成形工場のfactor4を目指して

「消費資源CUT」消費資源のムダとは?

2022.01.05

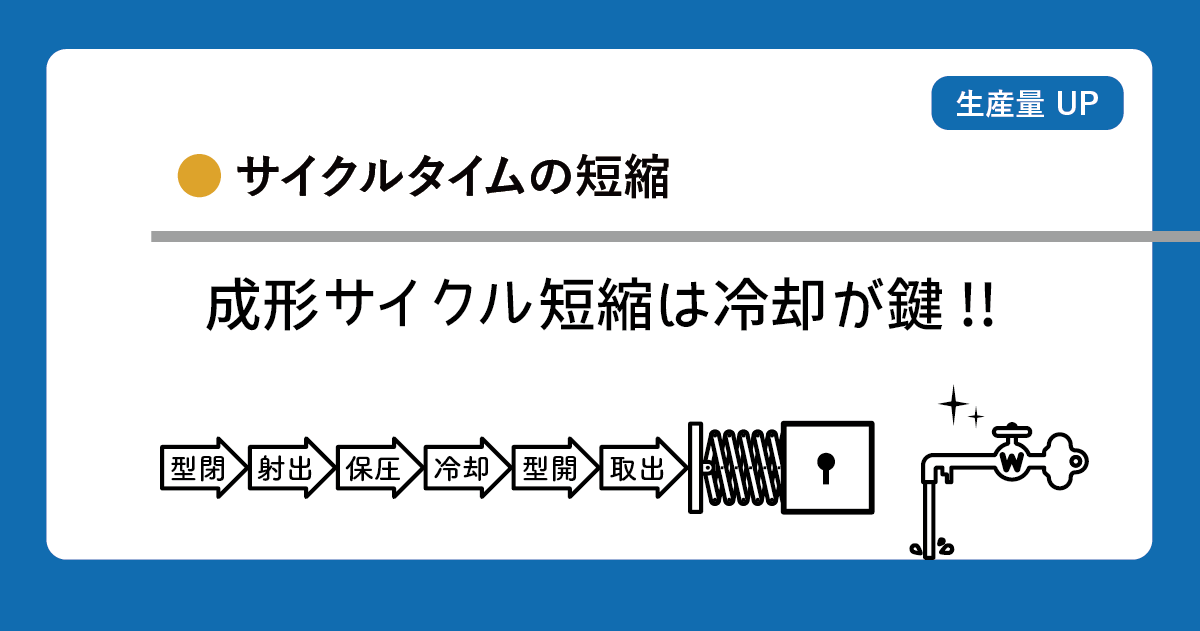

成形現場における資源には、成形に必要な樹脂原料の他に、機器を動かすための電気や、温度調節の用の水があげられます。また、見落しがちなものとして「時間」もその一つと言えるでしょう。

