DP(デジぺカ)とは? ー 基本動作説明

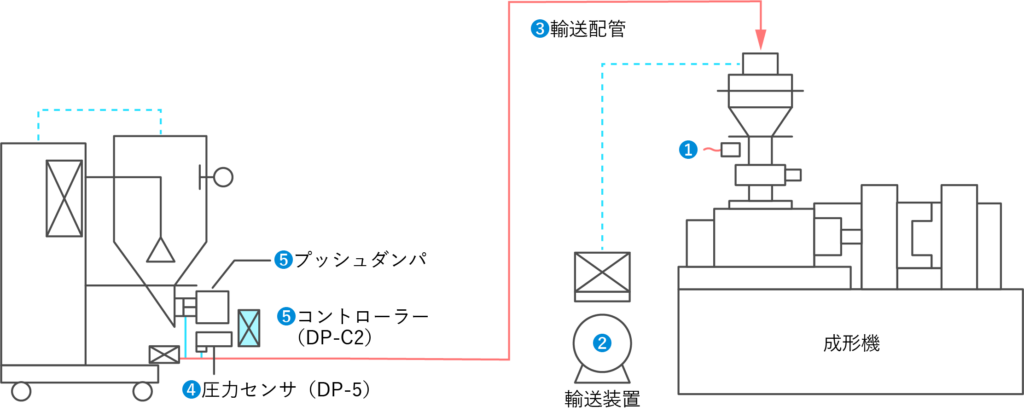

- 成形機上のレベル計が、材料を要求する信号を出します。

- 成形機横に設置された輸送装置ブロワが起動します。

- ブロワの起動により、輸送配管内が減圧状態になります。

- 材料供給側に設置された圧力センサ(DP-S)が、一定の圧力を検知します。

- 圧力センサからの検知信号を受け、デジペのコントローラー(DP-C2)が制御信号を出力し、その信号により切出し装置が動作します。

注1)出力の種類は「時間」と「回数」の2種類があり、いずれかを選択して設定できます。

注2)デジペカは、輸送ブロワの起動時間の長さに応じて、出力を変化させることも可能です。

特長

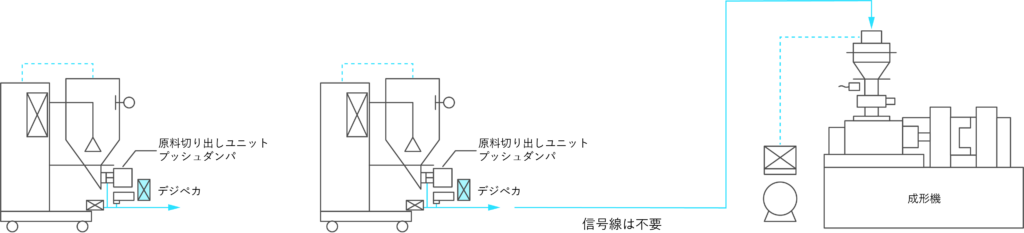

1. 長距離でも安定した材料輸送を実現(信号線不要)

DPは、輸送配管内で発生する吸引圧力の変化を輸送信号として利用する圧力検知システムです。

各装置にDPを取り付けることで、40m~50mといった長距離に離れた乾燥機からでも、信号線を使用せずに材料を定量輸送することができます。

この方式により、輸送区間における電気配線工事が不要となり、設置工事の手間やコストの削減に貢献します。また、建屋や工程が離れている場合でも、電気工事を行うことなく導入が可能なため、レイアウト変更や設備追加にも柔軟に対応できます。

さらに、輸送完了後に配管内へ材料が残留しにくいため、材料切替時のロス低減や、異材混入の抑制にも効果を発揮します。

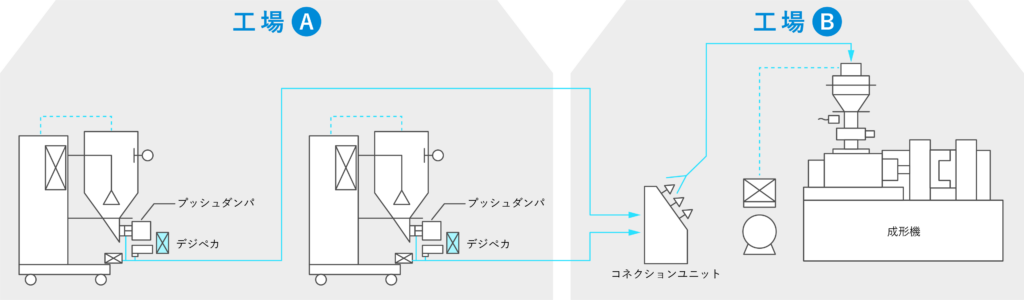

2. 装置の型式に縛られない柔軟な輸送システム構築

DPは、ホースを差し替えるだけで接続が可能なため、型式の異なる装置であっても、容易に材料輸送システムを構築することができます。また、既存設備で使用している標準ローターをそのまま活用したシステム構築にも対応しています。

新規導入だけでなく、既存輸送ラインの拡張や改造にも適した圧力検知式輸送システムとして、幅広い成形現場で活用できます。

解説員

装置メーカーや切出し機が異なる場合でも、導入することが可能です。