ソリューションテーマ

成形不良解消に必要なことは、大がかりな設備導入だけとは限りません。

松井製作所が取り扱うさまざまなソリューションアイテムをテーマ別にご紹介します。

-

エネルギーのムダを無くす

樹脂使用量が少ない時も乾燥機をフル稼働し続けますか?負荷に応じた風量コントロールで最大83%の省エネ!

-

エネルギーのムダを無くす

いつも乾燥機をフル運転するムダもうやめませんか?既存機にこれを追加で、最大40%省エネ!

-

エネルギーのムダを無くす

乾燥機の排熱による環境温度の上昇を空調で電気を使って抑えていますね?

排熱再利用で電気代最大6%+αの削減!

-

エネルギーのムダを無くす

いつも乾燥機をフル運転するムダもう止めませんか?既存機にこれを追加で、最大40%の省エネ!

-

エネルギーのムダを無くす

乾燥機の排熱による環境温度の上昇は、空調で電気を使い抑えていますね?

排熱再利用で電気代最大33%+αの削減!

-

エネルギーのムダを無くす

熱負荷は変動するのにチラーの消費電力はいつも一緒って変ですよね?

インバータ制御で最大57%の省エネ!

-

エネルギーのムダを無くす

寒い冬、なのにチラーを夏と同じように動かしますか?

フリークーリングで省エネ、電気代最大54%削減!

-

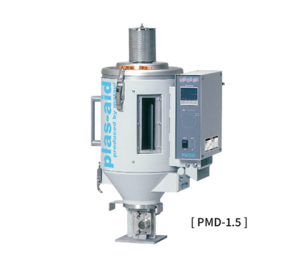

エネルギーのムダを無くす

適切な乾燥状態なのに、まだエネルギーを使って乾燥しますか?

定期的な計測で、成形不良の未然防止と、省エネを同時に実現!

-

エネルギーのムダを無くす

チラーと金型温調機を1つにまとめて、効率よく運転します。

温調が最も難しい30〜50°Cを精度良く温調します!

-

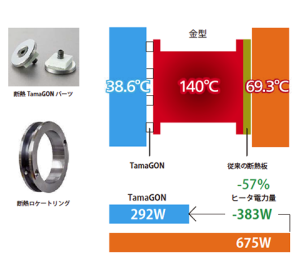

エネルギーのムダを無くす

断熱版があっても、取付板から熱がプラテンへ伝わっています。

熱を逃さず、エネルギーを大きく節約します!

-

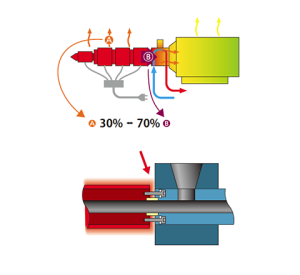

エネルギーのムダを無くす

バレル温調の熱がホッパ下ブロックへ逃げている事をご存知ですか?

バレルを斬って!? 効果的に断熱できます。

-

樹脂のムダを無くす

いったん混ぜたその材料、残りを毎回捨て続けますか?

配合の知能化で樹脂の混ぜ残りを99%削減!

-

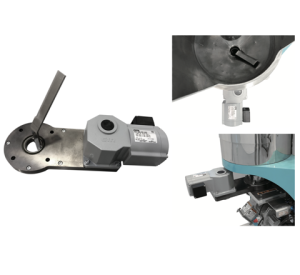

樹脂のムダを無くす

粉砕材の粒度が揃わずリサイクル率が上げられない?

専用粉砕刃で安定して確実にランナをカットします!

-

樹脂のムダを無くす

高価な材料のランナ、いつまで廃材にしておくのですか?

高機能樹脂のランナもこれでリサイクル!

-

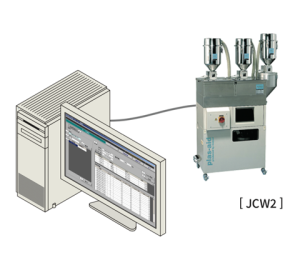

樹脂のムダを無くす

樹脂のムダが、見える化できてますか?

