Aiming for factor4 of molding factories

Achieving stable production through water quality control of cooling towers and cooling water.

2023.02.08

Have you ever experienced a situation in your factory where, over months or years of production, molding defects such as sink marks or warping begin to occur? And as a result of changing the molding conditions to ensure acceptable parts, you found that your cycle times had become longer?

These issues may be occurring because cooling efficiency has dropped due to the deterioration of the cooling water quality. Furthermore, continuing to use cooling water with degraded quality carries the risk of leading to equipment failure. For these reasons, the management of cooling towers and water quality is an indispensable initiative for achieving continuous and stable production.

In this article, we will specifically introduce the mechanism of molding defects and issues, and how to manage water quality, from improving water quality to maintaining water quality.

Issues caused by deterioration of cooling water quality and their causes

The role of factory water in molding includes cooling and temperature control of molding machines and molds, and cooling of other equipment. Water is indispensable for cooling and temperature control in a molding factory, but if the quality of the cooling water deteriorates, it will lead to problems such as molding defects and equipment failure.

Molding defects here mainly refer to phenomena such as sink marks and warpage that deform the molded product after molding. Good products were obtained under the conditions when molding was started, but deformation defects increased with the passage of time. In the situation where adjusting the molding conditions to obtain good products = lengthening the cooling time, it is highly likely that the cooling efficiency has decreased.

So why does the cooling efficiency drop that causes these issues?

Why does the cooling efficiency decrease?

Deterioration of cooling water quality does not immediately lead to a decrease in cooling efficiency. Deterioration of cooling water quality is actually caused by the concentration of various components such as silicic acid (silica/lime), calcium, and magnesium in the water over time. As a result of forming a film, the heat exchange efficiency with the temperature controlled object decreases = the cooling efficiency decreases.

Since this symptom progresses gradually, it takes time to become visible, such as a decrease in productivity due to molding defects or changes in molding conditions, and it is overlooked because sudden changes do not occur. , is an issue that tends to be postponed for fundamental measures.

Another question may have arisen here. I wrote that the deposition of scale is caused by the concentration of components in the water, but in the next chapter, I will explain why the components are concentrated and the mechanism behind this.

Why does the concentration of minerals in cooling water?

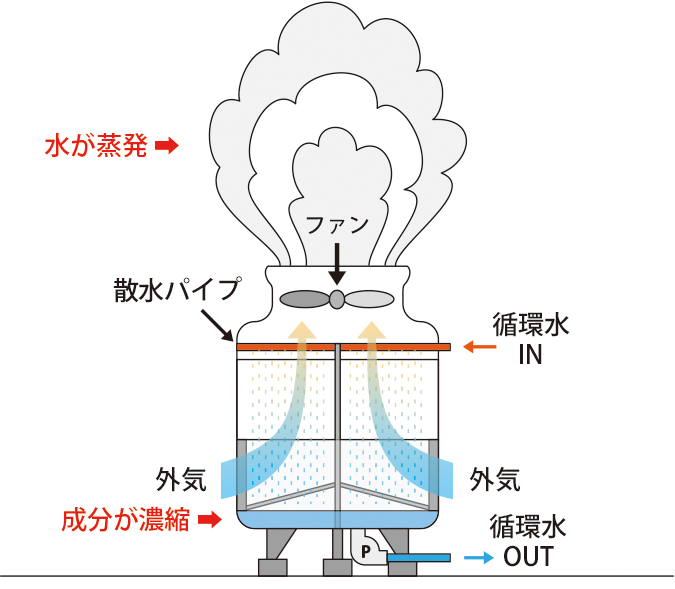

Cooling towers used to supply industrial cooling water are typically what we call "open-circuit cooling towers." These are widely adopted in many factories because they are cost-effective and space-saving. If you work in a factory, you have likely seen these cooling towers installed on the grounds or atop buildings at least once. Did you notice white plumes of "smoke" rising steadily from the top?

In an open-circuit cooling tower, the circulating water is sprayed inside the tower, and a fan blows outside air directly onto the water. Cooling is achieved by evaporating a portion of this water; therefore, that "white smoke" was actually evaporated water vapor. Since only the water evaporates, the minerals and components contained within the water remain inside the cooling tower. While fresh water is added to replenish what was lost through evaporation, this cycle causes the concentration of components to gradually increase. Furthermore, suspended dust, plant spores, and other particles from the outside air also enter the system, leading to further deterioration of the water quality.

