Diversification of resin materials and the role required for the measuring and blending process

Molding sites with complex material and compounding conditions

In recent years, at plastic molding sites, the resins used and compounding conditions have become increasingly sophisticated and diverse, driven by the need for higher added value, lighter weight products, and environmental friendliness.As complex compounding that combines virgin materials with Master batch, Regrind material, and various additives has become common, how to reproduce stable quality has become an important theme in the molding process.

The causes of variations in molding quality and molding defects are not limited to molds and molding conditions. Errors in measuring materials and unstable blending can also trigger quality problems.

The impact on quality and cost caused by discrepancies in measurements and blending

In particular, when mixing Master batch or Regrind material with materials such as polypropylene (PP) or polyamide (PA), or when handling engineering plastics such as polybutylene terephthalate (PBT) or polycarbonate (PC), even a slight deviation in measurement or excess or deficiency can cause serious problems.

- Variations in product appearance and physical properties

・Longer time required for setting conditions and setting up

-Increased material loss and defective shots

This can lead to significant losses in terms of both cost and quality.

Furthermore, in recent years, from the perspective of sustainability and effective resource utilization, there has been a strong demand for the molding process to adopt the concept of "using exactly the required amount in the required ratio."

No leftover material, no need to redo, no unnecessary re-measurement or waste. To achieve a molding process that doesn't produce waste, it is essential to have a measuring and blending system that is highly reproducible regardless of who uses it, rather than relying on the experience and intuition of the worker.

How can Gravimetric Blender help with these issues? We will introduce the specific features that support ease of use and stable operation.

Features of the JCW2-i

1. A weighing system that reduces material waste by approximately 99%!

◆ Supply optimization software

In terms of material mixing, there are many changes in materials, such as in molding with many varieties and small lots.

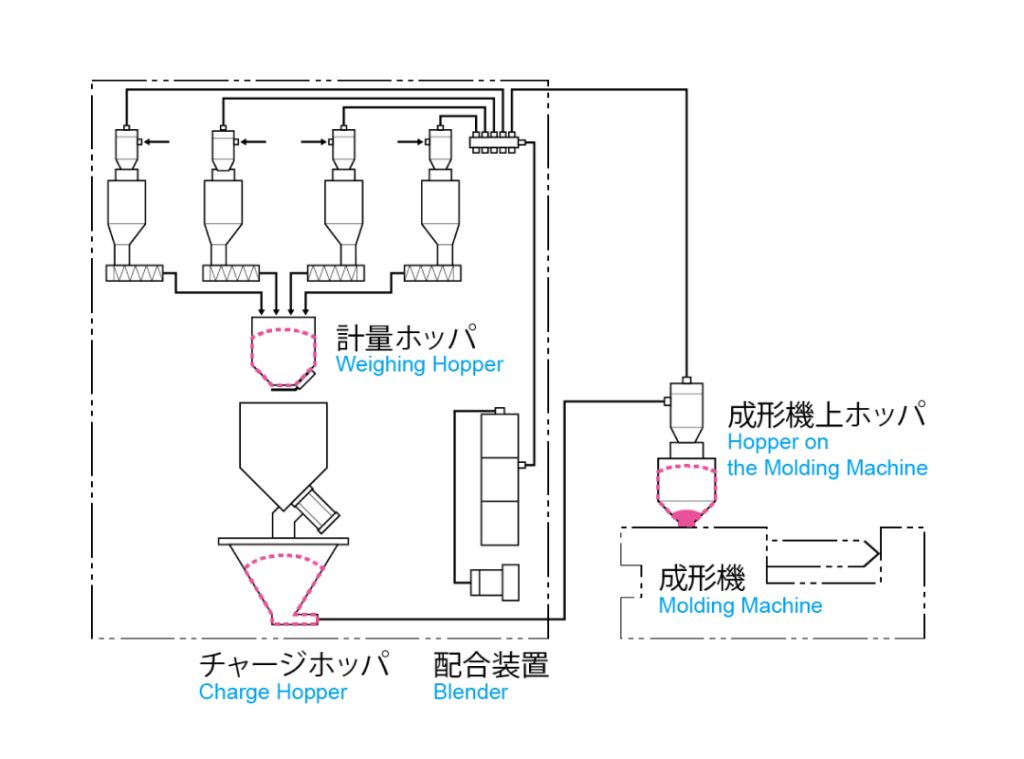

When the material is finished or just before changing materials, the remaining material in Measuring hopper, charge hopper, and hopper above the molding machine

The large amount of waste of mixed materials was a problem.

The required amount can be measured, making it possible to reduce material waste.

[The mixing device calculates and adjusts the amount of material per batch according to the amount of material used by the molding machine!]

Step 1: Compare the processing capacity of the molding machine and the measuring capacity of the blending equipment.

Step 2: If the computing power is excessive, reduce it to an appropriate value.

