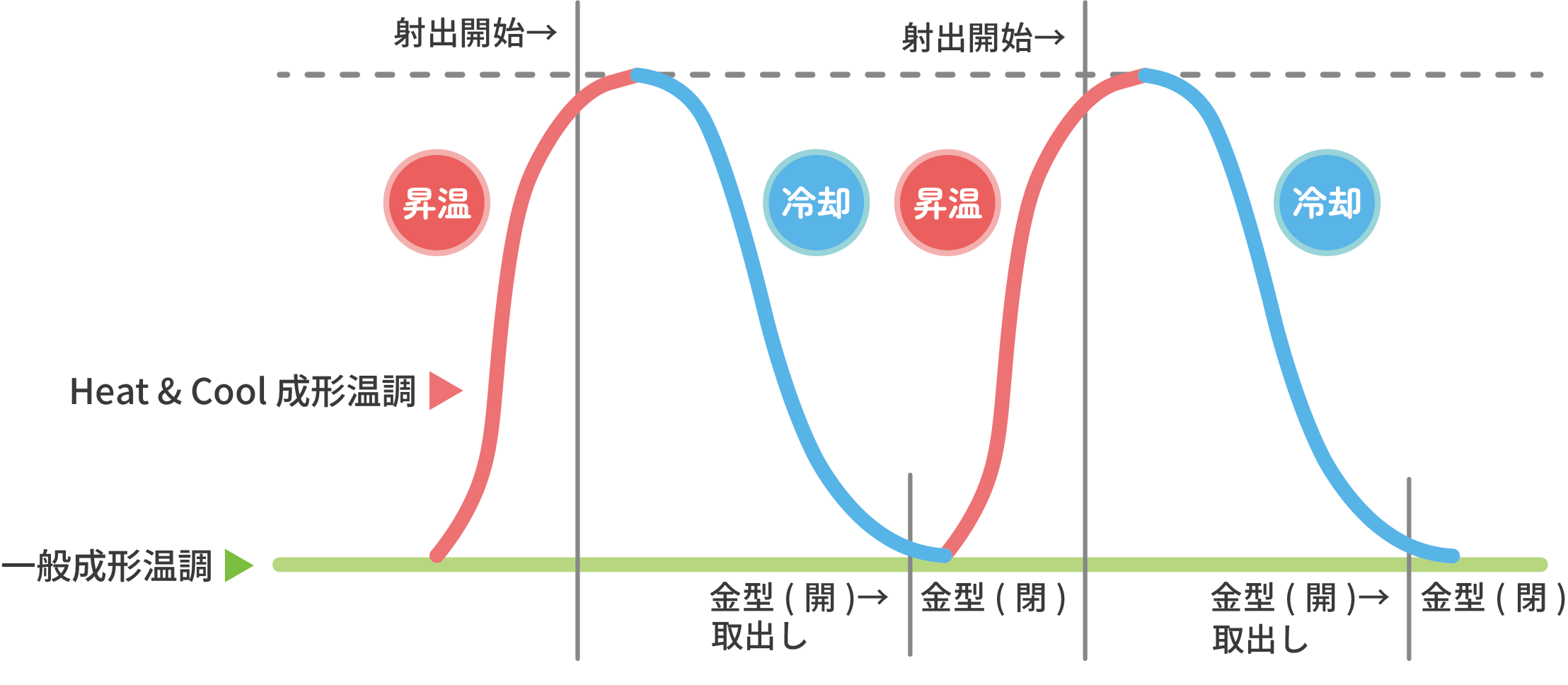

射出成型の品質を決定づける金型温度管理

高機能樹脂で顕在化する、温度制御精度の差

射出成形における製品品質は、金型構造や成形条件だけで決まるものではありません。

近年、ポリフェニレンサルファイド(PPS)やポリエーテルエーテルケトン(PEEK)といった高機能樹脂の採用が進む中で、金型温度の制御精度そのものが、成形品質を左右する重要な設計要素として認識されるようになっています。