原材料管理システムで樹脂使用の見える化とトレーサビリティを実現!

-

樹脂のムダを無くす

色替えの度、色ムラ防止で多くの材料を捨てていませんか?

均一混合と滞留レス構造により、効率的な色替えを実現!

-

樹脂のムダを無くす

材料替えの度に捨てる樹脂、勿体無くはありませんか?

高精度配合、簡単色替えで、高価なマスターバッチの使用量も削減可能です!

-

樹脂のムダを無くす

乾燥ホッパから樹脂が排出されず、度々状態を確認してませんか?

ブリッジを防止しスムーズな材料供給を実現します!

-

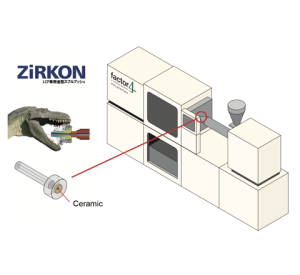

サイクルタイムの短縮

糸引きで困ってませんか?断熱スプルブッシュで糸引き防止、しかもノズル温度が安定して、品質も安定します!

-

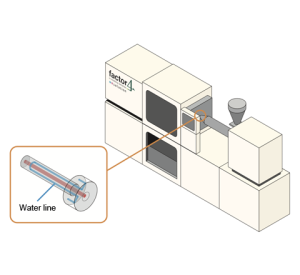

サイクルタイムの短縮

スプルが固まるのを待っていませんか?

水管付スプルブッシュでサイクルアップ!

-

サイクルタイムの短縮

スケールが付けば、せっかくの冷却効果も半減。

空冷式の金型温度調節機で心配無用!

-

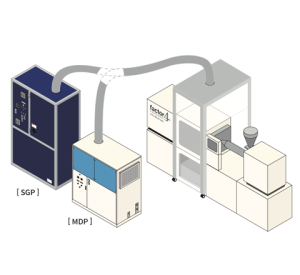

サイクルタイムの短縮

結露が心配で、金型温度を高めにしてませんか?

金型周辺の除湿で結露を無くし、ハイサイクル実現!

-

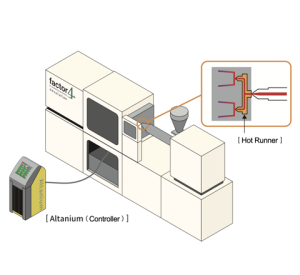

サイクルタイムの短縮

ホットランナも選択肢に入れませんか?

スプルランナをなくせば、サイクルは短縮され、更に樹脂のムダをなくせます!

-

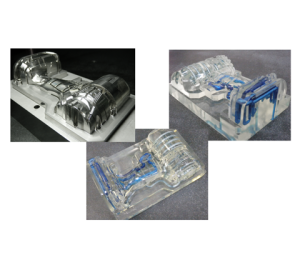

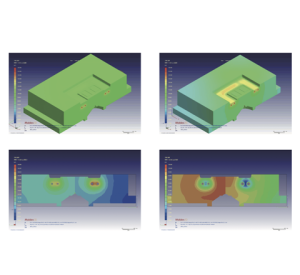

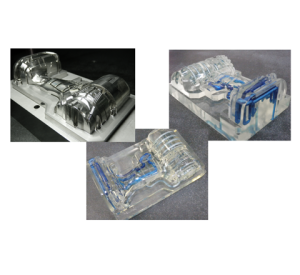

サイクルタイムの短縮

その金型、水管レイアウトは最適ですか?

3 次元冷却水管による均一な冷却で生産性を向上!

-

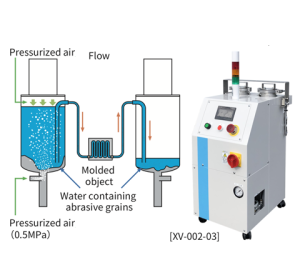

サイクルタイムの短縮

3D水管金型導入時の条件(サイクルタイム)では、良品が取れなくなってきた?

