金型で起きるガス問題とは?発生メカニズムと対策の重要性

品質と生産性を揺るがすガストラブル

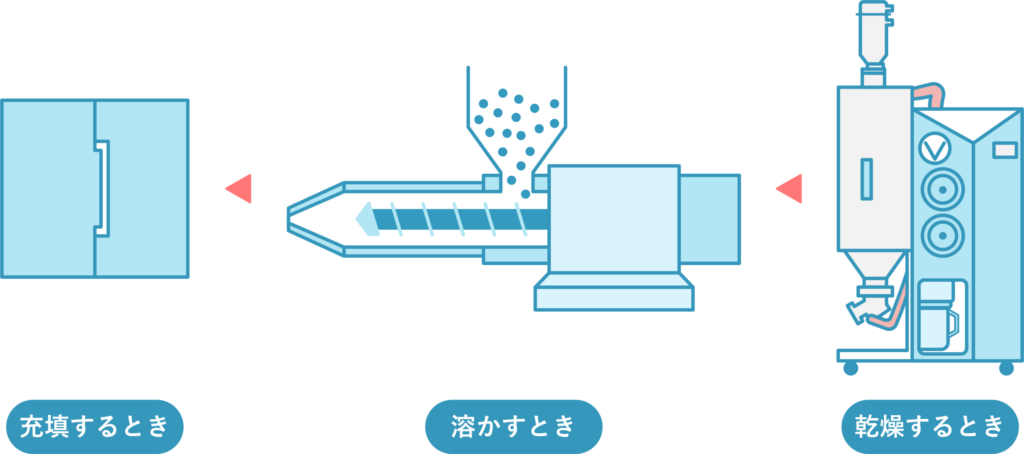

プラスチック成形におけるガストラブルは、成形不良の発生や金型メンテナンスの増加といった厄介なトラブルを招く要因のひとつです。樹脂は乾燥工程、溶融時、そして射出・充填の過程で過熱されることにより、ガスが発生します。このガスが金型に滞留すると「ヤケ」や「ショートショット」などの成形不良につながり、安定した生産を妨げる要因となってしまいます。

