A new type of molding site that doesn't rely on craftsmanship.

The unstoppable hollowing out of molding sites - A structural problem of a lack of engineers

In recent years, the decline in the working-age population in Japan has accelerated, making it difficult to secure human resources in all industries. The plastic molding industry in particular has been hit hard, with labor shortages becoming a chronic issue.

A characteristic of this industry is that once someone leaves, there is a structural issue that the gap cannot be filled immediately. In particular, many tasks that require "judgement based on experience," such as setting molding conditions and dealing with defects, can only be carried out by experienced molding engineers, and personalization is unavoidable. As a result, situations such as "molding stops because there is no one" and "defects do not decrease because there is no one who understands" are becoming a reality at work sites across the country.

As of June 2025, the job-to-applicant ratio for "product manufacturing and processing businesses (excluding metal products)," which includes plastic products, was 1.61, higher than the total for all occupations (1.17). Not only is there a shortage of human resources, there is also a shortage of people who can pass on their skills.

--That is the current situation at molding sites.

*Source: Ministry of Health, Labour and Welfare "General Employment Placement Situation (June 2025)"

Creating a workplace that doesn't rely on a limited number of people - Redefining the work of engineers

There are many tasks to be performed at molding sites where the labor shortage is becoming more serious. Among these, the work of molding engineers, who play a central role in production, is indispensable.

The work involves highly specialized tasks and also involves a heavy workload, including setting up new molds, setting up production at the start of production, preparing for production and clearing up, dealing with defects, production management, and even maintenance.

As the working-age population declines and the shortage of engineers begins to have serious effects, addressing this issue is an urgent task. However, the techniques that molding engineers are responsible for are in a field that can be called "craftsmanship," and training successors requires a long time and a great deal of experience. Increasing the number of personnel in the short term is almost impossible.

That's why what's needed now is the idea of "redesigning work." Rather than leaving everything to one engineer, we need to break down the work and determine which tasks can be replaced by other workers or systems. By appropriately "narrowing" the work of molding engineers, we can reduce their burden and increase the number of tasks each person can complete in a limited amount of time. Such ingenuity is required to achieve both improved productivity and sustainability on the job site.

So what kind of work can you delegate to other workers?

>What is the AI analysis system that reduces the labor required for injection molding?

Making technology accessible to everyone - AI for determining molding conditions.

We will review the work at the molding site and "redesign" the system.

To "redesign" the system, it is essential to break down existing production tasks into smaller pieces and reallocate them according to the number of people involved.

However, while people are calling for the importance of digital transformation, there are many voices on the front lines saying, "I don't know where to start." In particular, the important task of molding engineers, "determining molding conditions," is a craftsmanship supported by experience and intuition, and it is said to be difficult to break away from relying on individuals.

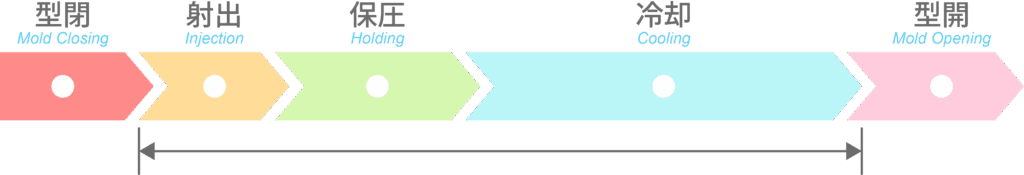

To address these challenges, Moldintel AI makes it possible to reproduce techniques that humans cannot quickly master, and enables even non-technical workers to set conditions. Moldintel AI is a molding support system that uses AI to calculate and propose optimal molding conditions based on information on the molding machine, resin, and molded product, targeting the region of the molding cycle from after mold closing to the end of cooling. This makes it possible for even non-expert technicians to set conditions, which is a setup task at the start of molding.

Furthermore, by linking with molding data, mold pressure gauges, cameras, etc., we can propose conditions with even higher precision.

AI will present the optimal molding conditions from mold closing to the end of cooling, but only for molding machines that are capable of communication.

