Special ContentsSpecial Contents

Aiming for factor4 of molding factories

Introduction

"Resource CUT" What is waste of resource consumption?

"Increase production volume" Reduce defects & stable production, shorten molding cycle

"Increase value-added" Improving the quality and value of molded products

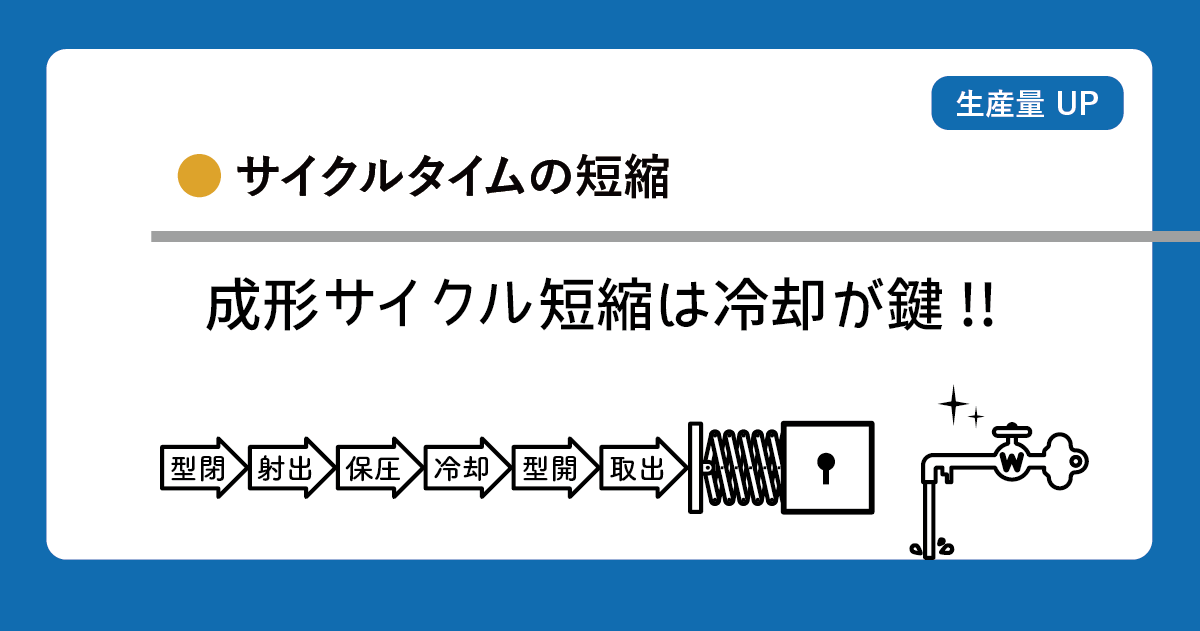

Cooling is a key to shortening molding cycle!

Proposing countermeasures against gas, the great enemy of molding, and new mold cleaning methods.

Environmentally friendly plastics factories - The first part

Environmentally friendly plastics factories - The latter part

Proposing foreign matter (contamination) countermeasures in molding by each process.

Shorter setup time is the key to higher efficiency.

How to prevent yellowing of plastic molded products.

Prevents uneven color in molding! Static control, changing the location of material blending, and blending uniformly.

Achieving stable production through water quality control of cooling towers and cooling water.

Causes of dimensional inaccuracy in plastic molding and countermeasures.

Three molding methods to save weight of plastic molded products.

Surface quality improvement of injection molded products.