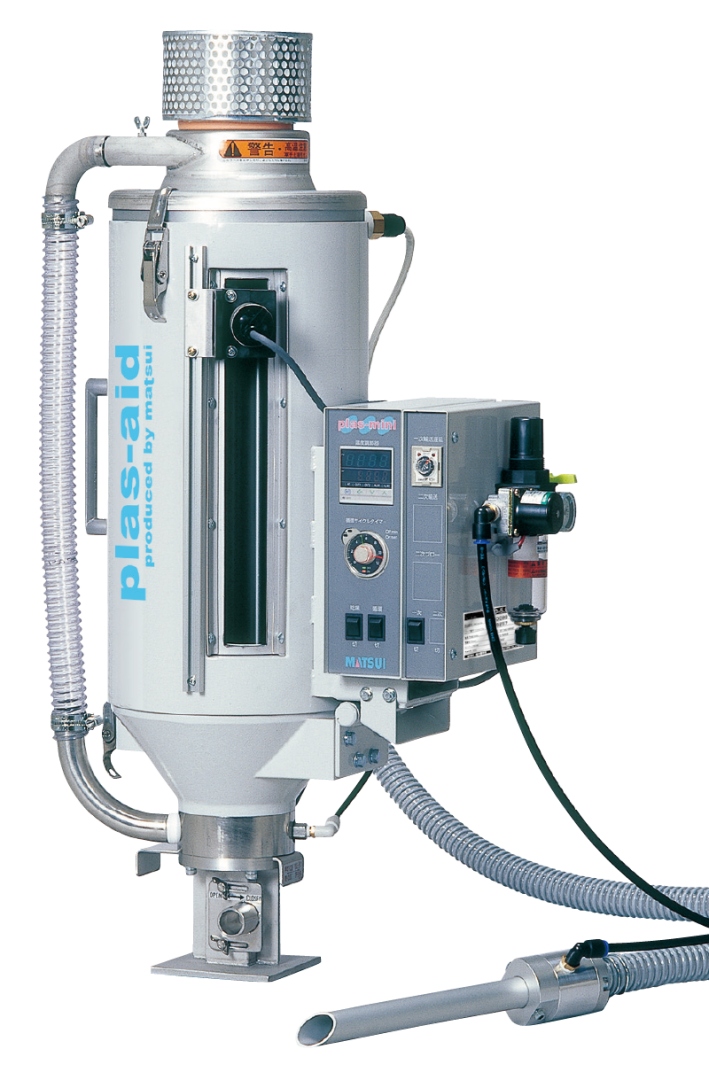

What is heat transfer drying?

Thermal Conduction Dryer is a drying method that applies the mechanism of "conduction and heat transfer," where a heated heat source directly contacts the resin and transfers heat. Because heat is applied without passing through the air, it is less affected by the humidity and temperature of the outside air, allowing for efficient drying with little heat loss. It can quickly evaporate the moisture in the resin, which also contributes to reducing running costs.

In addition, because the structure is simple and there are few moving parts, the entire dryer can be made compact, making it the drying method of choice for factory that prioritize long-term continuous operation and energy-saving operation.

Features

1. Clean and environmentally friendly low-exhaust structure

This small resin dryer uses a heat transfer drying method. It produces little exhaust during drying, and the double-structure hopper suppresses the diffusion of exhaust heat. It prevents heat buildup within factory, contributing to the creation of a clean and comfortable working environment in molding factory.

2. High energy-saving performance reduces running costs

The energy-saving design, which combines a heat transfer drying method with an air purge function, allows operation with approximately half the power consumption of a typical ventilation dryer. This significantly reduces the electricity cost for drying materials and reduces the running costs of the molding line.

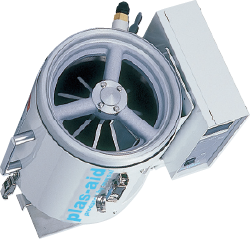

3. Excellent maintainability (foldable hopper and detachable fins)

The adoption of a retractable hopper makes it easy to clean the inside. The removable fins allow the material to slide easily, reducing the burden of material changes and cleaning work, and also shortening molding downtime (short stops).

4. Compact and lightweight design for excellent installation

Thanks to the space-saving design of the hopper with a built-in heater, Outer dimensions are W332 x D280 x H576 (741) mm and the weight is compact at 15 (20) kg.

*( ) indicates PMD-3.0

details

Nitrogen drying is available as an option.

By replacing the atmosphere in the hopper with nitrogen, deterioration due to resin oxidation is suppressed and material quality is stabilized. It is ideal for molding a wide variety of products in small lots (compatible with small molding machines: 1.5 kg to 3.0 kg loading).