高機能樹脂の採用拡大で高まる、金型温度管理の重要性

用途の広がりとともに求められる安定した温度制御

近年、高機能樹脂の採用がさまざまな分野で進んでいます。中でもポリフェニレンサルファイド(PPS)は、耐熱性・耐薬品性・寸法安定性に優れ、自動車分野の電装部品や機構部品、ガスケット・シール部品をはじめ、電気・電子部品や水道管・配管用継手などの水回り部品にいたるまで、幅広い用途で使用されています。

こうした用途拡大の影響には、金属部品の樹脂化による軽量化や耐腐食性の向上といったメリットがあります。一方で、PPSをはじめとする結晶性の高機能樹脂では、成形時の金型温度管理が製品品質に大きく影響するという特性があります。

一般的に、PPSの射出成形では金型温度を120℃~150℃程度に設定し、適切な温度環境下で成形を行うことで、耐熱性や機械的特性、寸法安定性といった材料特性を十分に引き出すことが可能です。しかし、金型温度が不安定な場合には、バリの発生や外観不良、寸法のばらつきといった品質トラブルにつながることがあります。

このような課題はPPSに限らず、他の結晶性エンプラや高機能樹脂においても共通しており、高温域でも安定した金型温度制御が求められる場面は年々増えています。

このような背景から、金型温度調節機は補助装置として一括りにできるものではなく、成形品質に直結する重要な要素として捉え、慎重に選定する必要があります。

特長

1. マツイ独自の間接冷却方式で、圧力損失によるトラブルを解決!

