらに、ご来場のお客様には、ドライアイスブラスト洗浄に加えて、各種金型メンテナンス機器や成形支援ソリューションもわせて体験いただけます。洗浄だけでなく、生産性や品質向上につながる成形現場の総合的な改善のヒントをご覧いただけます。

現在の洗浄方法に課題をお感じ方は、ぜひ一度お試しください。

一部地域では、お客様の工場へ装置を持ち込んでの洗浄テストも実施しております。