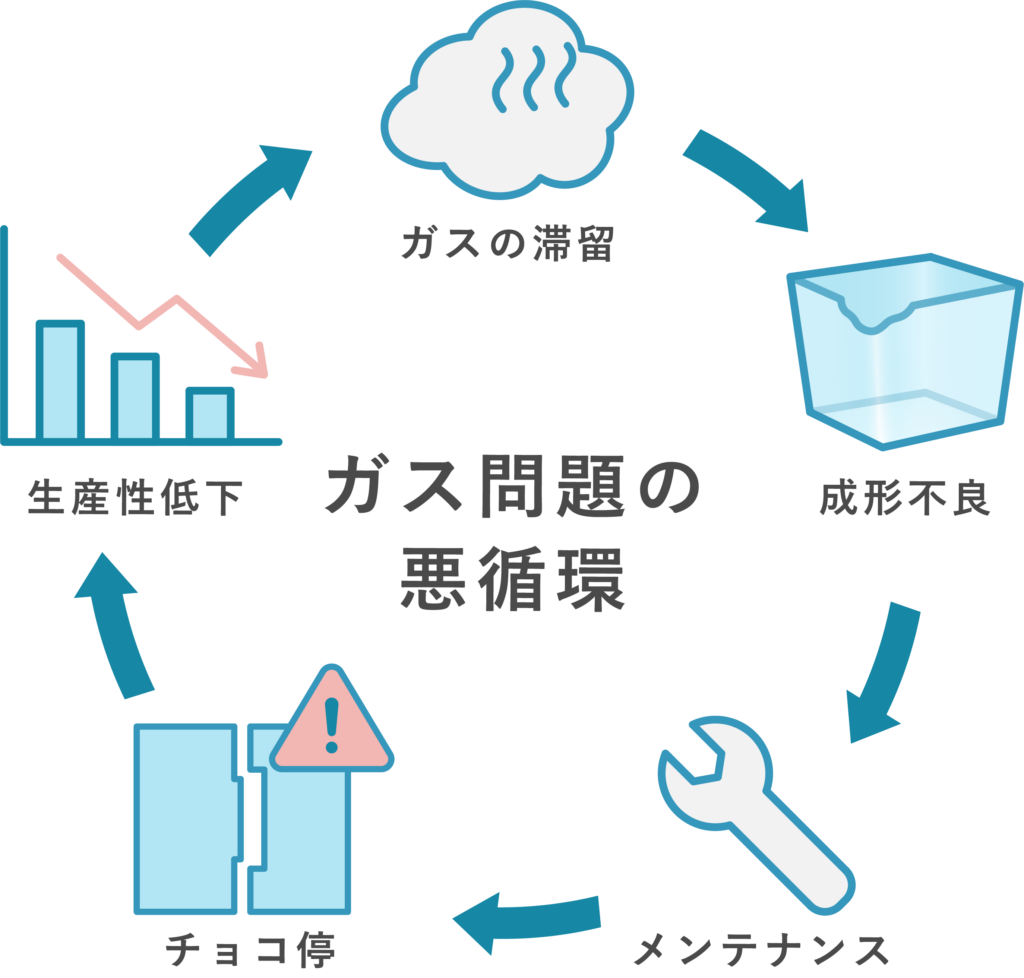

その対策として、多くの金型では設計段階からガスベント(排出機構)が設けられ、ガスの逃げ道を確保する工夫が施されています。しかし現場では、「ガスベントがあるのに、ガスが十分に抜けない。」「ガス焼けを避けるために、こまめなメンテナンスが欠かせず負担が大きい。」といった声が少なくありません。ガスが抜けきらず滞留したままだと、成形不良の発生だけでなく、頻繁なメンテナンスによるチョコ停が増え、結果として生産性が大きく低下してしまいます。

日頃から、「分かっているけど、なかなか改善が難しい」そんなガストラブルに心当たりがあるのではないでしょうか?

ガスの発生メカニズム

プラスチック成形におけるガスは、ひとつの要因だけで発生するものではありません。樹脂の状態、成形条件、金型設計など、複数の要素が重なり合うことで生じます。ここでは、ガスが「発生する理由」と「滞留してしまう理由」を整理してみましょう。

◆ ガスが発生する主な要因

① 樹脂に残った水分が蒸発する

乾燥不足の樹脂には、微量の水分が残ります。 この水分が溶融時や加熱時に蒸発し、水蒸気としてガス化します。

② 樹脂中の揮発性成分・添加剤の蒸発や分解

樹脂に含まれる添加剤や再生材の劣化成分は、加熱されると揮発・分解しガスを発生させます。また、溶融温度や金型温度が高すぎたり、滞留時間が長かったりすると、樹脂そのものが熱分解してガス量が増えることもあります。