熱交換器用に送る冷却水のフローを改善

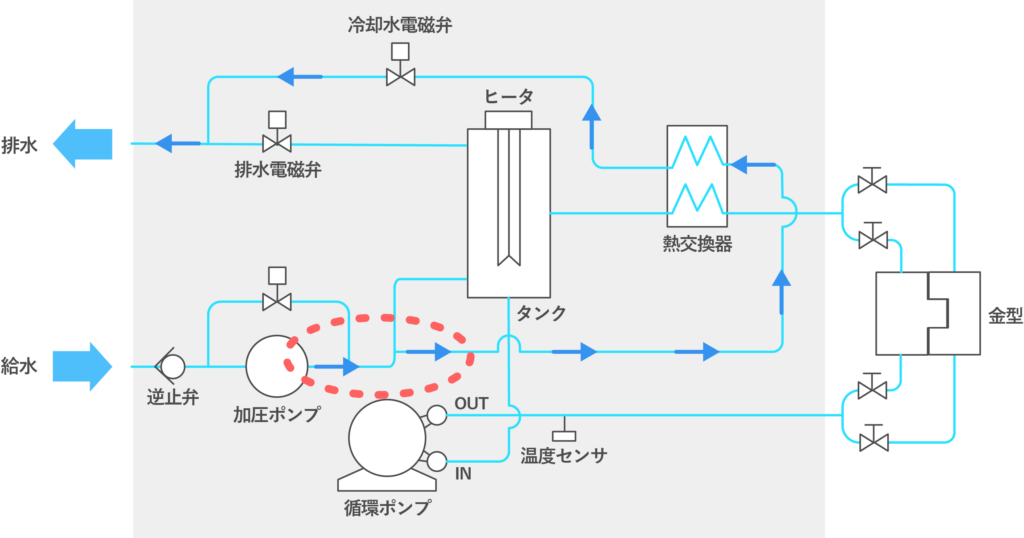

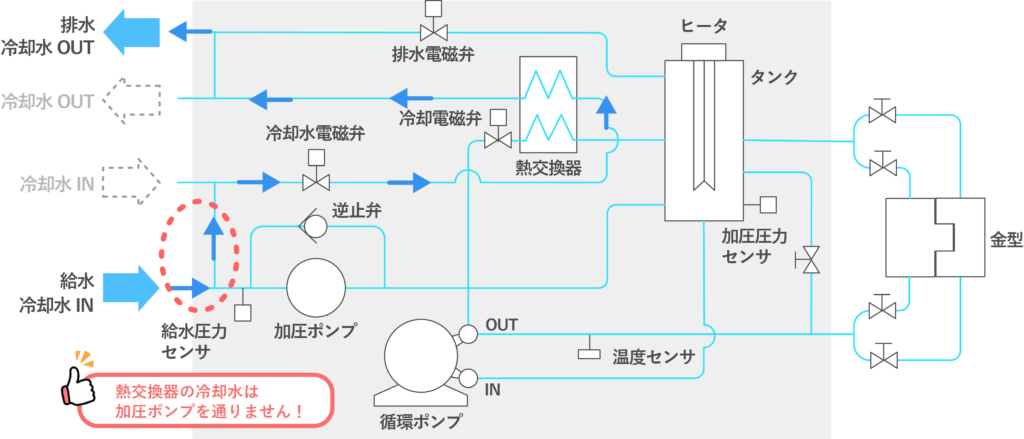

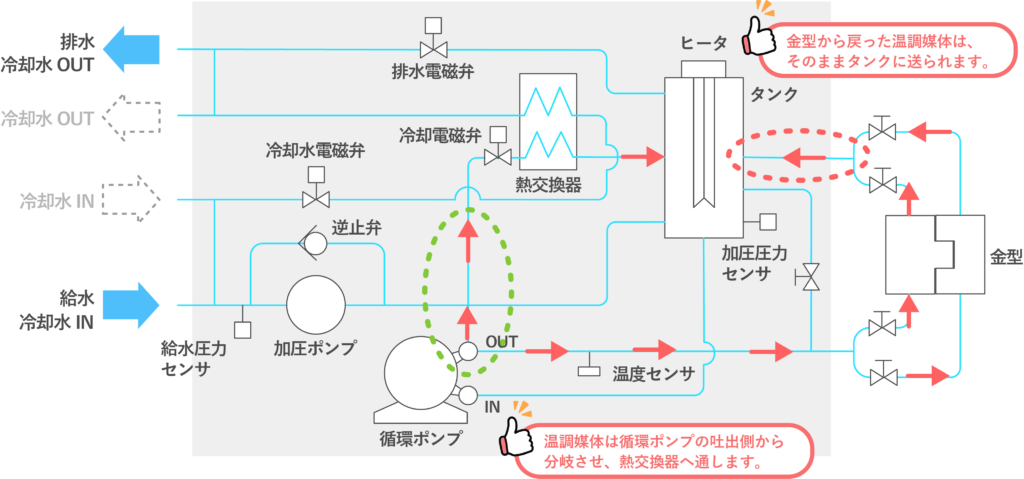

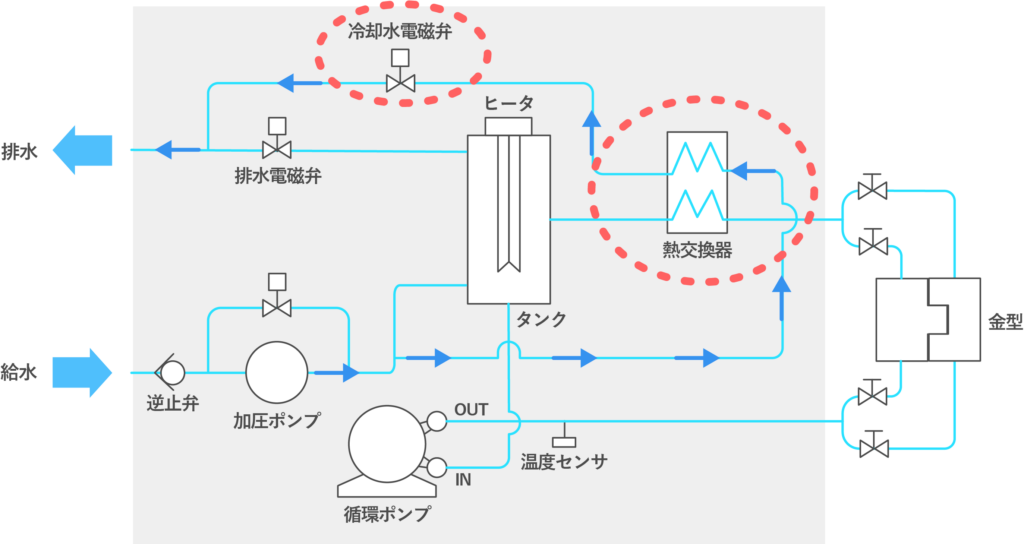

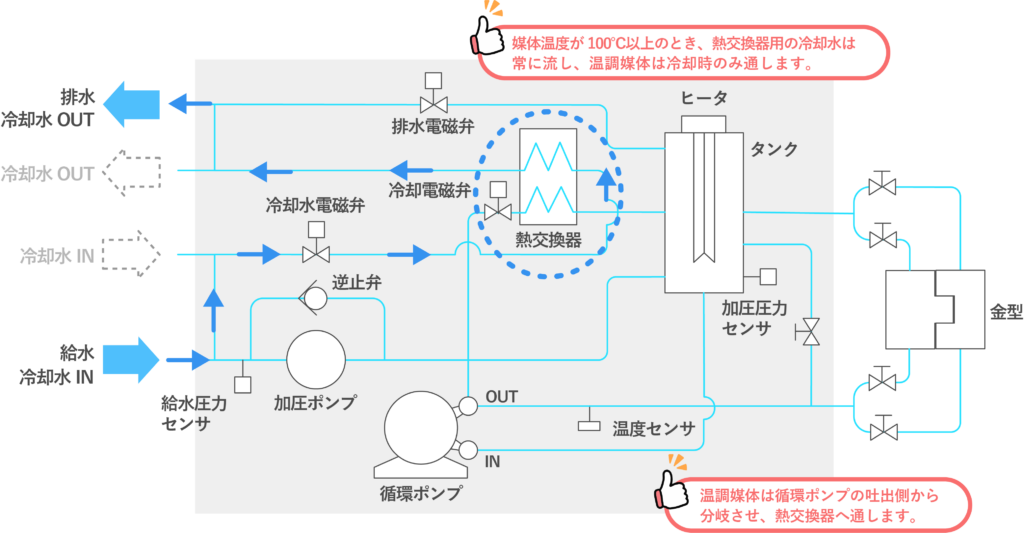