5-step operation flow to avoid confusion on-site

1. Create a project

Create a project, select the resin and molding machine to be used, and register information about the molded product.

2. Select a project

Select the target project from the list and the recommended molding conditions will be displayed.

3. Enter molding conditions

The proposed molding conditions are entered into the molding machine and molding begins.

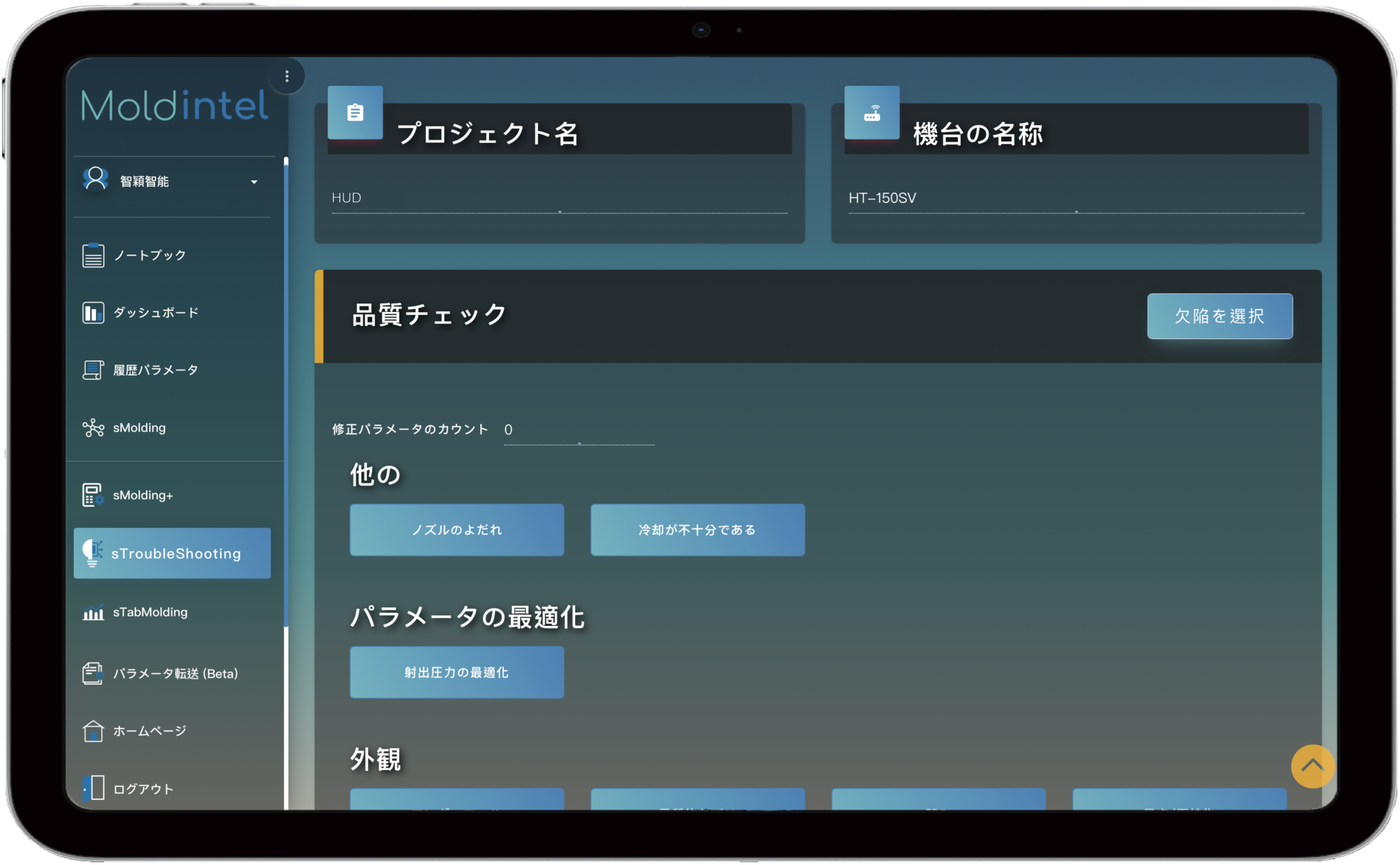

4. When a defect occurs, select the relevant item.

Select the item that corresponds to the defect that appears in the molded product.