水管のクリーニングが必要です!

-

サイクルタイムの短縮

どのように金型の水管を設計したらより効果的なのか?

実製作前にその適正を検証してみましょう!

-

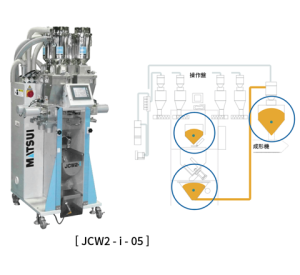

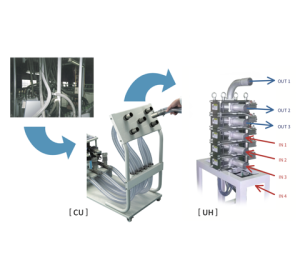

段取時間の短縮

材料の切り替えにムダな時間を使っていませんか?

指定した乾燥機から指定した成形機へ、簡単に輸送ラインを切り替えられます。

-

段取時間の短縮

材料切り替えの度に、混合ムラ防止の目的で、時間と材料をムダに使ってませんか?

均一混合と滞留レス構造により、効率的な色替えを実現!

-

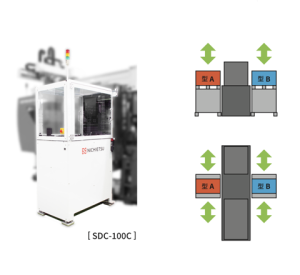

段取時間の短縮

金型交換待ちで、稼働率が下がっていませんか?

外段取りにより作業を効率化、安全に、しかも簡単に短時間で金型交換が可能になります!

-

黄変トラブルの解消

成形品の黄変でお困りではありませんか?

過乾燥を防止して、成形品の黄変を抑えます!

-

黄変トラブルの解消

成形品の黄変でお困りではありませんか?

真空により酸素濃度を下げ樹脂乾燥時の酸化・黄変を抑えます!

-

黄変トラブルの解消

成形品の黄変でお困りではありませんか?

N2乾燥、N2 置換で樹脂の溶存酸素を除去し酸化・黄変を抑えます!

-

黄変トラブルの解消

成形品の黄変でお困りではありませんか?

樹脂原料の除湿乾燥では抑えられない酸化・黄変に。

-

黄変トラブルの解消

成形品の黄変でお困りではありませんか?

既設の材料乾燥に追加する事で、成形品の黄変を抑えます!

-

色ムラトラブルの解消

成形品の色ムラでお困りではありませんか?

静電気を低減し成形機上ホッパ内壁への材料付着(静電気分級)を防止!

-

色ムラトラブルの解消

成形品の色ムラでお困りではありませんか?

成形機上設置で輸送による配合材の分離(比重および静電気分級)を防止!

-

色ムラトラブルの解消

成形品の色ムラでお困りではありませんか?

成形条件で調整できない色ムラを独自の成形機ノズルで解決!

-

コンタミトラブルの解消

材料タンクは最初のコンタミ混入源です。

クリーン仕様の専用タンクを!

-

コンタミトラブルの解消

乾燥機には、乾燥エア・材料切出しなど至る所に異物の発生源!

光学専用の乾燥機で微細なコンタミまで防止しましょう!

-

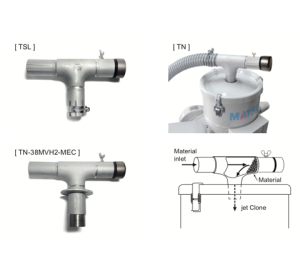

コンタミトラブルの解消

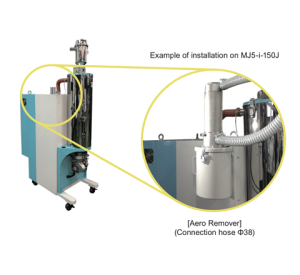

樹脂粉がコンタミの原因になっていませんか?

