成形工場のfactor4を目指して

冷却塔・冷却水の水質管理により安定生産を実現

2023.02.08

皆様の工場では、成形品を生産していく中で、月日が経つにつれてヒケや反りといった成形不良が発生するようになり、良品が取れるよう成形条件を変更した結果、サイクルタイムが長くなってしまった、という経験はないでしょうか。

これらは冷却水の水質悪化により、冷却効率が落ちたために発生している可能性があります。また水質が悪化した冷却水を使用し続けることで、設備の故障にもつながってしまう恐れがあります。そのため、冷却塔・冷却水の水質管理は、継続的な安定生産には欠かせない取り組みとなります。

この記事では、成形不良やトラブルが発生するメカニズムと、水質改善から水質維持まで、水質の管理方法についてそれぞれ具体的にご紹介します。

冷却水の水質悪化がもたらすトラブルとその原因

成形における工場用水の役割には、成形機や金型の冷却・温調、その他設備の冷却があります。成形工場にとって水は、冷却・温調のためになくてはならないものですが、その冷却水の水質の悪化が進むと、成形不良や機器の故障といったトラブルにつながってしまいます。

ここでいう成形不良とは、主にヒケや反りなど、成形後に成形品が変形してしまう現象を指しています。成形をスタートした時の条件では良品が取れていたものが、時間の経過とともに変形不良が増えてくる。良品を取るために成形条件を調整する = 冷却時間を長くする、という状況の場合、冷却効率が落ちている可能性が高いと考えられます。

ではなぜ、これらのトラブルを招く冷却効率の低下が発生してしまうのでしょう。

なぜ冷却効率の低下がおこるのか?

冷却水の水質の悪化が、即、冷却効率の低下につながるわけではありません。冷却水の水質悪化とは、実は水分中のケイ酸(シリカ/石灰)、カルシウム、マグネシウムといった様々な成分が月日の経過と共に濃縮される事で、これらの成分が配管内壁に析出硬化し、膜を形成した結果、温調対象物との熱交換効率が下がる = 冷却効率が下がってしまう、というわけです。

この症状は徐々に進行するために、成形不良や成形条件変更による生産性の低下など、目に見える形になって気付かれるまでには時間がかかる事と、急な変化がおきないため見過ごされ、根本的な対処が後回しになりがちな課題となっています。

ここでもう一つ、疑問が湧いてきたのではないでしょうか。スケールの析出は水分中の成分の濃縮が原因だと書いていますが、ではなぜ成分の濃縮がおきるのか、次の章ではこのメカニズムについてご説明します。

なぜ水分中の成分の濃縮がおこるのか?

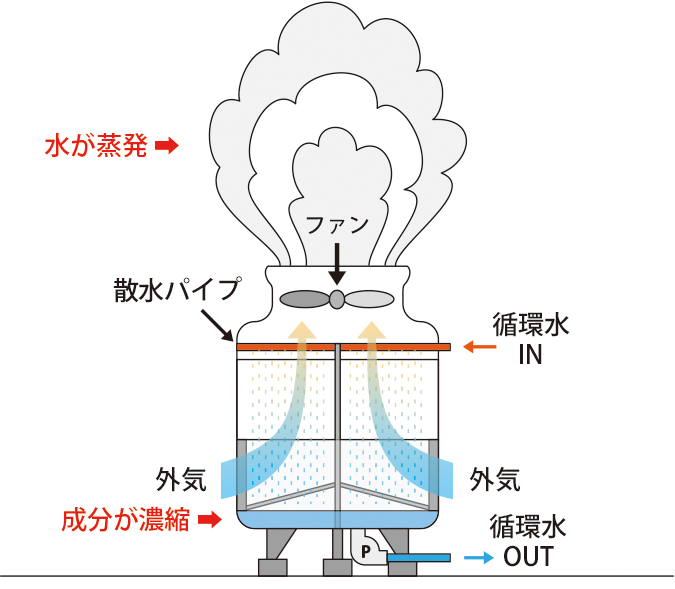

工場用の冷却水をまかなう用途で使用されている冷却塔は、開放式クーリングタワーと呼ばれるもので、コストも安く、省スペースで済むため多くの工場で採用されています。工場に勤務されている皆様なら、敷地や建物の上に設置されているクーリングタワーを、一度は目にした事があるのではないでしょうか。その上部からは白い煙がモクモクと上がっていませんでしたか?

