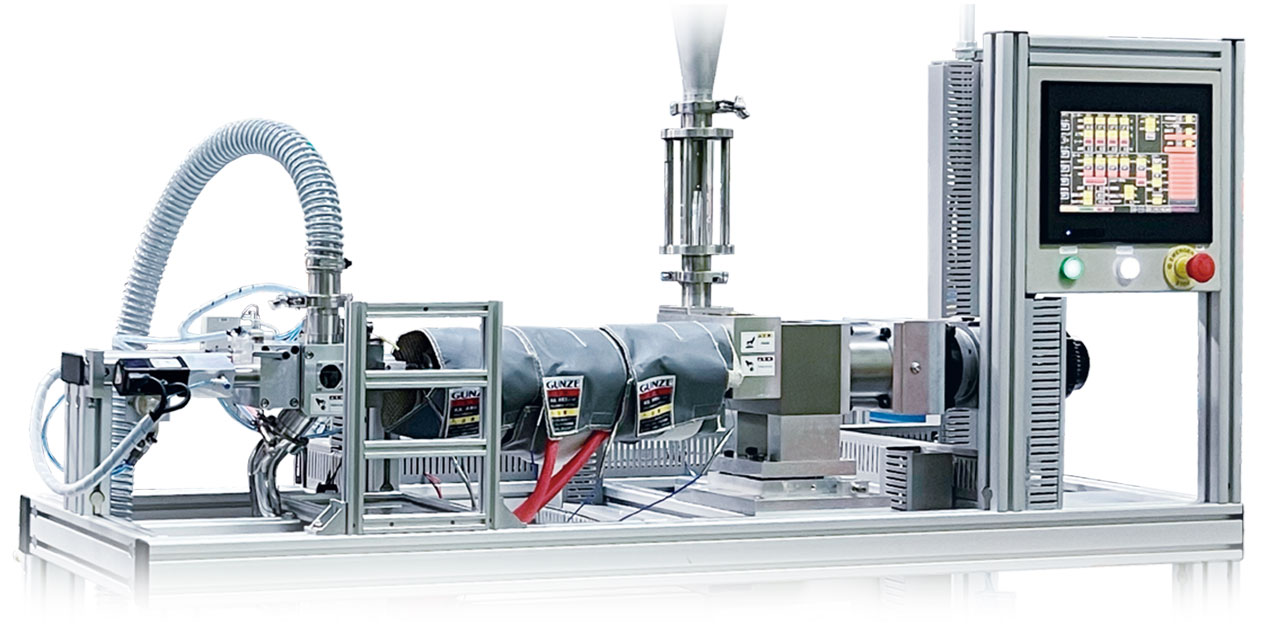

Features of Raptor22ST2

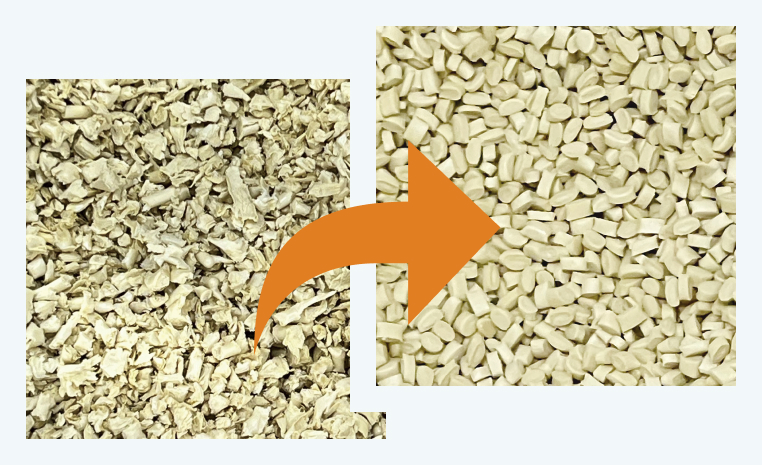

1. Compatible with a wide range of engineering plastics and super engineering plastics:

Engineering plastics and super engineering plastics are easily and efficiently pelletized. Our fully automated process ensures stable recycling and enables high-volume production of high-quality recycled pellets. This contributes to environmentally friendly recycling and supports the SDGs.