③ 金型内の空気が圧縮される

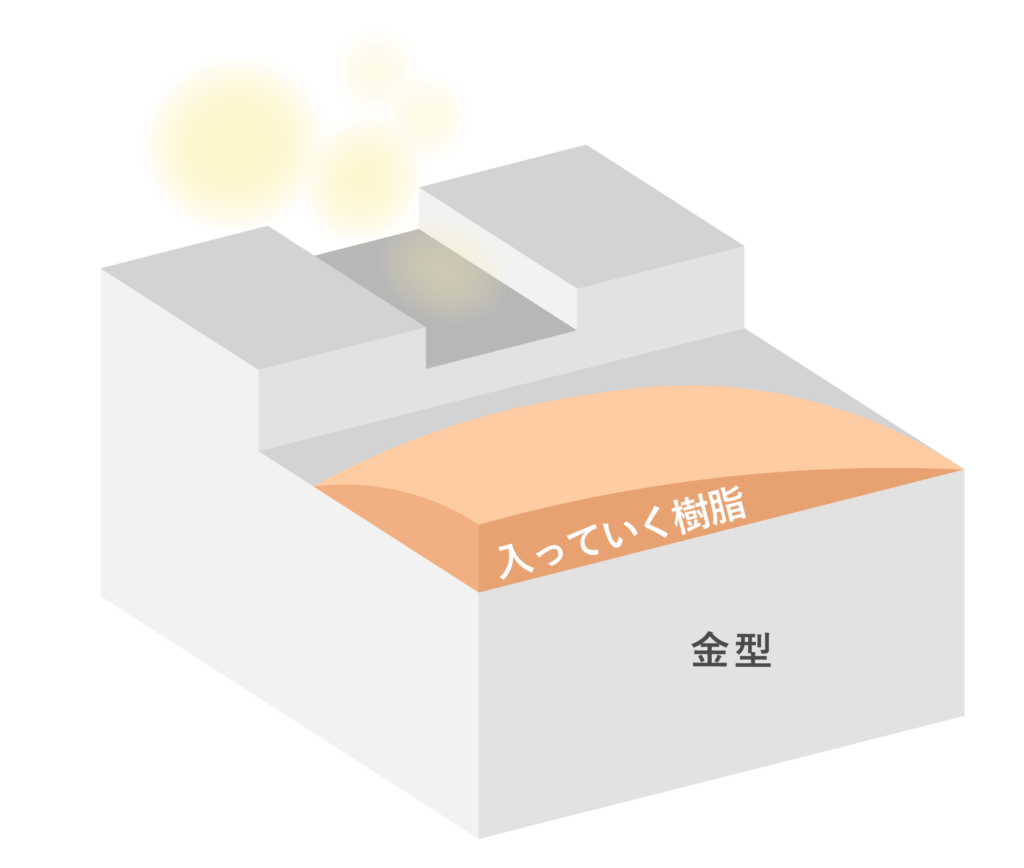

射出時、溶融樹脂が金型に充填される過程で、金型内に残った空気が逃げきれずに圧縮される場合があります。ベントが不十分だったり、詰まっていたりすると、圧縮空気が高温になり「ガス焼け」や「ショートショット」の原因となります。