開放式クーリングタワーでは、循環水をタワー内で散布し、ファンを使い直接その水に外気を当てて、一部の水を蒸発させる事で冷却しているため、あの白い煙は、実は蒸発した水分だったのです。蒸発するのは水分のみですので、水分中に含まれている成分はクーリングタワー内に残ってしまいます。蒸発で失った水分を補うため、新たに水を投入しますが、このサイクルにより、成分は徐々に濃縮されてゆきます。さらに外気に含まれる浮遊粉塵や植物の胞子なども混入するため、一層水質が悪化してしまうのです。

また、別の問題として、外気に晒されている部位の金属に錆が発生し易く、そこに触れる冷却水が、同じ経路にある他の機器へも錆を運んでしまうため、もらい錆の誘発につながりますし、放置しておくと様々な機器へ悪影響を及ぼしてしまいます。

ここまでの内容をご理解いただければ、水質悪化によるトラブルが目に見える形で現れてしまってからでは遅い!という事は容易に想像がつくのではないでしょうか。ですから、安定生産を継続するには、前もって冷却水の水質が悪化しないよう、初期状態を維持するための水質管理が必要不可欠と言えるでしょう。

具体的な水質の改善・維持手法

水質を改善・維持するためには主に以下のような施策があります。

- 冷却水の水質を整える

- 冷却水に含まれる濃縮成分を取り除く

- スケールが析出硬化した水管を洗浄する

- 大元から水質悪化を発生させない

それぞれの内容を実現するアイテムをご紹介します。

冷却水の水質を整える

冷却水コンディショナー「CALFA BAS(カルファバス)」は、水分中のスケールを凝集して取り除く(※)ことで、配管内へのスケール析出を予防します。

成分はすべて無機質から作られているため、後処理を必要とせず、そのまま排水に流しても環境に悪影響を与えることはありません。安全性・機能性はEU基準をクリアしています。また、金属表面に防錆皮膜を作るので、強い防錆効果も期待できます。

※CALFA BAS単体では、水分中のスケールを凝集させるところまでなので、これを取り除くためのフィルターを併用する必要があります。また、導入初期は多くの凝集物が出るので、フィルターをこまめに清掃する必要があります。

一方、赤錆の発生に対しては、酸化鉄の発生を抑える「サビレーヌ」をご用意しています。赤錆は、配管に含まれる鉄がイオン化して水に溶け出し、酸素に触れて酸化する事により発生します。「サビレーヌ」は、金属イオンを溶出させて、鉄のイオン化を抑制する事で赤錆の発生を防ぎます。