成形に必要な資源や時間は減らせませんので、ここで言う「消費資源CUT」とは、樹脂原料や水、エネルギー、時間を効率的に使い、ムダを削減していく事を意味します。

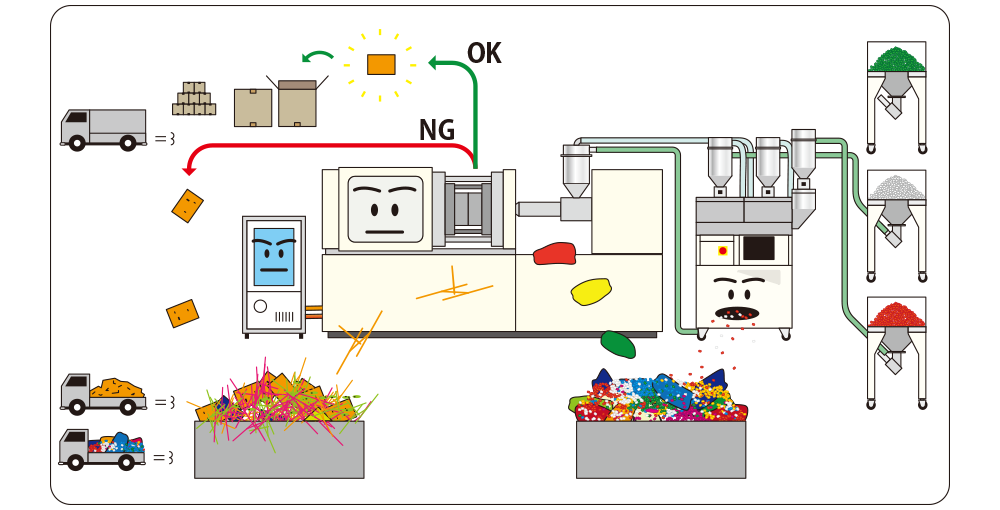

樹脂原料のムダにはどのようなものがあるでしょうか。

工場内を見渡してみますと、成形不良品の山、材料替えの度に発生する混ぜ残り材や、パージによる樹脂ダンゴ、成形ショット毎に発生するランナーも見方によってはムダと言えるでしょう。こうして出た樹脂は殆どの場合、廃棄されています。

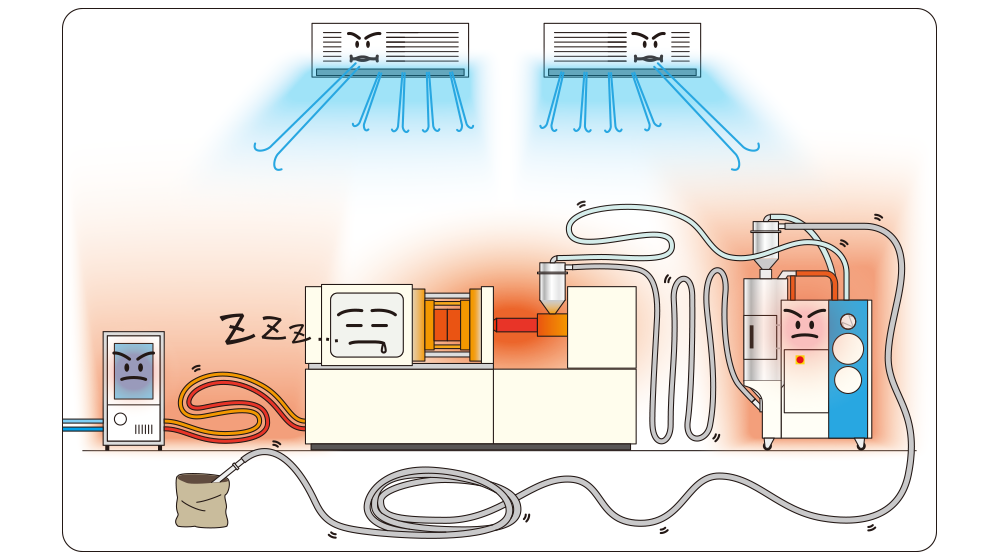

水やエネルギーについてはどうでしょう。

成形工場の現場は暑いですね。特に夏場は大変です。 これは成形機や乾燥機、材料輸送ライン、金型温度調節機など、あらゆる装置からの放熱によるものですが、稼働させるためのエネルギーのその多くが熱となってしまっているのです。更に、暑くなった工場内を冷やすために、空調でも相当量のエネルギーを使っています。