従来の間接冷却方式では、冷却水は加圧ポンプの吐出側から分岐させて熱交換器へ送り出していました。このため、冷却時(冷却水電磁弁が開いているとき)には、冷却水の分岐に伴う抵抗によって、加圧ポンプで加圧された系内の圧力が低下してしまいます。その結果、系内の圧力が飽和蒸気圧を下回ると、温調媒体が沸騰する恐れがありました。

そこで、MC5-HHでは、給水した冷却水を加圧ポンプの手前で分岐し、熱交換器へ供給するようフローを改良しました。これにより、冷却水は加圧ポンプを通らずに熱交換器へ送られるため、吐出側での圧力抵抗が改善され、冷却時にも温調媒体の圧力が安定し、沸騰によるトラブルを解消することができました。

金型を通った温調媒体のフローを改善

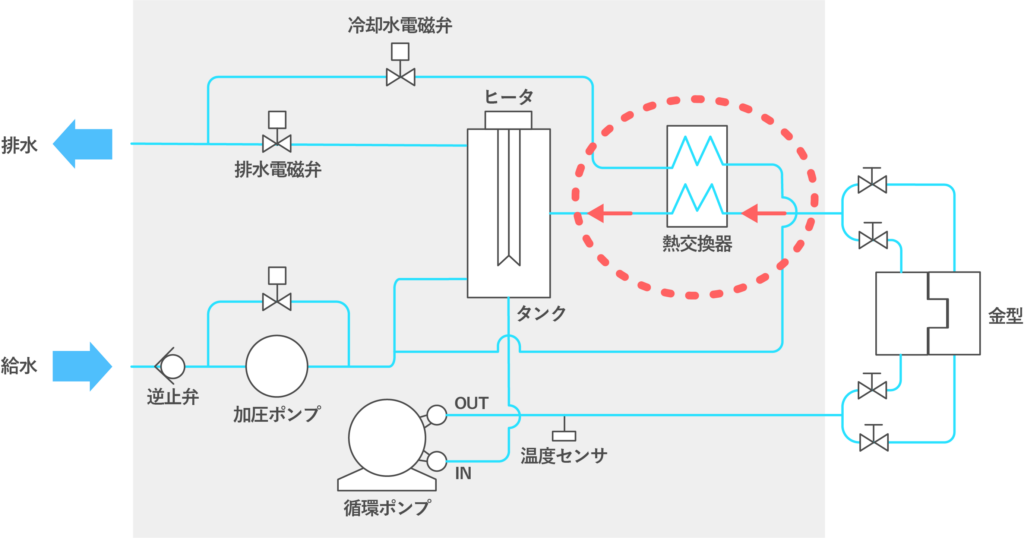

従来の間接冷却方式では、金型から戻ってきた温調媒体を常時熱交換器に通していました。しかし、温調媒体は熱交換器を通過する際に圧力損失を受けるため、流量が制限される恐れがありました。

