Features

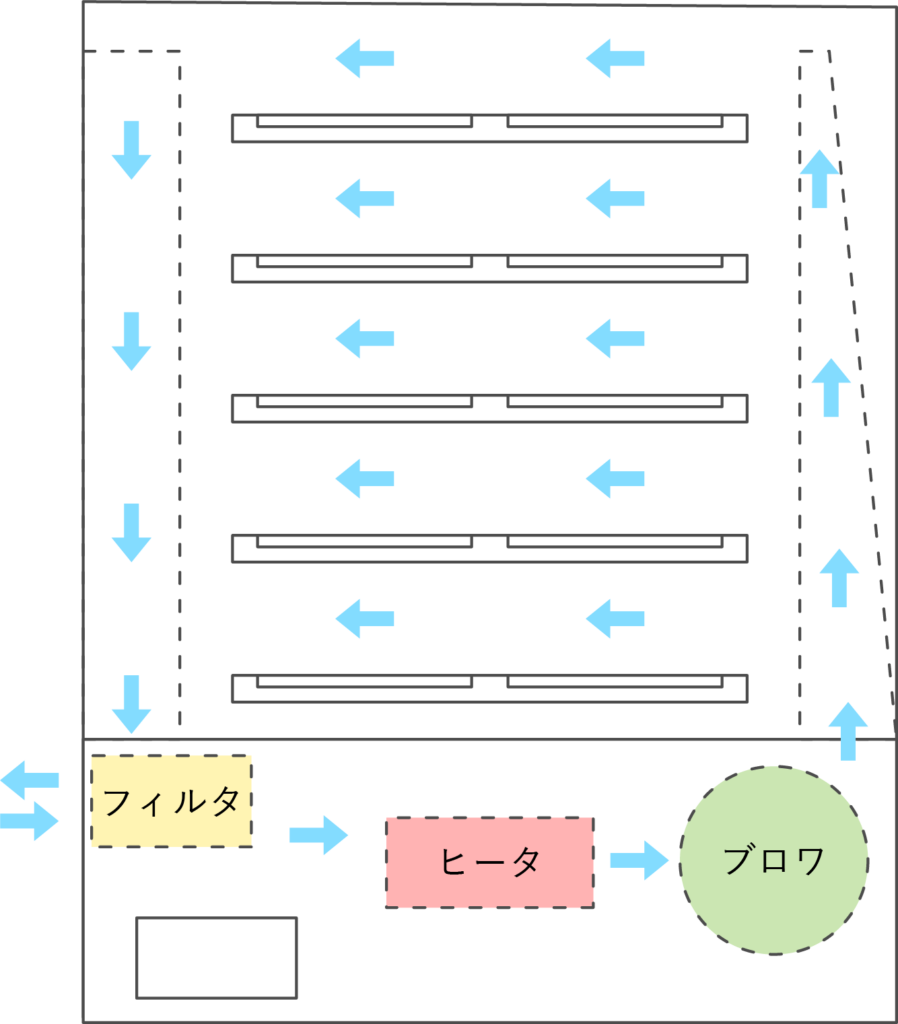

1. Hot air circulation method that achieves uniform temperature distribution

The horizontal hot air circulation structure heats the entire material container (pad) evenly. Furthermore, the use of PID control maintains the set temperature stably, enabling highly reproducible temperature control during drying and annealing processes.

This control method controls heater output based on the deviation between the set value and the current value, and maintains the set temperature stably with high accuracy.

2. Easy operation that anyone can use

Simple operation is achieved by simply setting the desired temperature on the temperature controller to start operation. Furthermore, by using the timer function in combination, you can set the start time as desired, allowing for efficient operation tailored to the task at hand.

3. Multiple safety devices ensure reliable protection Overheating and other abnormal conditions

A breaker with a shunt coil is included as standard, ensuring that the power supply is shut off in the event of an abnormality. Furthermore, a liquid expansion type Overheating protector is included as standard, safely stopping operation if the set temperature is exceeded. In addition, the heater switch contact welding detection function will shut off the power supply if an abnormality in the switch is detected, helping to prevent equipment problems before they occur.