News

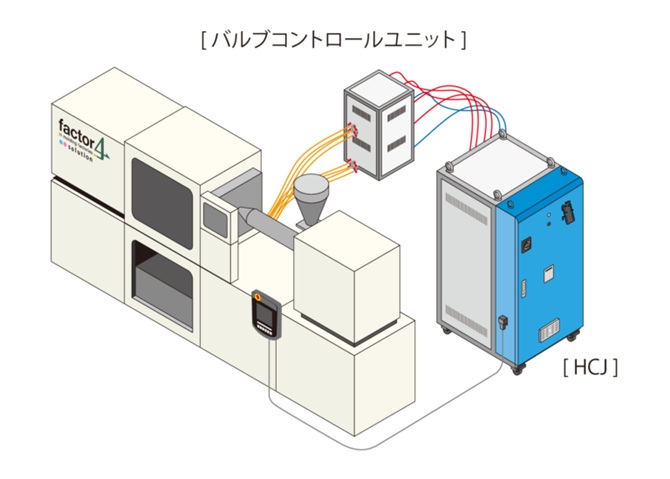

Introducing the new pressurized hot water heat and cool system "HCJ"

2025.11.17

We have now added the pressurized hot water type "HCJ" to our lineup to realize Heat & Cool molding technology.

Heat & Cool molding is a molding method in which the mold temperature is rapidly heated to the softening point of the resin during one molding cycle, and then rapidly cooled to a temperature at which the part can be removed, thereby improving mold transferability and achieving a high level of surface quality that cannot be achieved with general molding.This technology is expected to have a variety of effects, including improved weld lines, increased surface gloss, and reduced warping and sink marks.

This new product, "HCJ," can withstand medium temperatures up to 200°C. Heating the mold improves the fluidity of the resin, increasing adhesion between the edges of the molten resin and reducing weld lines to a level where they are no longer visible. Furthermore, heating reduces the viscosity of the resin, allowing it to penetrate into the fine details of the mold, improving transfer defects and contributing to a reduction in molding defects.

We offer Series steam and oil-based systems to provide optimal temperature control solutions according to the mold structure.

For more details, please see the product page.