Representative's Green Column

16. MATSUI and factor4

2009.07.15

In the previous column, "From" owning "to" using "", in order to realize factor 4, in addition to energy saving and resource saving of various Equipment and processes, and thorough 3Rs. Furthermore, it is important to shift from the era when "owning things" is the norm to "using services" only when necessary, and I explained some specific examples.

This time, I would like to talk about the relationship between MATSUI and factor 4.

● Mission of MATSUI

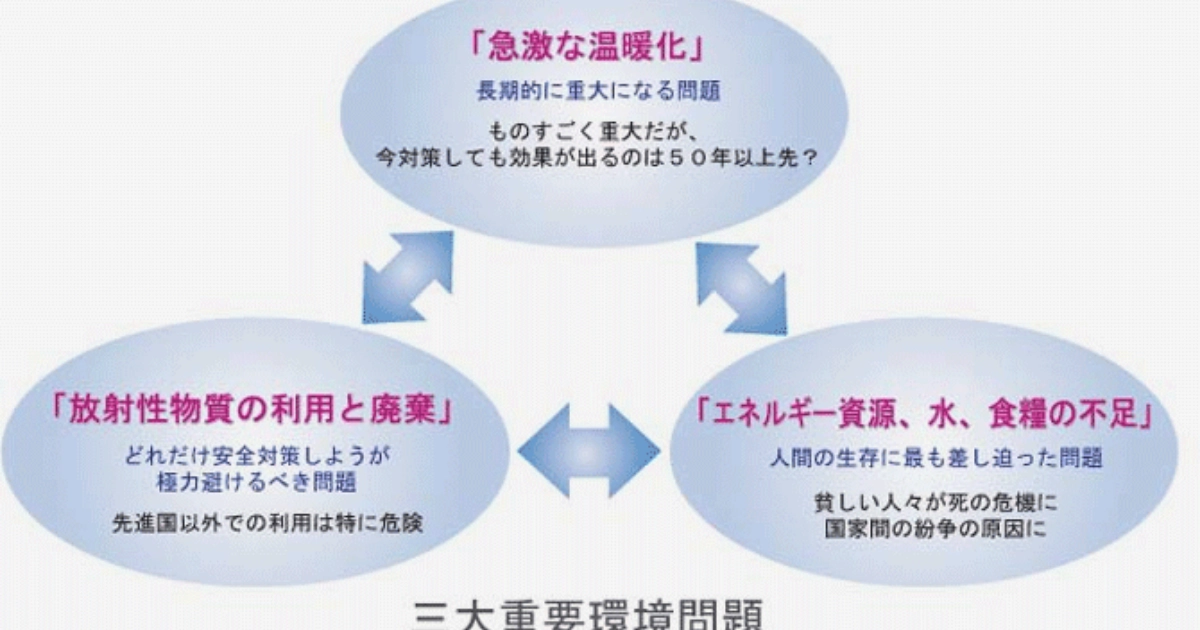

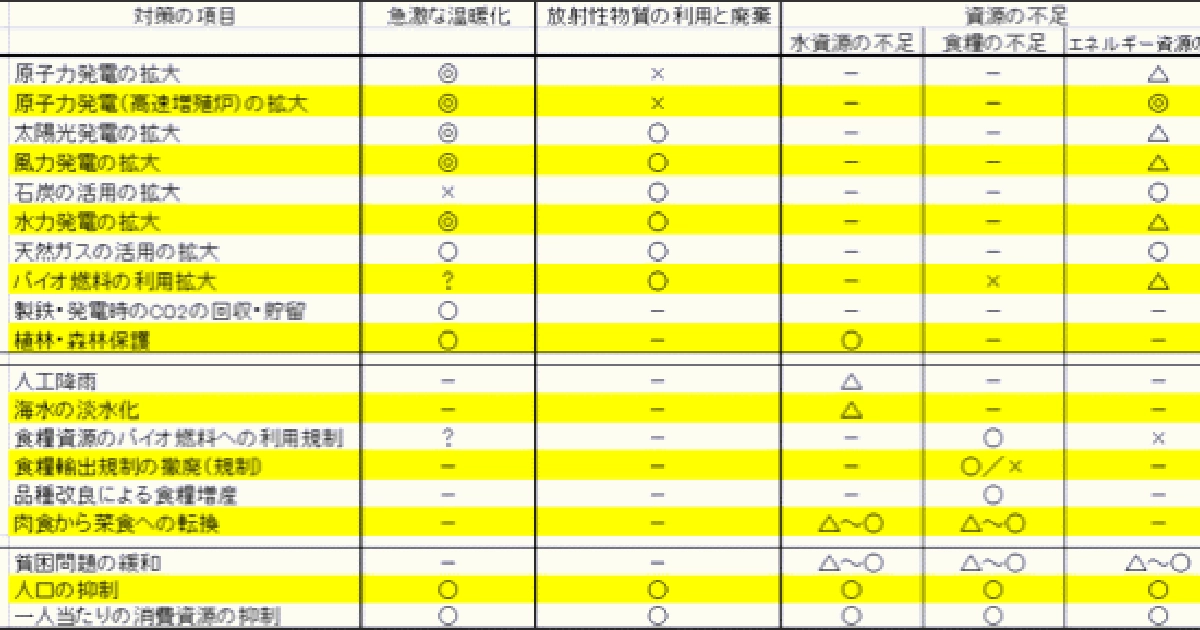

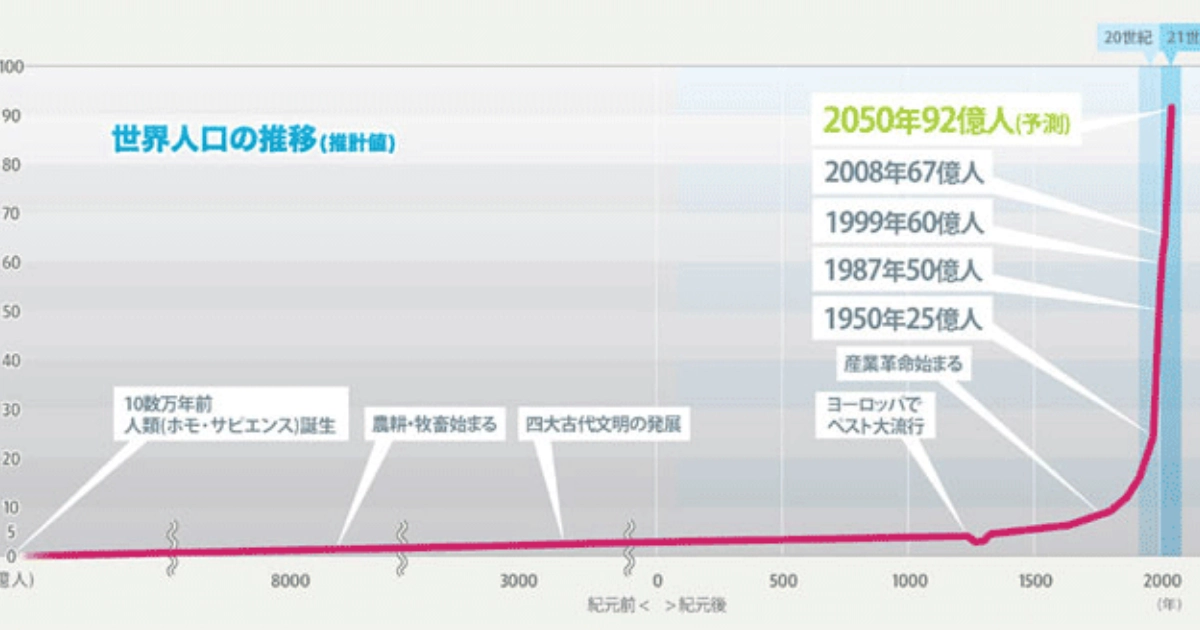

As I have explained in my previous columns, among the many major global issues, we believe that two of the most important and fundamental problems are resource shortages and depletion and global poverty. I think there is. We strongly factory with the idea of "factor 4: double the wealth, half the resource consumption" advocated to solve both of these two problems. I made it "Achieve factor 4 for molding factory by 2020"