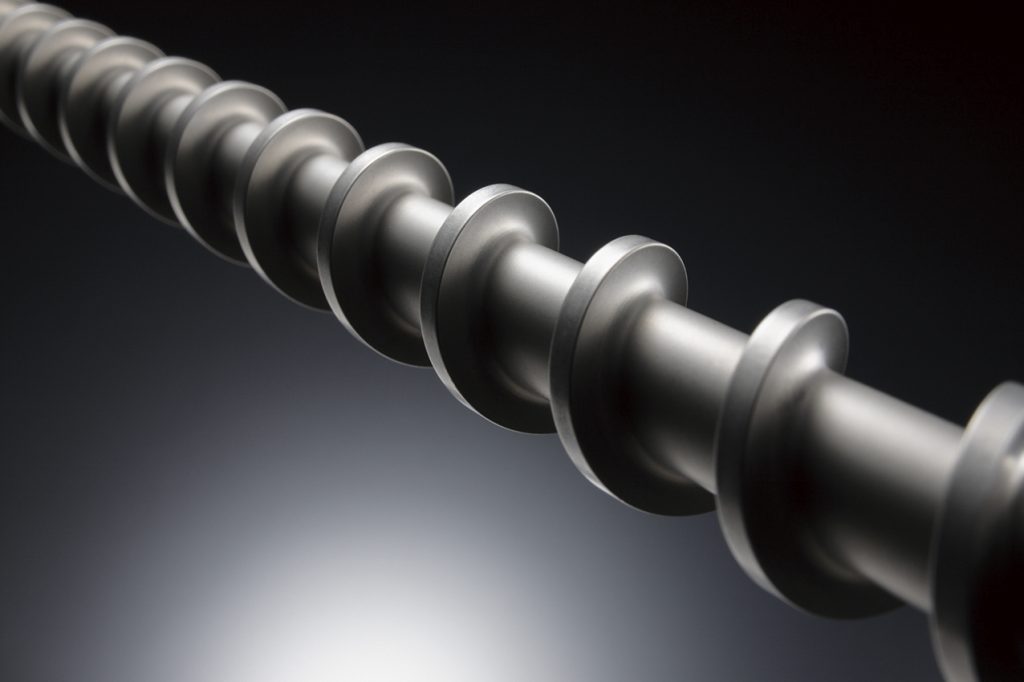

2. Minimal thermal history to maintain material properties:

Equipped with a specially designed non-compressive screw of short overall length. Since no shear heat is generated, precise and detailed melting temperature settings using a heater and minimal heat history enable recycling without changing the physical properties of the resin. This allows for repalletization with the same quality as virgin material.

