From management that relies on intuition to mold management that is based on data.

The key to good molding is "mold management"!

The importance of mold management is widely recognized at molding sites. However, in actual practice, there are many cases where the condition of molds is not properly understood, with maintenance being carried out after defects have occurred or more frequently than necessary. Behind this lies the challenge of being unable to grasp and manage information about multiple molds all at once. Therefore, we focused on "visualizing" the condition of molds.

Mold Connect is a cloud-based system that automates mold data collection and allows for easy management. This allows you to determine the optimal timing for mold maintenance, leading to reduced waste and stable operation at the molding site.

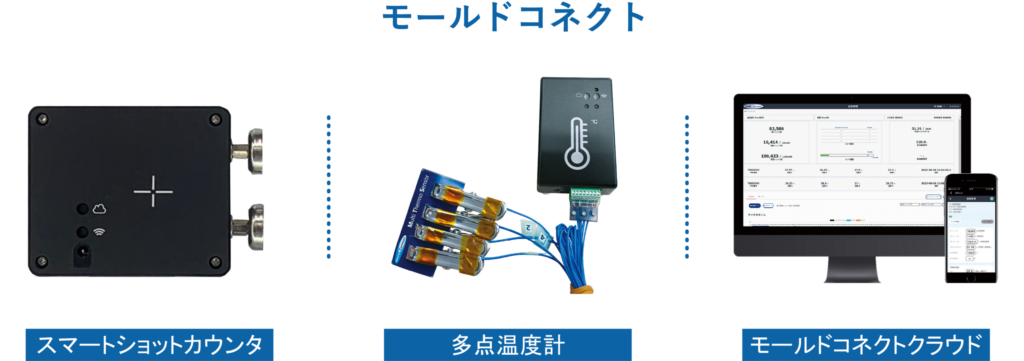

System Configuration

What is the mold management system "Mold Connect"?

Data acquired by the Smart Shot Counter (SSC) and Multi-Point Thermometer (MTS) is sent to the cloud, allowing anyone to check the information from anywhere, anytime, and enabling consistent management for all users.

It also helps ensure traceability by making it easy to review past data.