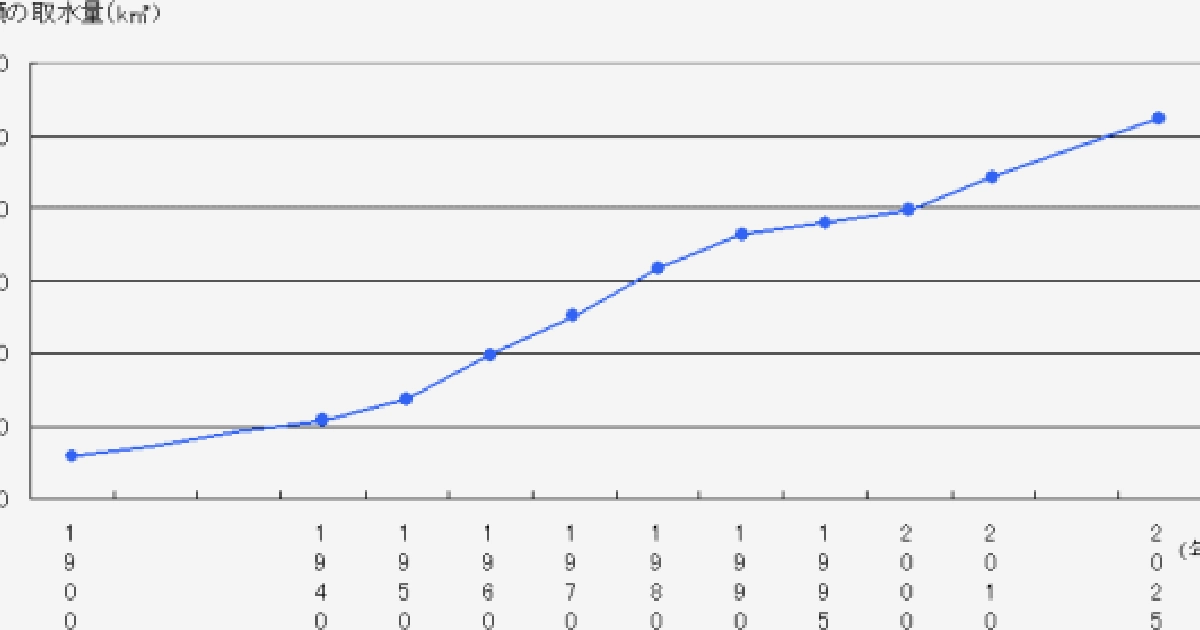

In order to eliminate the three wastes of "waste of energy," "waste of resin," and "waste of water," especially in molding factory, development of equipment to increase resource productivity, diagnosis of the factory, and resource I would like to make thorough proposals for improving productivity. In other words, our main job is not to manufacture and sell Mold Temperature Controller, but to dramatically improve the resource productivity of molding factory. I would like to come.

Through our work, we aim to achieve both the global environment and the affluence of our customers.

● Is the molding factory wasting so much resources?

In most molding factory, improvement activities are carried out every day to improve efficiency, and waste is thoroughly eliminated. Is there still so much waste in such a molding factory?

For example, consider the ultimate absolute energy requirement for a resin injection molding process. In fact, isn't it really the minimum requirement that "energy to heat the resin at room temperature to the melting temperature" and "energy to inject the molten resin into the mold"? Other than that, it's essentially extra energy in some way. However, if the heat generated when the molten resin is solidified is released outdoors through a Medium such as water, energy for circulating the water and energy for cooling the water again are required separately.

However, in reality, in most cases, many times more energy is wasted than these minimum required energies.

This is symbolized by the fact that the molding factory is considered "hot, it's only natural that it's hot." If the site of the molding factory is hot, it means that that much energy is being wasted.

The spool runner that comes out during molding requires extra energy to melt again, even if it is subsequently used for recycling. If it is not used in the recycle, it will be even more wasteful.

You may also see water vapor evaporating from the cooling tower even when it is relatively cold, such as in winter, which also symbolizes tremendous waste. In winter, the water can be cooled without having to do that. There are also places where chillers are used to make colder water than necessary and then heat it according to the conditions in which it is used.

Even at a site like a molding factory that strives to thoroughly eliminate waste, isn't it still a mass of waste from the perspective of resource productivity?

● Specifically, how do you go about achieving Factor 4 in molding factory?

Currently, we are aiming to realize factor 4 of the molding factory by carrying out the following three activities.