In addition, there is another issue: metal parts exposed to the outside air are highly susceptible to rust. As the cooling water comes into contact with these rusted areas, it carries oxidation particles to other equipment along the same circulation path. This leads to "induced corrosion" (secondary rusting) and, if left unaddressed, can have a detrimental impact on various other components throughout the system.

Given the points discussed so far, it is easy to imagine that waiting until troubles caused by water quality deterioration become visible is already too late. Therefore, to ensure continuous and stable production, proactive water quality management is absolutely essential. It is crucial to maintain the system's initial, optimal condition and prevent the cooling water from degrading in the first place.

Specific methods for improving and maintaining water quality

To improve and maintain water quality, the following primary measures are commonly implemented:

- Adjusting the quality of cooling water

- Removing concentrated components in cooling water

- Cleaning water pipes with precipitation hardening of scale

- Preventing deterioration of water quality from the source

We would like to introduce the specific items that will help you implement each of these measures.

Adjusting the quality of cooling water

Cooling water conditioner "CALFA BAS" prevents scale from depositing inside pipes by aggregating and removing scale in water (*).

Since all components are made entirely from inorganic materials, no post-treatment is required, and the water can be drained as-is without any negative impact on the environment. Its safety and functionality meet all relevant EU standards. Furthermore, it forms a protective anti-corrosion film on metal surfaces, ensuring a powerful and reliable rust-prevention effect.

*CALFA BAS is designed to facilitate the flocculation of scale within the water; therefore, it must be used in conjunction with a filter to physically remove these particles. Please note that during the initial stage of implementation, a significant amount of flocculated sediment will be generated, requiring frequent filter cleaning.

On the other hand, to combat the formation of red rust, we offer "SAVVYLAINE", a solution designed to suppress the development of iron oxide. Red rust occurs when the iron in the piping ionizes, dissolves into the water, and oxidizes upon contact with oxygen. "SAVVYLAINE" prevents red rust by releasing specific metal ions that inhibit the ionization of the iron itself.

Both items can be easily installed by simply placing them in the water tank on the cooling water path or in the tank inside the chiller, so you can easily try them out.

Removing concentrated components in cooling water

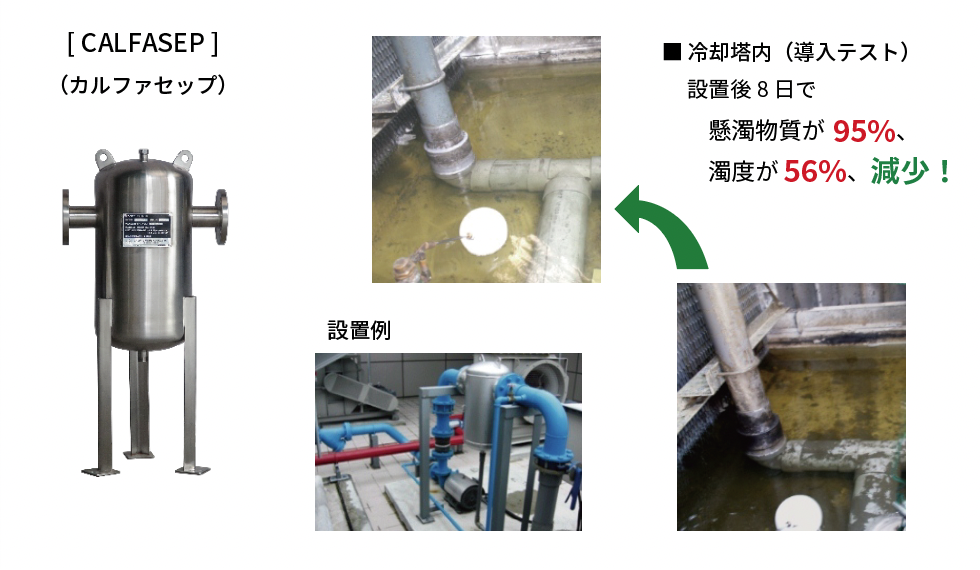

Installing a filter is the basic way to remove suspended solids and concentrated components in water, but the most recommended one is the filterless filter "CALFA SEP”. The RINGS high-speed separation method, which uses the world's first specially shaped ring (patented), separates and removes any component that is heavier than water (specific gravity of 1.0 or more).

Other features include the ability to separate ultra-fine impurities up to 7 microns with almost no pressure loss, no maintenance such as cartridge replacement or cleaning, and regular discharge of impurities accumulated under the tank. It can be used for a long time just by doing it.

