What is PET Continuous Crystallization Dryer

In order to mold PET (polyethylene terephthalate) with consistent quality, it is essential to have a process that properly dries the pellets while crystallizing them. PET Continuous Crystallization Dryer is a device that automatically processes uncrystallized PET in a continuous process from crystallization to drying, simply by feeding it in. Compared to batch-type systems, there is less unevenness in drying and the system can be started up quickly, making a significant contribution to stable production and improved quality on mass production lines.

Features

1. Stable quality through highly efficient continuous crystallization

By adopting a continuous process, crystallization efficiency is higher than that of a batch process, and pre-crystallized material is not required at start-up. Matsui's unique step temperature rise control prevents material adhesion, allowing for smooth temperature rise while preventing material adhesion, achieving uniform and stable crystallization.

2. Unique mixing system suppresses powder generation and ensures uniform processing

Matsui's uniquely shaped stirring Blade enable uniform stirring even at low speeds, preventing pellet crushing and the generation of frictional powder. The stirring motor is inverter controlled, allowing optimal rotation speed adjustment.

3. Reliable process control through hot air diffusion and exhaust temperature monitoring

Both the crystallization hopper and drying hopper are equipped with hot air diffusers, which distribute heat evenly to prevent variations in resin temperature.In addition, exhaust temperature sensors allow real-time monitoring of the crystallization status, contributing to the prevention of quality problems and stable operation.

4. Highly visible structure that makes it easy to understand the internal state

The hopper is equipped with two large observation windows, allowing the progress of crystallization inside to be easily observed from the outside. Being able to visually grasp the operating status facilitates smooth adjustments and inspections, and also provides peace of mind during operation.

5. Hopper structure that is easy to clean and maintain

A large manhole is installed in Conical section section and two inspection windows are installed on the side of the hopper body, making it easy to clean the interior and check for foreign objects. This makes it easy to perform everything from daily inspections to periodic maintenance, and also contributes to reducing line downtime.

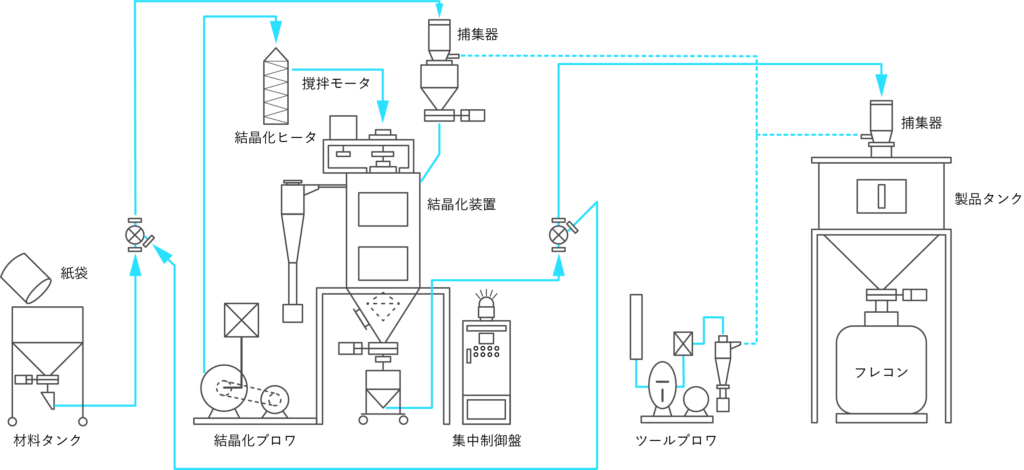

Flow Diagram