これらの樹脂が注目される理由は、結晶化の進行が金型温度に強く依存する結晶性樹脂である点にあります。金型温度が適正範囲から外れると結晶化が不十分となり、寸法安定性や機械的特性の低下を招き、結果として表面品質や強度のばらつきといった品質差が顕在化しやすくなります。

たとえゲート位置や流路設計が適切であっても、金型温度が安定していなければ、樹脂の流動状態や冷却挙動を均一にすることはできません。特にPPSやPEEKのように、外観・寸法・機能性を同時に要求される用途が多い材料では、金型温度のムラや応答遅れがそのまま品質リスクにつながります。

同様の考え方は、他の結晶性エンプラや高機能樹脂にも共通しており、安定した金型温度制御の重要性は、材料を問わず高まっています。

このため、現在の射出成形現場では、金型温度調節機に対しても、単なる加熱・冷却装置ではなく、金型全体を均一に保ち、成形条件を安定して維持するための温度制御システムとしての性能が求められています。媒体流量、温度応答性、制御安定性を金型回路設計と組み合わせることで、高機能樹脂においても安定した成形品質と量産再現性を実現することが可能になります。

MC6-HPの特長

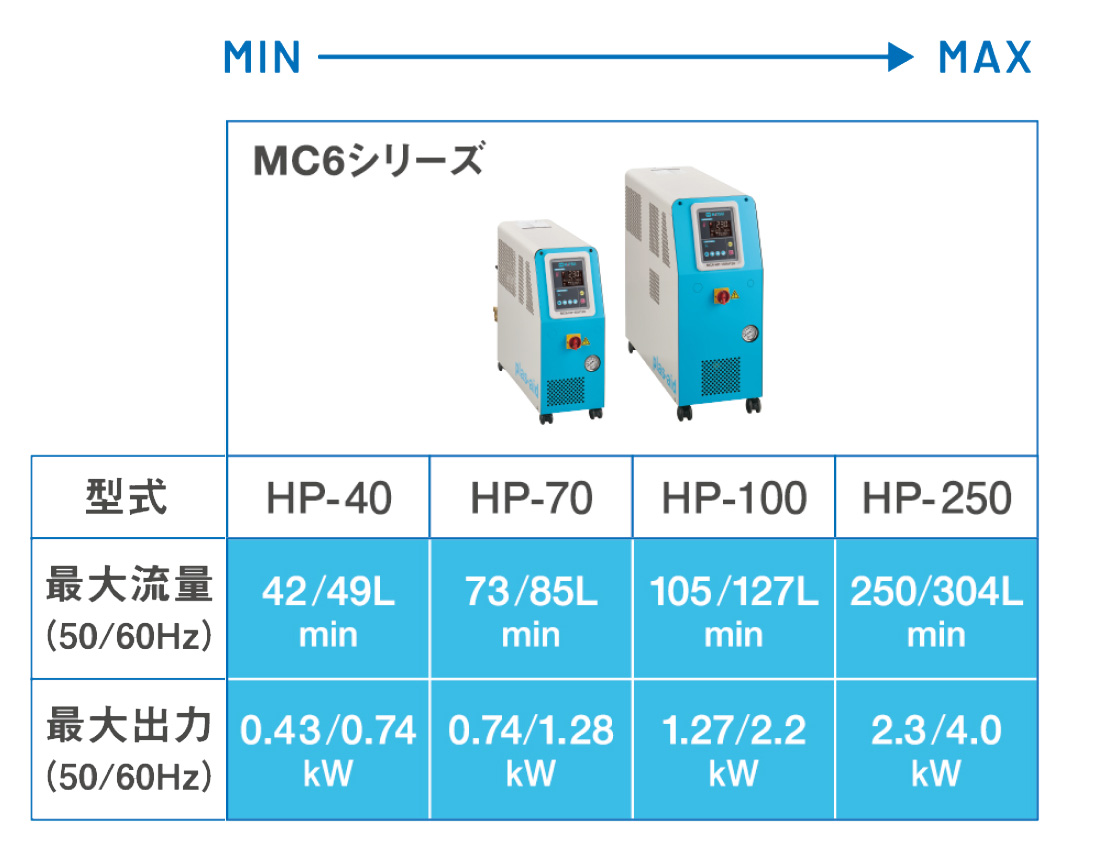

製品ラインナップ

長年にわたりプラスチック成形に携わってきたマツイの「カナオン」に、新たなシリーズ「MC6」が加わりました。

MC6-HPは、成形条件に応じて異なる流量の4タイプをラインナップしており、様々な金型サイズや樹脂特性に対応できる柔軟性を備えています。

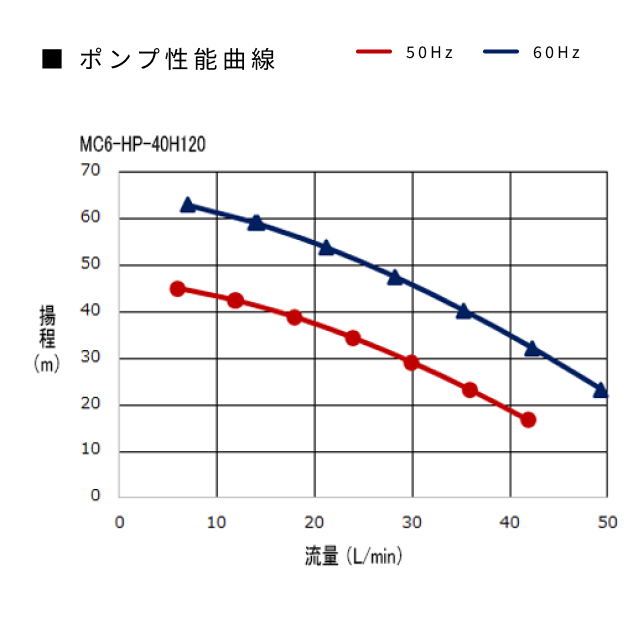

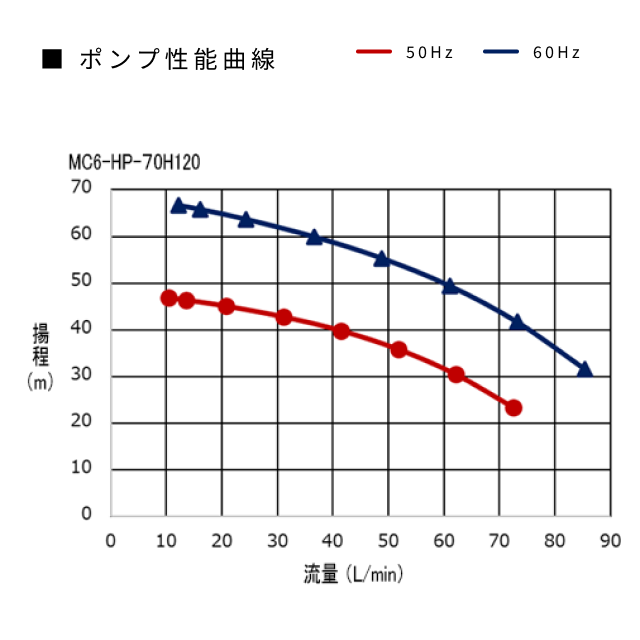

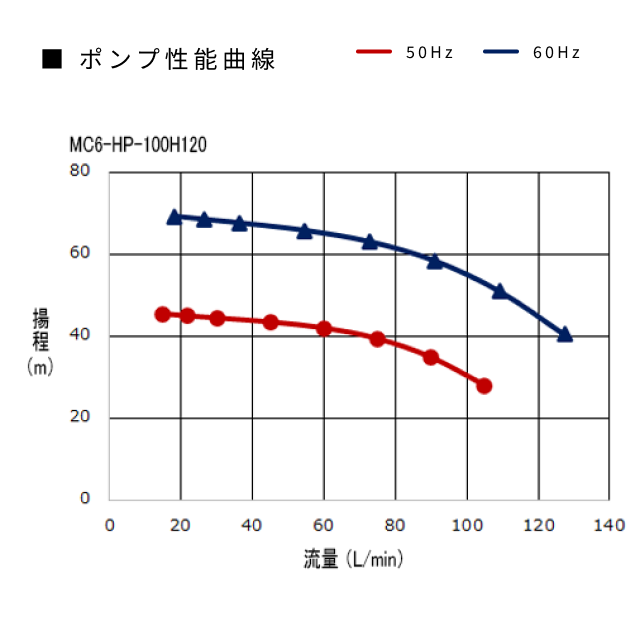

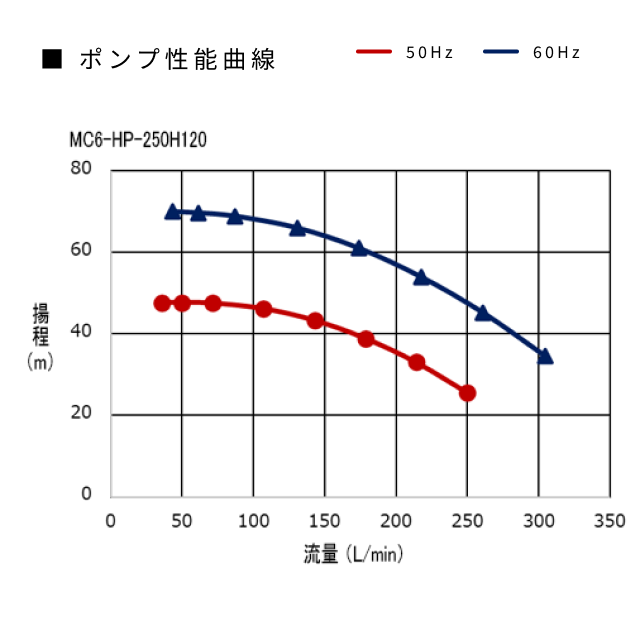

1.多様なニーズに対応する多段渦巻きポンプを採用しました!

