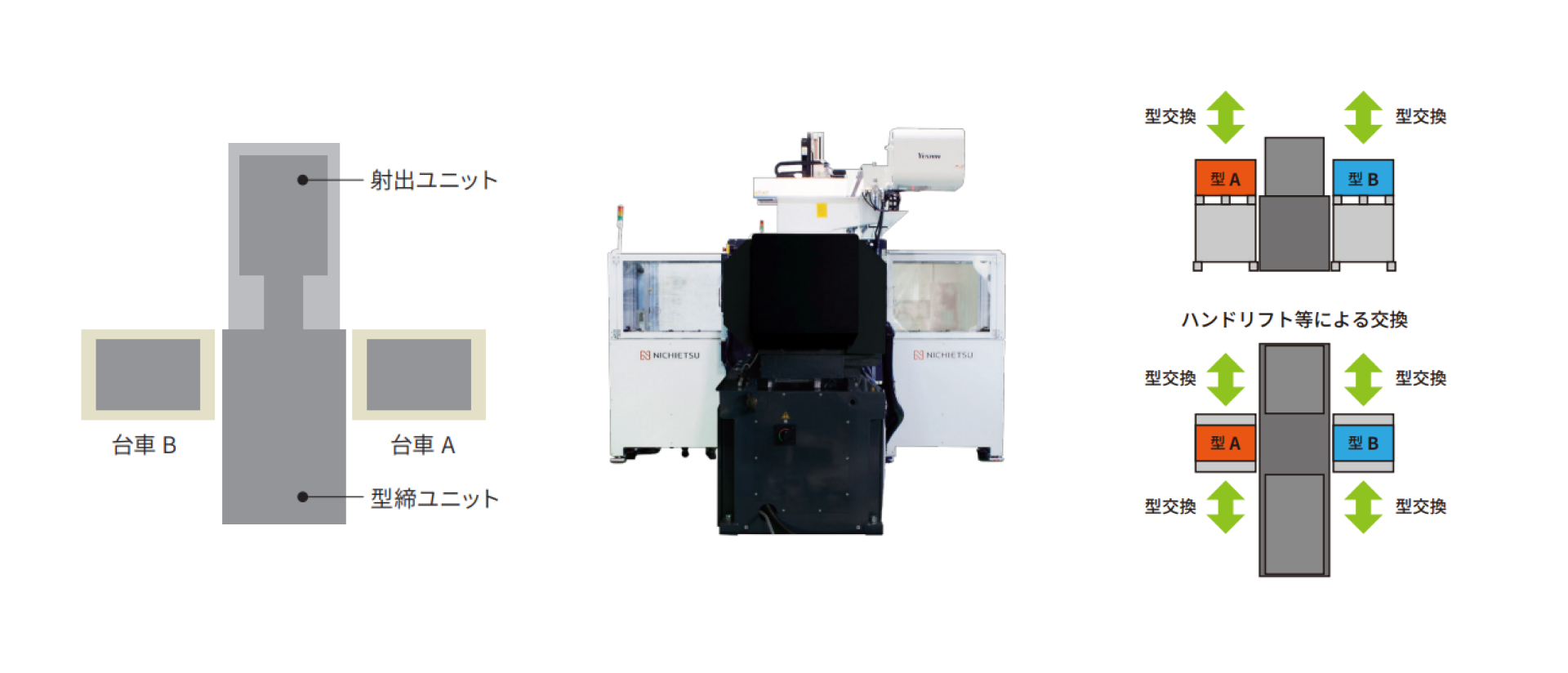

Features of the double-sided type

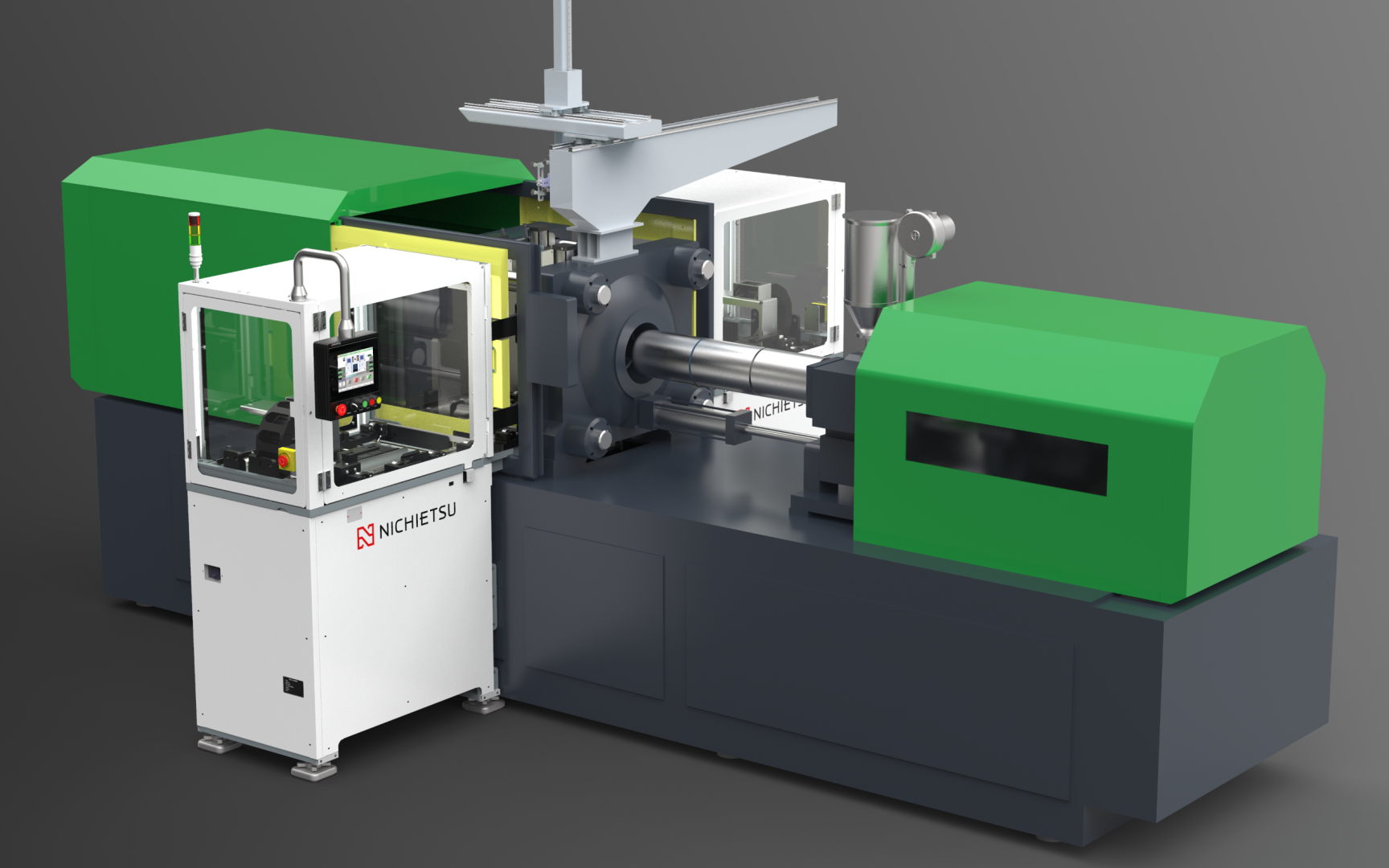

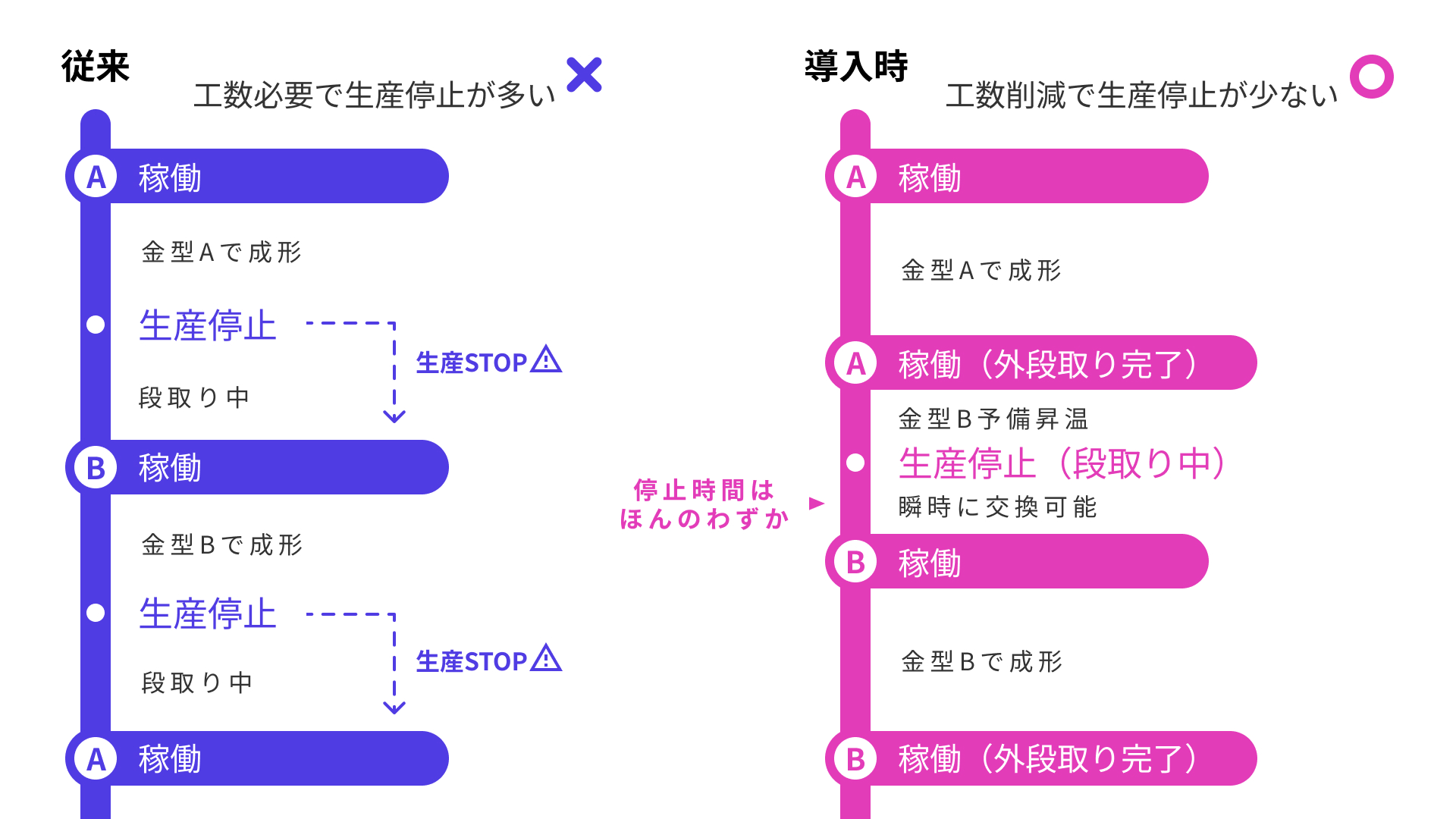

1. We will not let production stop! "It is natural for molding machines to be running all the time."

