Tech-LAB, a high-performance resin recycling lab, is fully equipped with high-performance pelletizers to recycle high-performance resins such as engineering plastics and super engineering plastics, as well as various measuring instruments, and is operated by specialized staff on-site. Through the recycling of our customers' valuable high-performance resins, we strongly support the improvement of production efficiency and contribution to the global environment.

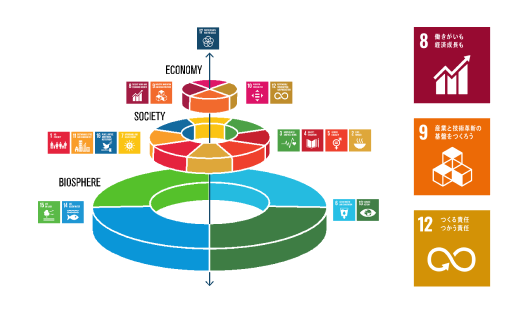

We were established with the aim of promoting activities that contribute to environmental protection by reducing waste and effectively reusing resources.

Our facility is fully equipped with a high-performance pelletizer that recycles high-performance resins such as engineering plastics and super engineering plastics, as well as various measuring instruments, and is run by specialized staff who are on-site at all times.

By recycling our customers' valuable high-performance resins, we strongly support their improvement in production efficiency and contribution to the global environment.

Repellet prototype contract

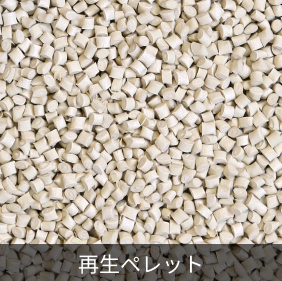

Repellet prototype contractWe will recreate an environment close to the normal operating conditions on your behalf and carry out re-pelletization measures. Please feel free to use this service as a trial before starting full-scale recycling of high-performance resins.

We have a proven track record in recycling a wide range of materials, including LCP, which has low viscosity and is difficult to recycle, expensive specialty resins that emphasize transparency and contamination-free properties, as well as elastomers and biodegradable resins.

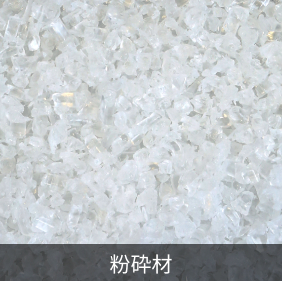

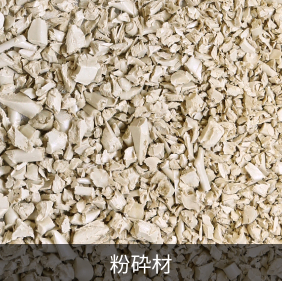

*The photo on the left shows Regrind material, and the photo on the right shows recycled pellets. Both are full-size.

Repellet test evaluation

Repellet test evaluationWe test the changes in physical properties of the prototype re-pellets and examine the resin from various angles.

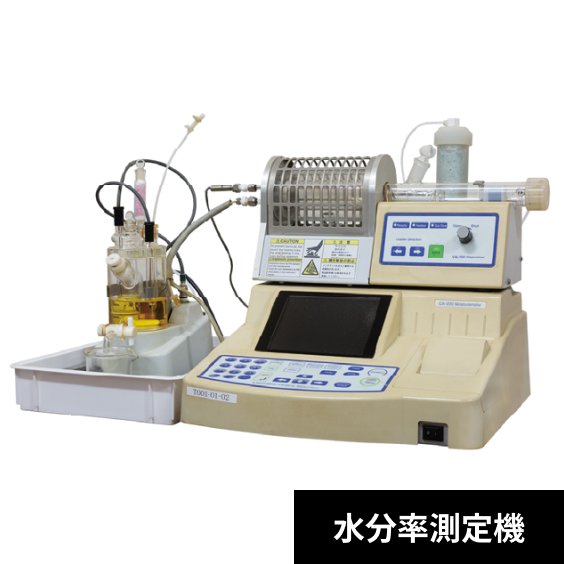

We test the drying and moisture absorption characteristics of resin. We measure Moisture content of virgin, Regrind material, and repelletized materials and test for changes in properties.

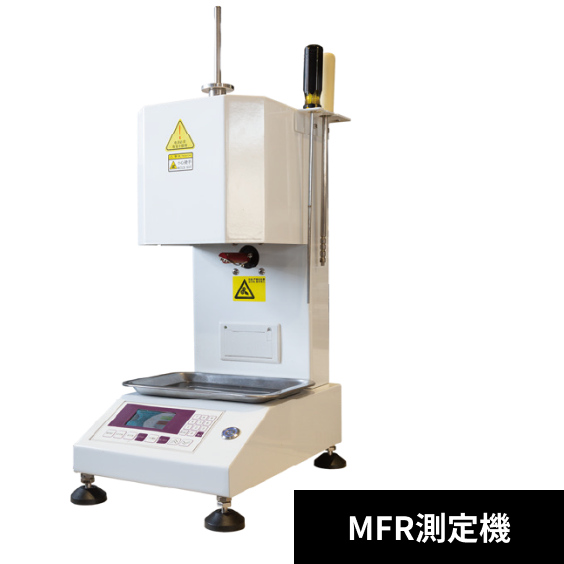

We analyze the fluidity of molten resin. We test virgin materials, Regrind material, repelletized materials, and mixed materials.

Test piece production A1, tests on dumbbell test pieces are carried out. Tests are carried out according to the request.

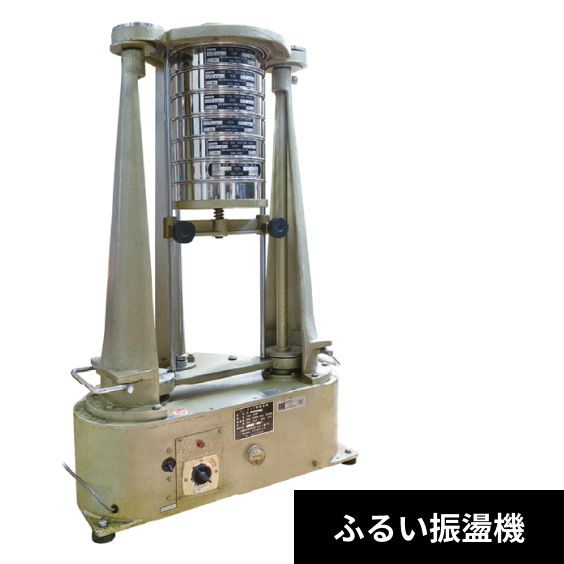

We perform powder ratio analysis using a sieve (to evaluate the wear on Granulators) and shape evaluation of Regrind material.

Test piece production A1, tests on dumbbell test pieces are carried out. Tests are carried out according to the request.

Based on the test results, we select Granulators that best suits your needs from our wide range of Granulators.