◆ ガスが滞留してしまう理由

本来、金型にはガスを逃がすためのベントが設けられていますが、次のような理由で十分に機能しないことがあります。

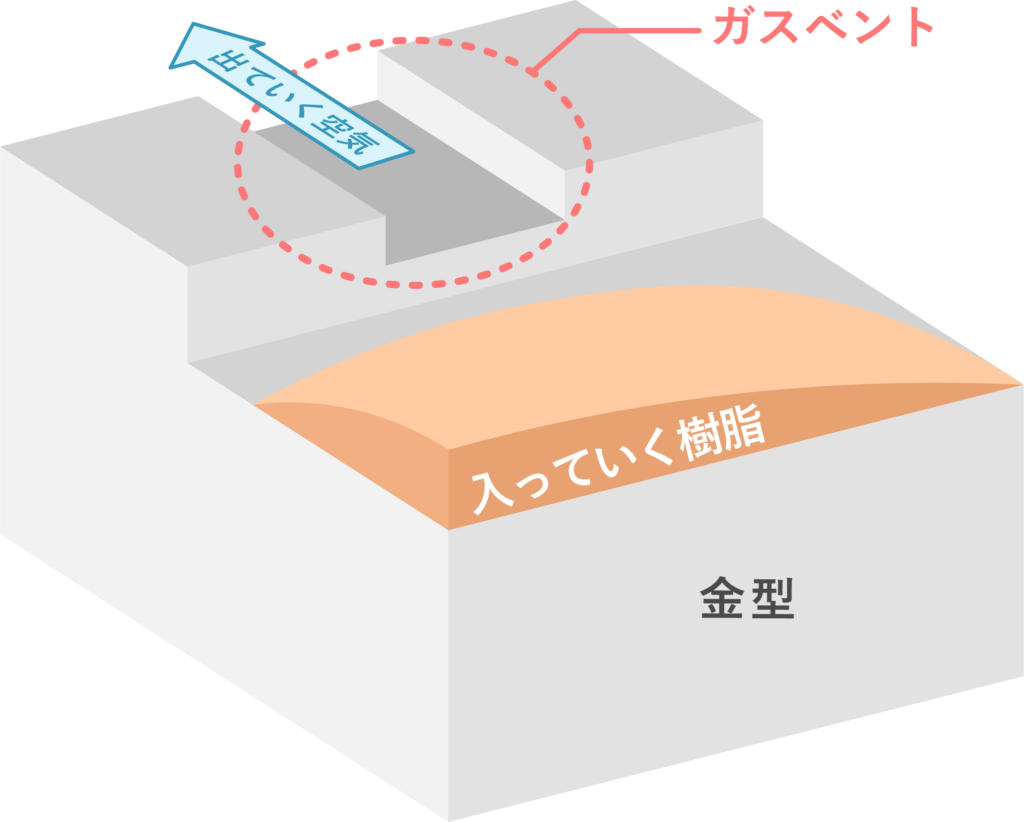

ガスは流入してくる樹脂に押し出されるようにしてガスベントから金型外に排出されます。

① ベントの排気能力が不足している

製品形状・流動末端の構造によっては、設計上のベントでは十分にガスを排出しきれない場合がります。

② ガスが冷えて固化し、ベントが詰まる

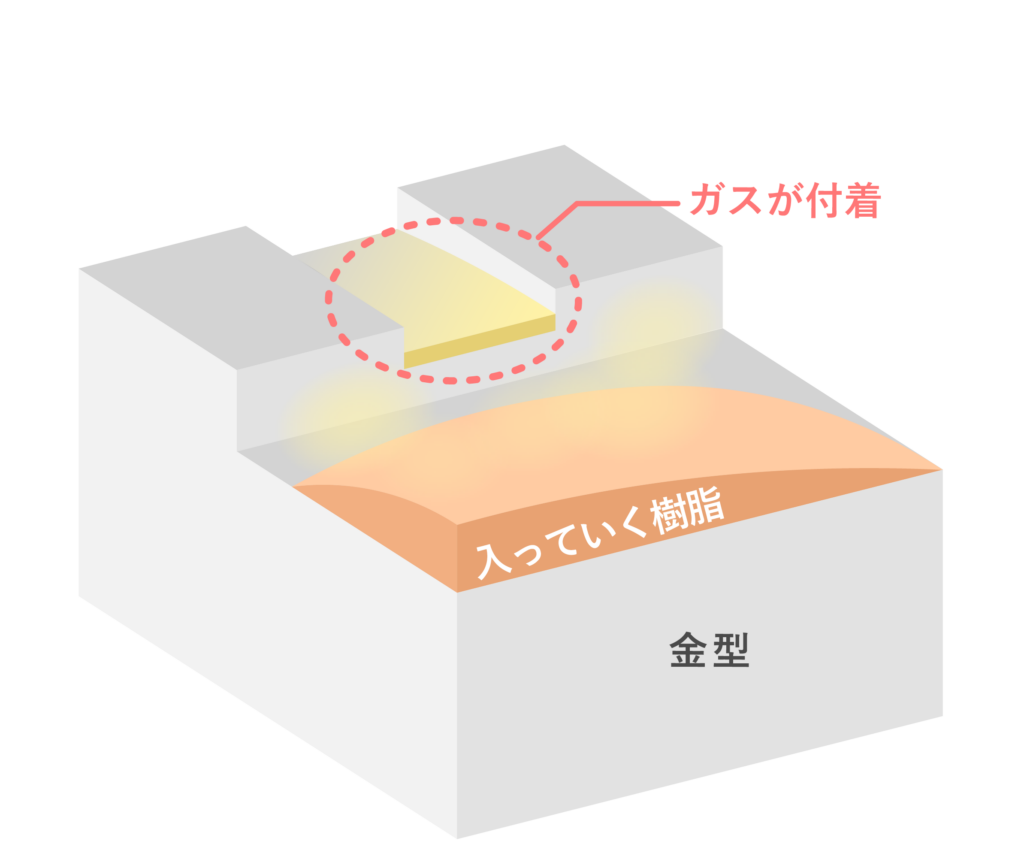

発生したガスは冷えると固化しやすく、ベント内部に付着して通気を妨げます。気体の状態なら抜けやすいガスも、固化してしまうと微細な隙間をふさぐ汚れとなり、ガス抜けが急激に低下します。

