- Simple gas venting with a vacuum ejector is available.

- The air booster allows the pressure to increase up to 4.5 MPa. Gas venting and backwashing of the porous section prevent gas clogging.

- Unique control allows any desired timing of operation setting.

- Fixes metal worms during hoop forming to prevent misalignment and biting.

- The number of protruding pins is reduced by using pressurized air as a mold release aid.

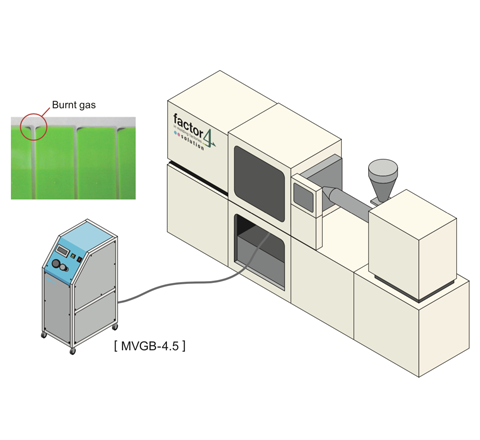

Gas Booster with Vacuum Function MVGB-4.5

Vacuuming and pressurization equipment with compressor air. During vacuuming, gas and air that accumulates in the mold are sucked out and exhausted. During pressurization, gas adhesion to gas bends and porous parts is prevented. The new application also contributes to improved productivity in hoop molding.