成形機上で輸送気流によりペレットから粉を取ります。

-

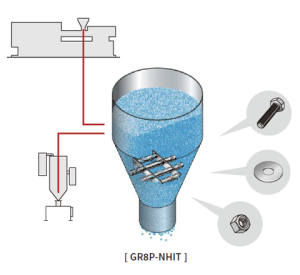

コンタミトラブルの解消

金属異物混入は成形時の大きなリスクです。

樹脂原料に付着・内包する全ての金属異物を検知・除去します!

-

コンタミトラブルの解消

乾燥エアは樹脂に異物を運んでくる要因です。

真空伝熱乾燥により最小限のエアで乾燥を!

-

コンタミトラブルの解消

粉砕機に金属が入ると大変です!

スプルランナ投入時の鉄系異物をキャッチ!

-

コンタミトラブルの解消

乾燥エアは樹脂に異物を運んでくる要因です。

伝導伝熱乾燥により最小限のエアで乾燥を!

-

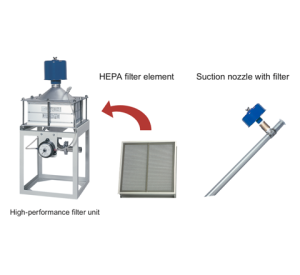

コンタミトラブルの解消

外気は異物だらけ。

高性能フィルタで外からの異物混入をシャットアウト!

-

コンタミトラブルの解消

金属異物混入は成形時の大きなリスクです。

配管をペレットで保護すれば異物発生の心配無し!

-

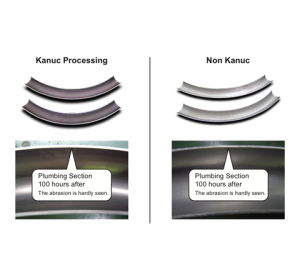

コンタミトラブルの解消

金属製の材料輸送配管は摩耗します!

表面硬化処理で異物リスクを最小限に!

-

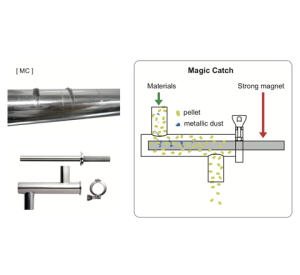

コンタミトラブルの解消

金属異物混入は成形時の大きなリスクです。

樹脂原料に混入した鉄系金属異物を磁力でキャッチし逃しません!

-

コンタミトラブルの解消

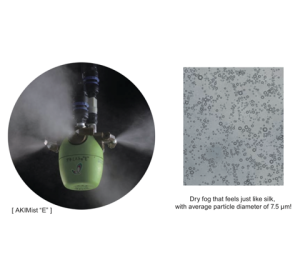

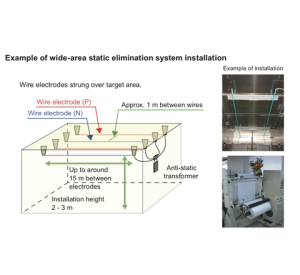

静電気の発生は、異物混入につながります。

空間まるごと、静電気の発生を予防します!

-

コンタミトラブルの解消

空間まるごと、無風で除電する事で、

製造工程の異物付着による不良を、大幅に削減します!

-

コンタミトラブルの解消

粉の多い樹脂原料や粉砕材リサイクル成形で

気泡、白点、焼け、黒点、重量バラツキを防止!

-

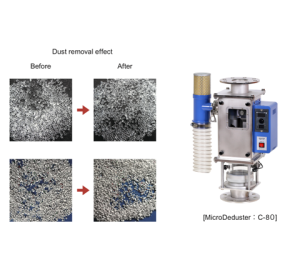

コンタミトラブルの解消

コンタミトラブルの元となる、樹脂原料に付着した粉塵を

成形直前で取り除きます!粉砕材リサイクルにも効果的!