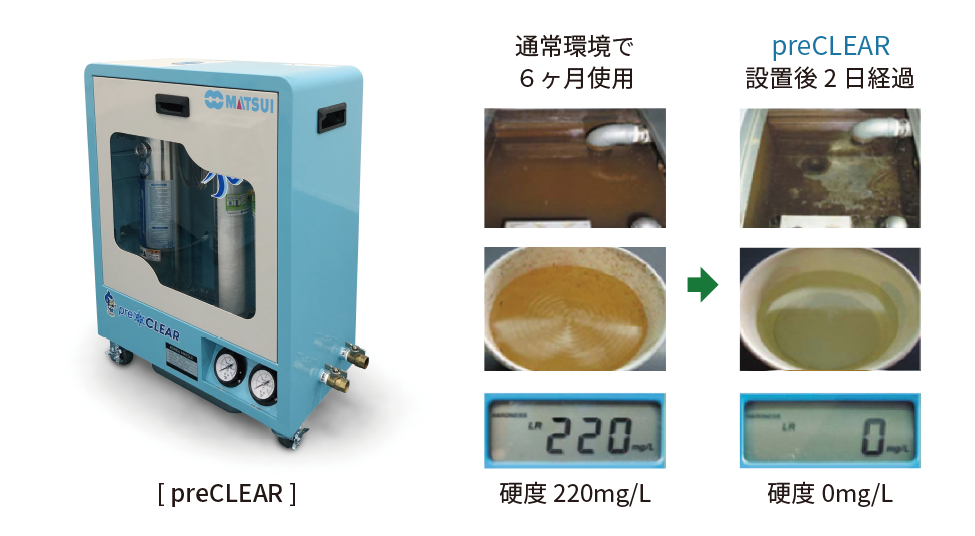

nother highly recommended solution ispreCLEARan ion-exchange water softening system equipped with integrated filtration. This system achieves both the recovery of concentrated components and the improvement of water quality simultaneously. By simply installing it into your existing circulation line, it not only removes suspended solids and rust from the water but also softens the water through ion exchange, effectively eliminating the calcium and magnesium that cause scale. While the primary filters and the ion-exchange filter require periodic replacement, the system operates without a power source and requires no salt or chemicals.

Cleaning water pipes with precipitation hardening of scale

You may find that by the time you realize the need for water quality improvement and management, scale and rust have already formed within your equipment's cooling water pathways. In such cases, our low-pressure composite water flow cleaning system,Water Way" cleans the internal piping of your equipment using physical actions such as cavitation and erosion. Since it uses only water and air—without any chemicals—it is environmentally friendly. After cleaning, the water can be drained directly into the factory's drainage system without requiring any special treatment (*).

*The scales and rust peeled off by washing are collected by the filter.

By regularly cleaning the water pipes of equipment such as molds and heat exchangers, you can maintain the initial state without clogging. It is also possible to automate cleaning and integrate equipment, which is useful for preventive maintenance.

Preventing deterioration of water quality from the source

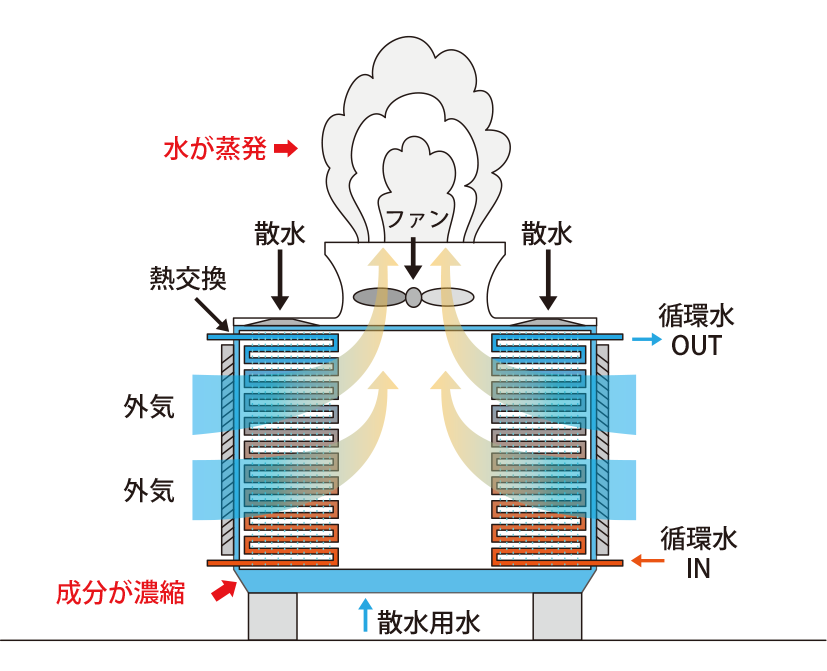

As previously mentioned, the concentration of minerals in cooling water occurs because only the water evaporates. Therefore, to prevent water quality deterioration at its source, it is necessary to reconsider the cooling method of the cooling tower itself. To address this, we introduced the "closed-circuit cooling tower." It is designed based on the same principles as the chiller mechanism introduced in the previous chapter, circulating the cooling water through a closed-loop system.