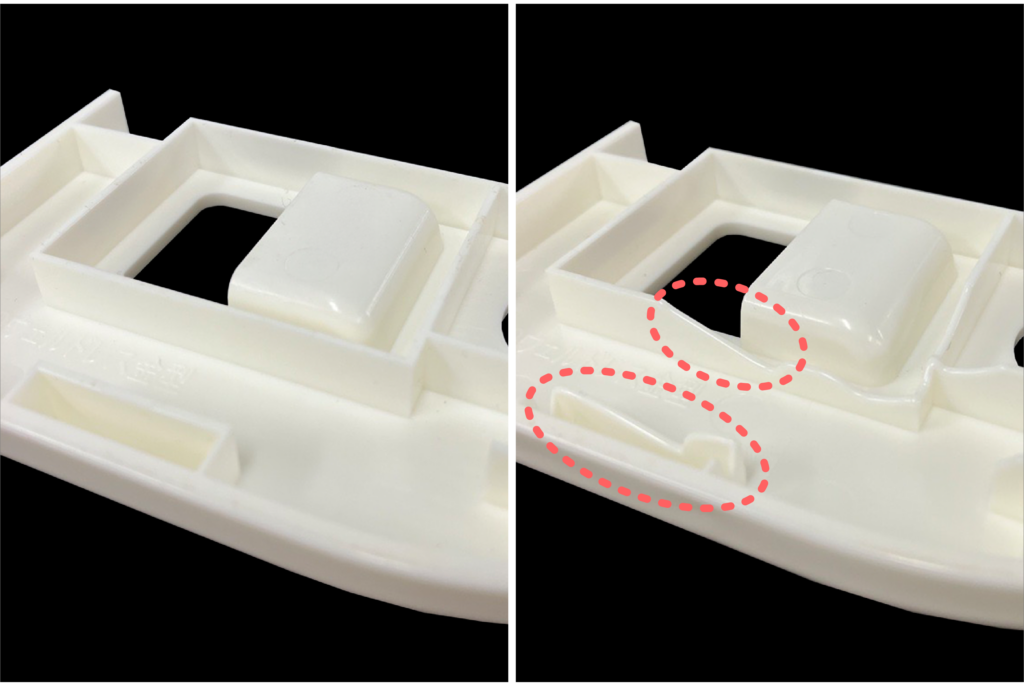

ガスが正常に排出されている状態

固化したガスがベントに付着した状態

◆ ガス滞留がもたらす悪影響

金型内でガスが滞留すると、まず金型内への付着や固化が進み、ベントがふさがるにつれ、さらにガスが抜けにくい状態になります。その結果、ヤケやショートショットなどの成形不良が発生しやすくなります。これを抑えるためには、金型の分解掃除などのメンテナンスが必要となり、メンテナンス頻度が増えるほどチョコ停が多発して生産時間が削られ、生産性は大きく低下します。メンテナンスによって一時的に改善しても、根本原因が解決されなければ再び発生し、現場には大きな負担がかかります。

このように、ガス滞留は成形不良や稼働率低下を引き起こす要因となり、現場の安定生産を阻害します。

なぜ今、ガストラブル対策が注目されているのか

成形現場ではここ数年で“ガス対策”への関心が一段と高まっています。その背景には、材料の変化や成形品の高精度化といった、産業全体の流れがあります。

◆ 高機能樹脂の採用が増え、ガス要因が複雑化

近年、電子部品や自動車、医療など幅広い分野では、耐熱性や強度を持つ高機能樹脂の採用が進んでいます。これらの樹脂は性能に優れる一方で、成形時にガスが発生しやすく、金型内にガスが残って不良につながるケースが増えています。(例:PPS、PEEK、LCP)

ガスが発生しやすい主な要因

・高温域での成形が多い

・吸湿性を持つ樹脂がある

・添加剤が多く使われている

こうした要因が重なることで成形時のガス発生が増え、金型内にガスが残りやすくなり、ヤケやショートショットといった不良の発生リスクが高まります。

特にポリフェニレンサルファイド(PPS)、ポリエーテルエーテルケトン(PEEK)、LCP樹脂(液晶ポリマー)は、ガストラブルが発生しやすい代表的な樹脂です。

◆ 微細・薄肉の成形品ではガスが逃げにくい構造に

光通信部品やコネクタなど、近年は微細化・薄肉化した製品が増えています。形状が複雑で狭い隙間が多い金型では、そもそもガスが逃げにくくく、わずかなガス残りでも不良につながることがあります。