どちらのアイテムも、冷却水経路にある水槽やチラー内のタンクに入れるだけの簡単設置で、お気軽にお試しいただけます。

冷却水に含まれる濃縮成分を取り除く

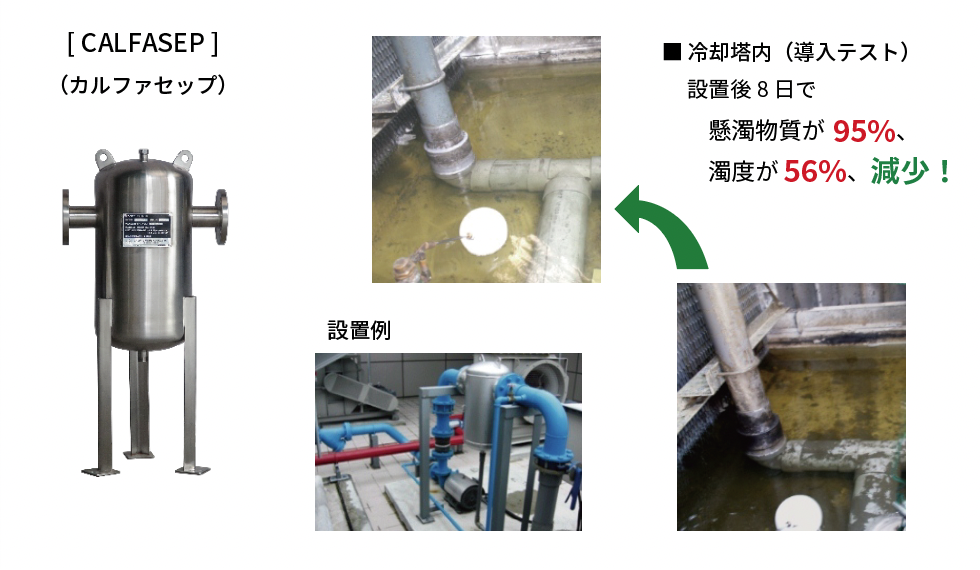

水分中の浮遊物や濃縮された成分を取り除くには、フィルターの設置が基本ですが、中でもお勧めなのが、冷却水経路の一部をバイパス接続して使用する、フィルタレスフィルター「CALFA SEP(カルファセップ)」です。世界初の特殊形状リング(特許取得済)を使用した「RINGS高速分離法」により、水よりも重い成分(比重 1.0以上)であれば、どのようなものでも分離、除去します。

その他の特長としては、圧力損失をほとんど発生させる事なく、7ミクロンまでの超微粒不純物までを分離可能、カートリッジの交換、洗浄などのメンテナンスは一切不要、タンク下に溜まった不純物を定期的に排出するだけで長期間に渡りに使用可能、などがあげられます。

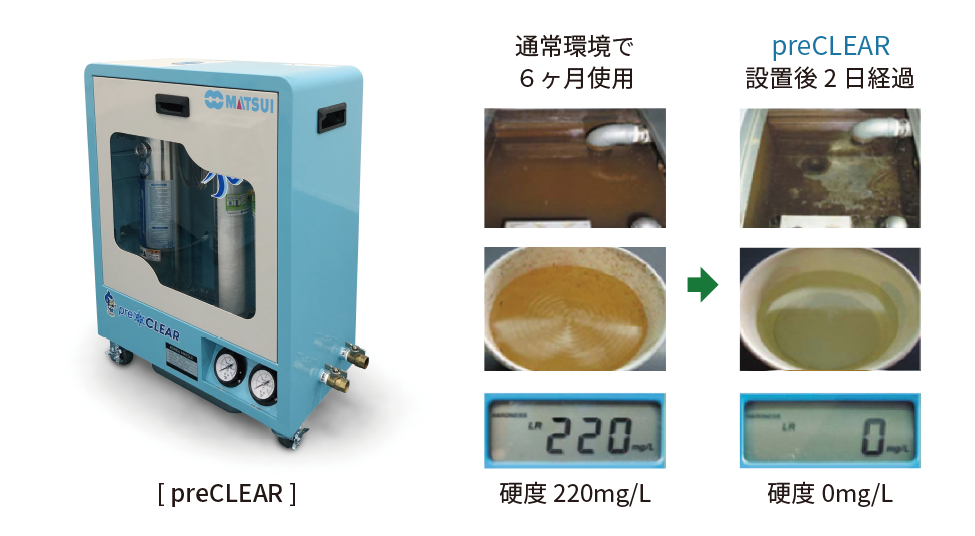

もう一つ、お勧めなのは、濃縮成分の回収と水質改善を同時に実現できる、フィルタ付きイオン交換方式軟水化装置「preCLEAR(プリクリア)」です。既存の循環系ラインに設置するだけで、水中の浮遊物や錆を取り除くだけでなく、イオン交換により軟水化し、スケールの原因となるカルシウムやマグネシウムまでも取り除きます。大小のフィルターとイオン交換フィルターは定期的に交換が必要ですが、電源不要で、塩や化学薬品も使用しません。