-

コンタミトラブルの解消

作業環境全体のクリーンルーム化は、高額で手が出ない!?

必要な場所に適切なクリーン環境を低価格で実現します!

-

コンタミトラブルの解消

金属異物混入は成形不良、装置の故障に繋がります。

樹脂原料に混入した鉄系異物を強力な磁力で捕集します!

-

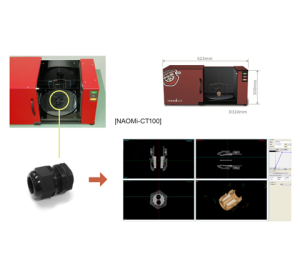

コンタミトラブルの解消

成形品内の異物に加え、ボイド、ウエルド部の状態、

発泡状態など、成形品内部を自在にどこでも確認できます!

-

ガスによるトラブルの解消

ガスによるトラブルで困っていませんか?

乾燥時に樹脂ガスを除去、又は置換して、安定成形を実現!

-

ガスによるトラブルの解消

ガスによるトラブルで困っていませんか?

乾燥時に樹脂のガスを除去、又は置換して、安定成形を実現!

-

ガスによるトラブルの解消

金型内のガスによるトラブルで困っていませんか?

ポーラスコマを通し、ガスや空気を吸引。逆洗機能で詰りも防止!

-

ガスによるトラブルの解消

成形機につけたまま金型に付着したガスを除去したい!

そんな場合は、ドライアイスブラストで!

-

ガスによるトラブルの解消

成形品メッキ処理後の不良で困っていませんか?

成形後のアニール処理でガス発生によるメッキ不良を低減できます!

-

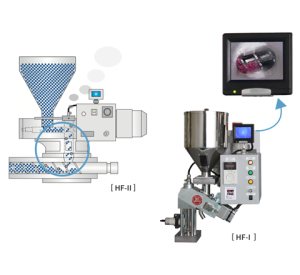

ガスによるトラブルの解消

可塑化時のガスによるトラブルで困っていませんか?

樹脂の定量供給でガス発生を抑制しトラブルを抑えます!

-

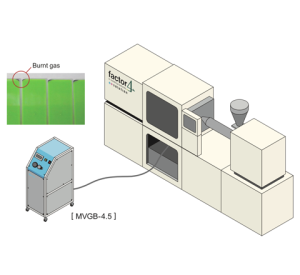

ガスによるトラブルの解消

金型へのガスの付着で困っていませんか?樹脂ガスを吸引し、金型メンテナンス周期を伸ばします!

-

ガスによるトラブルの解消

成形室天井に白い付着物がありませんか?

コンタミの原因にもなる樹脂ガスを固化・回収し、飛散を抑えます!

-

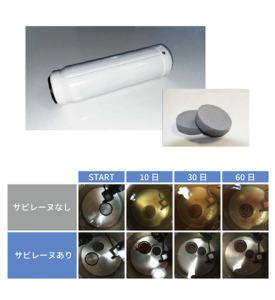

水質によるトラブルの解消

付着したスケールが工場全体の効率を落としていませんか?

ecobrid(エコブリッド) で水質によるトラブルをなくします。

-

水質によるトラブルの解消

付着したスケールが成形効率を落としていませんか?

空冷式チラーで水質によるトラブルをなくします!

-

水質によるトラブルの解消

付着したスケールが成形効率を落としていませんか?

水冷式チラーで水質によるトラブルをなくします!

-

水質によるトラブルの解消

付着したスケールが生産効率を落としていませんか?

予防保全で、安定成形を実現しましょう!

-

水質によるトラブルの解消

付着したスケールが生産効率を落としていませんか?

水質を管理して、安定成形を実現しましょう!

-

水質によるトラブルの解消

金型温調に使用している冷却水赤錆が発生していませんか?