5. Enter the reacquired molding conditions

The conditions re-presented by Moldintel AI are input into the molding machine and molding is carried out again.

Features of Moldintel AI that give freedom and flexibility to the workplace

1. sMolding+'s adaptability to fit any molding site

Moldintel AI is suitable for anyone, anywhere.

sMolding+ is compatible with a variety of molding machine manufacturers and tonnages, and can be used for a wide range of molded products, including automobile and motorcycle parts, household goods, medical products, and precision parts.

Project creation and molding condition settings are processed on the cloud, and can be operated via the web from any device, including PCs, tablets, smartphones, etc. Mobile communication is also supported, so it can be used even in places without a Wi-Fi environment.

It is also ideal for streamlining project management. The user interface is unified, allowing you to create projects and enter conditions from the same screen on any device. Simply select a project to instantly call up the necessary molding conditions.

Even if the AI can suggest optimal molding conditions, there is still the possibility of making a mistake when inputting the parameters into the molding machine, so I'm a bit worried...

Don't worry. If your molding machine is communication-enabled, the molding conditions calculated by AI can be automatically transferred to the molding machine. This eliminates the risk of errors caused by manual input.

It also saves you the trouble of manually entering data, and even small savings in operation time can add up to a big reduction in waste!

2. AI learns and evolves. Autonomous improvement power through sTroubleshooting

Moldintel AI automatically stores calculated molding condition parameters and continuously learns molding know-how. Based on the accumulated data, it efficiently learns the necessary setting conditions and provides more accurate molding conditions.

Furthermore, even if molding defects occur with the suggested settings, the operator can select the relevant item from the defect list on the screen and provide feedback, allowing the AI to readjust the parameters and improve the defect.

In this way, Moldintel AI learns by incorporating information obtained on-site, enabling innovative troubleshooting. It supports early resolution of injection molding problems, contributing to improved quality and reduced work time.

I understand that AI will use the cloud to accumulate molding know-how, but are there any concerns that this information could be leaked to the outside?

Yes, rest assured. All data is encrypted and stored in a secure environment, so it will not be leaked to anyone.

So, does this mean that your company's molding conditions will be used by other companies?

Please rest assured about this point. An independent project management area is set up for each client, so there is no need to worry about information being mixed up or shared with other companies.

Molding conditions are important know-how for the company, so I was relieved to hear that!

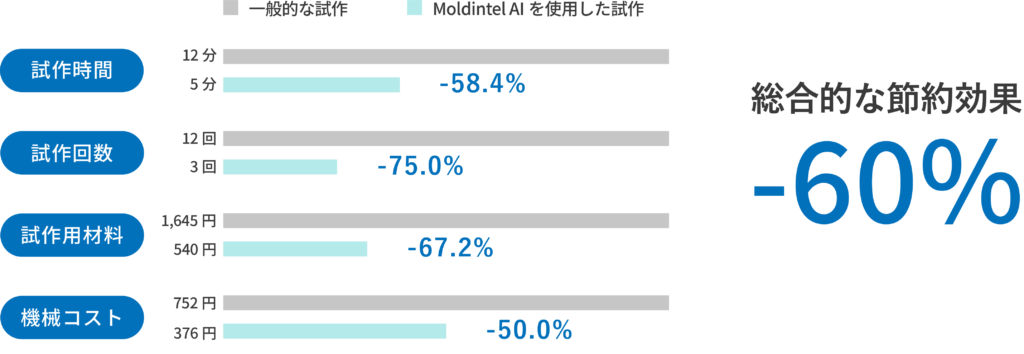

Introducing Moldintel AI significantly reduces the cost and labor required for the prototype process

Overwhelming reduction effects backed by data

The introduction of Moldintel AI has resulted in improvements in prototype time, number of trials, material costs, and machine costs, achieving an overall reduction of up to 60%.

Without relying on experience or intuition, AI-based molding condition prediction enables efficient and high-quality start-up.