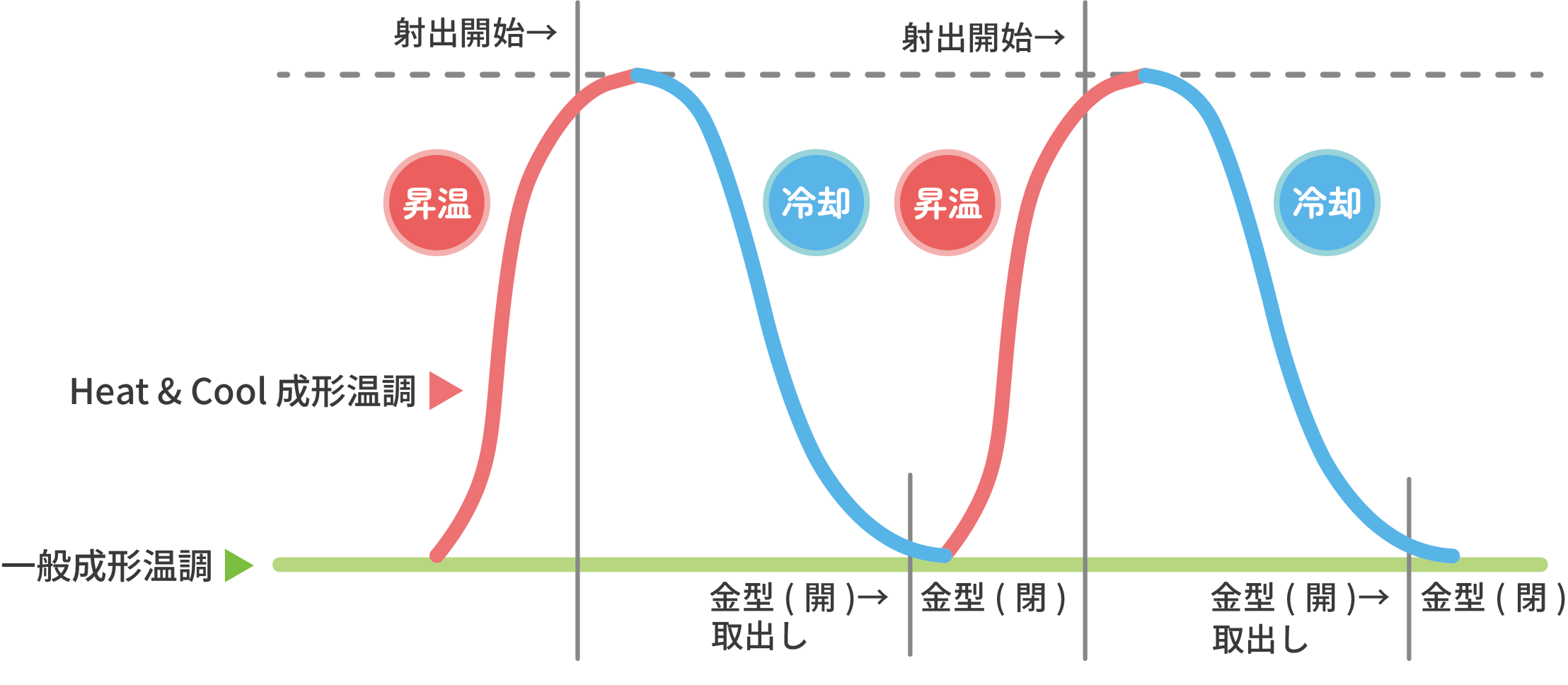

Cooling quality changes with Lift- When pressure is needed to control mold temperature

In Mold Temperature Controller, there are many situations where the "flow rate (L/min)" is important in order to improve the efficiency of cooling and heating. By ensuring a large flow rate, a large amount of cooling water or heat transfer medium can be supplied to the mold, and heat can be removed efficiently. In particular, under molding conditions where cooling efficiency is directly linked Reduction in cycle time, it is important to ensure a large flow rate.