カナオンMC6-HPは、多段渦巻きポンプを採用。ゆとりある流量で、多様な成形条件にお応えします。信頼性にも定評のある新型ポンプは低振動・低騒音で、ステンレス製のため防錆性にもすぐれています。

2.精細な温度管理を支える3つの特徴

これら3つの柱によって高機能な温度コントロールを支えます。

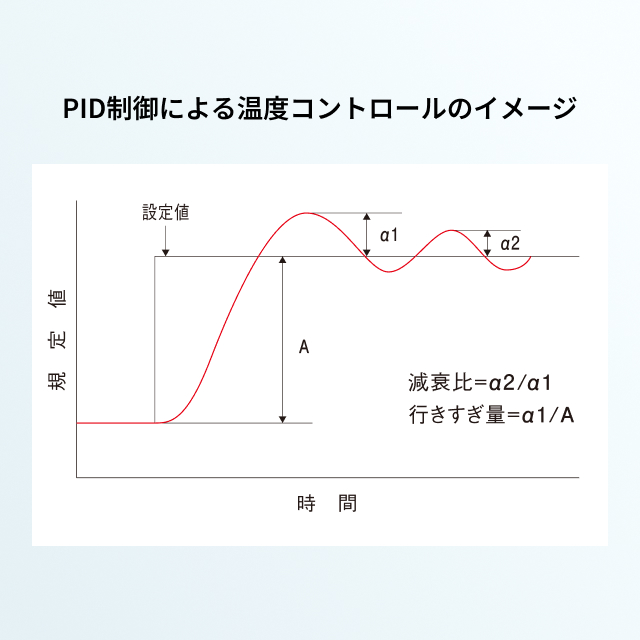

PID制御(フィードバック制御)

PIDとは、Proportional(比例)、Integral(積分)、Derivative(微分)のことを指し、比例制御に積分制御と微分制御を加えたものをPID制御といいます。PID制御において、設定値と現在値の偏差が操作量に比例する、比例制御が基本動作になります。そして、積分制御によってオフセット※を自動的に解消します。微分制御では、外乱による急激な変化に対応し、出力を修正します。これにより、媒体の設定温度を安定化させます。