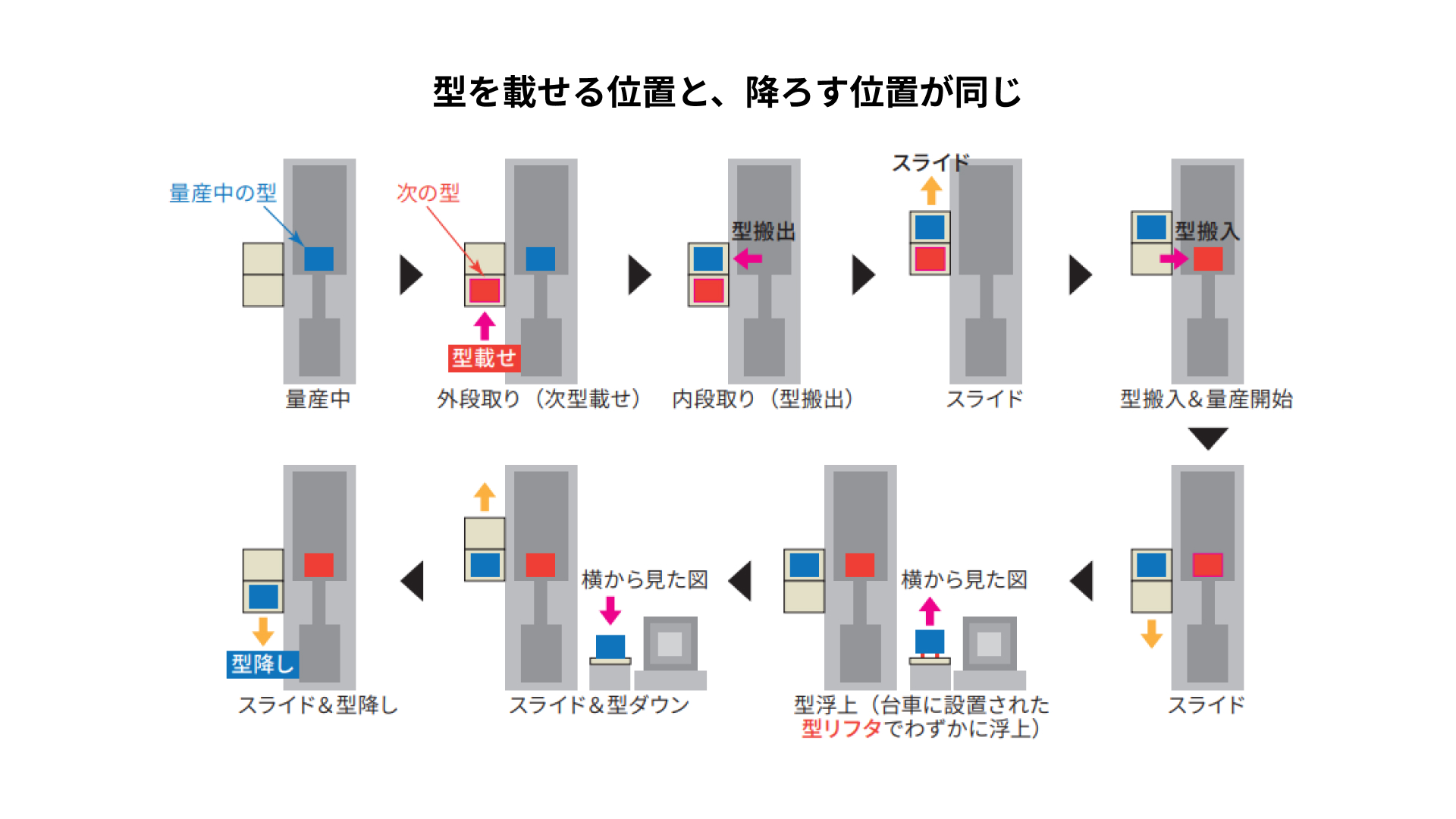

During production, the next mold can be set on Mold Changer and a cooling hose can be attached to prepare for production. By preheating the mold, the mold can be switched instantly and molding can be resumed without the production loss caused by stopping the molding machine for mold change.

2. Labor-hours reduced by 52.9%, reducing the number of workers required for die replacement

This reduces the total man-hours required for changeovers and helps alleviate labor shortages in factory.

Most of the work is done while production is ongoing, so there is no need to worry about impacts on operating rates.