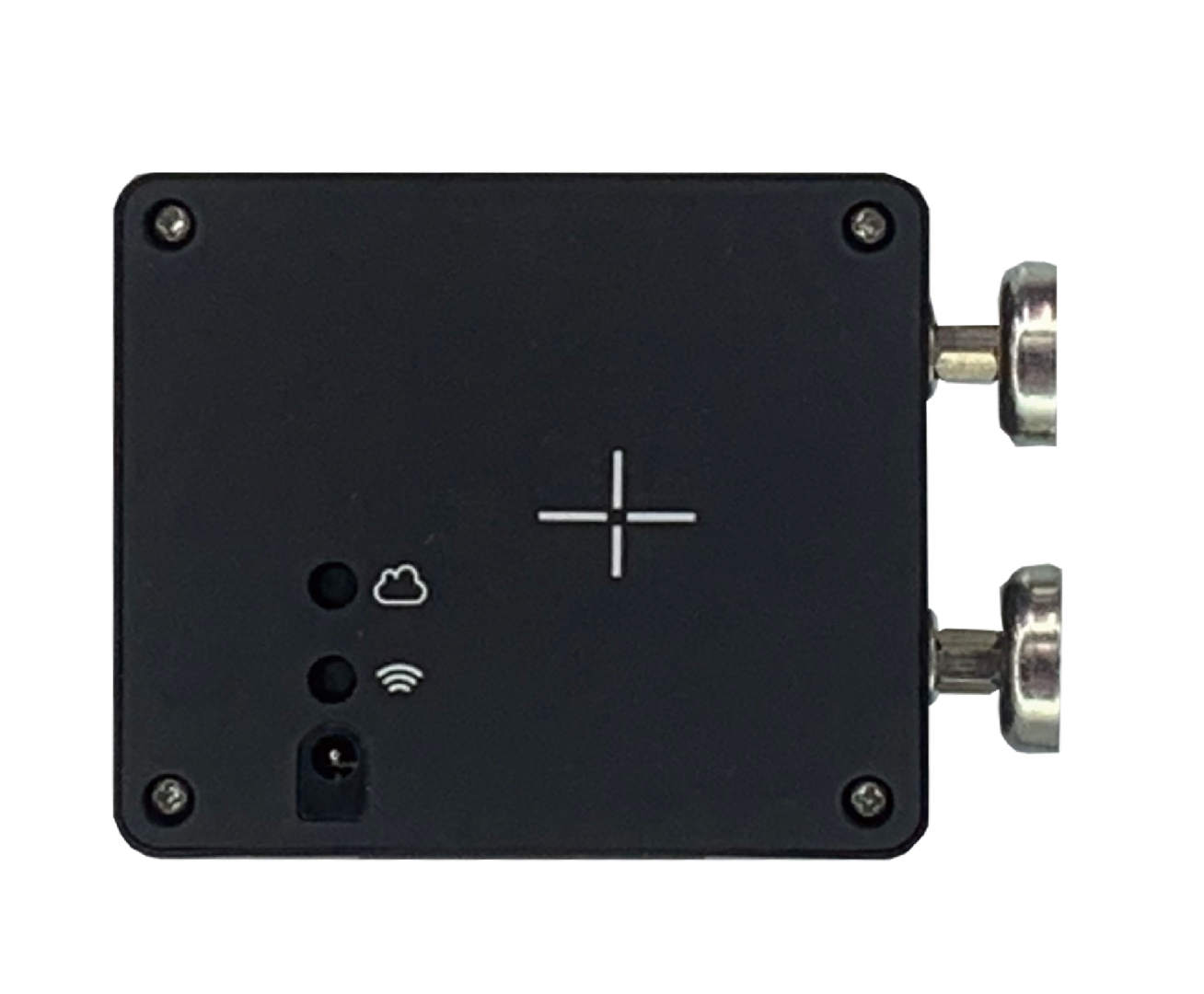

Smart Shot Counter (SSC) Features

The SSC itself collects the following three pieces of information and automatically records them in the cloud system.

① Number of shots

② Cycle time

③ Data acquisition date and time

When the SSC recognizes the tag, it reads the number of shots written on the tag and writes the new number of shots by adding 1 to that value. It also calculates the cycle time from the tag reading interval and sends this information to the cloud.

