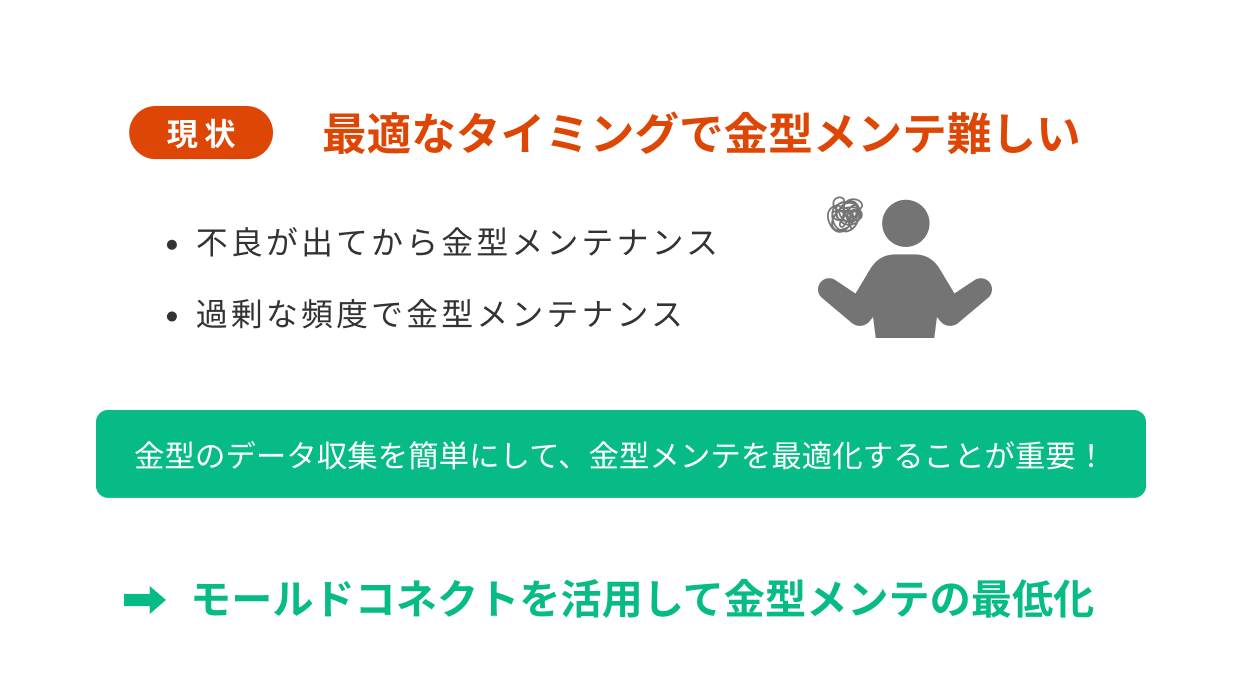

Importance of mold management

[Mold] is the most important element in molding quality products. However, mold management is currently not sufficient. In order to properly manage the status of molds, it is necessary to manage a lot of information all at once, which is a difficult situation.

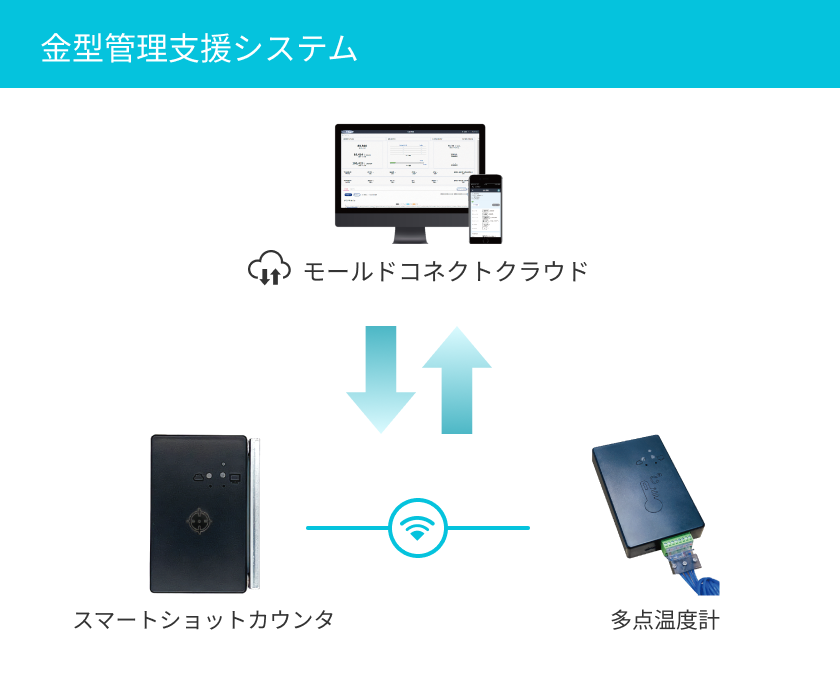

What is Mold Connect?

