真空式乾燥がもたらすメリット

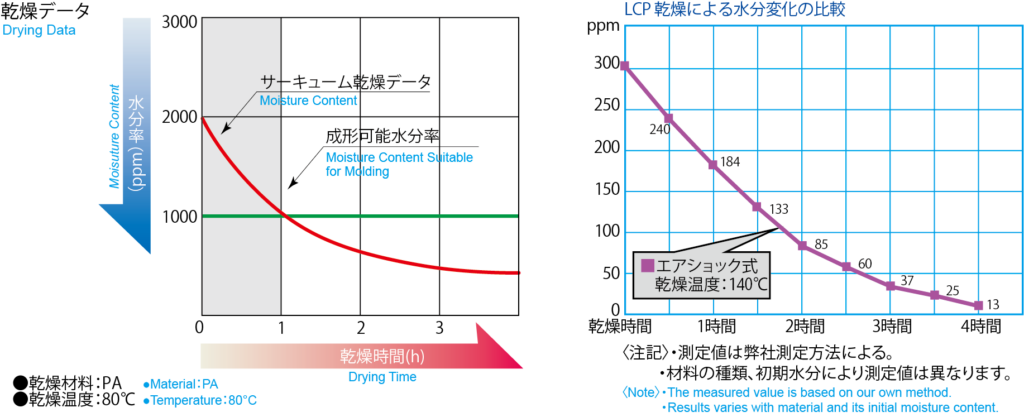

真空乾燥機は、乾燥槽内の圧力を下げることで樹脂中の水分を効率よく除去します。圧力を落とした真空環境では水の沸点が下がるため、比較的低温でも水分を蒸発させることができます。そのため、熱に弱い樹脂や高機能樹脂の乾燥に適した方式です。

特に光学用途など、透明性や外観品質が求められる樹脂成形においては、低温での乾燥により熱による劣化リスクを抑えられる点が大きな強みです。微細な光学部品などでは、わずかな熱ダメージが最終製品の性能や光学特性に影響を及ぼすため、真空式乾燥機が有効な手段となります。

また、真空環境下では水分蒸発が促進されるため、乾燥時間の短縮が可能です。これにより、成形ラインの立ち上げ時間の短縮やエネルギー使用量の低減といった、生産性・コスト面での利点が期待できます。さらに、ホッパーないが均一に乾燥しやすいため、樹脂全体の含水ムラが少なく、安定した成形品質に貢献します。

特長

1. 真空乾燥で黄変発生を防止します!