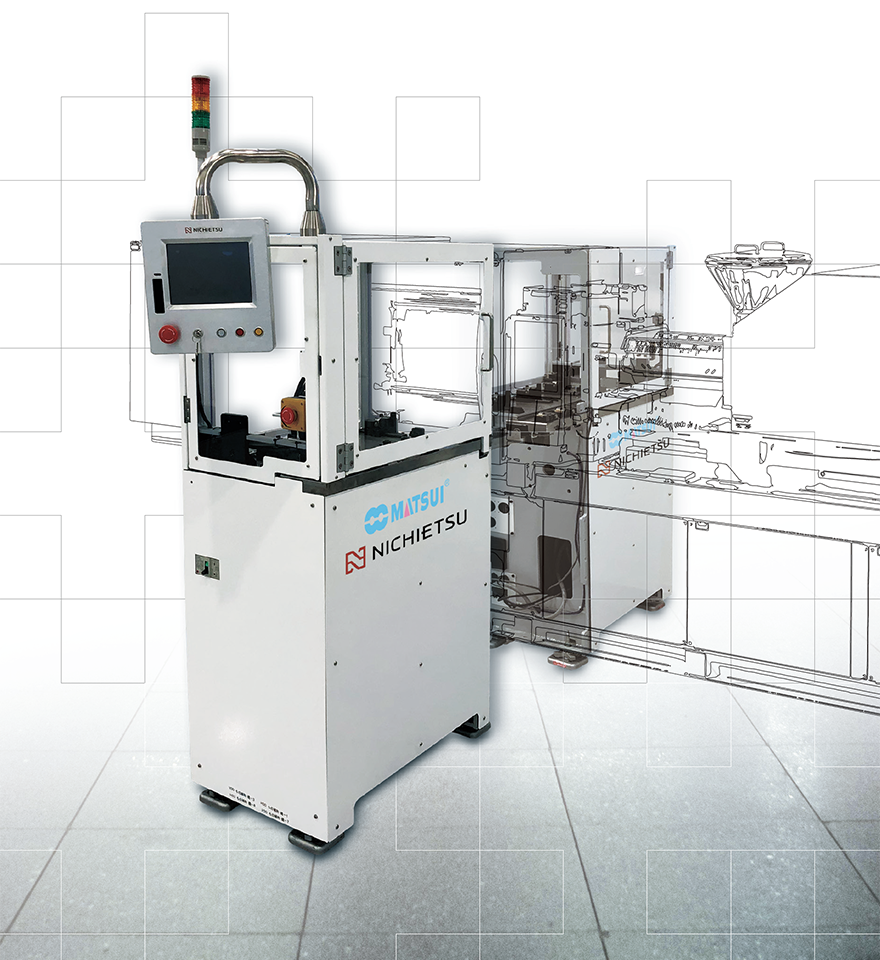

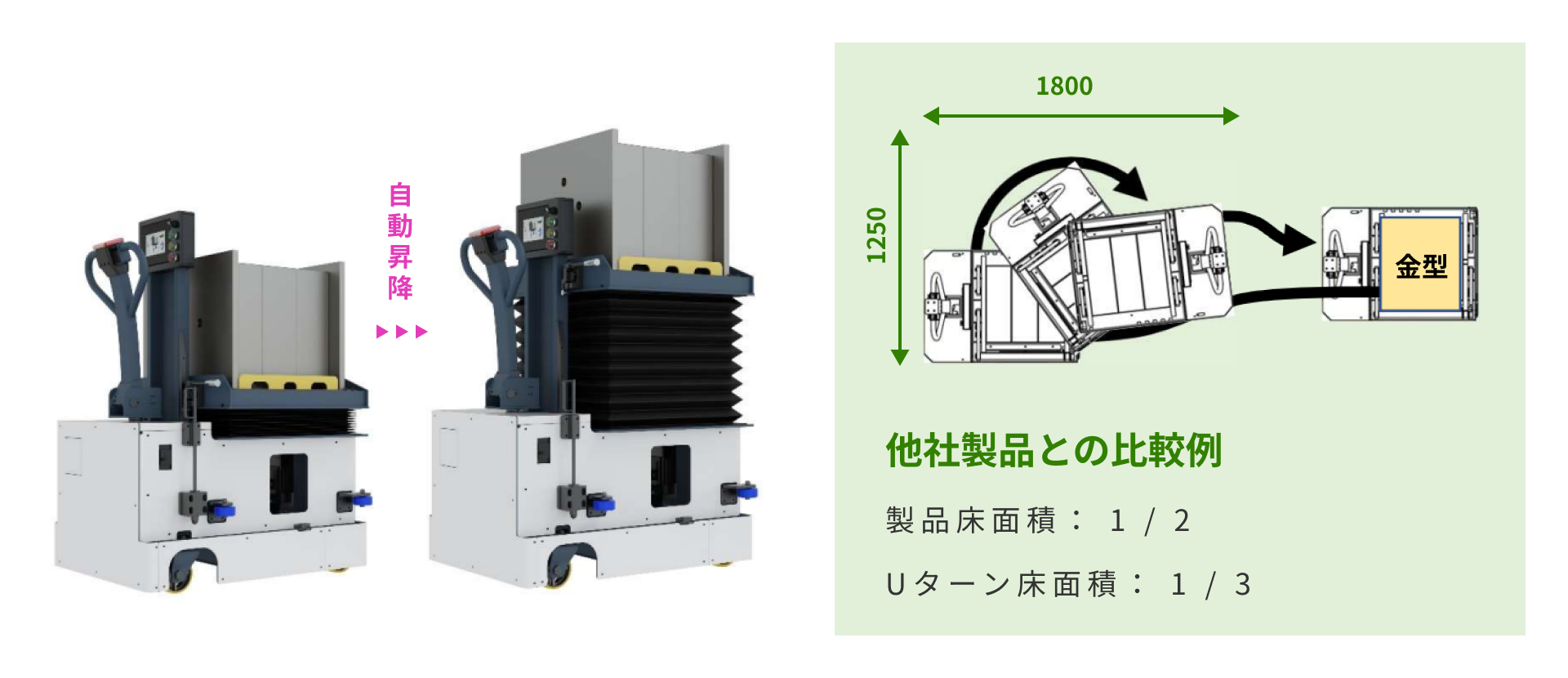

3. *With one of the world's smallest installation areas, it won't block on-site wiring!

This allows easy and safe work with minimal space required for installation of the replacement mold.

