Drying Quality that Maximizes the Potential of Engineering Plastics

In recent years, high-performance resins such as liquid crystal polymer (LCP) and polyphenylene sulfide (PPS) have been increasingly used in electronic components and precision mechanical parts. While these resins have low moisture absorption, even a small amount of moisture can cause molding defects, so sufficient drying before molding is essential.

Especially for materials that require high-temperature molding, the quality of the drying air is directly linked to the stability of the product.

MJ3 supplies stable air with a low dew point, and is more effective at suppressing molding defects than conventional hot air drying methods.It also prevents resin deterioration due to oxidation, contributing to improved yields and reduced manufacturing costs.

Features

1. Honeycomb Dehumidifying Dryer that achieves a low dew point of -40°C

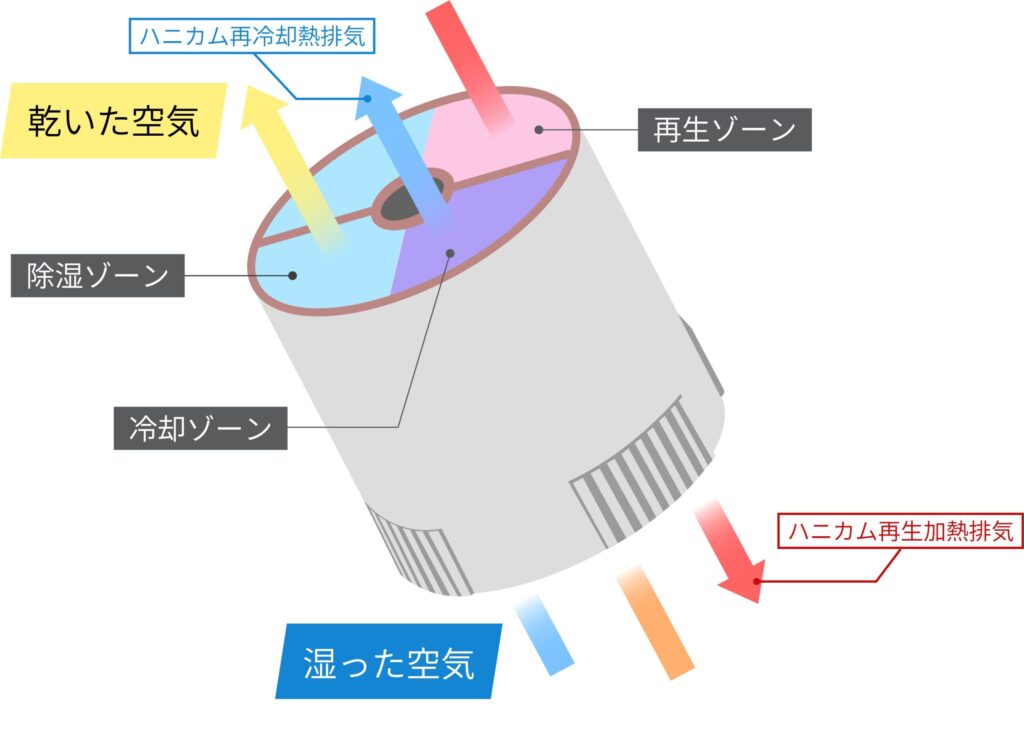

The MJ3 uses a honeycomb rotor to provide a three-zone continuous cycle of "dehumidification, regeneration, and cooling," providing a stable supply of dry air with an ultra-low dew point of -40°C under normal use.

As the rotor slowly rotates, it absorbs moisture from the air sent to the drying hopper in the "dehumidification zone," and then in the following "regeneration zone," the absorbed moisture is evaporated by superheating with high-temperature air to restore its absorption power.Furthermore, in the "cooling zone," the rotor, which has become hot after regeneration, is cooled to an appropriate temperature to prepare for the next dehumidification.

By continuously performing this cycle without stopping, the dew point of the dried air can be maintained stably.The complete regeneration cycle prevents deterioration of the adsorbent's performance, maintaining drying quality close to its initial performance for a long period of time.

2. Stable control achieved by using SSR (contactless relay)

SSR (contactless relay) for the heater control circuit reduces maintenance frequency and greatly improves safety.

A Solid State Relay (SSR) is a semiconductor-based relay that controls electrical signals without any physical contact. It features semiconductors in place of mechanical contacts, making it free from moving parts. This design gives SSRs a longer lifespan and faster switching speeds compared to traditional contact relays. Additionally, with no risk of contact failure, SSRs ensure reliable and stable performance.

By the way, a contact relay (mechanical relay) is a relay type that uses the power of an electromagnet to mechanically operate a switch.

It is typically used in larger equipment such as electric motors.

3. Double hopper provides reliable drying quality

It uses a double-type hopper with a space between the inside and outside of the hopper. This structure makes it less susceptible to the effects of outside temperature, ensuring stable drying quality regardless of the season or weather. It is also ideal for drying resin, which has high moisture absorption and can cause molding defects even with a small amount of moisture.

In addition, the excellent insulation effect of the double structure keeps the temperature inside the hopper constant, which results in improved drying efficiency and uniform drying, and also reduces heat radiation to the outside, contributing to reduced energy loss.

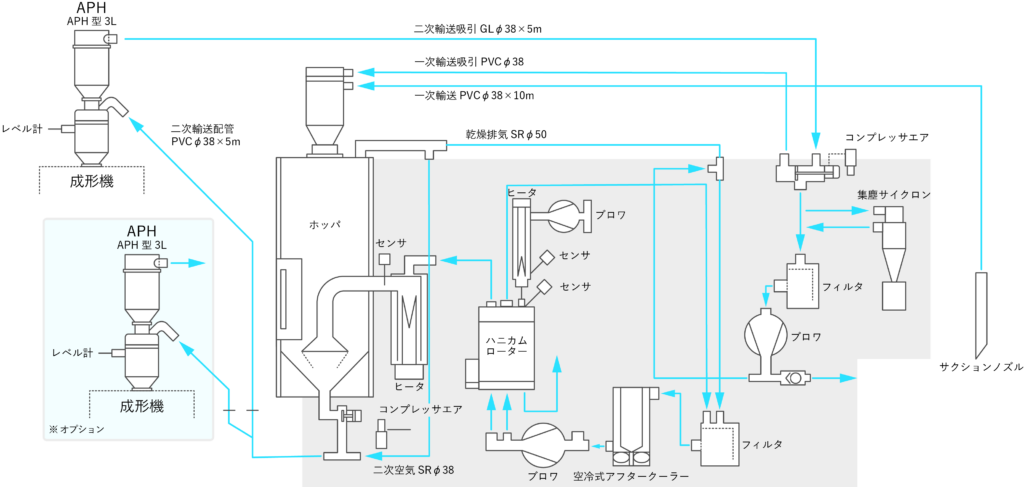

Flow Diagram

Example: MJ3-50J, 70J

Secondary NO2 transport (two-way transport) is available as an option.