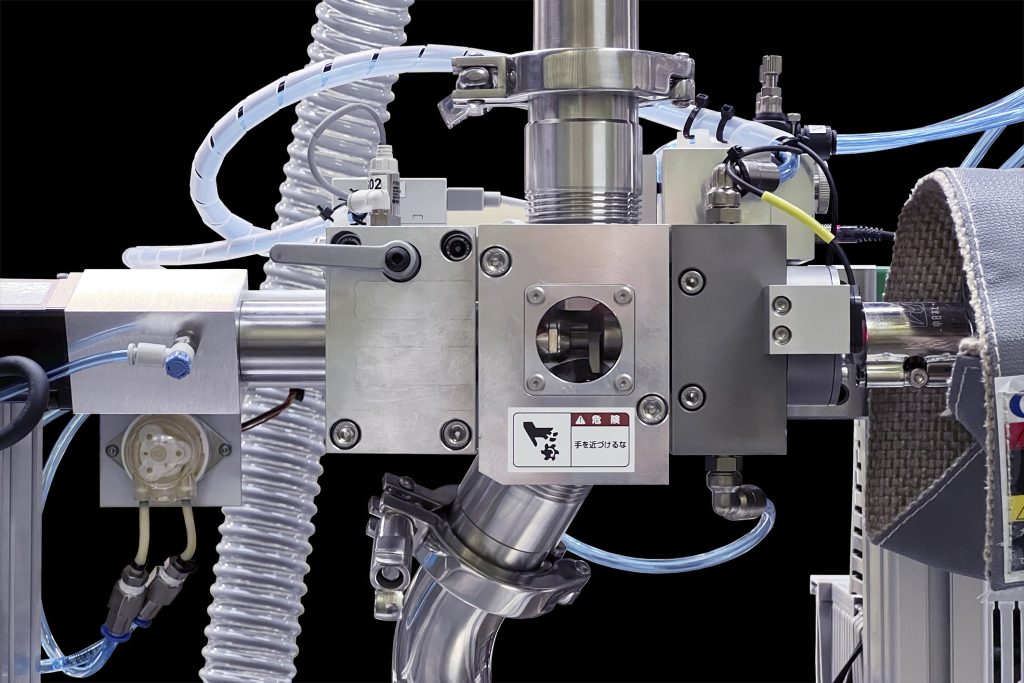

3. Excellent stability by PID control:

Based on the monitored screw torque value, the resin supply device is PID controlled to optimize the supply amount, enabling extremely stable plasticization and strand discharge.

4. Easy to operate and fully automatic operation:

Just slide the cutter unit and touch the start key to start. After that, mass production will be fully automated by sequence control.

