Features

1. Powder is separated by suction air vibration waves

By applying suction air vibration waves with a frequency of 10 to 20Hz to the material, powder adhering to the pellet surface and fine powder mixed in the material are efficiently separated. Because it uses air vibration waves, powder separation is possible without placing a large load on the material itself.

It supports stable powder removal as a material treatment before the molding process.

2. Dust collection structure that collects only separated powder

The separated powder is collected in a dust box. The pellets and powder are accurately separated, allowing only the powder to be removed without wasting the necessary materials. Because the collected powder is collected in the dust box, cleaning and disposal after processing are easy, and the design also takes into consideration ease of operation during daily maintenance.

3. Clean pellet supply stabilizes molding quality

By performing a powder removal process, it is possible to supply fine pellets that are free of powder. This reduces the risk of foreign matter getting mixed in or contamination during the molding process. By steadily supplying clean material, it is possible to suppress variations in the appearance and quality of molded products, and is highly effective in producing products with little contamination.

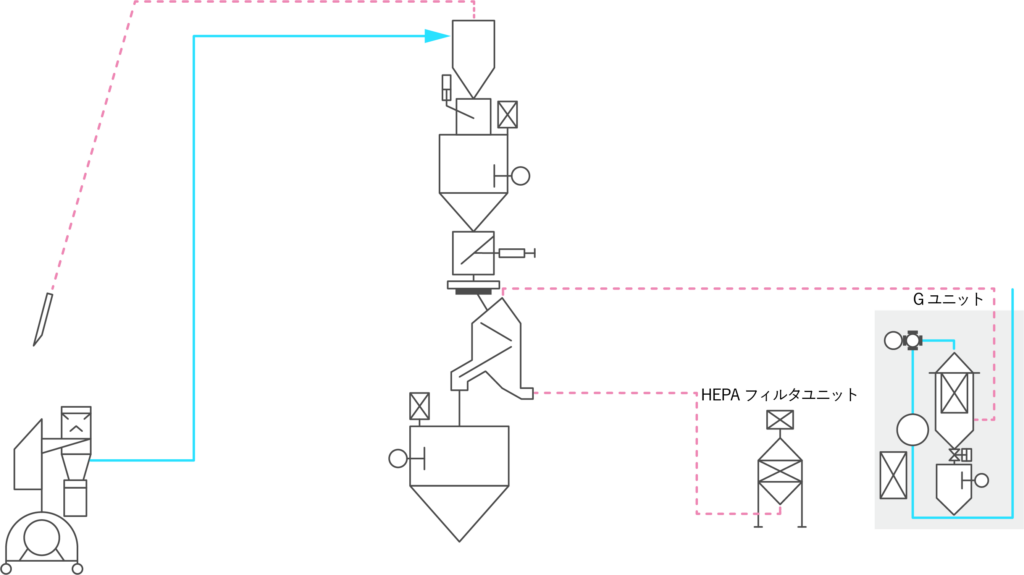

Flow Diagram