そこで、MC5-HHでは、温調媒体を循環ポンプの吐出側から分岐し、冷却時のみ熱交換器へ通すようフローを改良しました。金型から戻ってきた温調媒体は、そのままタンクへ送られます。循環路に熱交換器が接続されないことで圧力損失が減少し、従来に比べて温調媒体の流量が向上しました。

循環ポンプから冷却水を分岐して、金型と熱交換器に送るとなると・・・。

冷却水、ちゃんと金型に送る媒体流量って確保できているの?

金型側の配管径の方が熱交換器側よりも太くなっているため、温調媒体のほとんどは自然と金型の方に流れるようになってるんです。そのため、温度コントロールに影響が出るほど流量が減ってしまう心配はありません。

温調媒体がほとんど金型の方に流れているのに、ちゃんと温度を下げられるの?

まず、媒体の温度と設定温度を比べて、加熱制御と冷却制御を切り替えながら温度を調整します。媒体の温度が設定より低いときはヒーターで温め、高いときは冷却電磁弁を開いて一部を冷やすので、温度を下げすぎずにしっかり調整できるんです。

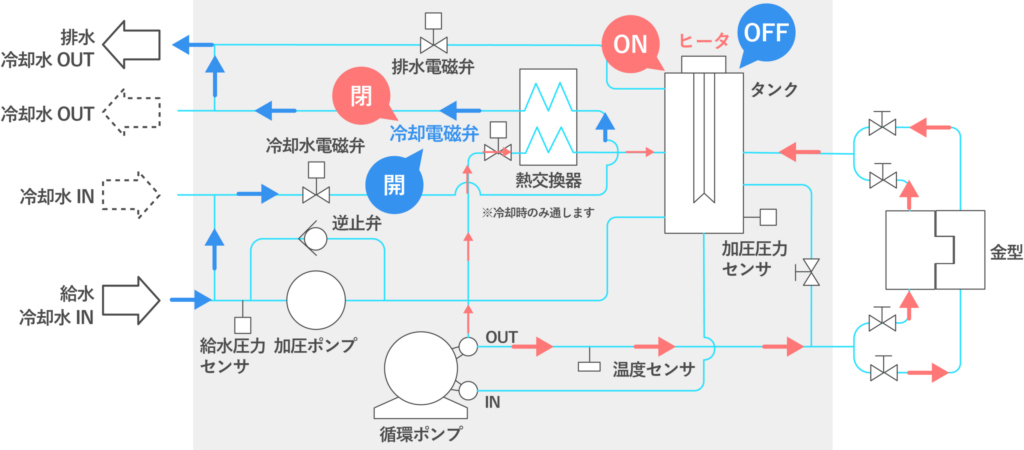

冷却水電磁弁のフローを変更し、冷却動作を改善

従来の間接冷却方式では、熱交換器の冷却水側にある冷却電磁弁で冷却動作を制御していました。そのため、冷却時(冷却水電磁弁が開いているとき)には配管内の圧力が低下し、熱交換器内の冷却水が気化してしまい、スケールが蓄積する恐れがありました。

そこで、MC5-HHでは、媒体温度が100℃以上のとき、熱交換器用の冷却水は常に流します。そして、媒体温度が設定温度より高い場合には冷却電磁弁を開き、一部の温調媒体を熱交換器に通して冷却します。

冷却水をずっと熱交換器に流しっぱなしにするなんて、ムダではないの!?

熱交換器をいつも冷えた状態にしておけるため、停留中の温調媒体は、加熱制御中に冷やされます。そのため、冷却するときには、温度が下がった状態に準備ができているんです!

なるほど。冷却電磁弁が開いたときに、わざわざ熱交換器を冷却する時間がいらないんだね。それに温調媒体もちゃんと冷却の準備ができているから、スムーズに冷却制御ができそうだね。

2.マツイ独自の加圧制御が省エネかつ省力化を実現!

