Features

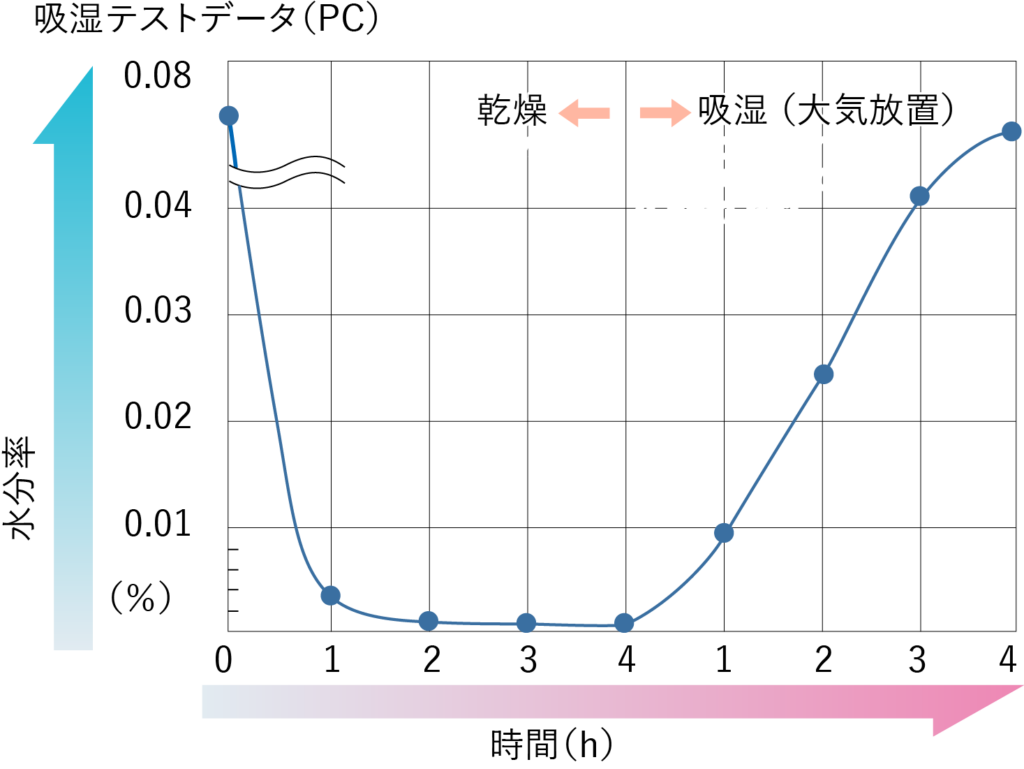

1. Batch transport reduces the risk of moisture absorption and ensures clean material supply

PLP uses a method of transporting small batches of 30g to 100g to the molding machine. Because only the required amount is transported each time, it is possible to supply materials with reduced risk of moisture absorption.

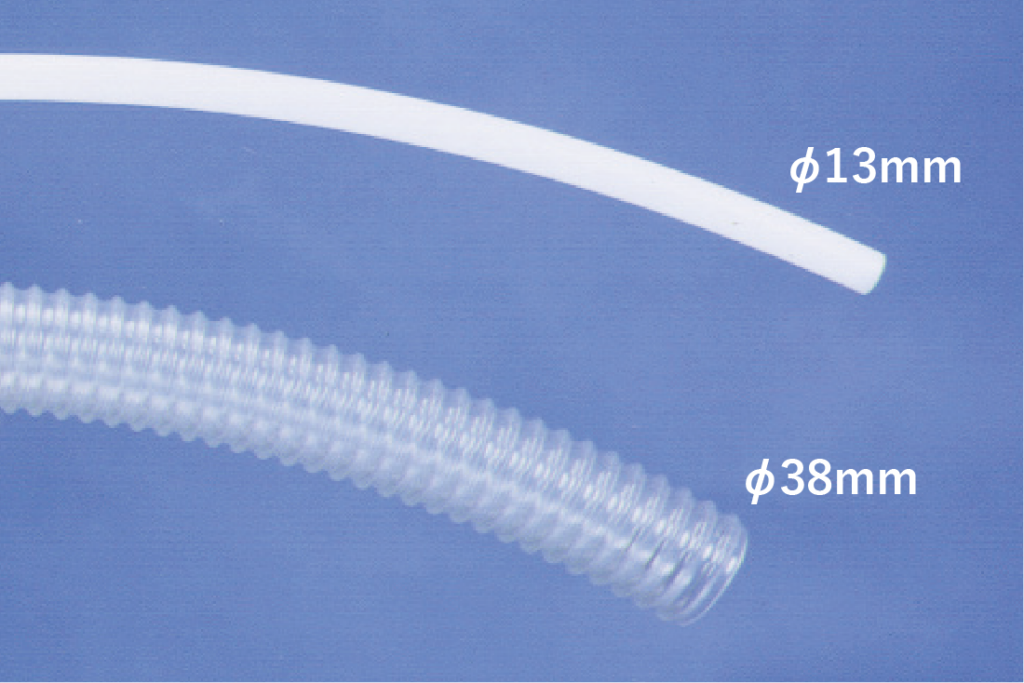

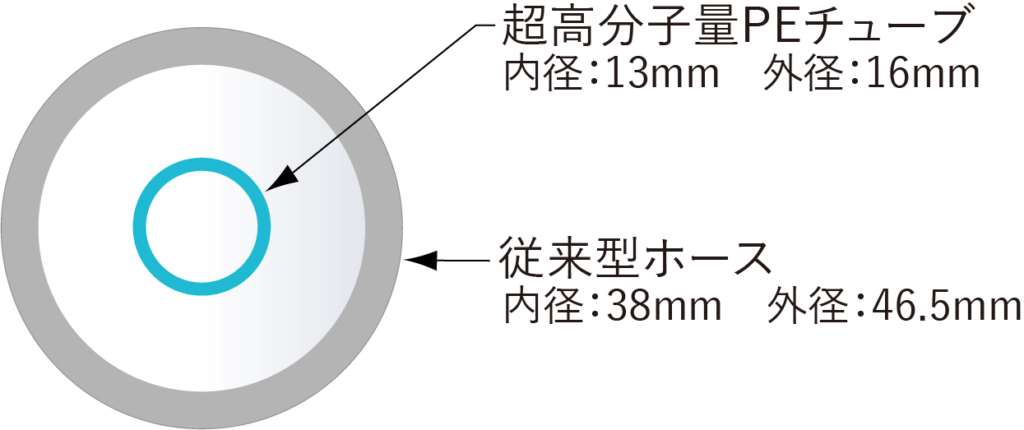

In addition, ultra-high molecular weight polyethylene tubing with excellent slip properties is used for the piping. By using dry-puff transport, materials are less likely to accumulate inside the tubing, which helps prevent mixing when switching materials and maintains stable transport conditions.

2. Compressed air transport using a small diameter tube with Inside diameter of 13 mm

The transport piping uses small-diameter tubing with Inside diameter of 13 mm. Because the pellets are pressure-fed using compressed air, piping is easy even in limited spaces, allowing for the creation of a highly maneuverable material transport system.

The pressure feeding method using small diameter piping makes it easy to stably control the transport volume, and is a suitable transport method for supplying a fixed quantity to the molding machine, making it compatible with a variety of molding lines.

Ingenuity to keep factory beautiful

Eliminating complicated piping and hoses is an effective way to improve the image of factory.

It is not easy to remove all the piping, but by transporting the pellets using thin tubes or small-diameter piping, it is possible to keep the area around the molding machine neat and tidy.