tech-studio: An Immersive experience center where you can explore

Experience Before You Commit.

Move Forward with Confidence.

Content Overview

An experiential solution facility where you can experience factor4

What is tech studios?

"Ah, so that’s how it works."

The true capabilities of products that cannot be understood from drawings and Specifications alone, the true nature of on-site losses and waste, and the real effects of introducing solutions - all of this can be seen, felt, and understood at the Tech Studio.

We provide solutions for product development and on-site improvement under the mission of "Achieve factor 4 in molding factories. factor4 refers to the idea of aiming for a quadruple effect in resource productivity by halving resource consumption and doubling added value production.

Specifically, in a plastic molding factory,

- Reducing resource consumption (materials, water, energy)

- Increased productivity

- Adding value to products

With these three themes as its pillars and 12 solution themes, the company aims to improve resource productivity throughout factory.

To achieve this factor4, we created the "factor4 tech-studios," an experiential solutions facility that provides a place for customers to "see, try, and think about improvements."

What can you do at Tech Studio?

This surprising and satisfying experience will give you a clearer image of what it will be like after implementation.

① See the actual product demo up close

You can actually see the operation and effects of the equipment, which cannot be fully conveyed through catalogs and Specifications alone. Furthermore, if you send the desired mold to Tech Studio in advance, we can conduct molding tests under conditions close to the actual molding conditions. You can experience the performance and effects of the product in a way that is suited to the actual site.

②Simulation of improvements after introducing the solution

When working on solving problems, many customers have concerns about whether the solution will actually be effective. To dispel such concerns, Tech Studio conducts simulations of improvements with an eye toward post-implementation. For example, we use thermography to verify the efficiency of mold cooling, making the effects of the solution visible and eliminating concerns before implementation.

3) Discovering and recognizing hidden issues at molding sites

At Tech Studio, we have set up experience booths divided into 12 solution themes based on the concerns we often hear on-site. We will clearly introduce the issues and solutions for each theme, using actual equipment. When dealing with molding defects, it is not uncommon to stumble in the early stages, saying, "I don't know what the cause is," or "I don't know where to start." First, let's "look at" the current situation and organize it together, starting with the issues that concern you.

State of factor4 tech-studios

studio1

This booth is ideal for those who feel they "don't know what is being wasted" or "can't see a way to improve" at their workplace, and who can come up with solutions with a sense of satisfaction.

This studio features Enhance surface quality and value sites, such as "Eliminate wasted energy," "Eliminate wasted resin," "reducing Reduction in cycle time Shorten set up times," "Eliminate contamination Resolve problems caused by gas problems," "eliminating contamination problems," and "improving surface quality and value."

In particular, at the booth themed on "Enhance surface quality and value," we will be introducing concrete solutions to on-site challenges through demonstrations of pressurized hot water and steam Heat & Cool molding.

For example, in heat & cool molding, by optimizing the control of the mold temperature, it is possible to expect effects such as Reduction in cycle time by improving cooling efficiency and improving surface quality through high transferability.

In the demonstration, these improvements will be made visible using actual molding machines and molds. The demonstration will allow you to visually and physically understand the effects of introducing the technology, which are difficult to convey through explanations of theory and specifications alone.

