overview

What is Metal Laser Sintering Hybrid Processing?

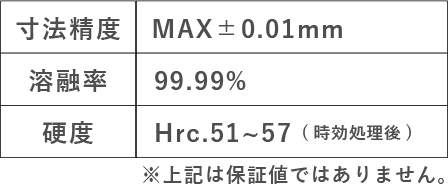

Powdered metal material is selectively sintered with a laser and layered to create highly accurate shapes. Machining is also performed as necessary at each step of the process to further improve dimensional accuracy and surface quality.

This makes it possible to create free-form cooling circuits and porous structure shapes that were difficult to achieve with conventional processing, providing many benefits such as improved product quality, Reduction in cycle time, and prevention of gas burns.

It can be used for mold parts.

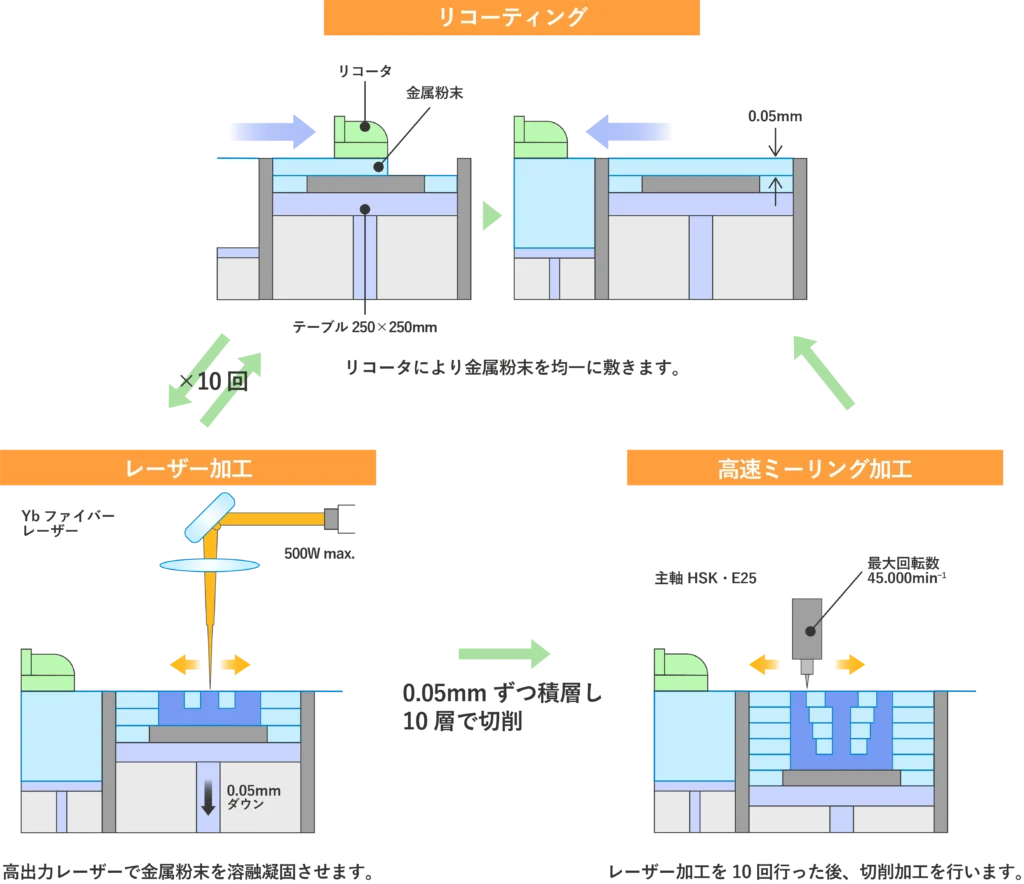

Processing flow

The recoater spreads the metal powder evenly to a thickness of 0.05 mm, and then the layer is selectively melted and solidified with a high-power laser. After repeating this process for 10 layers, the laminated surface is precisely finished by high-speed milling. After that, the cycle starts again with recoating, and by repeating this process, highly accurate 3D shapes and excellent surface quality are simultaneously achieved.