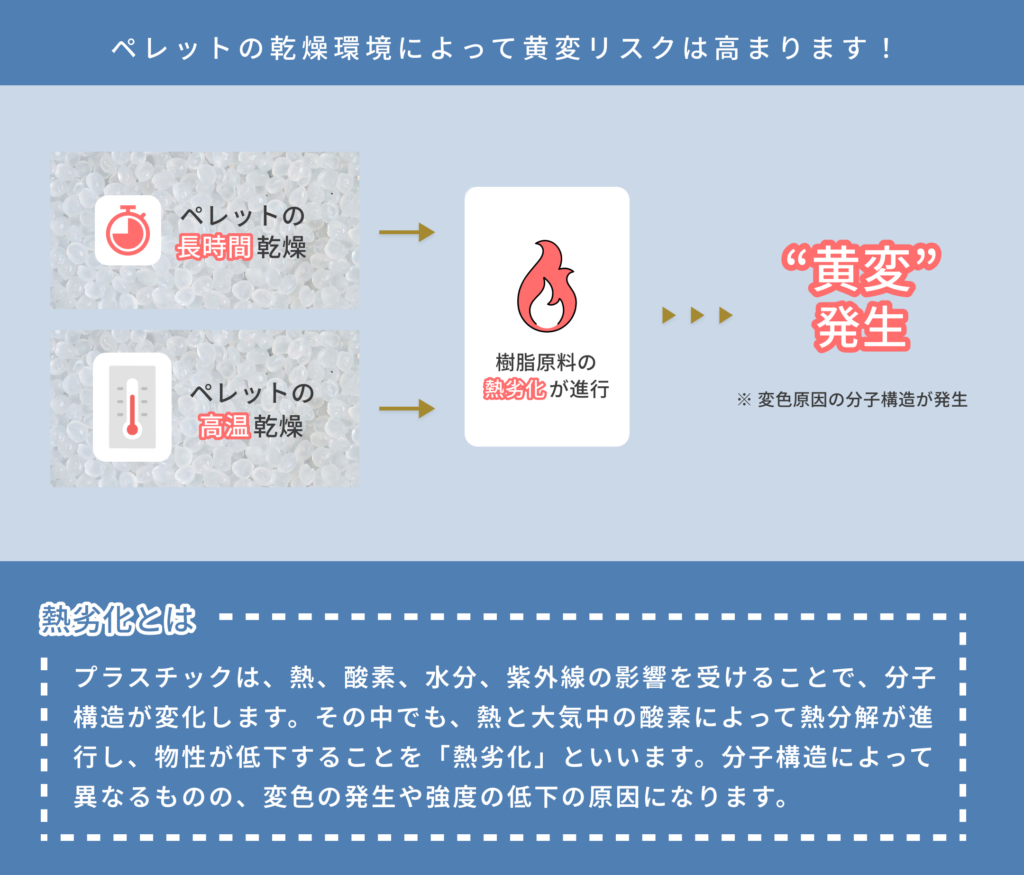

ペレットの高温乾燥や長時間乾燥といった乾燥環境は、変色要因のひとつである樹脂原料の熱劣化を進行させ、黄変を発生させます。真空伝熱方式は、水の沸点が下がる真空空間を利用し、低温で水分を蒸発させることができます。そのため、 DPD3.1では可能な限り温度を上げることなく、短時間での樹脂乾燥を可能とします。

2. 短時間乾燥により、熱劣化を抑制します!

ホッパー内部伝達フィンを外周部と中心部に設置し、個別に温度コントロールしています。これにより、短時間で効率よく昇温、乾燥ができます。

3. 輸送制御の操作性を改善しました!

多くの原料の中には、二次輸送のバッチ量を調整しなければならないものがあります。従来機では、それをバルブ調整で行っていました。そのため、DPD3.1ではタッチパネルの設定でバッチ量を調整できるよう改善し、材料輸送時の操作性を向上させました。

4. エアショック機能搭載で、ブリッジやブロックなどの問題を解決します!

プラスチックの原料の中には、ブリッジやブロックなどを起こしやすいものが存在します。DPD3.1は、初期乾燥の際のエアショック機能を標準装備しており、それらの問題を解決します。

5. 減圧による乾燥と断熱仕様の改善により、省エネルギー化を実現!

「減圧乾燥」による省エネ

樹脂を熱風ではなく、伝熱により加熱し、減圧により乾燥させます。そのため、消費エネルギーが従来の除湿ドライヤーの約半分です。

「断熱仕様の改善」による省エネ

従来機に対して断熱性を細部まで改善し放熱を防ぐことによって省エネ性を向上させました。

6. メンテナンス時間の短縮とメンテナンス頻度の削減に貢献します!

メンテナンス時間の短縮

昇降リフトと大型排出ダンパの採用により、材料の抜き取り交換が短時間で完了します。また、押出し材の採用により、表面が滑らかで樹脂の付着はほとんどなく、清掃が簡単です。

メンテナンス頻度の削減

ガス性材料の成形等で問題となる金型表面への膜状付着物が激減し、金型メンテナンスの頻度を大幅に削減します。

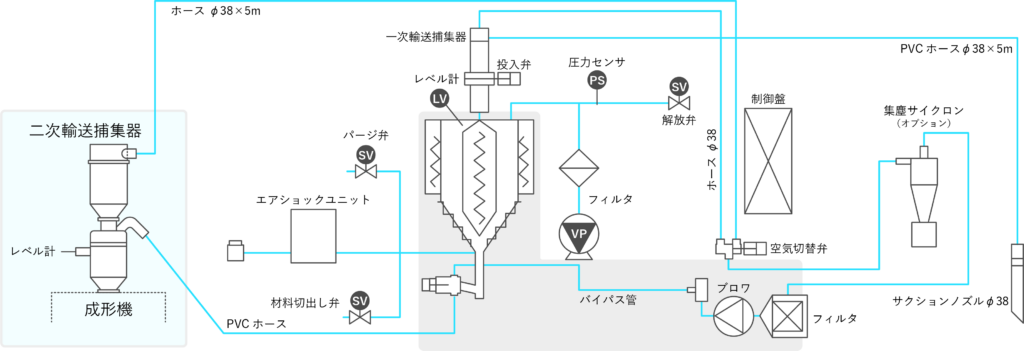

フロー図