Drying technology that protects optical quality

Drying affects the quality of evolving optical devices

Smartphone multi-lens cameras incorporate multiple lens modules into a single housing, enabling a wide range of shooting, including wide-angle, telephoto, and macro, greatly evolving the everyday photography experience.

With the spread of ADAS (Advanced Driver Assistance Systems), the use of camera modules and lens units to support Automatic operation is rapidly increasing in automobiles. Applications directly related to safety, such as pedestrian detection and lane recognition, require the accurate capture of high-resolution images, day or night.

Furthermore, in the medical field, endoscopes and optical objective lenses are becoming increasingly 4k/8k compatible, clearly showing minute blood vessels and tissues inside the body, contributing to the early detection of lesions.

For all of these optical components, the lens shape precision must be controlled to the micron level, and even the slightest variation in transmittance and refractive index is not permitted. Furthermore, they must also be resistant to temperature changes and chemicals. Even the slightest molding defect can lead to image distortion and reduced resolution, significantly reducing product value.

The fight against minute defects that plague molding sites

Optical molding requires precision down to the micron level. One of the fundamental causes of molding defects is insufficient drying of the resin. At optical component molding sites, defects such as silver streaks, voids, yellowing, and slight haze that appear on the lens surface continue to plague workers.

This is often caused by trace amounts of moisture mixed in with the resin. Optical-grade resins are highly hygroscopic, and even a slight fluctuation in moisture just before molding can make a big difference in yield and optical performance.

If defects occur, polishing or remolding will be necessary in subsequent processes, which not only puts pressure on costs and delivery times but also increases the risk of damaging the value of the entire product.This is why the "resin drying quality" is the key to supporting the quality of optical components, not just the molding conditions.

It's true that we are careful not to let it dry out too much, but sometimes the resin dust can be a concern...

That's right! Resin powder can be blown up by air currents and can cause adhesion to optical surfaces or silver streaks. Maintaining a clean transportation environment is just as essential for optical molding as drying quality.

Optical defects caused by small amounts of moisture inside the resin

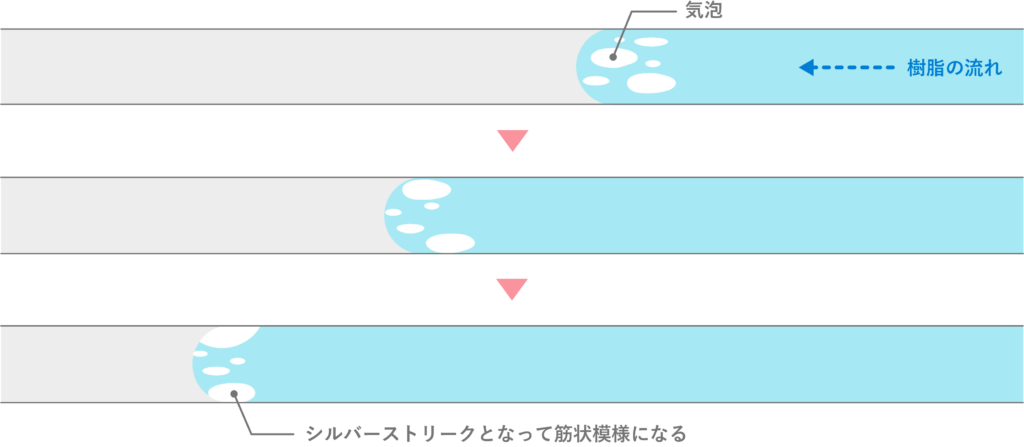

Many optical grade resins have extremely high moisture absorption. If the resin is heated and melted before it has been sufficiently dried, the moisture remaining inside the resin will be thermally decomposed and gasified at high temperatures. If this gas remains as bubbles during flow, it will form voids (cavities) that are dragged in the direction of flow and appear on the surface as silver streaks.