必要な分だけ加圧して省エネ化

温度センサーで検出した媒体温度に合わせ、そのときの飽和蒸気圧以上を保つように加圧ポンプを自動制御。必要なときに必要な分だけ加圧することで、ムダのない効率的な運転を実現します。さらに、MC5-HHに採用している加圧ポンプ(ピストンポンプ)は、常に駆動しなくても系内の圧力を安定して維持できるため、ポンプ停止による圧力低下の心配もありません。

自動圧力調整の導入で操作を省力化

加圧ポンプの圧力調整を自動で行うことで、操作の手間なく系内の圧力を常に適正に保ちます。これにより、給水圧の変動による圧力調整ミスを防ぎ、系内の圧力が飽和蒸気圧を下回って温調媒体が沸騰したり、逆に圧力が高くなりすぎて装置が故障する、といったリスクを解消します。

系内の圧力が高くなりすぎたらどうするの!?

昇温中は、媒体の熱膨張によって系内の圧力が上昇します。設定圧力を超えた場合には、排水電磁弁を開いて圧力を下げることで、安全弁が作動する前に圧力を適切に調整します。

3.系内の気泡抜きでキャビテーションによるトラブルも解決!

循環ポンプのON/OFFを繰り返して気泡抜き

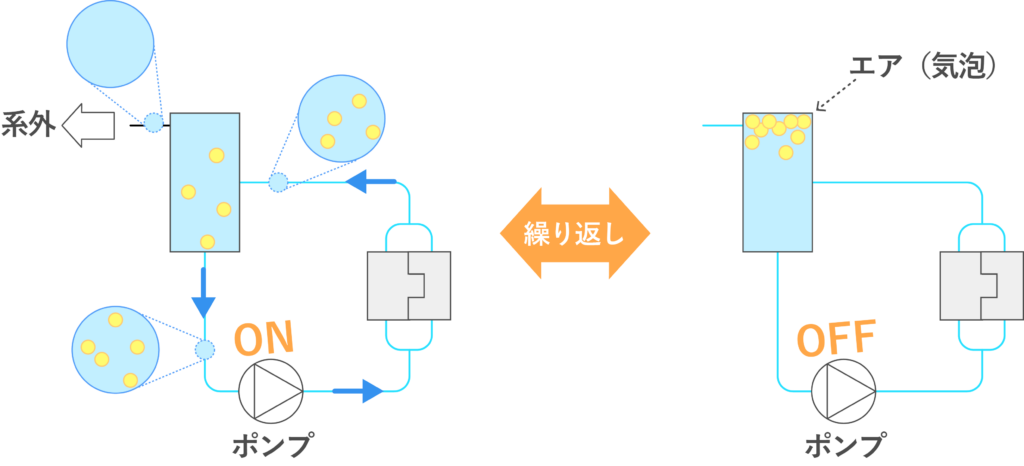

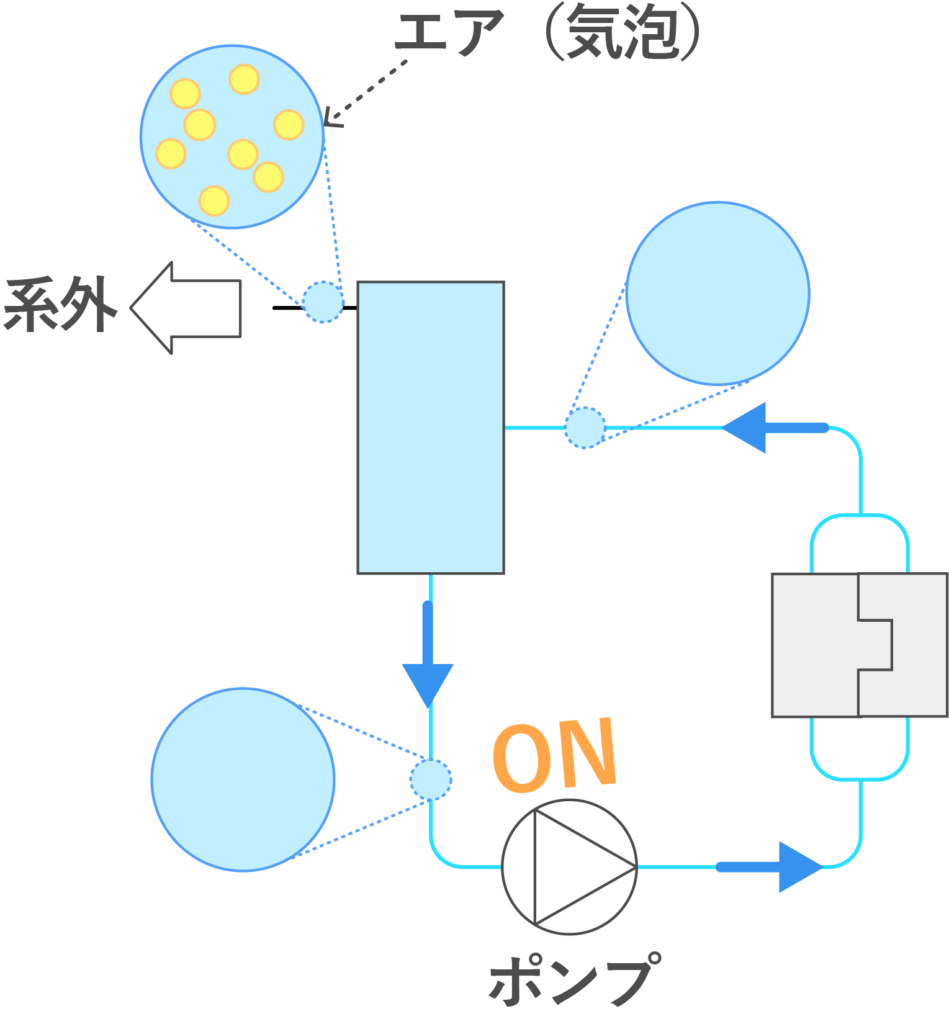

金型交換やメンテナンス、ホースの交換などで、金型と金型温度調節機をつなぐホース内の水を抜く際、エアが入り込むことがあります。この気泡によってポンプ内でキャビテーションが発生すると、媒体の吐出量が減少したり、振動・騒音の原因となり、ポンプの故障につながる恐れがあります。そこでMC5-HHでは、タンクに給水した後に循環ポンプのON/OFFを繰り返すことで、気泡をしっかり抜く仕組みを採用しています。

え、ポンプの ON と OFF を繰り返して気泡を抜くって、どういうことなの?

実はポンプの動きを上手く使って、エアベントと媒体ブローを行うんです。

まず、ポンプを ON と OFF で何度か動かして、循環してる媒体と一緒に気泡をタンクに送り込みます。それから、ポンプを止めて媒体の流れを止めると、軽い気泡は自然にタンクの上の方に集まります。

最後にポンプを常時 ON にして、オーバーフローする媒体と一緒に、その気泡を系外に流してあげる、という流れになります。

あぁ、なるほど。ポンプを動かして気泡をタンクに集めて、最後にまとめて外に出すってことか!