ガスが逃げにくい主な要因

・形状が複雑で狭い隙間が多い

・微細なキャビティが増えている

・薄肉化によりガスの通り道が限られる

こうした要因から、寸法が安定しない、離型不良が発生しやすい、メンテナンスサイクルが短くなるといった課題が顕在化してきました。

◆ 現場が求める「確実にガスを排出する方法」

このように、材料の高機能化や製品要求の厳格化によって、従来以上に“ガス管理”の重要性が高まっています。「ガスのベントだけでは十分に抜けきらない」「メンテナンス頻度が増えて困っている」と感じる現場が増え、金型内のガスを確実に排出できる手段へのニーズが強まっています。

その解決策のひとつとして、金型内のガスを強制的に吸い出す「ガス吸引装置」が注目されています。ガスを気体のうちに排出し、ベント詰まりを未然に防ぐことで、安定した成形とメンテナンス負荷の軽減をめざすアプローチです。

MAGの特徴

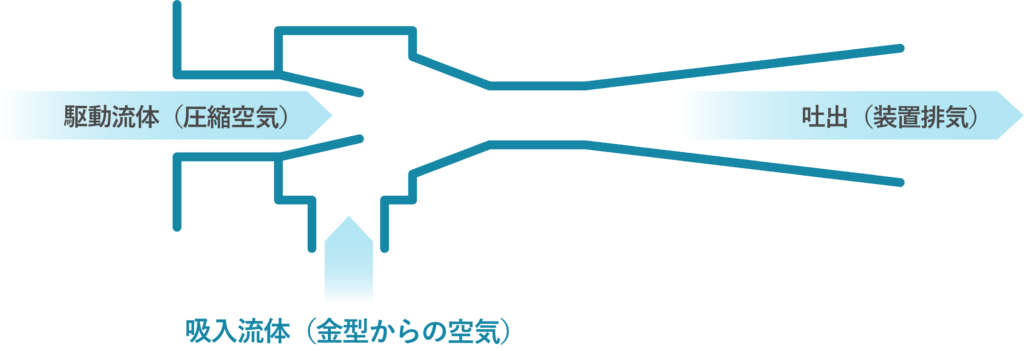

1. エゼクター搭載による瞬時のガス吸引を実現

金型へのガス付着を防止するためには、樹脂が充填されるまでの射出後のわずか数秒でガスを吸引することが不可欠です。本装置では「エゼクター」を採用することで、成形サイクルに追従した瞬発力のあるガス吸引を可能にしました。

2. 2種類の吸引モードで金型温度の低下を防止

ガス吸引の際、金型温度が低下してしまう場合があります。樹脂の流動性が損なわれると、抵抗熱の増加によってガス発生の原因となる可能性が懸念されます。つまり、金型を冷やさないためには「必要以上に吸引しない」ことが重要です。