スケールが析出硬化した水管を洗浄する

水質の改善や管理の必要性を認識した時点で、既に装置の冷却水経路にスケールや錆が発生してしまっている!という事もあるかと思います。低圧複合水流洗浄装置「Water Way(ウォーターウェイ)」は、キャビテーションやエロージョン(侵食)といった物理的な作用によって装置の水管経路洗浄します。使用するのは水と空気だけ、化学薬品などは一切使用しないので、環境にもやさしく、洗浄後は、特別な処理を必要とせず、そのまま工場の排水に流せます(※)。

※洗浄により剥がれ落ちたスケールやサビはフィルターにより捕集されます。

金型や熱交換器など装置の水管を定期的に洗浄することで、詰まりのない初期状態を維持できます。また、洗浄の自動化や設備の一体化も可能ですので、予防保全に役立ちます。

大元から水質悪化を発生させない

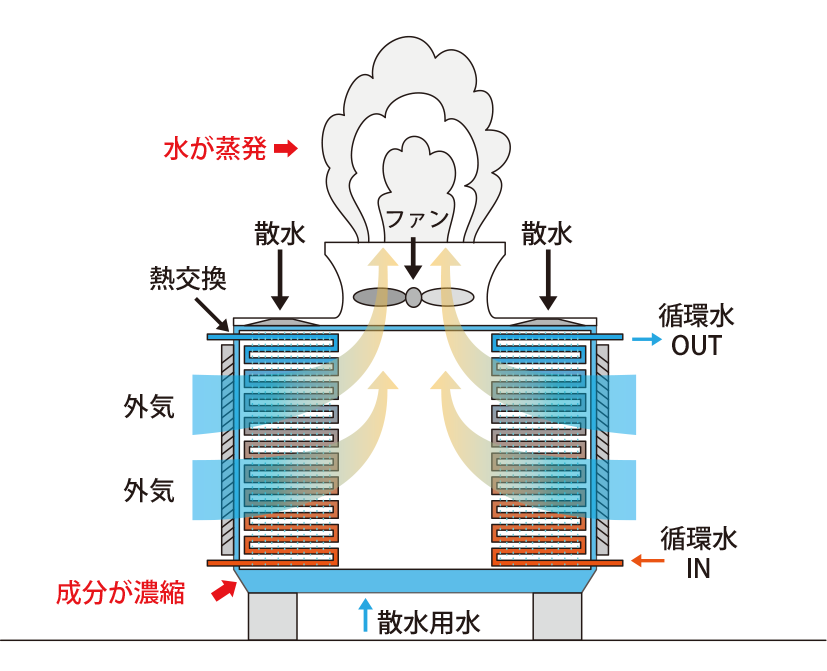

先にお伝えしました通り、冷却水の水分中の成分が濃縮してしまうのは、水分だけが蒸発してしまうためですので、この大元から水質悪化を防ぐには、冷却塔自体の冷却方式を見直す必要があります。そこで登場したのが、前の章でご紹介したチラーの仕組みと同じ考え方で作られた、閉回路で冷却水を循環させる密閉式クーリングタワーです。

この方式であれば、循環している冷却水は蒸発しませんので、初期の水質が長期間維持されます。しかし、この密閉式クーリングタワーにも弱点があります。工場内で使用される冷却水は閉回路で循環していますが、循環している水の冷却に、別系統の水を使用して熱交換器を冷却しているのです。ここでの水分の蒸発により成分濃縮がおきるため、熱交換器の外側にではありますが、スケールや、植物の胞子などによるヘドロ状の物質が付着し、熱交換効率が落ちますし、そのまま放置すると腐食が進行し、熱交換器にピンホールが開いたり、クラックが発生してしまいます。

