Features of KI blow

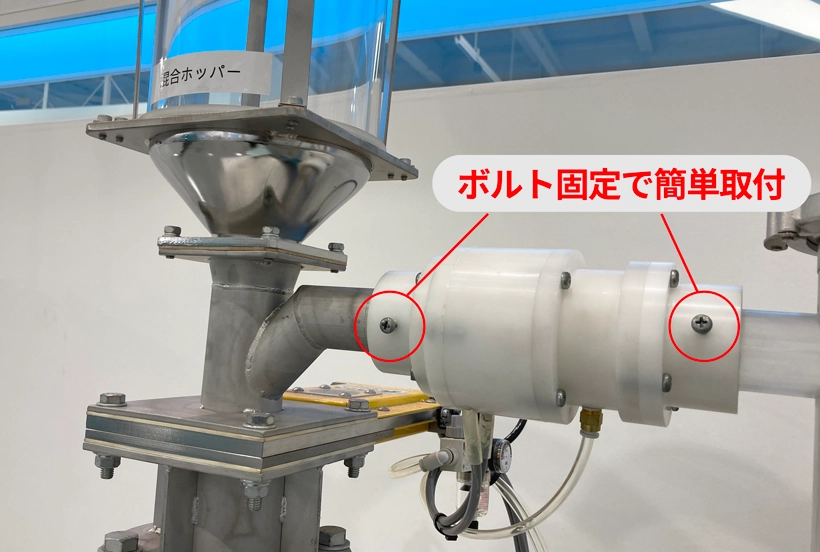

Easy connection

Just join the hose to connect!

(Utility connection: 100V, dry air)

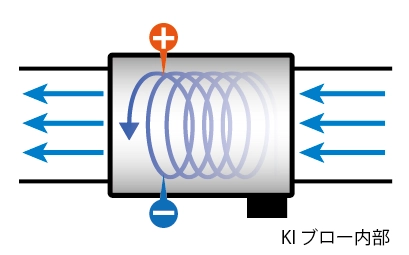

Eliminates static during conveyance for greater effectiveness!

Eliminating static electricity in the air that is not in contact with an object improves static elimination efficiency.

Airflow inhibits needle deterioration.

By generating a spiral air flow in the pipe, collision with the resin electrode needle is suppressed.

Case Study

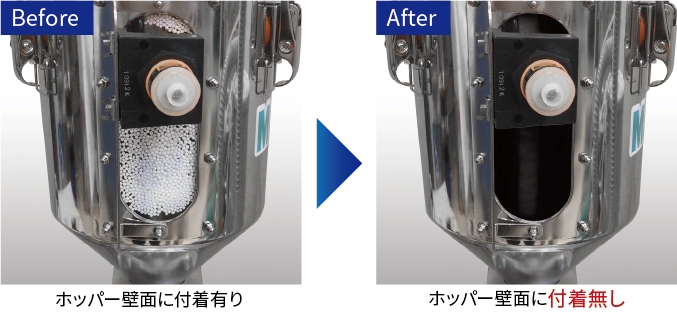

[Case 1]

Sensor abnormality occurred 3 to 5 times / day, but it was improved to 0 sensor abnormality by installing KI blow.

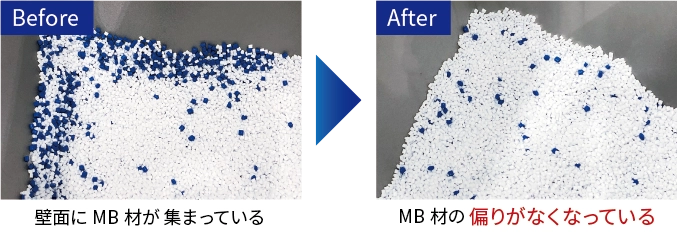

[Case 2]

The dispersion variation is suppressed and the defect rate is reduced; the mixing ratio of master batches also be reviewed and the material cost is reduced.

Easy connection to existing piping

It can be easily connected and installed simply by connecting it to the pipe and fixing it with two bolts.

(Joints for hose connection can be arranged)

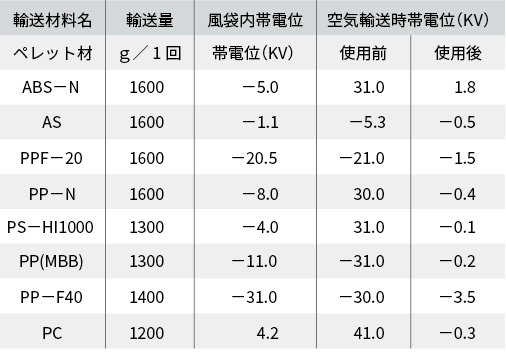

Static elimination for each resin (comparison of charge levels)

Some errors may occur due to differences in diameter, humidity, temperature, particle size, material Maker, etc.

* Hopper sticking occurs from about ± 3kV

Model information

We have a product lineup that supports Φ25, 38, 50, 65 (mm).

In addition, we also support pipes that are not in the lineup such as 〇〇A with a reducer with a taper.

* Equipment may be changed due to improvements.