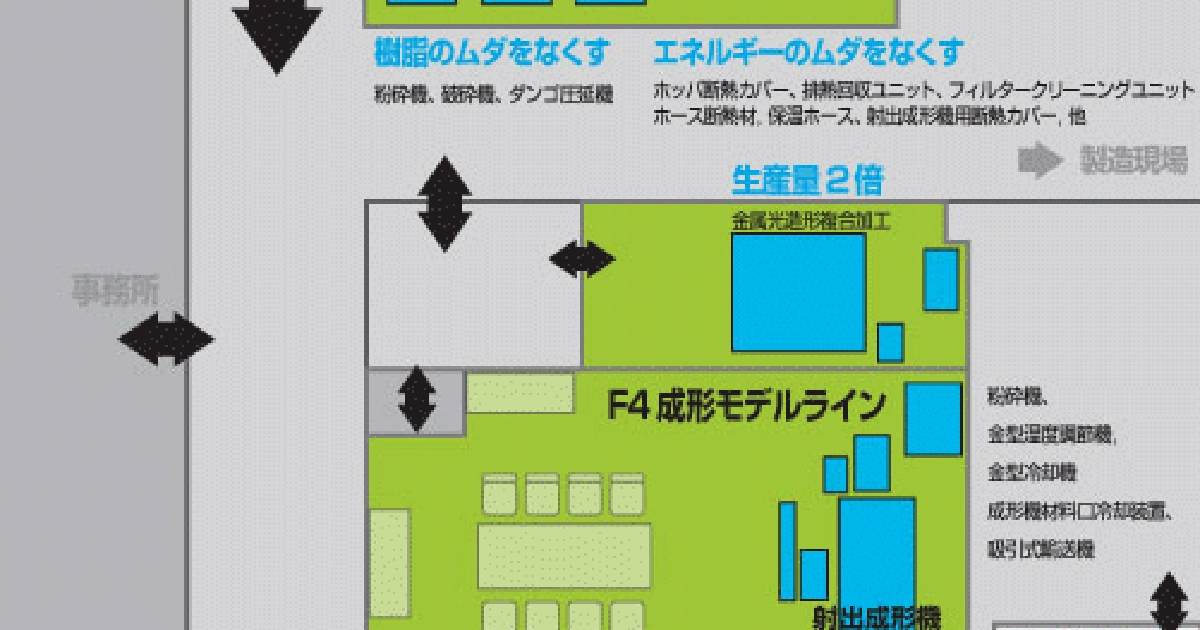

1. 1. We will continue to enhance the proposal menu that collects methods for increasing the resource productivity of molding lines.

Specifically, we have created a "Molding factory Energy and Resource Conservation Handbook" and have put together a menu of proposals for customers to increase their resource productivity. This "handbook" currently contains 24 proposals, but the menu will continue to grow.

2. 2. Diagnose energy saving and resource saving of molding factory and molding lines.

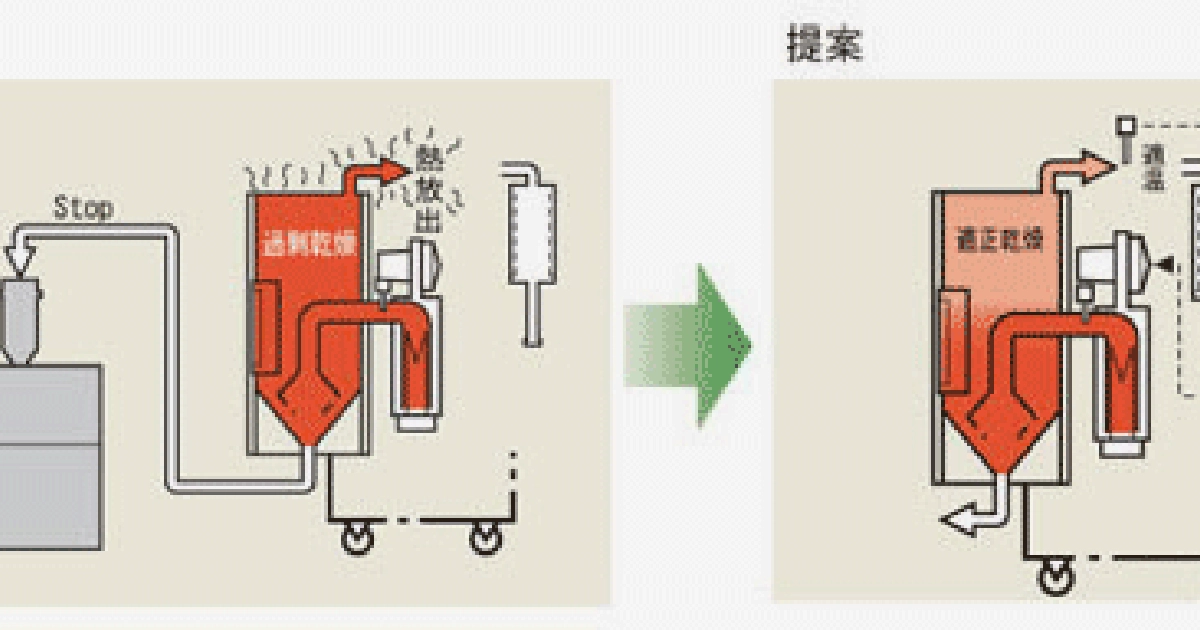

As a preparation for making a concrete proposal, we have started a diagnosis of energy saving and resource saving in the molding factory. Currently, we have started "Water Circulation Diagnosis" to diagnose waste of water and electricity related to the water cooling system of the entire factory, and "Energy Saving Diagnosis" to diagnose waste of energy related to molding mainly on material drying. .. By doing this, you can determine how much water and electricity can be wasted and how much cost can be reduced.

3. 3. Based on the diagnosis result, we will customize and propose according to the customer from the proposal menu.

Comparing the cost reduction effect of energy saving and resource saving with the cost of adding or remodeling equipment, we can recover the cost in the shortest possible time and propose the contents according to each case so that it will lead to the subsequent profit. I will continue to do.

None of the activities 1 to 3 are ideal yet, but we are working hard to improve them in the future.

In the next column, I would like to introduce some of the proposal menus for increasing the resource productivity of molding lines.

July 15, 2009 Hironobu Matsui