studio2

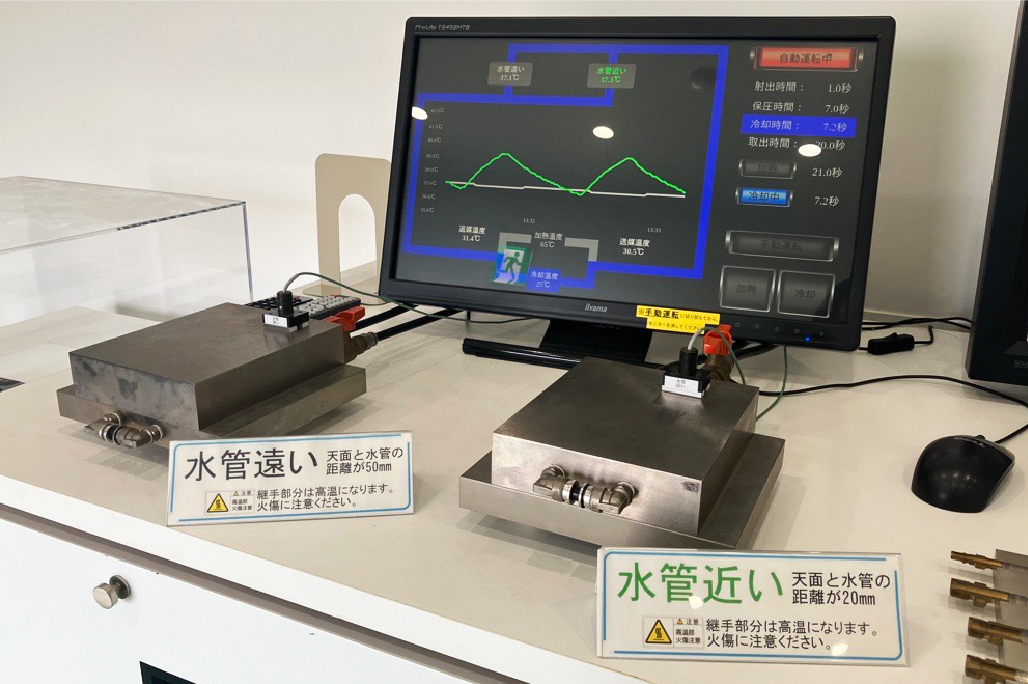

We make visible the issues and effects in areas that are difficult to see with the naked eye, such as differences in mold temperature control and the effects of water quality problems, and clarify any doubts or concerns.

In this studio, under the theme of "Resolve problems with water quality," we use a water tank to explain the mechanism by which components contained in cooling water accumulate as scale (deposits), and through experiments, we "visualize" the adverse effects on cooling efficiency and heat conduction. You can visibly confirm the causes of problems such as poor cooling caused by the accumulation of scale and the instability of molded products.

Furthermore, if you wish, you can experience mold water tube cleaning without using chemicals by sending us your mold in advance. This is a practical experience in which you can remove dirt and scale from inside the water tubes using your actual mold and experience the change in cooling performance. By comparing the difference before and after cleaning, you can be more convinced to consider introducing the system.

We will also be exhibiting the application of Heat & Cool molding that is being demonstrated in studio 1. While viewing actual molded products, we will be introducing in detail from an on-site perspective the difference in molding quality that can be achieved through temperature control, the effects that can be expected from its introduction, and key points for operation. We will not only introduce the equipment, but also provide explanations in line with on-site issues, such as "why it is necessary" and "where the effects will be seen."

In addition, in the demonstration of temperature rise and fall using a demo mold, the change in mold temperature under different temperature control conditions is visualized on a monitor. This content allows you to concretely understand the impact that mold temperature control has on product quality and molding conditions. This will convince even those who say, "I've heard that temperature control is important, but I don't really know what changes and how."

In addition, we are exhibiting actual temperature control equipment such as the Eco Hybrid Chiller and the Ecobrid dry cooler. These devices achieve both stable temperature control and energy conservation, and you can see their actual operation to get a concrete idea of how they will be used after installation.

studio3+High-performance Resin Recycling Lab

From material testing to equipment verification and recycling, this is a studio where you can "try and verify" everything. This reduces the anxiety of trial and error and supports satisfactory equipment investment.

We have consolidated the testing environments that were previously scattered around the site into one location and established a dedicated testing building where we can consistently verify and complete various processes related to molding, from material transportation and blending, to drying and crushing, and even operation and capacity confirmation before delivery.

We have created an environment where we can respond more quickly and flexibly to the diverse requests of our customers, and inspection work that previously required off-site facilities and was divided into multiple processes can now be carried out efficiently.