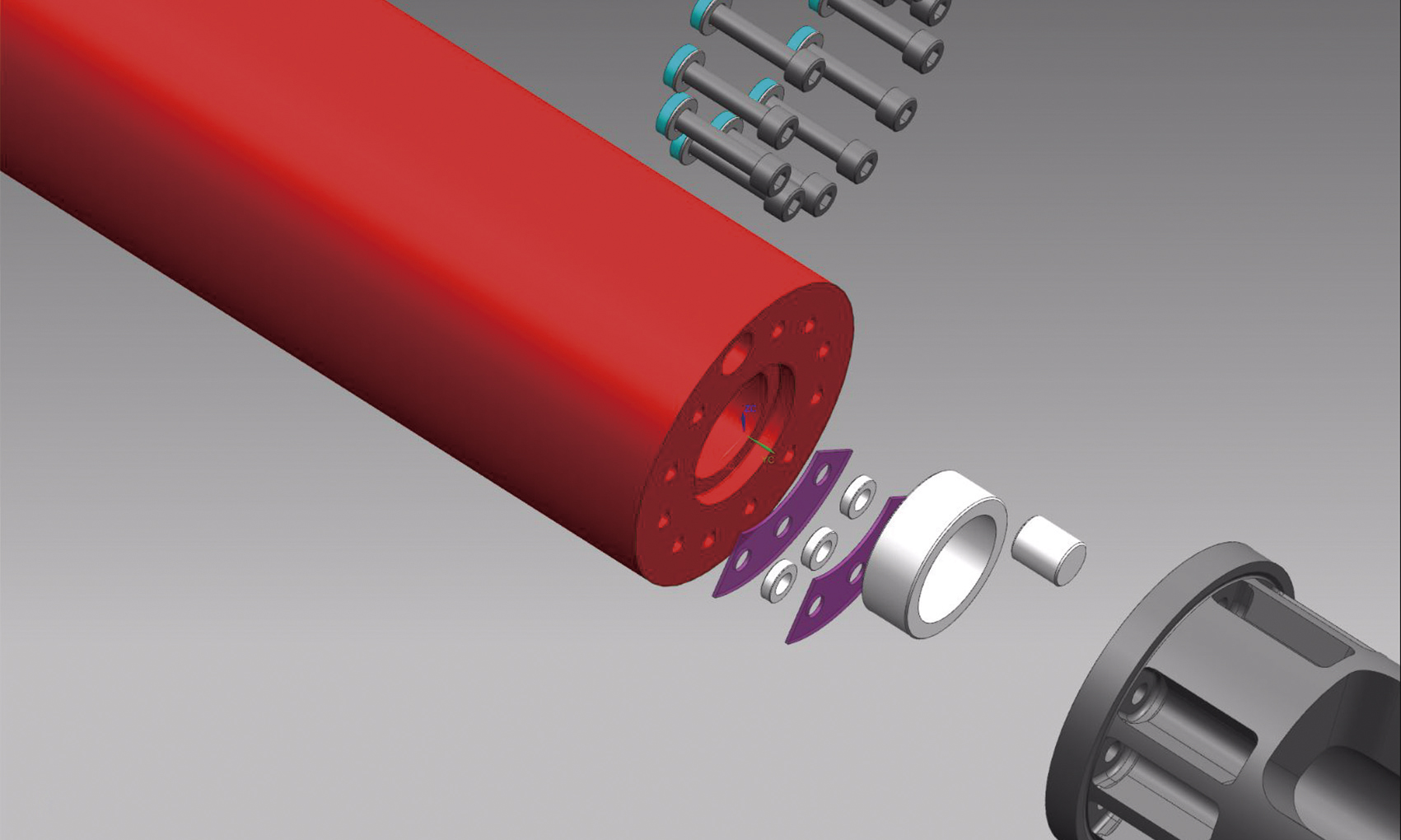

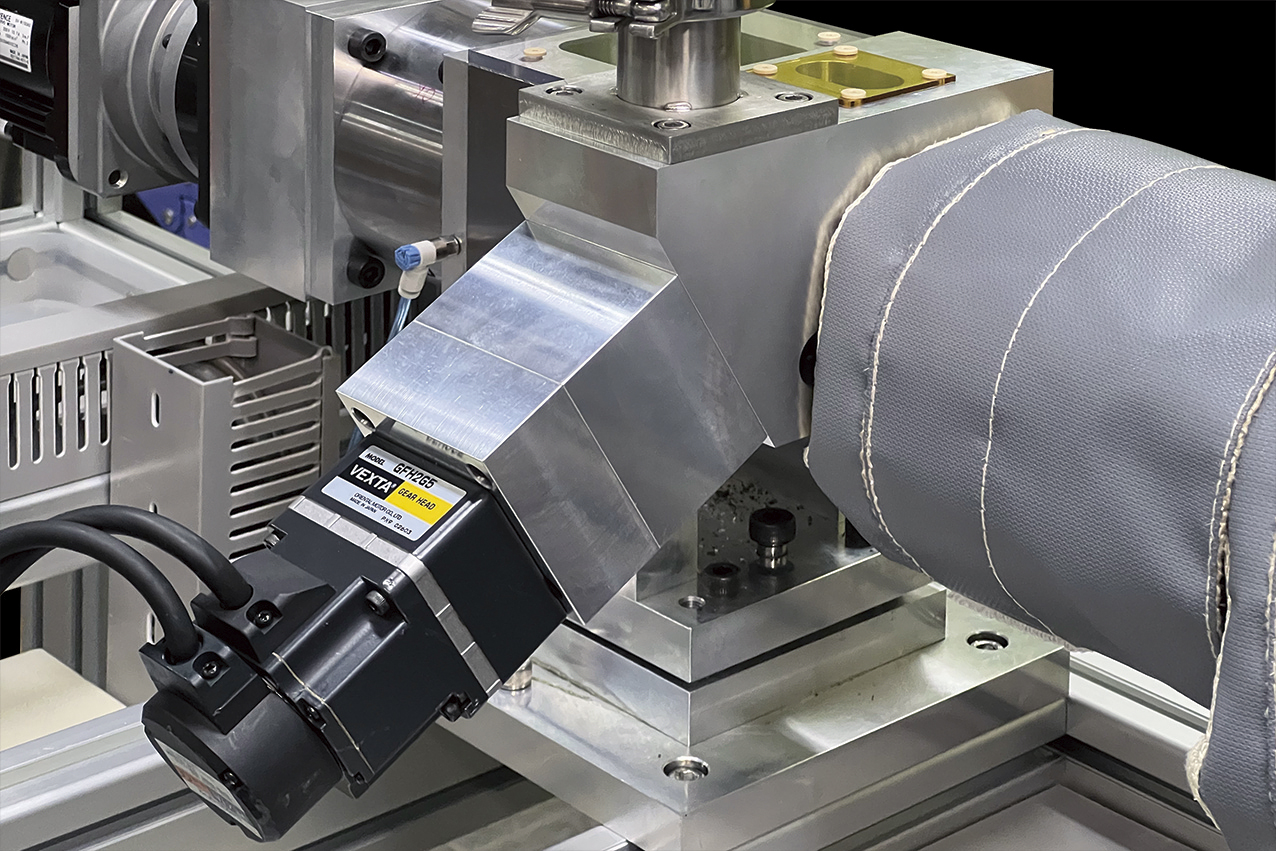

5. Reduced power consumption by installing insulated barrel:

The barrel (cylinder) is separated at the hopper block connection and fixed via an insulating zirconia ring. This is an energy-saving specification that blocks heat transfer from the heater to the hopper block and significantly reduces power consumption.