With this method, the circulating cooling water does not evaporate, so the initial water quality is maintained for a long period of time. However, this enclosed cooling tower also has its weaknesses. The cooling water used in the factory circulates in a closed circuit, but a separate system of water is used to cool the heat exchanger. As the water evaporates here, the components are concentrated, so scales and sludge-like substances such as plant spores adhere to the outside of the heat exchanger, reducing heat exchange efficiency. Corrosion progresses, causing pinholes and cracks in the heat exchanger.

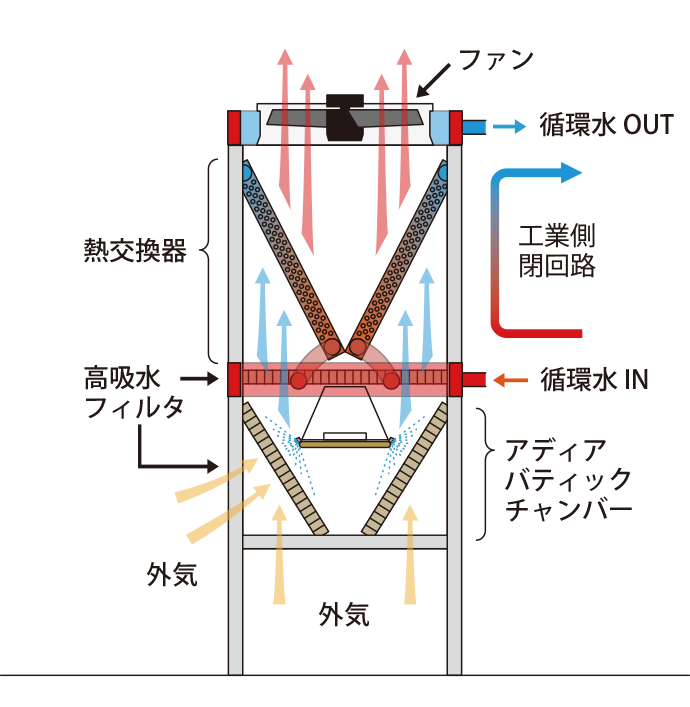

Therefore, we recommend Air Cooled Closed Type Water Cooling System" ecobrid". This Next-generation type cooling tower not only solves these problems of water evaporation → component concentration → reduced cooling efficiency → equipment failure/damage, but also enables significant water and electricity savings.

The ecobrid cools the circulating water by passing outside air through a heat exchanger. When the outside temperature is low, the temperature will drop as it is. When the temperature rises and the outside air alone is not sufficient to cool the room, the upper fan is turned on to force the air to cool down. If the temperature rises further, tap water is sprayed on the high water absorption filter installed in the outside air passage to cool the cooling air and lower the temperature. Thanks to this mechanism, the device itself can be used for a long period of time with regular inspections and simple maintenance.

As an aside, I think it's easier to understand if you imagine this Air Cooled Closed Type Water Cooling System, a car radiator. If the temperature rises too much, the fan will rotate, and if you drive at high speed on a rainy day, rainwater will be splashed, but as you rarely need to maintain or replace the radiator, this "ecobrid" has a very long life. To do.

Compared to open and closed type cooling towers, the water saving rate is about 95% and the power saving rate is about 25%, achieving significant energy and resource savings. Furthermore, in terms of service life, compared to the 7-year design of typical cooling towers, ecobrid is designed to last 20 years, which is significantly longer. You could call it a device.

Summary

The deterioration of the cooling tower and cooling water quality progresses gradually, and it takes time for defects such as molding defects and equipment failures to appear in tangible form, making it one of the problems that are difficult to recognize. However, if water pipe clogging or equipment failure occurs, it will take time, effort, and money to recover, resulting in a significant drop in productivity.

In order to achieve long-term stable production, it is important to manage the quality of cooling water on a daily basis. Matsui proposes various solutions to improve and maintain water quality. Please feel free to contact us.