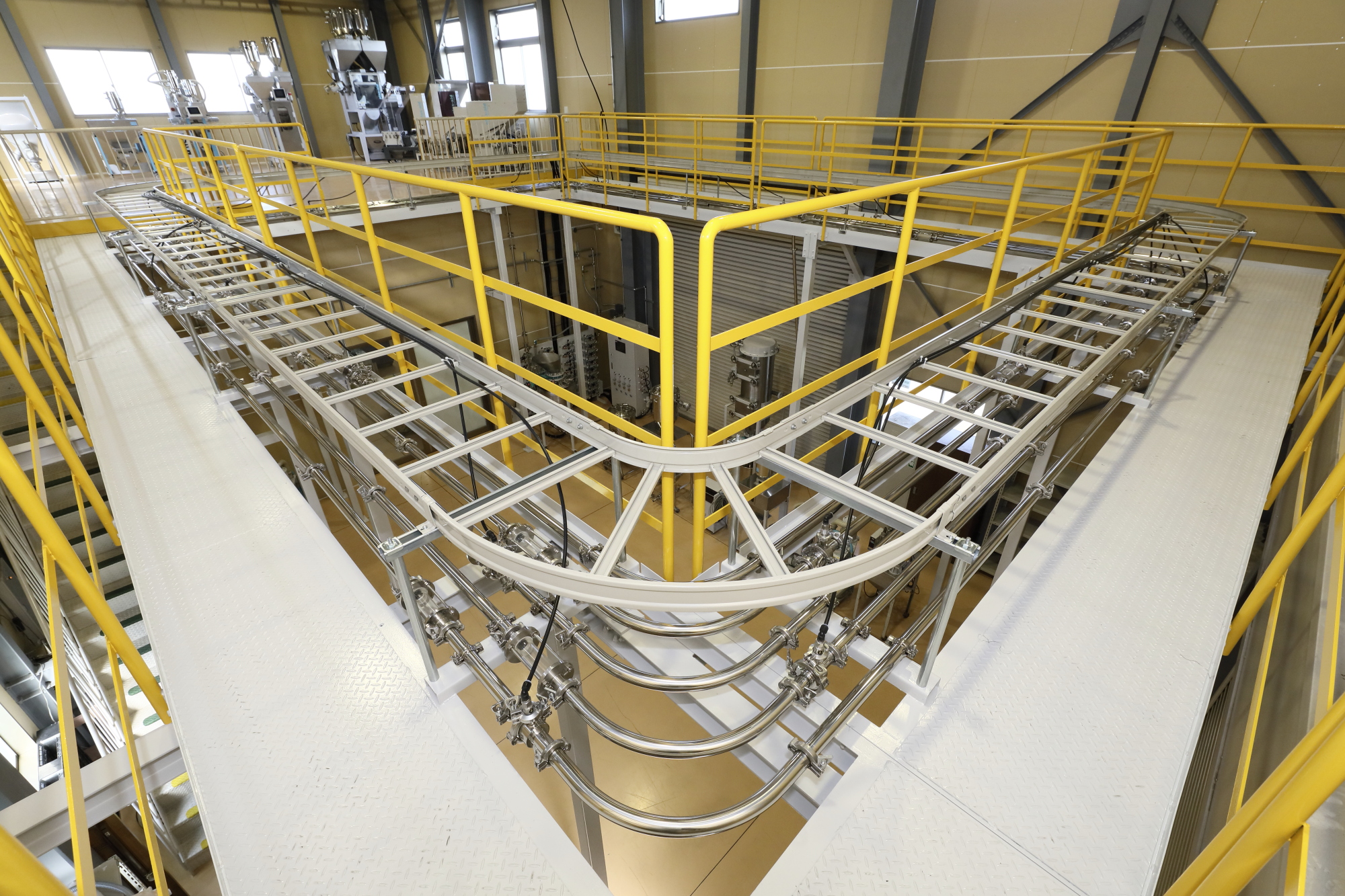

In particular, for material transport tests, the facility is equipped with piping just like that of a molding factory. It is possible to carry out reproduction tests of raw material transport under conditions close to those of actual operation. By simulating long-distance transport and transport lines with elevation differences, issues such as deterioration, separation, and dust generation during transport can be verified in advance, which significantly reduces the risk of problems after introducing the equipment.

In addition, for customers considering the blending equipment, dryers, Granulators and other equipment exhibited in Studio 1, we also offer pre-introduction tests, allowing you to check the performance and suitability of the equipment in advance. This prevents companies from "realizing the failure of equipment after it has been installed," and allows them to confidently decide to make capital investments.

We can also handle physical property tests such as measuring the moisture content of materials. Molding under appropriate conditions according to the characteristics of the resin leads to reduced molding defects and stable product quality. We believe that the first step to stable molding is to "correctly know" the resin to be used.

Additionally, the Tech-Lab, a high-performance resin recycling laboratory with the theme of recycling high-performance resins, is also located within Studio 3. The laboratory supports efforts to improve production efficiency by utilizing recycling technology for high-performance resins such as engineering plastics and super engineering plastics while also being considerate of the global environment.

Tech-Lab is unique in that it allows you to carry out a full range of recycling-related considerations in one place, from checking the state of waste resin generated during molding to proposing recycling processes and consulting on equipment installation.In addition, staff with specialized recycling knowledge are always on-site, and they can flexibly respond to technical questions and consultations regarding material properties.

"Create a molding factory that does not waste limited resources." Your experience at Tech-Lab will surely provide you with hints to achieve this. If you are interested in reusing high-performance resins and recycling resources, please give it a try.

Click here for details on the high-performance resin recycling lab "Tech-Lab"

About studio tours and experiences

Information on tours and experience sessions

Tech Studio regularly holds tours and trial sessions. If you are interested, please first take a look at the Tech Studio and the virtual tour course below. If you would like to visit in person, please make a reservation through the "Tour Reservation Calendar" or feel free Contact our sales representative or your nearest sales office.

*For details about the exhibition content, please contact us using the "Inquiry Form" on the top right of the page.

*Please note that depending on the date, only some areas may be open to the public.

Virtual tour

You can easily see the atmosphere inside the studio from your PC or smartphone.

Click on the "Virtual Tour" banner below to experience it for yourself.

Access Map

Please see the following page for access to factor4 tech-studios.