Features

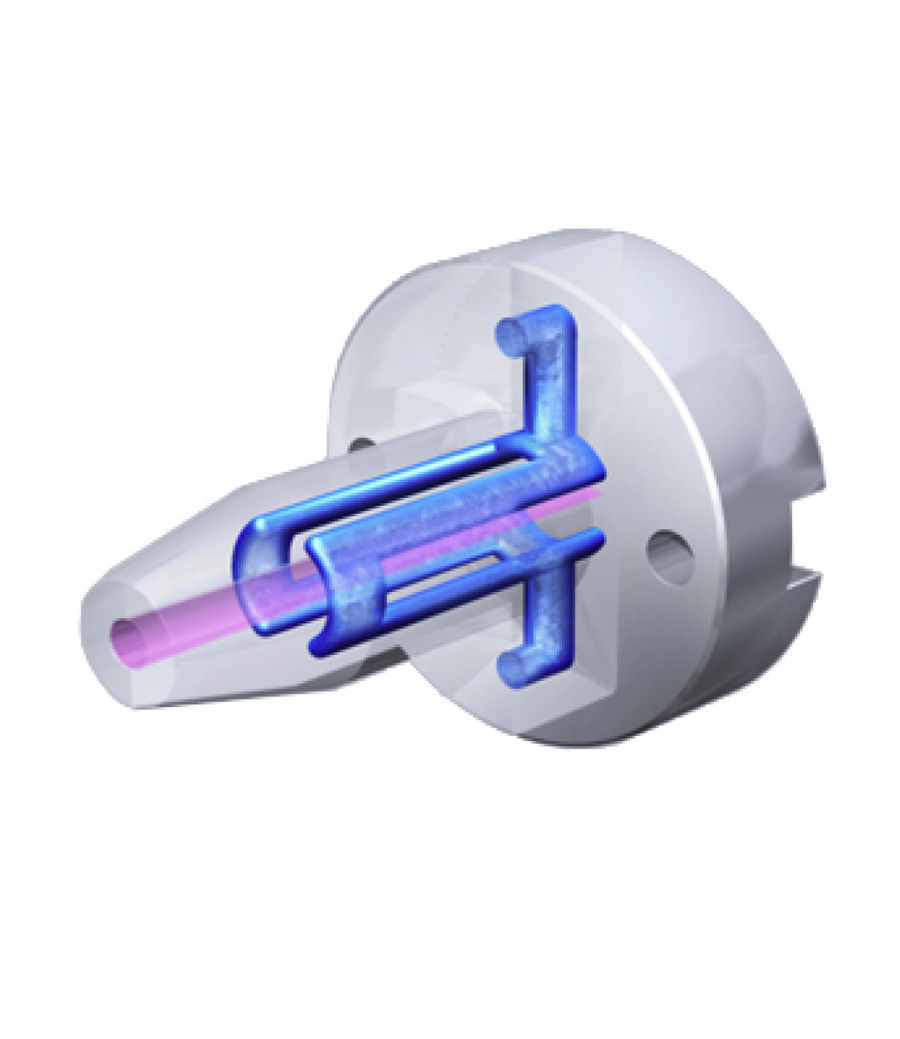

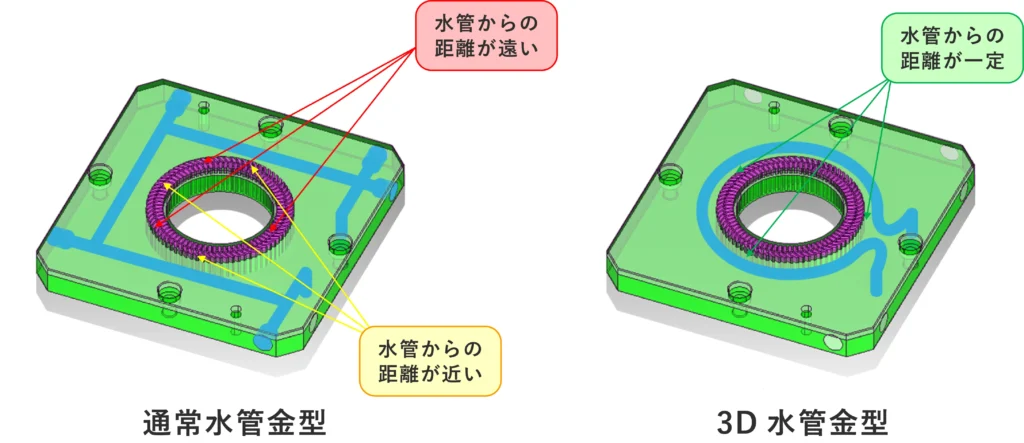

1. Highly efficient cooling using 3D cooling water pipes shortens molding cycles

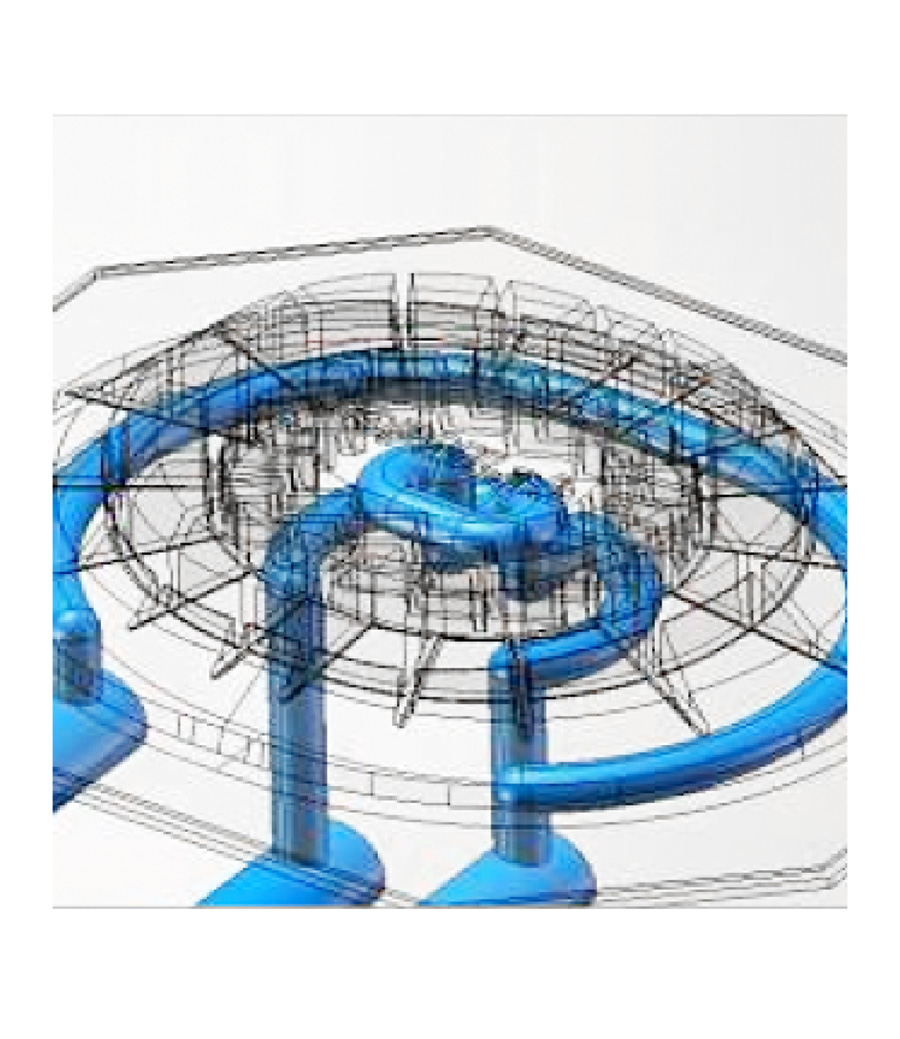

3D modeling technology allows us to create 3D cooling circuits inside the mold. This allows us to place cooling water pipes along the optimal locations of the molded product, significantly improving cooling efficiency, shortening molding cycles, and improving productivity.