Are the air bubbles inside the resin the voids, and when they surface they become the silver streaks?

I'll explain in detail!

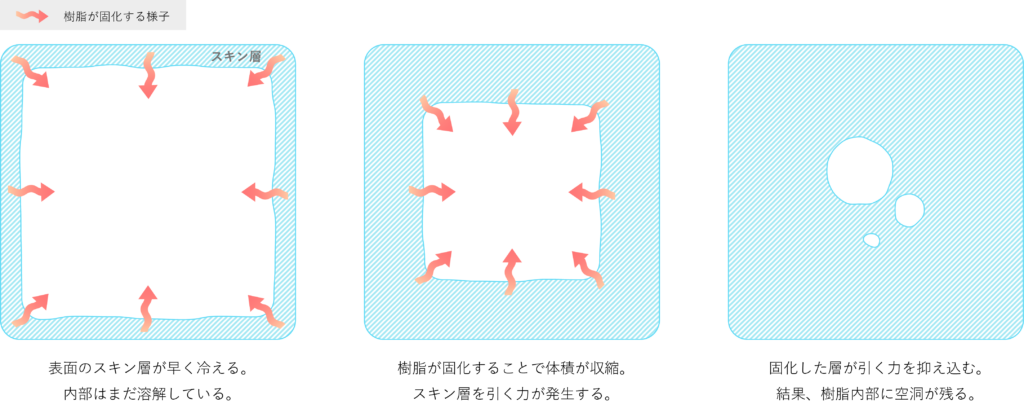

Cavities (air bubbles) that occur inside molded products are called voids. During molding, the center of thick parts cools slowly, and solidification begins from the outside first. When this happens, even if the resin inside shrinks, the solidified outer layer holds it back, so resin cannot flow in to compensate for the volume change in the center, and voids remain.

I see, please tell me the mechanism behind silver streaks!

Silver streaks are a phenomenon in which silvery white streaks appear on the surface of molded products. They occur when air bubbles generated during molding are dragged to the surface of the molded product along the direction of resin flow. In optical components, this can significantly impair transmittance and appearance quality.

Furthermore, thermal decomposition can sever molecular chains, causing yellowing and a loss of transparency. Even traces of moisture can affect molecular orientation and refractive index, resulting in minute defects such as haze and optical distortion.

As you can see, moisture, which is invisible to the naked eye, can cause serious damage that can affect optical performance.

The importance of drying conditions as a function of material properties

Resins such as PC (polycarbonate), which are often used in molding optical components, have high transparency and dimensional stability, but they also have high moisture absorption and are very sensitive to drying conditions.

Even if the material absorbs only a small amount of moisture from the air, the heat generated during molding causes the moisture to decompose and gasify, resulting in defects such as silver streaks, voids, and yellowing.

In optical molding, it is essential to accurately understand the moisture absorption characteristics and drying temperature of each resin and maintain stable "drying quality" until just before molding.

Optimal drying control according to the material properties is the first step to achieving high-precision optical molding.

Precise drying control supports optical quality

To stabilize the quality of optical molding, simply drying at high temperatures is not enough.

It is essential to accurately control the moisture absorption characteristics, drying temperature, and processing time, which differ depending on the type of resin, and to perform consistent moisture management right up until just before molding.

That is why the optical field requires Dehumidifying Dryer are specialized Optical, rather than general dryers.

Maintaining stable drying quality of resin and supplying it to molding in a consistent state leads to stable yield and high optical performance.

"Drying quality" is the foundation that supports next-generation optical devices.

This page introduces the latest dehumidifying and drying technology and operational key points to ensure that this quality is achieved.