※ 設定値と現在値に偏差が発生すること

SSR(無接点リレー)

SSR(Solid State Relay)とは、物理的な接点を持たずに電気信号を制御する半導体リレーを指します。リレーの出力部分に半導体を使用しており、可動接点がありません。そのため、SSRは接点リレーと比較し長寿命で動作速度が速いことが特長です。また、接触不良といったリスクがないため、安定した動作が可能となります。

ちなみに、有接点リレー(メカニカルリレー)とは、電磁石の力を利用し、機械的にスイッチを稼働するリレー方式です。

電動機など比較的大きな設備や機器に導入されています。

K熱電対

熱電対とは、2種類の金属線の先端同士を接触させて回路をつくり、接触点に発生する熱起電力を通じて温度差を測定する温度センサです。水銀計、サーミスタといった他の温度計と比較し、応答が早く、温度の測定可能範囲が広いことが特長です。また、温度情報は電気信号として検出されるため、情報処理や解析がシンプルです。

Kタイプの熱電対は、+極:クロメル、−極:アルメルで構成されており、ー40℃~1200℃と高温域の測定が可能なため、工業用途として普及しています。

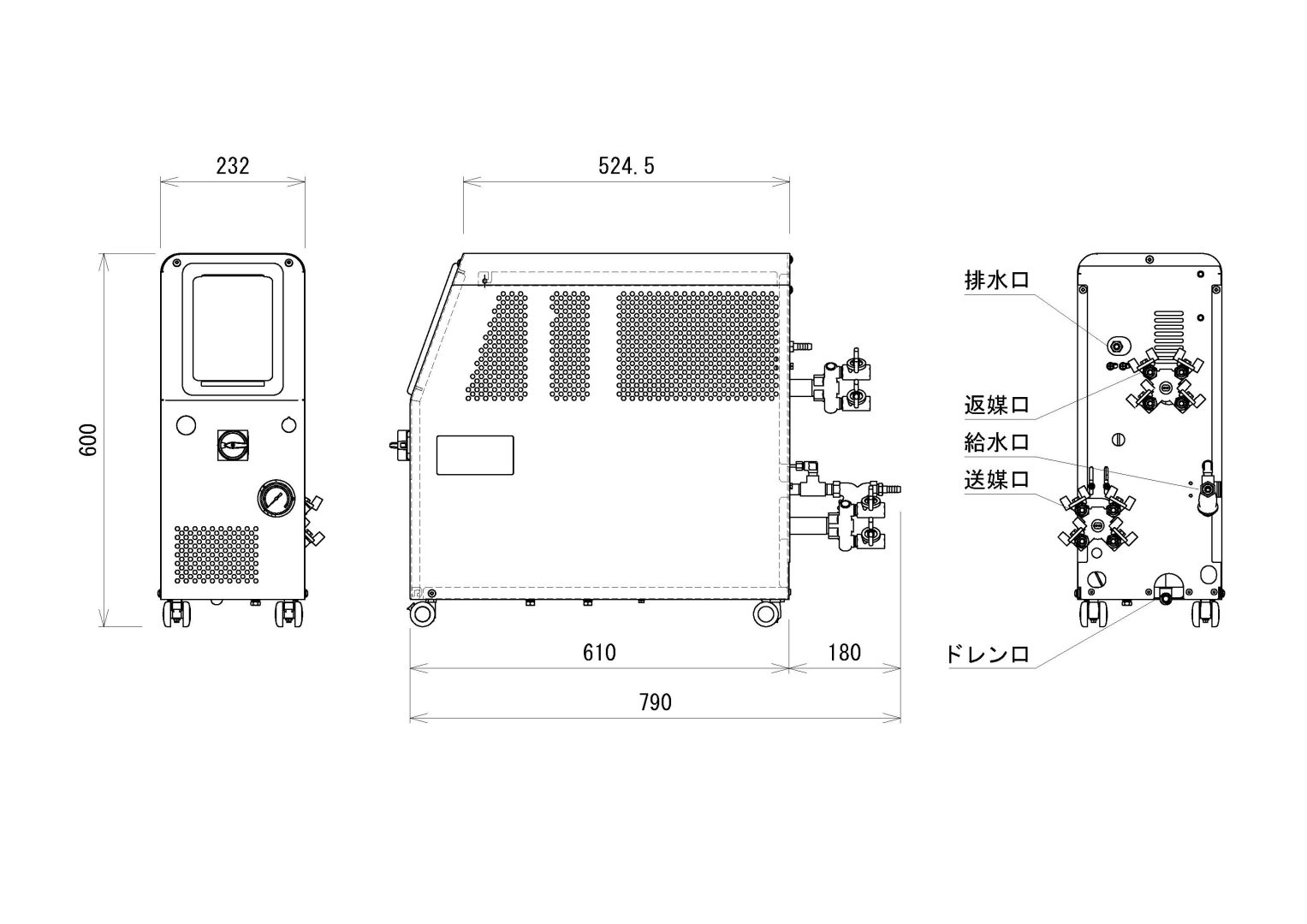

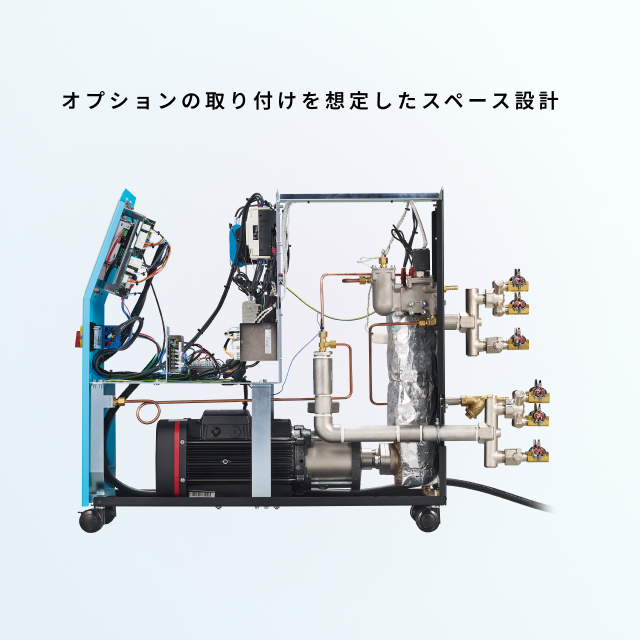

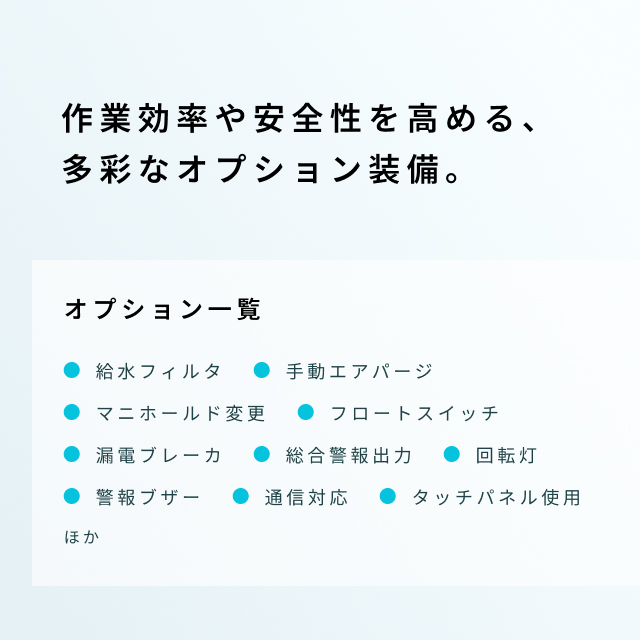

3.成形現場に配慮した筐体サイズを採用!