Mold Connect is a general term for devices for managing molds (smart shot counters, multi-point thermometers) and the cloud system for recording that data (Mold Connect Cloud).

Mold maintenance can be performed at the optimal timing.

Since mold maintenance News via signals and emails, mold maintenance can be carried out before defects occur.

You can look back on past data.

Since we have the time when the number of shots, cycle time, and temperature were measured, we can trace back past data and improve traceability when dealing with quality defects.

You can check the operating status of molding machines and molds even if you are not on site.

Because it is a cloud system, you can check the operating status from a remote location, allowing for early detection of abnormalities.

You can see the date and time of the Choco stop, and the stop time.

Since the SSC cycle time is recorded, it is possible to trace the stoppage time back in the past.

MTS can monitor the temperature status of the temperature controller and mold.

You can identify signs of clogging in temperature control piping, and monitor problems such as forgetting to open valves in real time.

Smart Shot Counter (SSC)

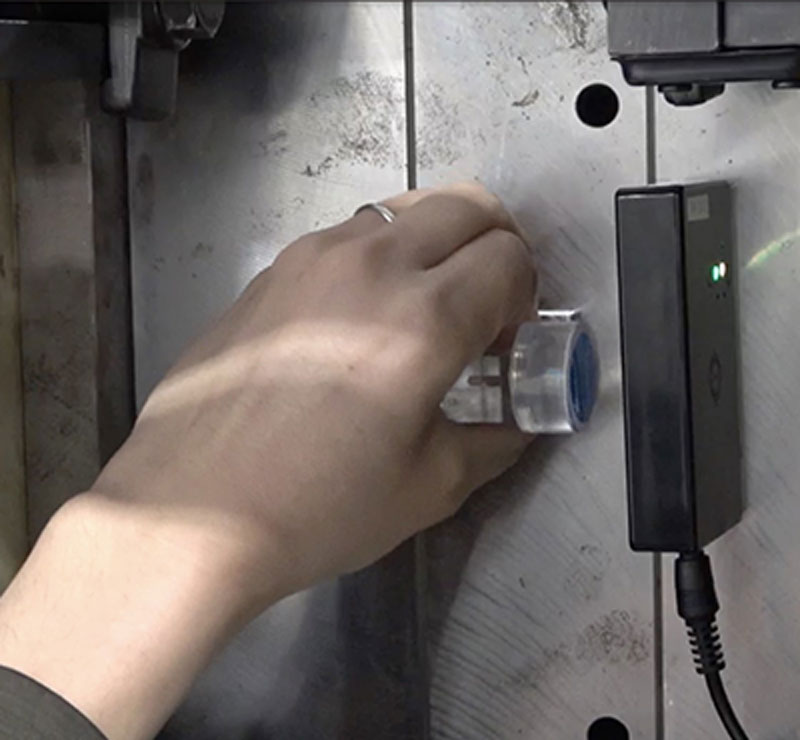

The tag is read by the SSC itself, and the mold's ➀ number of shots ② cycle time ➂ data acquisition date and time are automatically recorded in the cloud system.

When the SSC recognizes the tag, it reads the number of shots written on the tag, adds 1 to the number of shots, calculates the cycle time from the reading interval, and sends it to the cloud.

Multipoint thermometer (MTS)

K type thermocouple sensor module that can measure 4 points simultaneously

Existing K type thermocouples can also be connected. ➀Temperature ②Data acquisition date and time are automatically recorded in the cloud system. In addition to regular observation, it is also possible to record temperature synchronized with SSC (temperature recording for each shot).

mold connect cloud

Records operating data of molds. News of mold maintenance time by email

- You can check and review the operating status of the mold in real time.

- Any abnormality in temperature or cycle time can be detected immediately.

- You can see at a glance which molds require maintenance.

IoT system for mold management that can be used from the day it arrives

No mold processing required! Effortless mold management is now possible from the day it arrives!

- Automatically records the number of shots and cycle time, eliminating tedious handwriting.

- Since there is no need to install special software, mold management can be automated from the day it arrives.

- It can be used regardless of the molding machine manufacturer.

No troublesome settings! You can instantly check the latest mold data and quickly respond to problems.

- Real-time monitoring of production sites helps prevent problems.

- Past data can be easily checked, making traceability and trouble analysis easier.

- Accurate mold data enables optimization of mold maintenance.

Low introduction risk! Ideal for first-time IoT implementation.

- It is easy to operate and can be used without any IoT expertise.

- You can start with less than 10,000 yen per month.

- No annual updates or maintenance contracts required, no additional costs.