そこで弊社がお勧めするのが、空冷密閉式水冷却システム「ecobrid(エコブリッド)」です。この次世代型クーリングタワーであれば、これらの、水分蒸発 → 成分濃縮 → 冷却効率低下 → 機器の故障・破損といった問題を解決するだけでなく、大幅な節水と節電が可能となります。

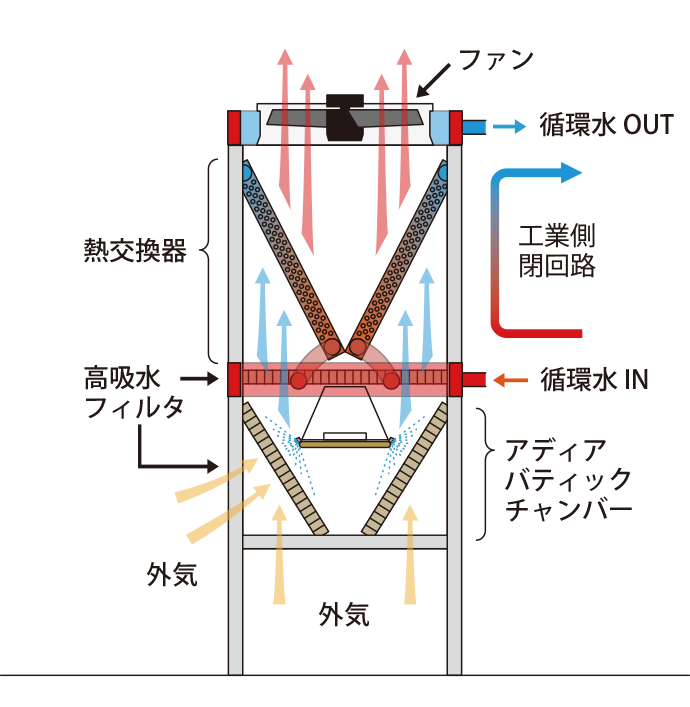

「ecobrid」は、外気を熱交換機に通過させることで、循環水を冷却します。外気温が低いときはそのままで温度が下がります。気温が上がり、外気だけでは十分に冷却できなくなると、上部のファンを回して、強制的に空気を通して温度を下げます。さらに気温が高くなった場合は、外気の通り道に設置された高吸水フィルタに水道水を噴霧し、冷却用の空気を冷やして温度を下げます。このような機構のおかげで、この装置自体も定期的な点検と、簡単なメンテナンスを施すだけで長期間ご使用いただけます。

余談ですが、この空冷密閉式水冷却システム、自動車のラジエーターをイメージしていただくと、わかりやすいかと思います。温度が上がり過ぎるとファンが回り、雨の日に高速走行すれば、雨水はかかりますが、ラジエーターの手入れや、交換する必要に迫られる機会が滅多に無いように、この「ecobrid」はとても長持ちします。

節水と省エネ効果については、開放型、及び密閉型のクーリングタワーと比較して、節水率がおよそ95%、節電率はおよそ25%と大幅な省エネ・省資源を実現します。さらに耐用年数で見ますと、一般的な冷却塔の 7年設計に対し「ecobrid」は20年設計と、大幅に長く設定されていますので、SDGs 的な観点から見ても、環境配慮型の装置と言えるでしょう。

まとめ

冷却塔や冷却水の水質の悪化は徐々に進行し、成形不良や機器の故障など、それとわかる形となって現れるまでには時間がかかるため、認識されにくい不具合の一つです。しかし、水管詰まりや機器の故障などが発生してしまうと復旧に時間も手間も費用もかかり、生産性が著しく低下してしまいます。

長期的な安定生産を実現するためには日々の冷却水の水質管理が大切です。松井では水質の改善、維持を実現するさまざまなソリューションを提案しています。ぜひお気軽にご相談ください。