MC6シリーズは、基本性能を高めながら、可能な限りコンパクトな設計を追求した2サイズの筐体を用意しました。あわせてオプション装備等の取り付けを想定したスペースも確保し、拡張性においても優れています。

4.豊富な通信機能をご用意!

IoTに対応する通信機能として、制御パネルは「SPI、MODBUS通信」に対応。

MC6-HPは、標準プロトコルで成形機からの制御や動作確認など品質管理が可能になります。

あわせて、新たにOPC40082-1( EUROMAP 82.1 )への対応をオプション追加しました。

OPC-UAを導入してみませんか?

Industry 4.0 による機器間通信の需要増加に対応し、MC6-HPはオプション機能として、OPC-UA ※ の導入が可能です。

※ Open Platform Communications- Unified Architecture

OPC-UAとは、機種、オペレーティングシステム(OS)、メーカーの縛りなく、安全で信頼性の高いデータ交換を可能とする、 相互運用を行うための国際基準規格です。

リアルタイムデータや履歴データへのアクセス、稼働情報の監視、警報の表示など、 プラットフォームに依存することなく、成形現場の情報を監視制御システムや生産管理システムとやり取りすることが可能です。 現在、射出成型機の上位接続標準 (EUROMAP77) で採用されるなど、プラスチック成形業界でも普及が進んでいます。

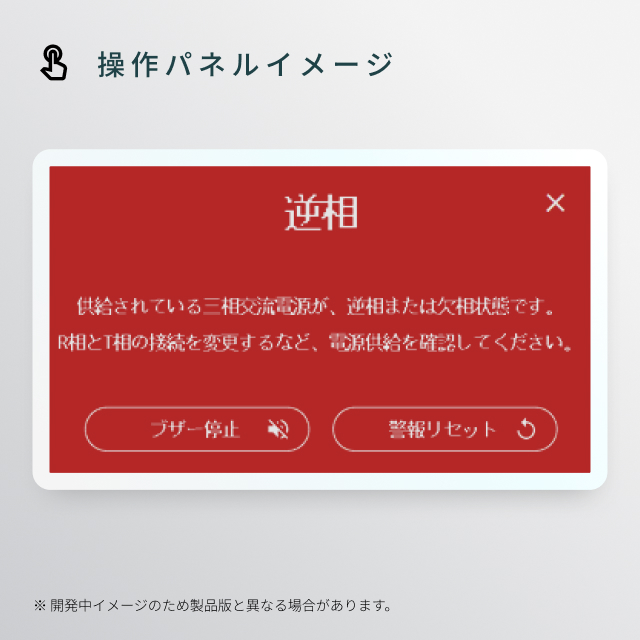

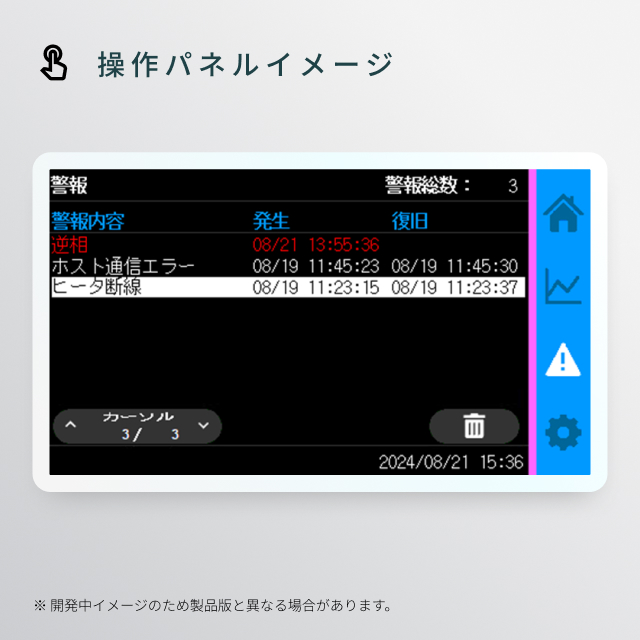

5.タッチパネルをオプション追加しました!