似たようなエネルギーのムダは、成形機や周辺装置でも見られます。

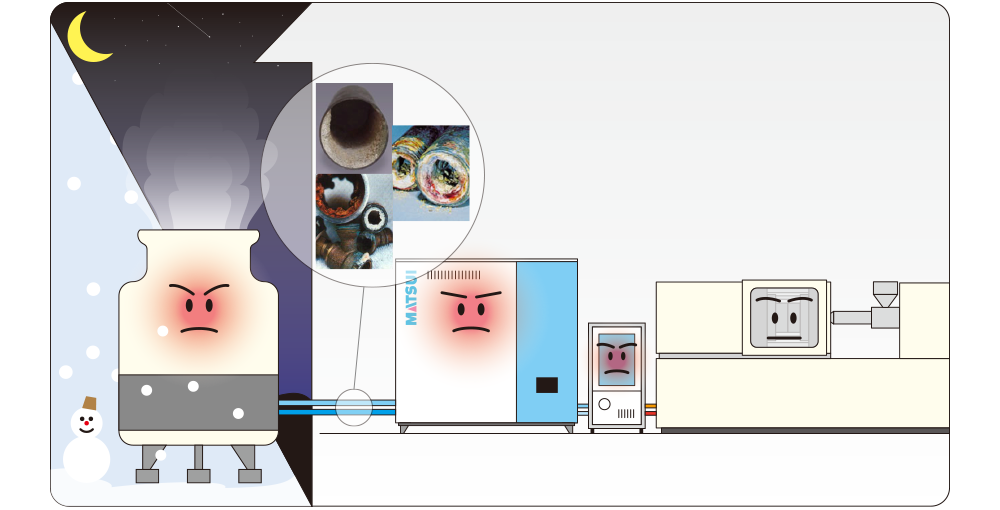

成形工場では、機器や金型の温度調節に用いられる工場循環水を供給するためにクーリングタワーを設置されているかと思います。よく見られる開放型のクーリングタワーでは、モクモクと毎日大量の水が蒸発しています。これは単に水のムダというだけでなく、水分だけが蒸発する事で不純物が濃縮され、配管や装置内にスケールとして付着、冷却効率の低下や装置の故障を引き起こす原因にもなっています。

また、チラーをお使いの工場も多いのではないでしょうか。クーリングタワーから供給される水の温度に関係なくチラーは稼働し続け、複数の金型に冷却水を供給する都合から、一部の金型では手前に金型温度調節機をおき、温めて使っているという場合も少なくありません。エネルギーを使って冷やして、その先ではまたエネルギーを使って温めるといいうムダが見られます。

成形不良により作り直しとなった場合は、時間もエネルギーも必要以上の浪費となりますし、先の水管詰まりによる冷却効率の低下から冷却時間を長く設定せざる終えなくなったり、装置レイアウトやオペレーション的な要因から段取りに時間がかかったりと、目に見えない部分で時間が消えていっています。

一見しようがないと思われるムダも、見方や考え方、適切な対処方法を知る事で、消費資源を必要最小限に抑えられるようになるはずです。

それぞれ改善点として考えられるポイントを上げていってみます。

まず、樹脂のムダを削減するために取り組みたい内容としては、なんと言っても不良を無くす事が一番なわけですが、それは他の全てに関わってくる事なので、ここでは一旦横に置いておくとして、

樹脂のムダを削減するには、

- 廃棄しているスプルーやランナーをリサイクルする

- 混ぜ残り量がなるべく少なくなるようにする

- 材料替えを効率よくおこなう(少ない量で材料が置き換わるように)

水やエネルギー関連のムダを削減するには、

- 循環水を冷却後に昇温して使用しているような所がないかラインを見直す

- 冷却水管や、エアー、材料輸送ラインを見直す(機器のレイアウトや適切な長さかなど)

- スケールなどで詰まり始めている水管経路をクリーニングし、初期状態に戻す・維持する

- 開放式クーリングタワーから密閉循環式クーリングタワーにする事を検討してみる

- 装置からの放熱を抑える、熱の再利用を考える

- 必要以上に稼働し続けている装置がないか見直す

- 複数の装置で実現している機能を1台にまとめた機種がないか探してみる

などが考えられるかと思います。

後のテーマ別ソリューションコラムの中で、具体的な方法やアイテムをご紹介いたします。

グローバルソリューション推進部 飯島 泰彦