Features

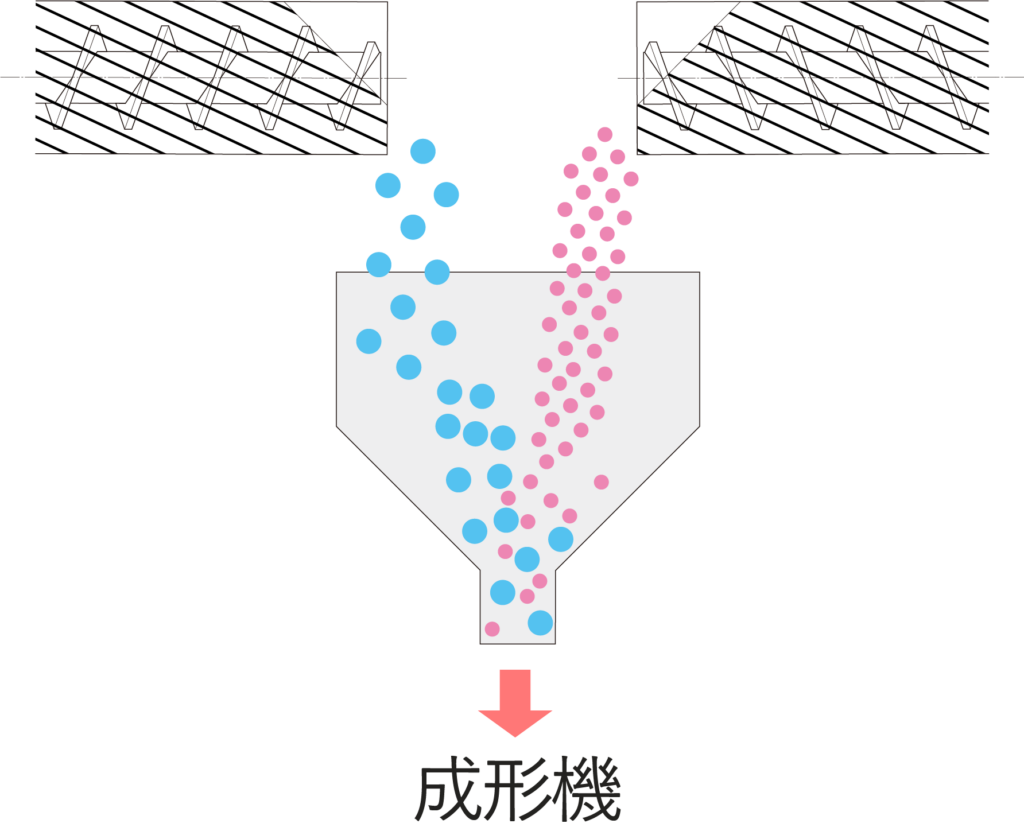

1. Synchronized calculation method to stabilize the blending ratio

The JC3 uses a synchronized calculation method that synchronizes the mixing and weighing of secondary materials such as Master batch and Regrind material with the flow of Virgin material (virgin material).

Because Virgin material and secondary materials are weighed out simultaneously at the set blending ratio, the ratio is always stable, achieving blending with little variation. Stable blending not only suppresses variations in molding quality, but also leads to reduced consumption of high-quality virgin materials and Master batch materials, thereby reducing material waste.

2. No stirring required for stable mixing and anti-static measures

The synchronized calculation method allows for blending without the need for a mixing process. This means that raw materials with different specific gravities or particle sizes are less likely to separate, making it possible to maintain a stable mixture.

It also suppresses the generation of dust caused by static electricity and friction that tend to occur during agitation, and is effective in reducing molding defects caused by uneven color and dust.

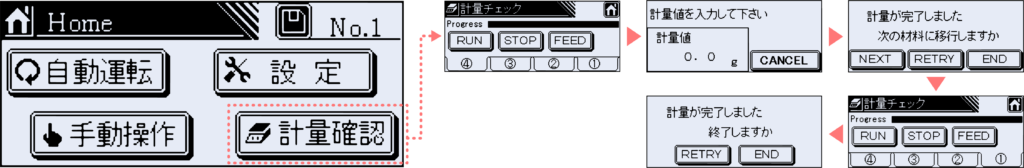

3. Intuitive composition settings and easy operation via touch panel

The operation panel is equipped with a touch panel that uses icon display.

Measurement confirmation and composition settings can be completed simply by following the on-screen instructions, allowing for intuitive and easy operation. Operational errors are unlikely to occur and settings can be completed in a short amount of time, making operation less dependent on the operator's experience.

* Measuring Capacity, Measurement accuracy, and processing Capacity may vary depending on the target material and are for reference only.