Features

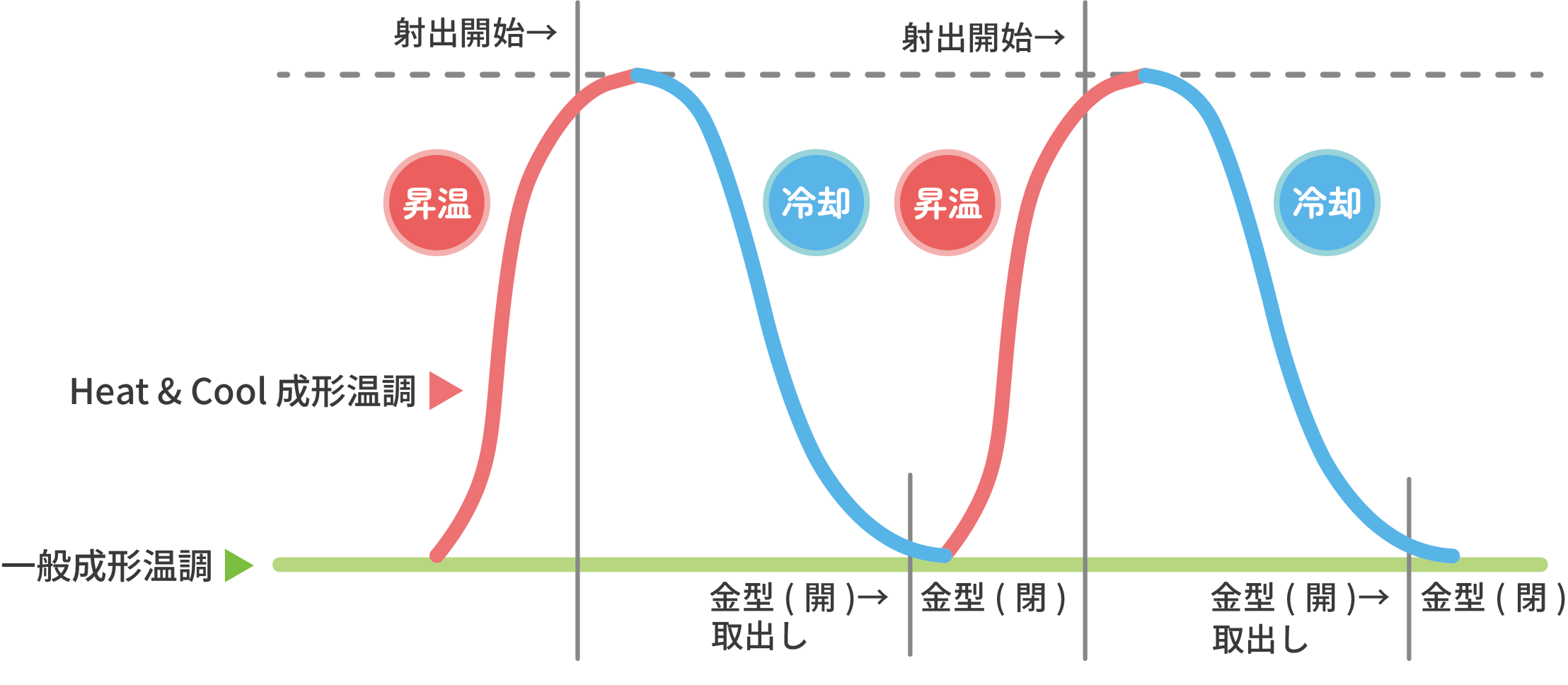

1. Highly accurate temperature control ensures stable molding

By using an SSR (contactless relay) in the heater control circuit, stable temperature control with excellent responsiveness is achieved. By suppressing temperature variations and maintaining the set temperature with high precision, it contributes to stabilizing molding quality. As it is a large flow type, stable temperature control is possible even in molding with large molds with large surface areas or multi-cavity molds, and in high-cycle molding with cooling times shortened to the limit.

2. High safety thanks to multiple protection designs

The floatless switch (L/H) with no moving parts is used to improve the reliability of transition detection.In addition, it has a protection function that trips the power breaker in the event of Overheating.

The safety-focused design allows you to operate the equipment with peace of mind.

3. Excellent maintenance design reduces operational costs

The use of SSR reduces contact friction and other trouble factors, ensuring long-term stable operation. Reducing the frequency of part replacement and maintenance work contributes to reducing maintenance burdens and running costs.

Additionally, alarm signals can be output via a connector (optional), making facility management easier.