MC6-HPでは、新たにタッチパネルをオプションで選択していただくことが可能です。多言語にも対応しています。ぜひマツイスタッフにご相談ください。

※タッチパネルをご選択された場合、タッチパネルと併用しての選択が不可となるオプションがごさいます。 詳細につきましてはマツイスタッフ、または本サイトの右上にある「お問い合わせ」フォームよりご確認ください。予めご了承いただきますよう、よろしくお願い申し上げます。

もっと知りたい!金型温度調節機と流量の関係

金型温度調節機で流量が必要となる具体的なシーンとは?

金型温度調節機では、温度管理と同様に冷却用熱媒体の流量管理が非常に重要です。

以下に、流量が特に重要となる代表的な成形シーンをご紹介いたします。

✅ 1. 結晶性樹脂の成形(ポリアセタール、ポリアミド、ポリエチレンテレフタレート など)

- 背景:ポリアセタール(POM)、ポリアミド(PA)、ポリエチレンテレフタレート(PET)などの結晶性樹脂は、成形時に冷却が速すぎると結晶化が不十分となり、寸法精度や機械的強度に悪影響を及ぼすことがあります。

- 流量が必要な理由:金型全体を一定の温度に保つために、十分な流量で熱媒体を循環させる必要があります。大型金型やゲートが複数ある金型では、温度ムラが発生しやすいため、安定した流量で均一な冷却を行うことが品質確保につながります。

✅ 2. 高サイクル成形(短時間での大量生産)

- 背景:生産効率向上のため、冷却時間を短縮して成形サイクルを速めたい場合です。

- 流量が必要な理由:熱をすばやく金型から排出するには、温調機からの熱媒体の流量を十分に確保する必要があります。冷却が遅れるとサイクルタイムが延び、製品の歩留まりや寸法安定性に悪影響を及ぼします。

✅ 3. 複雑形状や肉厚差のある製品の成形

- 背景:肉厚が不均一な製品や、複雑な形状の成形品では、部分ごとに冷却速度が異なりやすく、反りやヒケの原因となります。

- 流量が必要な理由:各冷却回路に適切な流量を配分しないと、部分的な過熱が生じ、製品の寸法精度や外観品質に問題が生じます。

✅ 4. 透明樹脂(ポリカーボネート、ポリメタクリル酸メチル など)の成形

- 背景:ポリカーボネート(PC)やポリメタクリル酸メチル(PMMA)は、透明性が求められる製品に使用されるため、微細な応力や白化も許されません。

- 流量が必要な理由:金型内の温度ムラがあると、樹脂の冷却に差が生じ、クラックや光学的欠陥が発生するおそれがあります。透明性を保つためには、金型全体に均等な流量で熱媒体を供給し、温度の安定を図る必要があります。

✅ 5. 高温エンジニアリング樹脂(液晶ポリマー、ポリフェニレンサルファイド など)の成形

- 背景:液晶ポリマー(LCP)やポリフェニレンサルファイド(PPS)などのエンジニアリングプラスチックは、高温での成形が必要です。

- 流量が必要な理由:高温状態で安定した温度制御を行うには、熱媒体の流量を確保する必要があります。温度変化が急すぎるとヒートショックによるクラックが生じやすくなるため、適切な流量制御が非常に重要です。

🔧【補足】流量と温度の関係について

なぜ「流量」が重要なのか?

金型に熱を供給・除去する能力は、以下の式で表されます:

Q=m⋅c⋅ΔT

- Q:熱量(J)

- m:流量(kg/s)

- c:比熱(J/kg·K)

- ΔT:温度差(K)

つまり、温度が高くても流量が少なければ、熱の移動が不十分になります。

そのため、設定温度が正しくても流量が不足していると、十分な冷却や加熱が行われず、温調が安定しない場合があります。特に、近年の高機能樹脂や高精度製品では、温度制御だけでなく、熱媒体の流量の安定と均一性が製品品質に直結します。