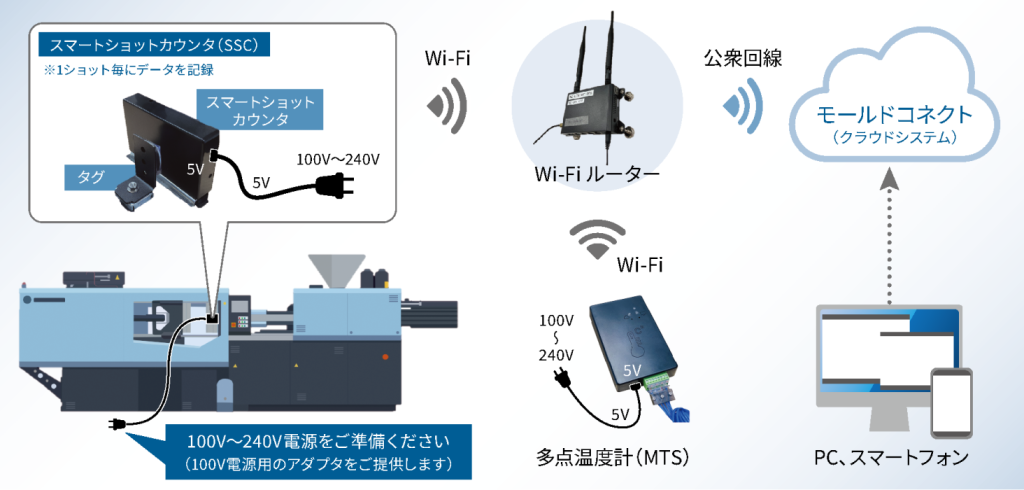

System configuration image

Sends smart shot counter (SSC) and multipoint thermometer (MTS) data to the cloud. All users can see the same data anytime, anywhere.

You can easily look back on past data, and traceability is perfect.

specification

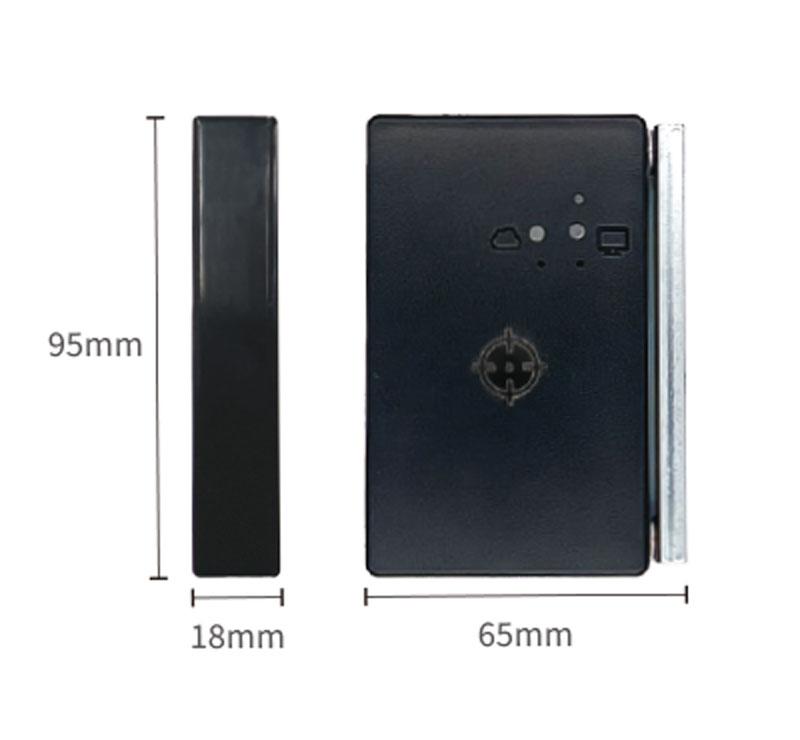

smart shot counter

- Outer dimensions

- Body: 65mm(W) x 18mm(D) x 95mm(H)

Tag: 30mm(W) × 16mm(D) × 30mm(H)

Tag mounting jig: 25mm(W) x 23mm(D) x 55mm(H) - data record

- Records data for each shot

- Communication function

- WiFi network compatible

- power requirements

- AC 100-240V, 50/60Hz

Multipoint thermometer (MTS)

- Outer dimensions

- Body: 65mm(W) x 18mm(D) x 95mm(H)

- sensor

- Round terminal/Magnet/Clip

- Communication function

- WiFi network compatible

- power requirements

- AC 100-240V, 50/60Hz

Mold Connect Cloud (WEB service)

- Service name

- mold connect cloud

- User authentication

- Authentication by user ID and password

- Supported browsers

- Google Chrome, Mozilla Firefox, Microsoft Edge, Safari, etc.

- corresponding device

- Computers, tablets, smartphones, etc.

- Dashboard function

-

- Display of real-time production data

- Shot quantity transition graph

- Checking the communication status

- Data analysis function

-

- Search and view past production data

- Anomaly detection and troubleshooting

- Notification function

-

- Notification when production is completed or abnormality occurs

- Alerts via email and push notifications

- data export

-

- Exporting data in CSV format

- Saving the report in PDF format

- Security

-

- Encrypted communication using SSL

- Access control and privilege management

- language support

- Supports multiple languages such as Japanese and English

Our products are used by customers in various industries.

injection molding

- general merchandise

- Auto parts

- home appliance parts

- optical lens

- medicine container

- tag

- building materials

- Medical equipment

sheet molding

- food containers

- Packing materials

Press molding

- metal casing