Features

1. Honeycomb Dehumidifying Dryer that achieves stable drying

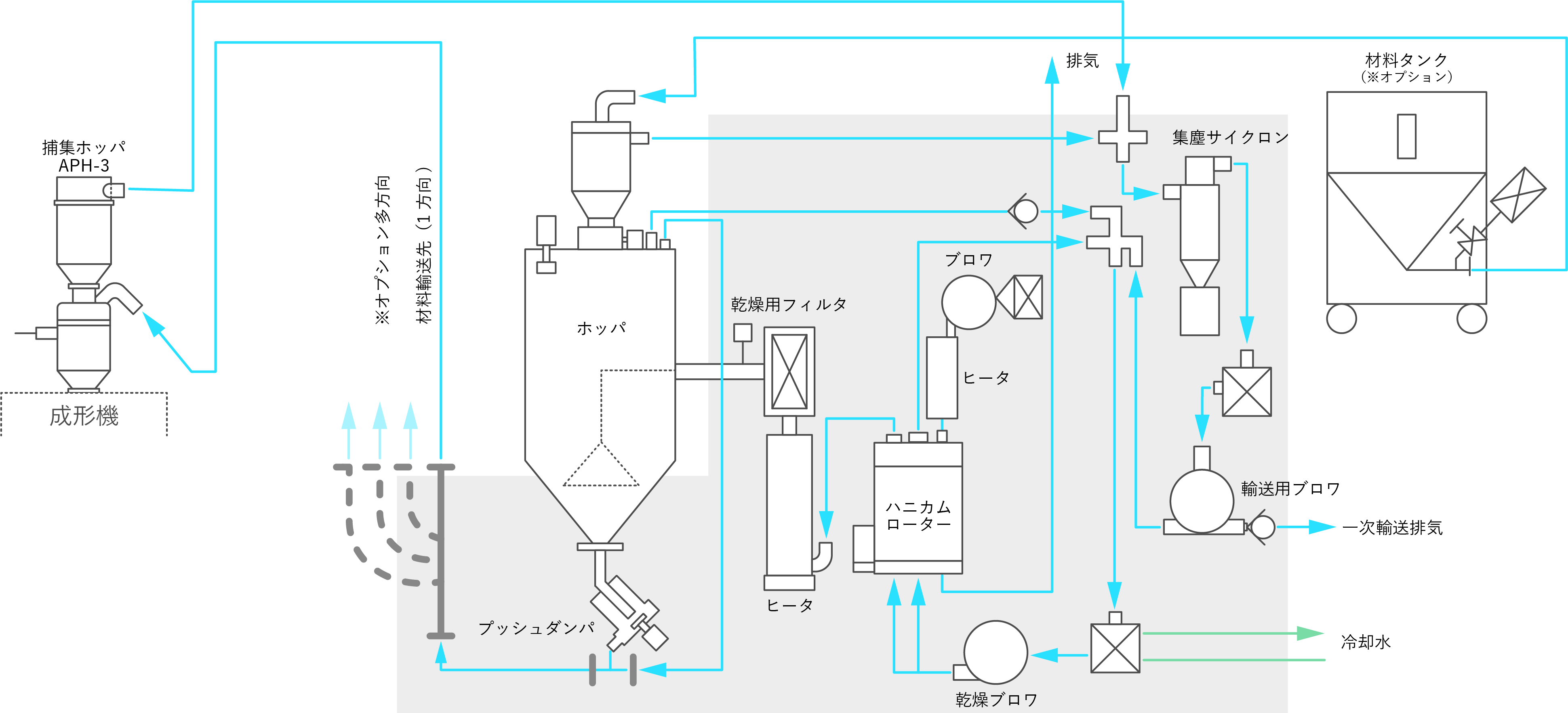

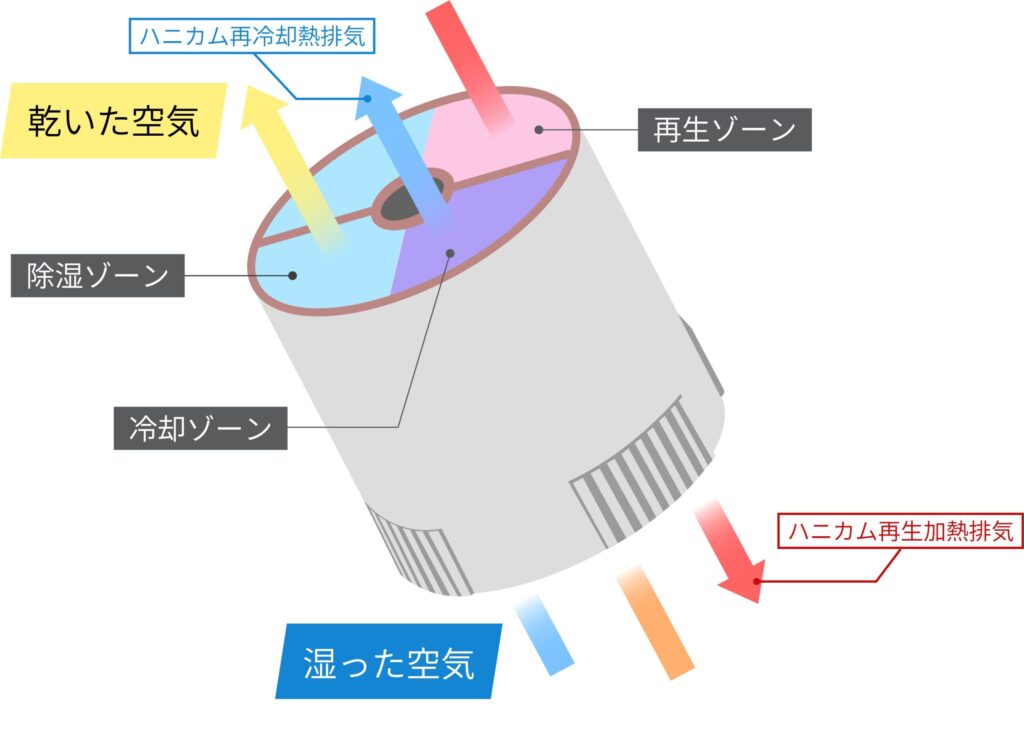

The DMD4 uses a honeycomb rotor to provide a stable supply of dry air with a low dew point thanks to its three-zone continuous cycle structure of "dehumidification, regeneration, and cooling."

As the rotor slowly rotates, it absorbs moisture from the air sent to the drying hopper in the "dehumidification zone," and then in the following "regeneration zone," the absorbed moisture is evaporated by superheating with high-temperature air to restore its absorption power.Furthermore, in the "cooling zone," the rotor, which has become hot after regeneration, is cooled to an appropriate temperature to prepare for the next dehumidification.

By continuously performing this cycle without stopping, the dew point of the dried air can be maintained stably.The complete regeneration cycle prevents deterioration of the adsorbent's performance, maintaining drying quality close to its initial performance for a long period of time.