An example of a use where flow rate is particularly important is molding using "polypropylene (PP)" or "polystyrene (PS)".

High speed molding with these general-purpose resins requires cooling in a short time, so large flow rate temperature control that can supply a large amount of temperature control medium is effective.

On the other hand, depending on the molding conditions, mold structure, and resin used, there are cases where "pressure (Lift)" is more important than the flow rate itself. If the piping resistance is large or the cooling circuit is complex, the fluid may not reach the end of the circuit unless it is pushed out with sufficient pressure, resulting in poor cooling.

In such a situation, Mold Temperature Controller requires high Lift performance. If the pressure is insufficient, even if the pump is outputting a high flow rate, the fluid will not enter the circuit, and there will be areas that are not cooled. As a result, the risk of defects such as warping, sink marks, whitening, and gas burns in the product increases.

An example of a use where pressure (Lift) is particularly important is molding using "polyacetal (POM)" or "polyamide (PA)".

For these crystalline resins, temperature control has a significant effect on the quality of the molded product, so the cooling circuits tend to be complex and long. Therefore, high-pressure temperature control is essential to ensure the extrusion of the medium.

Therefore, it is important to select Mold Temperature Controller that balances flow rate and pressure according to the mold and product design, and the properties of the resin used.

Kanaon introduces the new Mold Temperature Controller MC6-SP!

Product lineup

The MC6-SP comes in three types with different flow rates depending on molding conditions.

It is particularly suited to achieving both low flow rate and high pressure, which is required for small precision molding, and allows you to select the optimal mold temperature control according to the shape of the water pipes inside the mold.

As a new Matsui solution, it will contribute to your plastic molding.

Features

1. High pressure temperature control without compromise even with low flow rates.

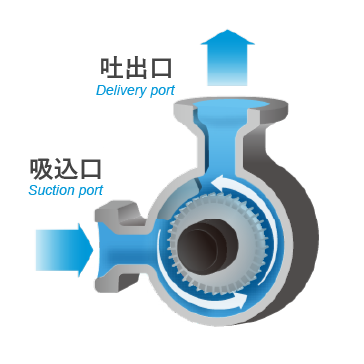

The MC6-SP uses a cascade pump to supply temperature control medium at a stable pressure even at a small flow rate.

In particular, in molding with strict cooling conditions, such as small molds with thin water pipes and high piping resistance, or multi-cavity molds with complex water pipes, the medium is pushed out reliably to every corner of the circuit, suppressing temperature unevenness, achieving stable quality of molded products and optimized cycle time.

It uses a vortex turbine impeller that applies strong pressure even with a low flow rate, efficiently supplying a stable water flow.

2. Diverse communication functions suitable for data sharing and remote monitoring.

The MC6-SP comes equipped with a control panel that supports serial communication (RS-422A/485) as Standard specification, and it is possible to send and receive control signals from the molding machine and check the operating status through a general standard protocol. This allows the operation of the equipment to be centrally managed from the molding machine side, leading to more efficient quality control and process management.

Furthermore, an optional control panel that supports OPC-UA is also available, allowing you to monitor operation data in real time from a remote location, helping to reduce the burden of management tasks and ensure timely responses.

It also supports SPI and MODBUS communication, allowing centralized management of changes to settings, etc.

3. Flange structure improves water resistance and workability.

The connection uses a flange structure, allowing for smooth disconnection and reconnection when working. In addition to the highly airtight flange structure, we have also redesigned the internal structure to reduce the burden of working around water and further reduce the risk of water leaks.

The mechanism behind the "flange structure" that is essential for ease of maintenance

A flange structure is a structure in which a flat, plate-like protrusion like a brim is provided at the connection point of the parts, allowing them to be firmly fastened together with a bottle or similar object.

This structure not only enables the pipes to be securely fixed together, but also makes it easy to disassemble and reassemble, making it easy to maintain.

Another major feature is that a high level of sealing (watertightness) can be ensured by inserting packing into the connection surface. It is widely used in the connections of machinery and piping equipment, and is often used in sites where repeated inspections and part replacements are required.