Step 3: After charge hopper outputs a request signal, Measuring hopper starts weighing. (This is when "Measuring hopper no standby mode" is selected.)

◆ End warning signal

[After calculating the required amount based on the number of remaining shots, the measuring operation will stop!]

Step 1: Set the number of remaining shots.

Step 2: Calculate the required amount based on the remaining number of shots you set.

Step 3: Calculate the standby amount for the weighing Measuring hopper, charge hopper, and hopper above the molding machine.

Step 4: Subtract the waiting amount from the required amount to calculate the remaining number of weighings.

Step 5: After the remaining number of weighings have been completed, the weighing operation will stop.

2. Achieving a highly accurate supply system by creating a "supply system where the machine thinks"!

When the initial setting of the drop amount is not appropriate or when changing the material, the measurement value variation caused by the error caused by neglecting to change the drop amount has been considered a problem. The JCW2-i's unique control system enables automatic, quick and accurate measurement.

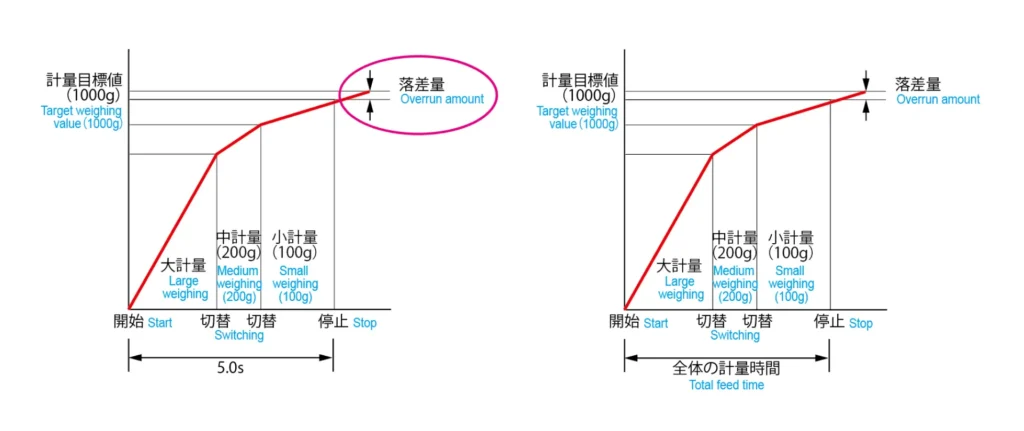

◆ Three-stage supply

[Three-stage supply enables high-speed weighing and shorter supply time compared to conventional two-stage supply.]

Step 1: Change the head amount based on the moving average value of the actual measured head amount.

Step 2: Change the weighing switch value to shorten the overall calculation time so that the medium and small weighings can be calculated within the target weighing time.

When raw materials change and their properties change, the JCW2 will measure and supply the optimum amount to suit the material.

This means there's no need to worry about checking the weight or manually changing settings!

3. Easy to use, anyone can operate it!

The interactive settings make it easy for anyone to operate.

The controller can measure and display in increments of 0.1g.

4. Main units and other parts are extremely easy to maintain!

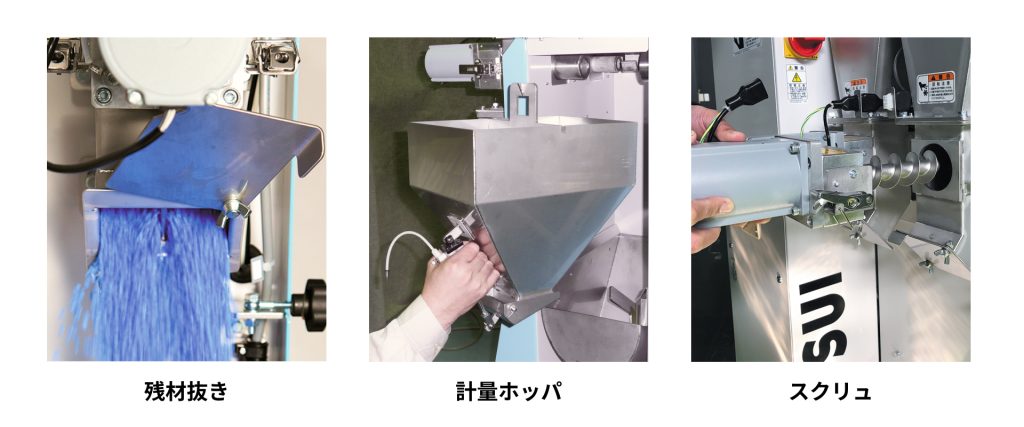

The remaining material is discharged from the bottom of the hopper, and the adhering powder can be brushed off from the top to the bottom.

Yes, that is possible. In addition, Measuring hopper and screw of the main unit can be easily attached and detached.

This contributes to easy maintenance.