2. Clean drying with a high-performance filter

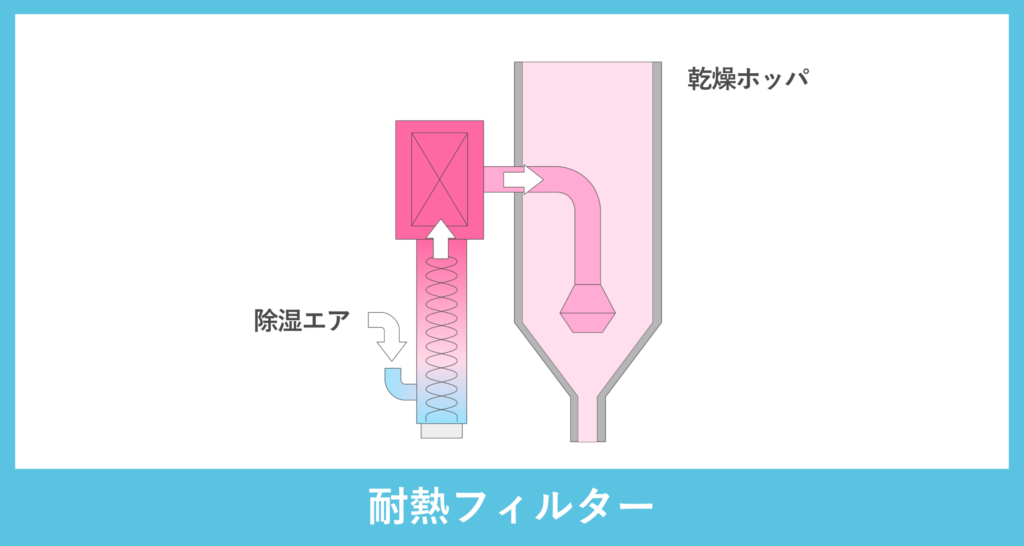

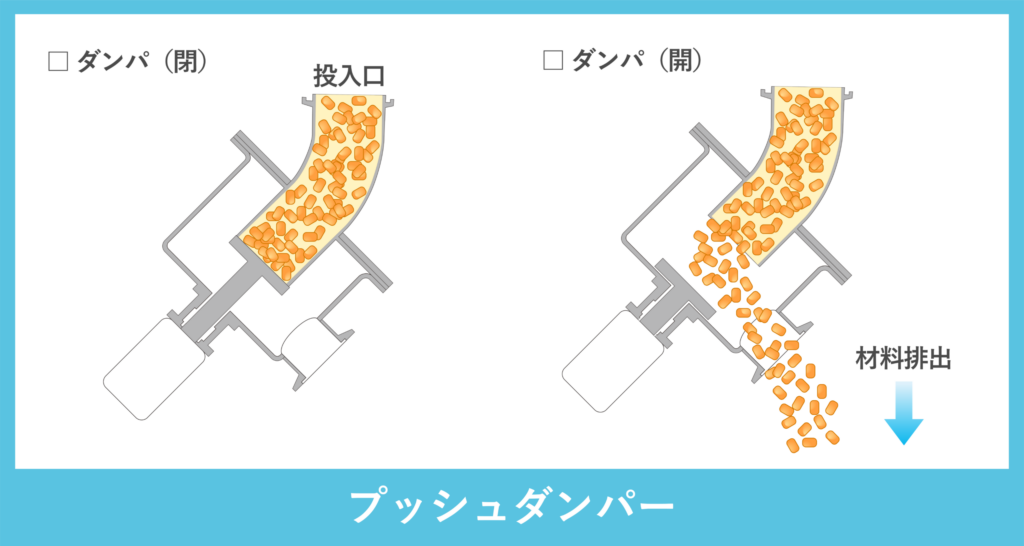

The drying filter is a heat-resistant resistant, high-performance filter (0.3μm/99.97%) that cleans the heated air at the end. In addition, Matsui's original push damper is used for batch transport, which prevents contamination.

3. Resin dust-free transport to prevent poor appearance

Matsui's original Aero Power Hopper removes resin powder with the power of airflow while transporting materials. By removing fine powder before it reaches the molding machine, it prevents defects in appearance and achieves higher quality molding.

Contamination prevention is essential for optical molding.

4. Stable control achieved by using SSR (contactless relay)

SSR (contactless relay) for the heater control circuit reduces maintenance frequency and greatly improves safety.

A Solid State Relay (SSR) is a semiconductor-based relay that controls electrical signals without any physical contact. It features semiconductors in place of mechanical contacts, making it free from moving parts. This design gives SSRs a longer lifespan and faster switching speeds compared to traditional contact relays. Additionally, with no risk of contact failure, SSRs ensure reliable and stable performance.

By the way, a contact relay (mechanical relay) is a relay type that uses the power of an electromagnet to mechanically operate a switch.