はい、そうなんです。その流れでしっかり気泡を抜いてあげることで、ポンプも安心して動かせるんですよ。

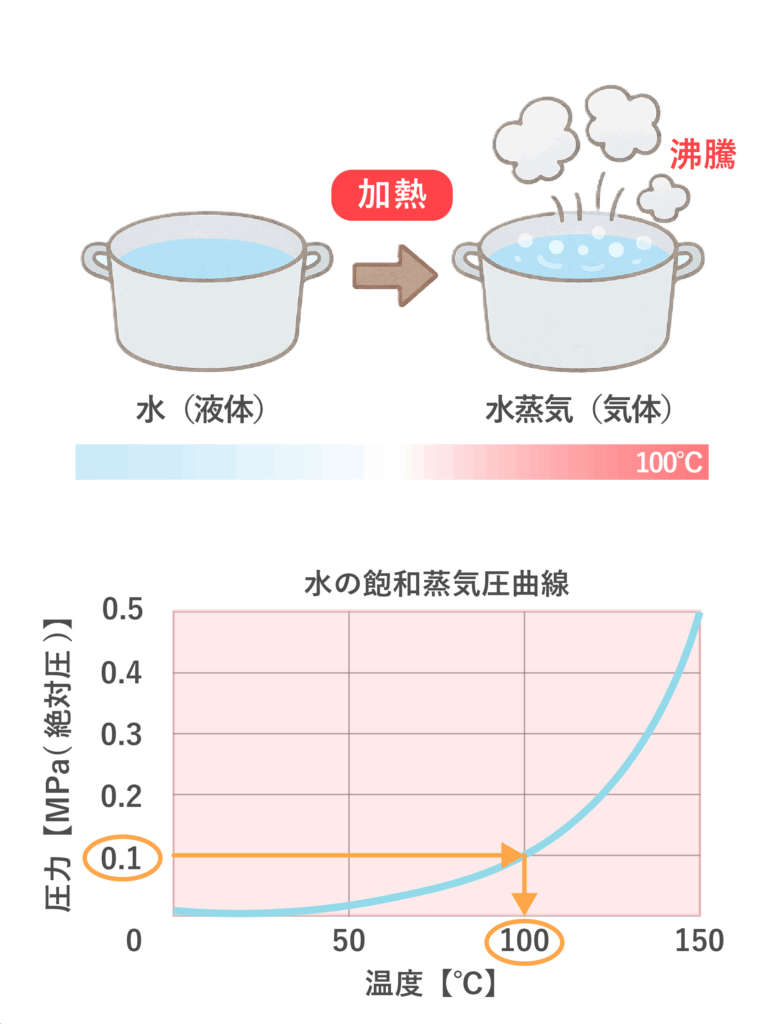

飽和蒸気圧とは

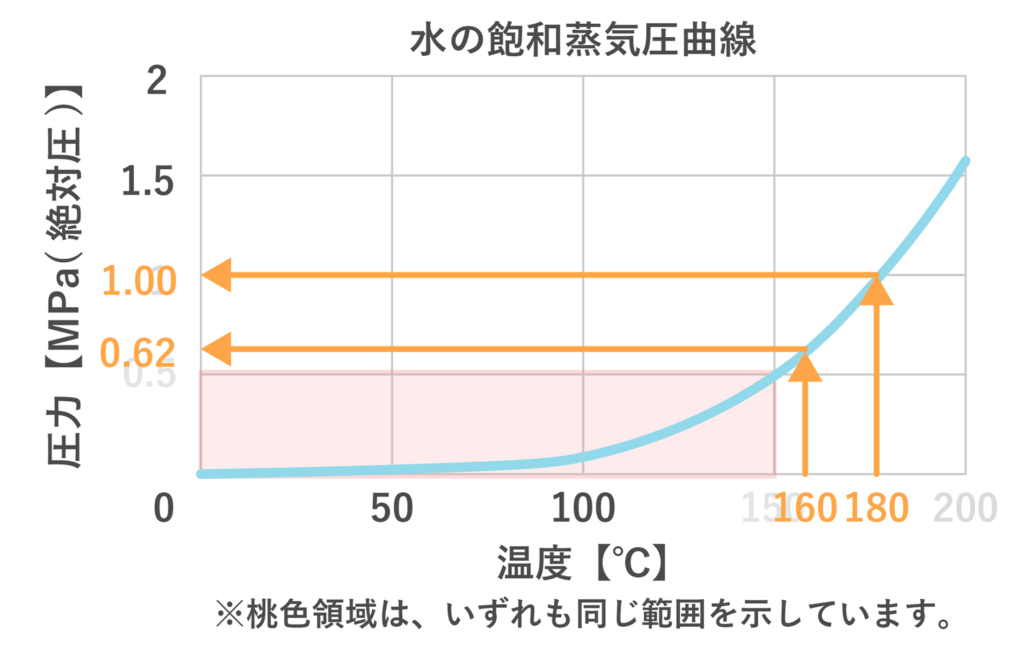

物質が液体のままでいられるか、気体(蒸気)になるかは、その時の温度と圧力のバランスで決まります。

ある温度で物質が液体から気体に変わろうとする圧力のことを「飽和蒸気圧」といいます。この飽和蒸気圧は、温度が上がるほど高くなり、物質ごとに異なる値が決められています。たとえば、水の場合、100℃では約0.1MPa(メガパスカル)の飽和蒸気圧となり、このとき沸騰が始まります。この関係を利用し、温度と圧力のバランスを保つことで、液体が沸騰せず安定した状態を維持できます。

高温仕様の温度調節機で、必要な圧力が決まります。

水を沸騰させずに金型へ循環させるには、系内の圧力をそのときの飽和蒸気圧以上に保つ必要があります。

しかし、通常の設備では給水圧が 0.2〜0.4MPa(ゲージ圧)程度であることが一般的です。

そこで MC5-HH では、媒体温度から必要なタンク内圧を算出し、不⾜する分の圧力を加圧ポンプで補うことで、安定した加圧制御を実現しています。