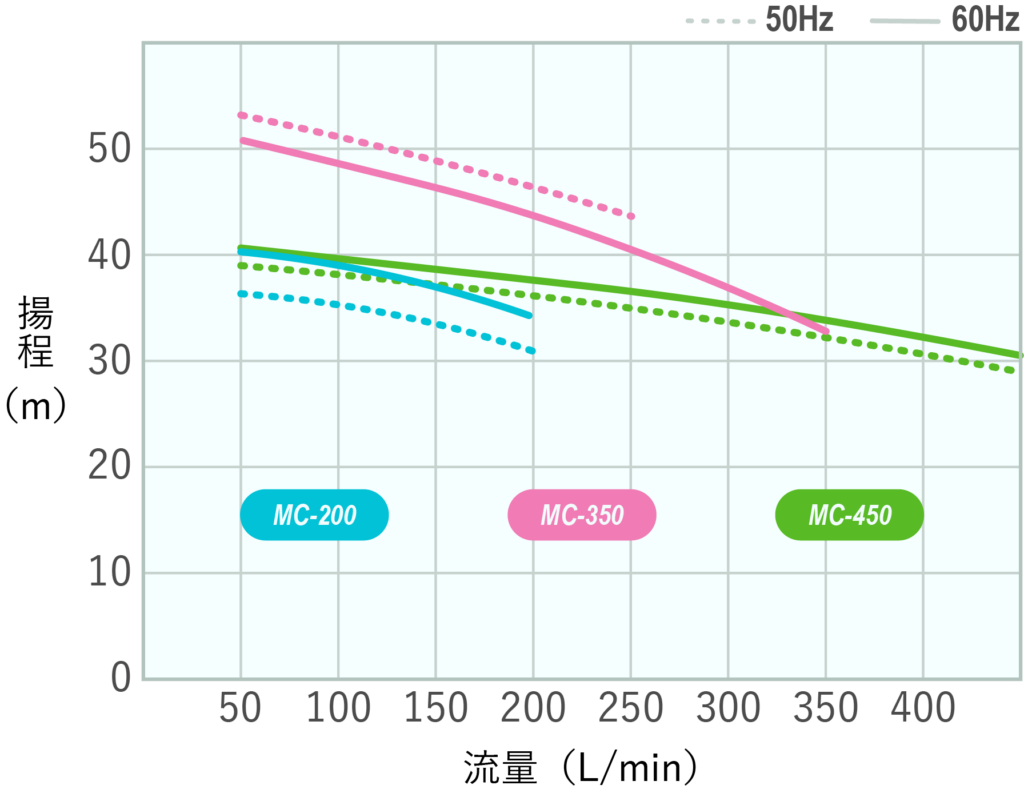

■ Pump performance curve

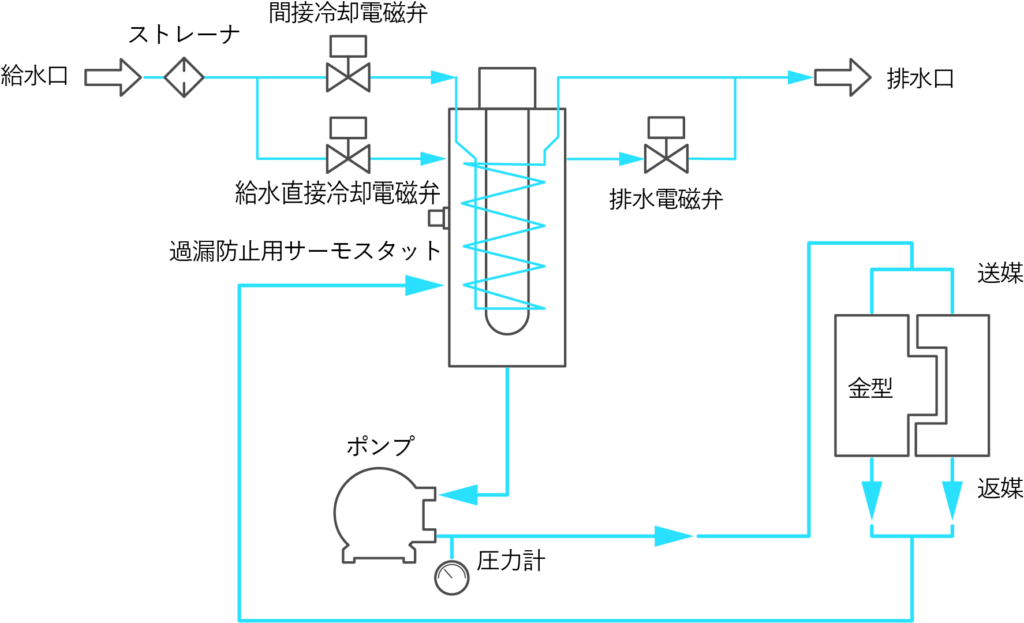

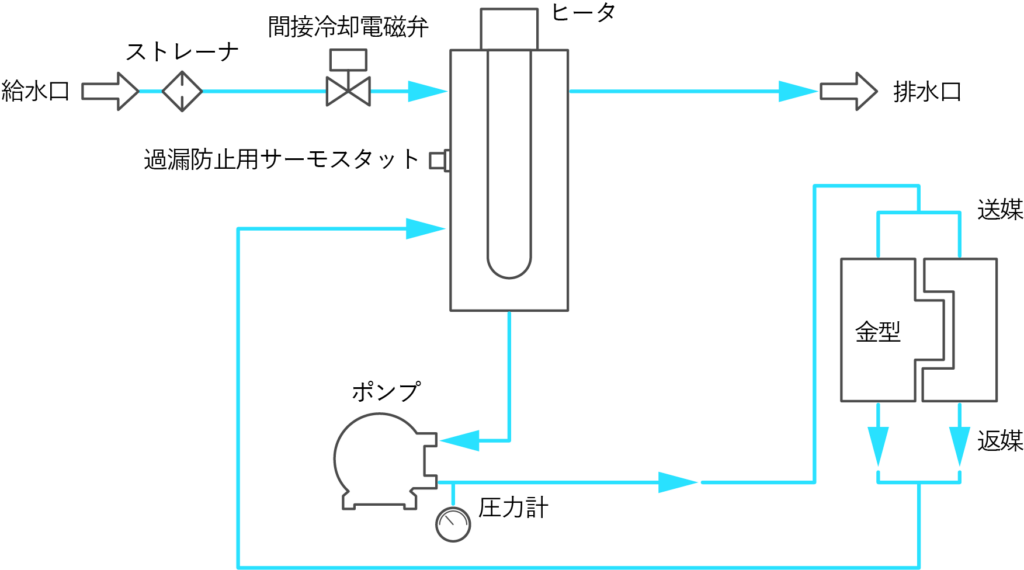

Flow Diagram

Direct cooling LX

Indirect cooling HX