そのまま放置すると、成形不良だけでなく装置の故障に繋がります。

-

水質によるトラブルの解消

スケールや錆びが生産効率を落としていませんか?

水質を管理して、安定成形を実現しましょう!

-

水質によるトラブルの解消

冷却水の汚れが生産効率を落としていませんか?

水質を管理して、安定成形を実現しましょう!

-

水質によるトラブルの解消

冷却ラインの藻や微生物は防げないと思っていませんか?

バクテリア、スライム、バイオフィルム、藻類に効く!

-

寸法精度の向上

成形後の不均一な変形で困っていませんか?

3 次元冷却水管による均一な冷却で寸法精度を向上!

-

寸法精度の向上

度重なる型修正、ヒケや反りでお困りではありませんか?

寸法精度が向上し、開発期間の短縮にもつながります!

-

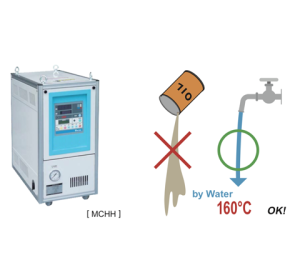

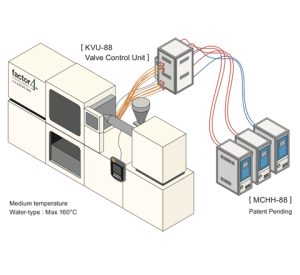

寸法精度の向上

もっと高温で精密成形したいけど油はイヤ !?

水で160℃ まで高精度で安定した温調ができます!

-

寸法精度の向上

成形後の変形防止には内部に残る応力を逃す事が有効です。

箱型乾燥機はアニール炉としてもお使いいただけます!

-

寸法精度の向上

アナログ流量計では管理が大変ではありませんか?

金型内部状況を可視化し、適切な条件設定を可能にします!

-

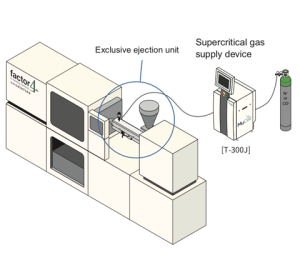

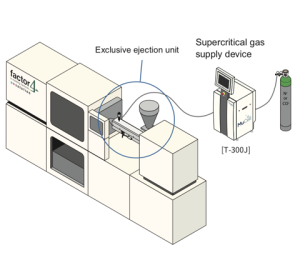

成形品の軽量化

軽量化は全世界のトレンド。

材料減でのコストダウン、サイクルタイム短縮、寸法精度の向上も同時に実現!

-

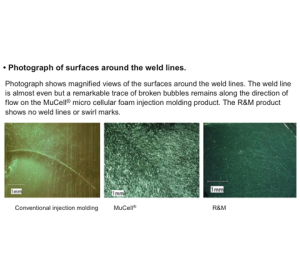

成形品の軽量化

RHCM® と MuCell®微細発泡成形の組み合わせにより、

成形品を軽く、また外観品質を向上させます!

-

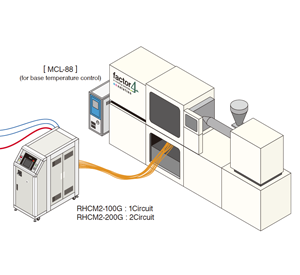

表面品質・価値の向上

もっと手軽にウェルドをなくしたい。

ウェルドレスと外観の光沢を実現!

-

表面品質・価値の向上

ワンランク上の表面品質を。

PP 対応、抜き勾配ゼロなども実現!

-

表面品質・価値の向上

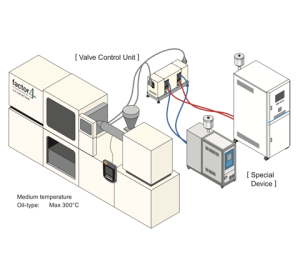

メタリック成形など、 180°C以上の高温が必要なウェルド レス成形には、

オイル式ヒート&クール成形システムを!