特長

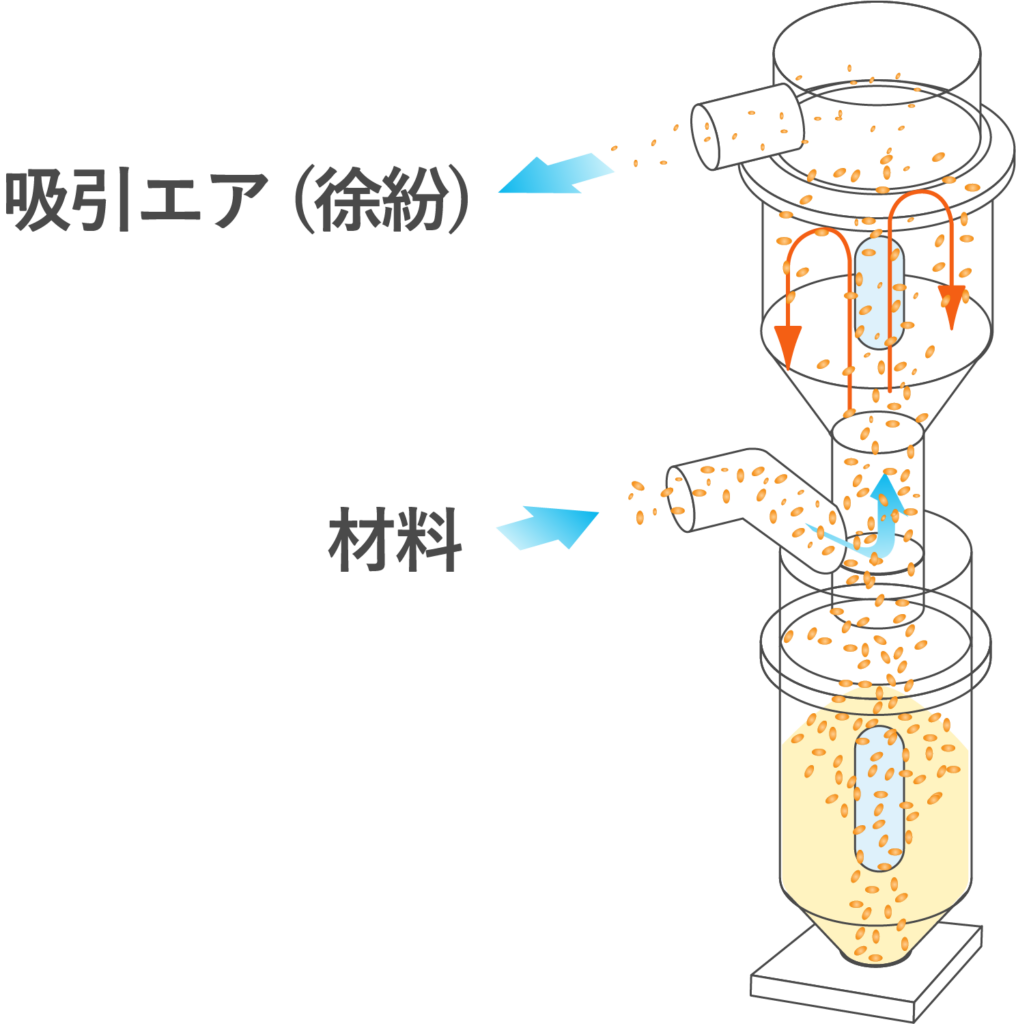

1.動力不要で材料の輸送と混合を同時に行います!

材料を輸送しながら、主材と粉砕材を混合します。

また、輸送の動力で混合するため、他の動力を必要としません。

2.不要な粉の除去もお任せください!

かみ込み防止対策をした吊下げ式フラップダンパーを内蔵し、粉取混合性能を高めました。成形機に届く前に微細な粉を取り除くことで、外観不良を防ぎ、より高品質な成形を実現します。

解説員

光学成形は特にコンタミ対策が欠かせません。

3.材料の混合比の安定化を実現!

成形機上で混合するため、輸送時に懸念される材料の分離に関する心配は必要ありません。

4.清掃簡易性を高め、メンテナンスの負担を軽減しました!

構造がシンプルなため、簡単に清掃を行うことが可能です。

日々のメンテナンスに掛かる負担を極限まで軽減しています。

5.破紛、帯電無しで成形不良を防止!

気流を利用し混合するため、機械混合時などに発生する材料の破紛、帯電がありません。

6.APHシリーズはラインナップが豊富です!

APHGは成形機直付け専用です。

APHGは、1ブロワーの1by1での使用を基本として設計しています。主に小、中型成形機向けです。

成形機の1ショット重量、サイクタイムによって必要な型式を選択してください。

APHSはバリエーションがあります。

サイトグラスタイプの他にチャージホッパータイプもご用意しています。