Introducing four other types of Mold Changer

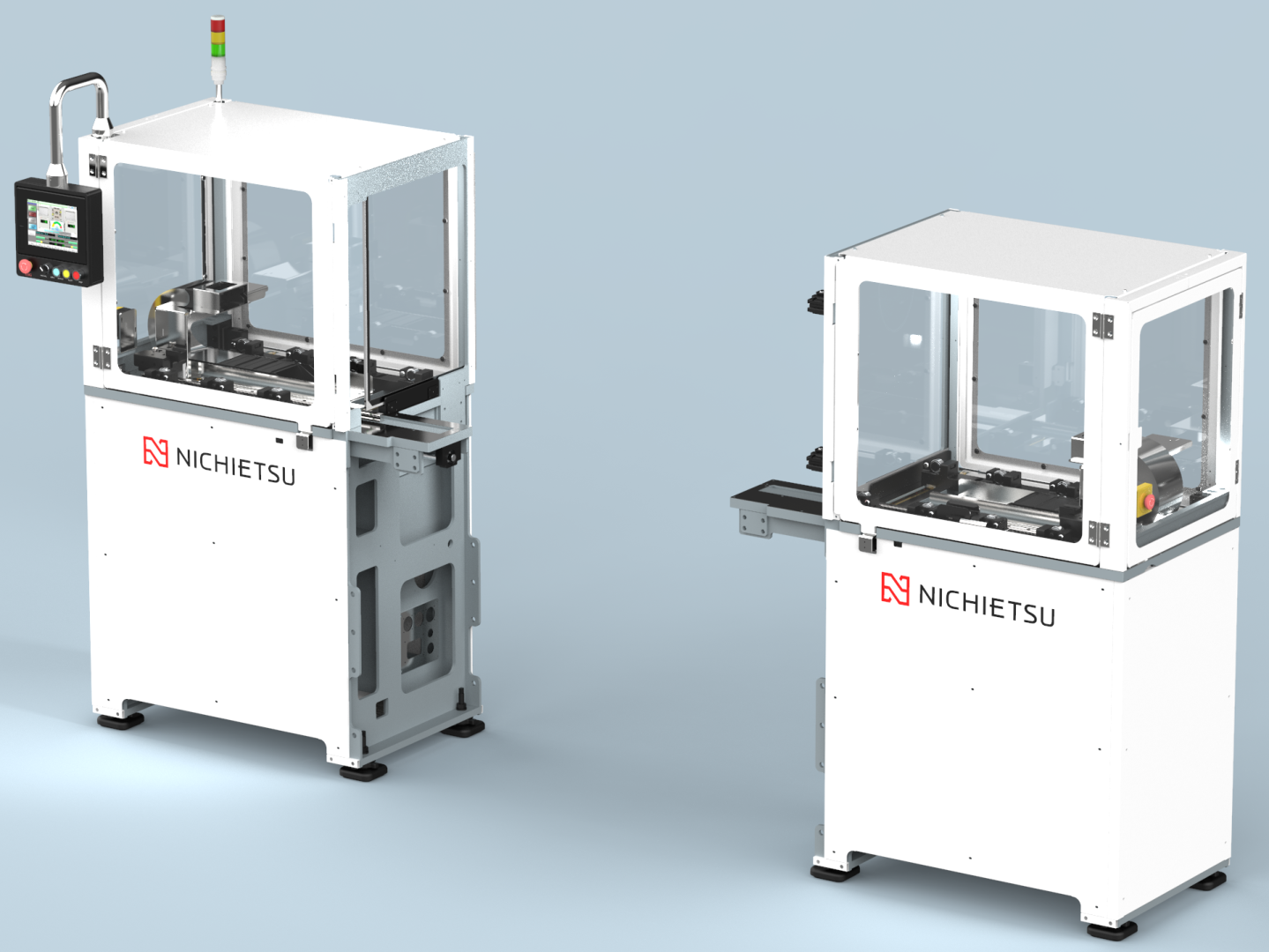

1. Single-sided track type

◇ Install the device on one side of the molding machine

The space opposite Mold Changer can be used for box packing, 2D processing, etc.

It also supports auto couplers*1 and mold waiting tables*2, and we can provide a wide range of solutions from fully manual to fully automatic depending on your needs.

*1 Mold Temperature Controller and hot runner controller are connected, making it possible to automatically preheat before switching over to production.

*2 Molds can be Selection automatically or manually from one or multiple mold waiting tables.

By using a mold waiting table, it is also possible to load and unload molds using a hand forklift.

2. One-sided track type (moving stage type)

◇ Install the device on one side of the molding machine

This type is highly space efficient. It is possible to load and unload the mold using a hand forklift, and the molding machine can be installed even in places where there is no floor crane.

3. One-side fixed type (moving stage type)

◇ Fix the device to one side of the molding machine

The main body Mold Changer is fixed to the floor, and only the stage on which the mold is placed can slide. As with the one-sided track type (moving stage type), molds can be loaded and unloaded using a handle forklift.

The dies can be loaded and unloaded from the same direction, making operation easy. *Applicable Truck: Track type single-sided Truck and fixed type single-sided Truck (depending on the specifications, Truck may not be able to move the dies as described below).

4. Trackless

Since it is a non-track type (hand-pushed type) that can be installed anywhere, work space can be secured and it is possible to cover the molding machine of the compound table.

When transporting the molds, they are kept at a low position, and when changing the molds, the stage is raised to a position according to the height of each molding machine.

The lift is electrically powered and can also be fitted with a built-in battery.

Video explaining the mold setup procedure

Please refer to this for setup procedures for the SDC Series.