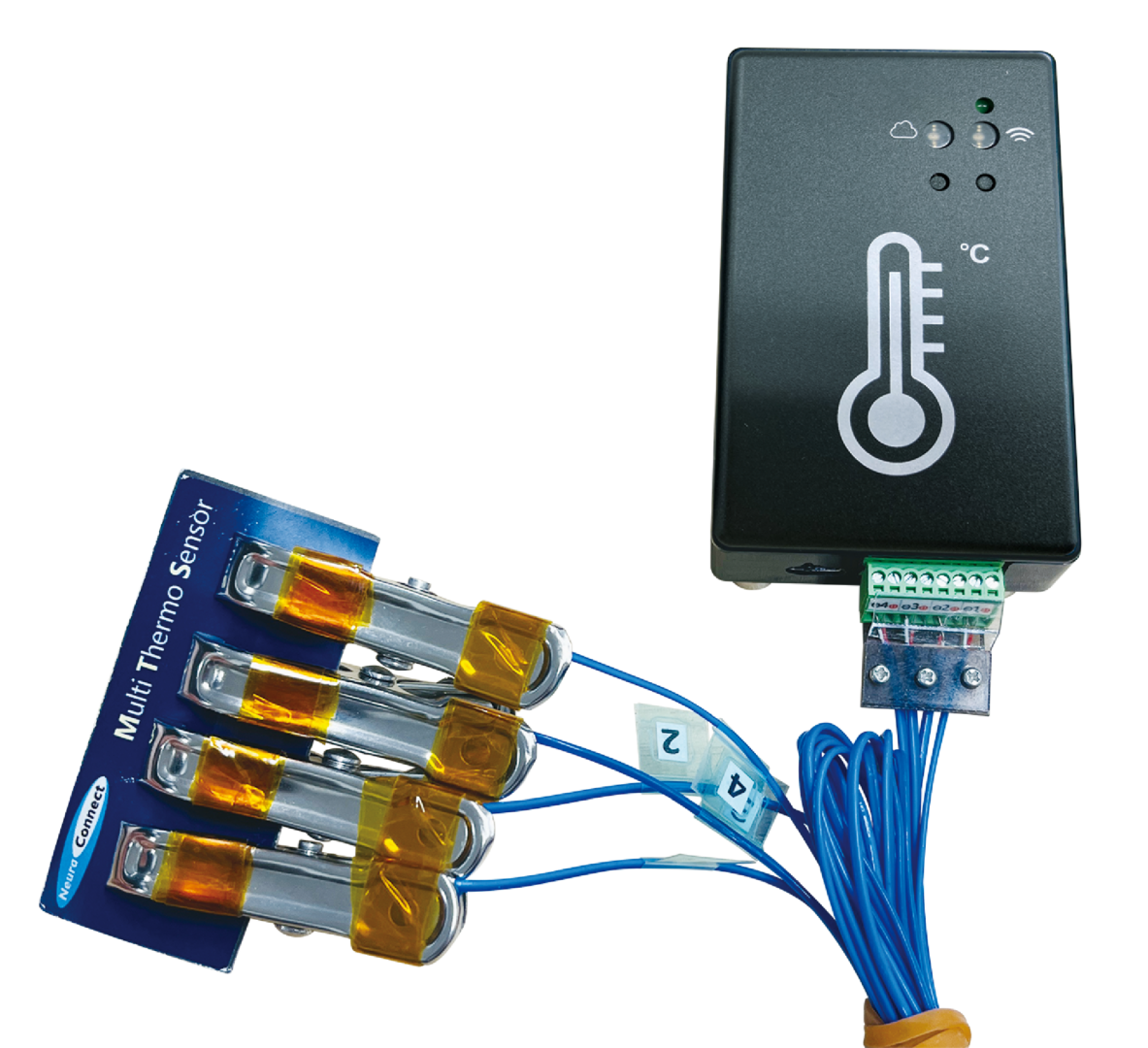

Multi-point thermometer (MTS) functions

This sensor module is compatible with K-type thermocouples and can measure four points simultaneously. It acquires the following two items of information and records them in the cloud system, just like SSC.

① Temperature

② Data acquisition date

In addition to regular observations, it is also possible to record the temperature for each shot in conjunction with the SSC. You can also use existing K-type thermocouples.

We offer three types of thermocouple sensors. Cable extensions can be made on an individual basis. Please feel free to contact us if you have any requests.

■ Round terminal: Screw into any desired location.

■ Magnet: Attach to the mold surface.

■ Clip: Attaches to Mold Temperature Controller or mold piping.

I see, so you can choose the installation method. In that case, it seems like you can use it in different ways depending on the site.

Mold Connect Cloud Features

Mold operating data is recorded and maintenance times are determined based on the accumulated information. News by email as necessary. By "visualizing" the condition of molds on the cloud, efficient and planned mold management is achieved.

① Check and record the operating status of the mold in real time

You can easily review past data, which helps you understand trends.

② Immediate notification with anomaly detection function

If an abnormality occurs in the temperature or cycle time, you will be notified immediately, allowing for a quick response.

3. Understand the need for maintenance at a glance

The status is displayed in different colors, making it visually easy to understand and supporting on-site decision-making.

Furthermore, by measuring temperatures at four points simultaneously, it is possible to compare temperature changes inside the mold and detect minute abnormalities.Continuous recording of operation data also makes it possible to identify signs of sudden stoppages and analyze their causes.Measurement data can also be downloaded as an Excel file and used for internal reports and traceability materials.

IoT system for mold management that can be used from the day it arrives

You can start using it from the day you start, and it's easy to manage your molds!