本装置では、2種類の吸引モードから最適な機能を選択することで、PL面を冷却しすぎることなくガスを効率的に吸引し、金型温度の低下を防ぎます。

0.1秒単位での動作調整が可能で、成形に適した温度条件を安定して保ちます。

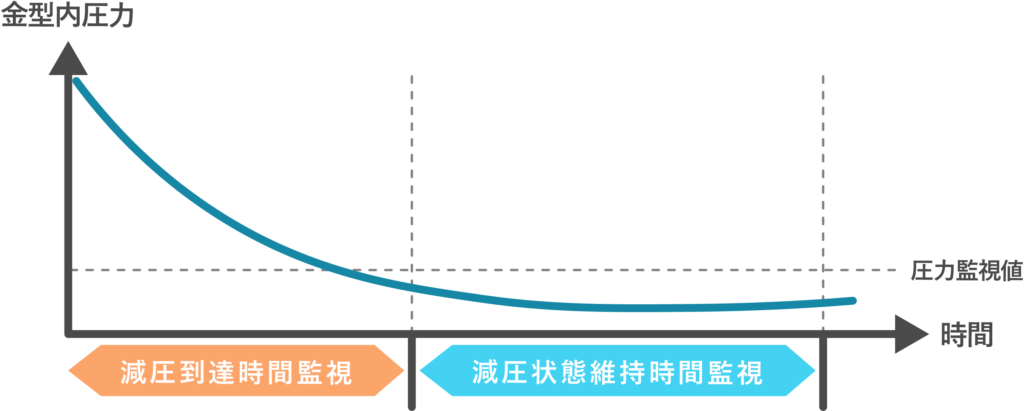

圧力制御モード

一定の吸引圧力に適した段階で、あらかじめ設計した時間のみ吸引を行うモードです。高転写が求められる成形や、圧量管理を厳密に行いたい場面に適しています。

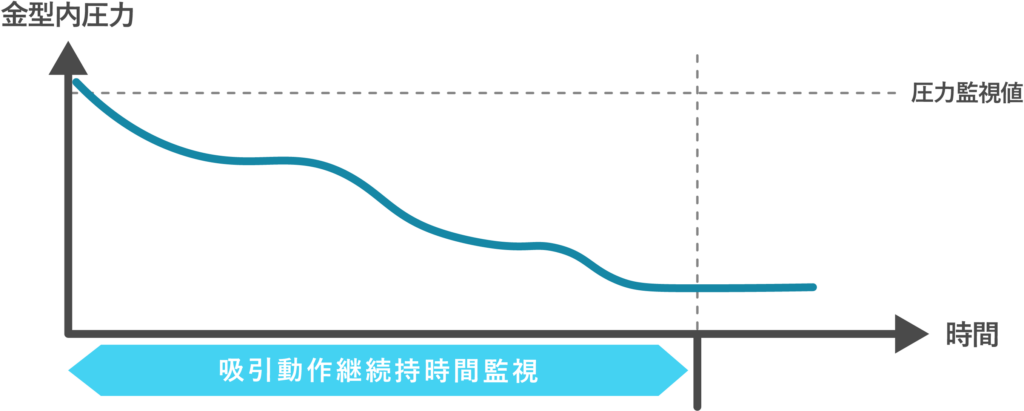

時間制御モード

吸引圧力の変動にされず、指定した時間だけ吸引を行うモードです。圧力が変動しやすい条件下でも、連続して安定した吸引セ家を行いたい場合に有効です。

3. メンテナンスの最適タイミングを確実に把握

フィルタ排気風速計の搭載により、感覚や定期的な時間管理に頼らず、フィルタ状態を「数値」で把握できます。背面フィルタの捕集状況を可視化し、ガス捕集量(捕集効率)を把握することで、適切なメンテナンス時期を確実に判断可能です。これにより、吸引力を安定して維持し、成形品質の低下を防ぎます。

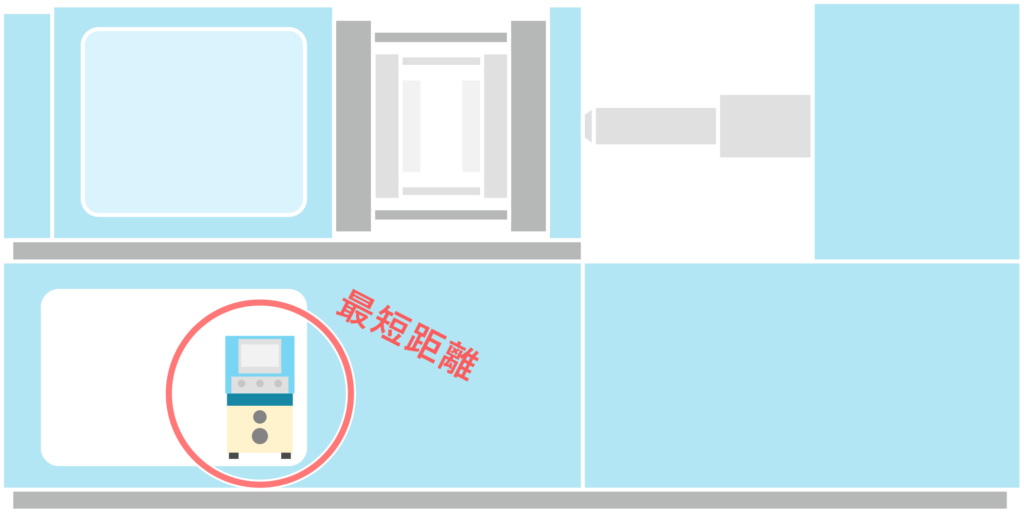

4. コンパクト設計で現場の導線を妨げません

金型近傍への設置を可能にするコンパクト設計を採用。装置導入によって作業者の導線や周辺スペースが圧迫される心配がなく、既存ラインにもスムーズに組み込めます。