3D molds can maintain a constant distance between the molded product and the water pipes, enabling uniform cooling, which contributes to Reduction in cycle time and quicker mold start-up.

2. High-precision molding is achieved with an integrated structure that does not require division

By molding in one piece, there is no assembly error between parts. This improves dimensional accuracy, concentricity, and surface accuracy, leading to reduced variation in molded products. This is particularly effective for products that require precision and for high-performance resin molding.

3. Freely design and install porous structures for gas release

Since a porous structure can be formed during the molding process, gas vents inside the mold can be freely designed. This helps prevent molding defects such as gas burns and short shots, and contributes to stabilizing quality.

Metal 3D printers can produce porous structures (low density models). They can produce partially porous structures with gas vents, such as inserts and gas vent pins, which eliminate molding defects.

4. Complex shapes can be manufactured in one go, and post-processing can be reduced for quick delivery

Conventionally, complex mold structures were divided into multiple parts, but with 3D printing, they can be molded as a single unit. This eliminates the need for machining and assembling each part, allowing for significant shortening of delivery times and cost reductions.

5. Verification of effects at the design stage through flow and cooling analysis

When designing a mold, it is possible to perform a prior simulation of the resin flow and temperature distribution during molding. This allows for visualization of the cooling efficiency and gas removal effect, supporting quality improvement and design optimization.

*Requests for the production of mold parts using a 3D printer are accepted via the inquiry form.

Performance results

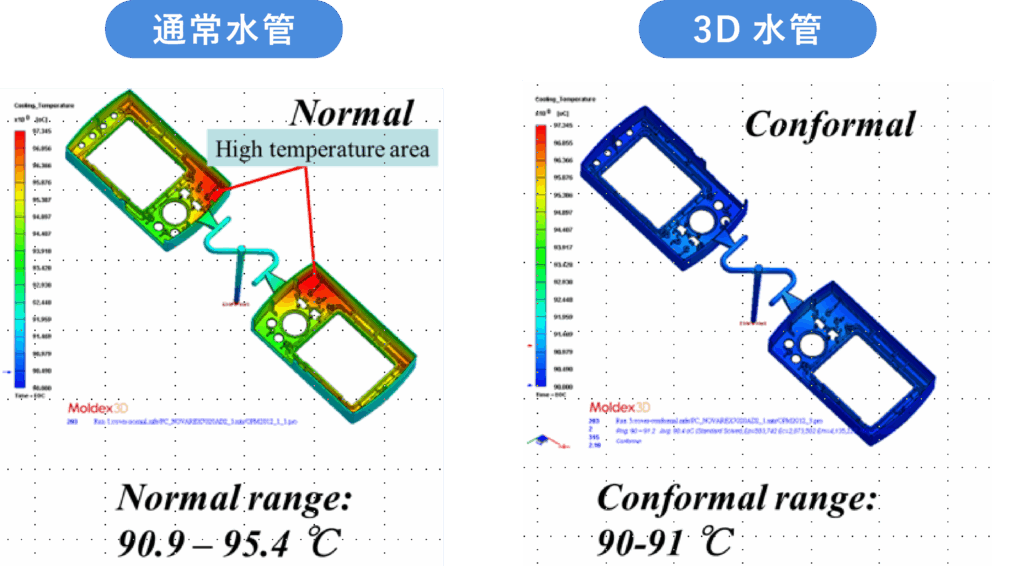

The figure below is a thermograph of a molded product in the temperature range of 90 to 97°C.

The normal water pipe on the left has a temperature difference of more than 5°C, and the molded product has a high overall temperature. This temperature difference gradually increases from the start of molding, and as continuous molding continues, the difference widens, causing quality variations. In contrast, there is almost no temperature difference in the 3D mold on the right.