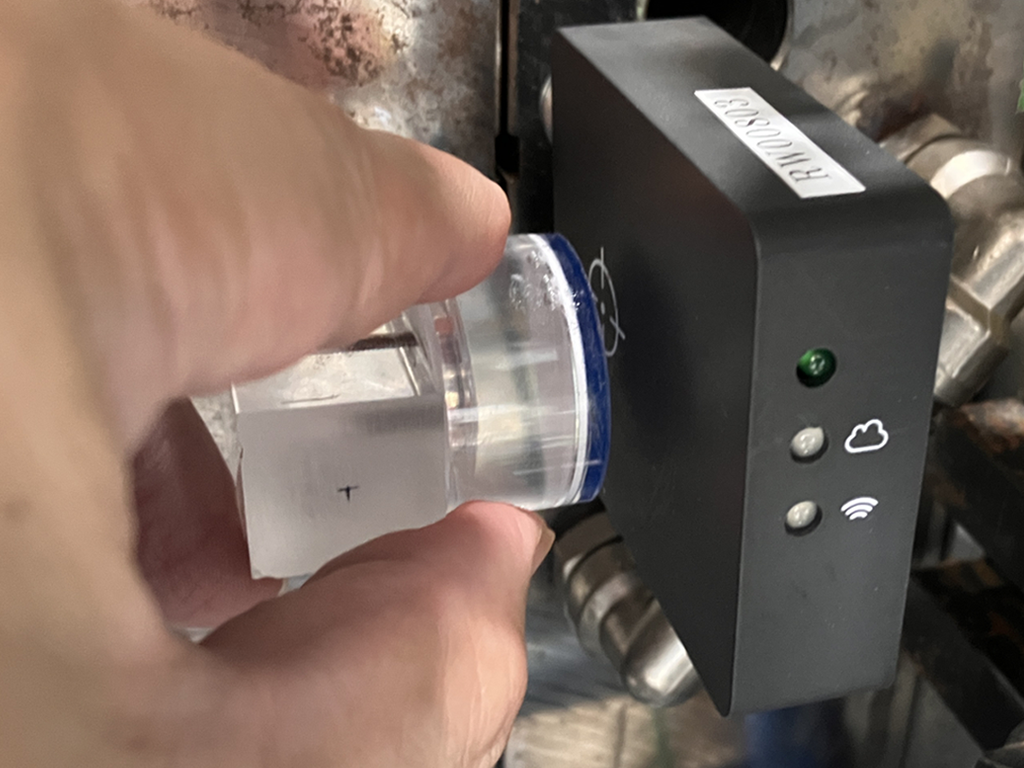

Mold Connect does not require any mold processing, complicated initial setup, or dedicated software installation.From the day it arrives, it can automatically record mold operation data such as the number of shots and cycle time, significantly reducing the tedious work that was previously done by hand.

It can be installed directly on existing molding machines and is compatible with a wide range of manufacturers, so another major feature is that it can be introduced without changing the on-site environment.

It's easy to install and operate, so even IoT beginners can use it with confidence!

When you hear about IoT implementation, many people may think it sounds difficult or requires specialized knowledge, but Mold Connect is extremely simple to operate. It is designed so that even on-site personnel can quickly become fluent in it, making it ideal for first-time IoT implementation.

You can start with a plan that costs less than 10,000 yen per month, and there are no complicated procedures or additional costs such as annual renewals or maintenance contracts.

By minimizing the effort and cost burden of initial implementation, it is easy to start small without putting a burden on the site, and has been highly praised by many customers.

Customer testimonials

\ Used in a variety of industries /

specification

smart shot counter

- Outer dimensions

- Body: 76mm(W) x 18mm(D) x 55mm(H)

Tag: 30mm(W) x 16mm(D) x 30mm(H)

Tag mounting jig: 25mm (W) x 23mm (D) x 55mm (H) - data record

- Records data for each shot

- Communication function

- WiFi network compatible

- power requirements

- AC 100-240V, 50/60Hz

Multipoint Thermometer (MTS)

- Outer dimensions

- Body: 65mm(W) x 18mm(D) x 95mm(H)

- sensor

- Round terminal/Magnet/Clip

- Communication function

- WiFi network compatible

- power requirements

- AC 100-240V, 50/60Hz

Mold Connect Cloud (WEB service)

- Service name

- mold connect cloud

- User authentication

- Authentication by user ID and password

- Supported browsers

- Google Chrome, Mozilla Firefox, Microsoft Edge, Safari, etc.

- corresponding device

- Computers, tablets, smartphones, etc.

- Dashboard function

-

- Display of real-time production data

- Shot quantity transition graph

- Checking the communication status

- Data analysis function

-

- Search and view past production data

- Anomaly detection and troubleshooting

- Notification function

-

- Notification when production is completed or abnormality occurs

- Alerts via email and push notifications

- data export

-

- Exporting data in CSV format

- Saving the report in PDF format

- Security

-

- Encrypted communication using SSL

- Access control and privilege management

- language support

- Supports multiple languages such as Japanese and English