It is typically used in larger equipment such as electric motors.

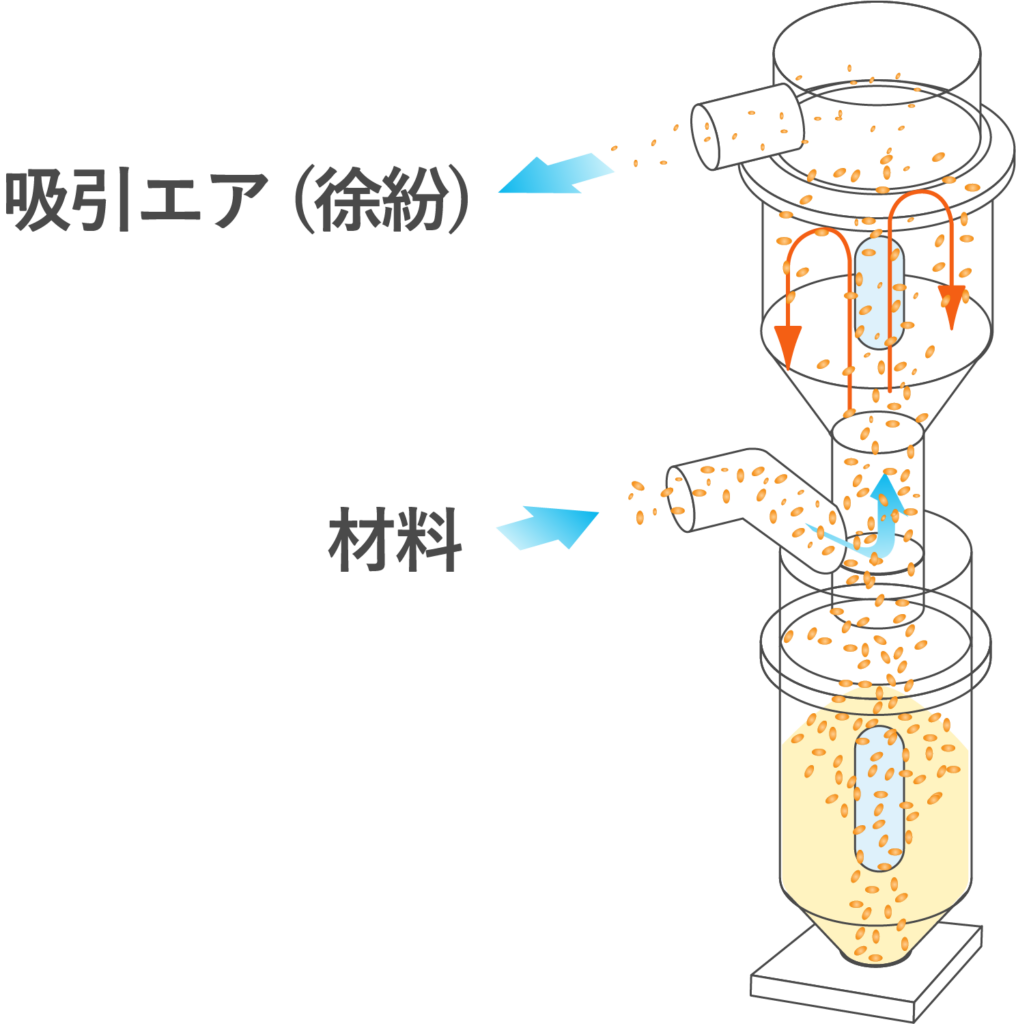

5. Cyclone separation structure reduces filter cleaning frequency

The Cyclone separator separates dust by its own weight, preventing filter clogging and significantly reducing cleaning frequency. Furthermore, the use of a manual butterfly valve allows maintenance to be performed even during drying operation, maintaining stable, clean operation without stopping production.

Flow Diagram

Example: DMD4-50J, 100J, 200J