Crushing is an option that supports in-factory recycling

The expansion of the recycled plastics market and the changes required for the manufacturing industry

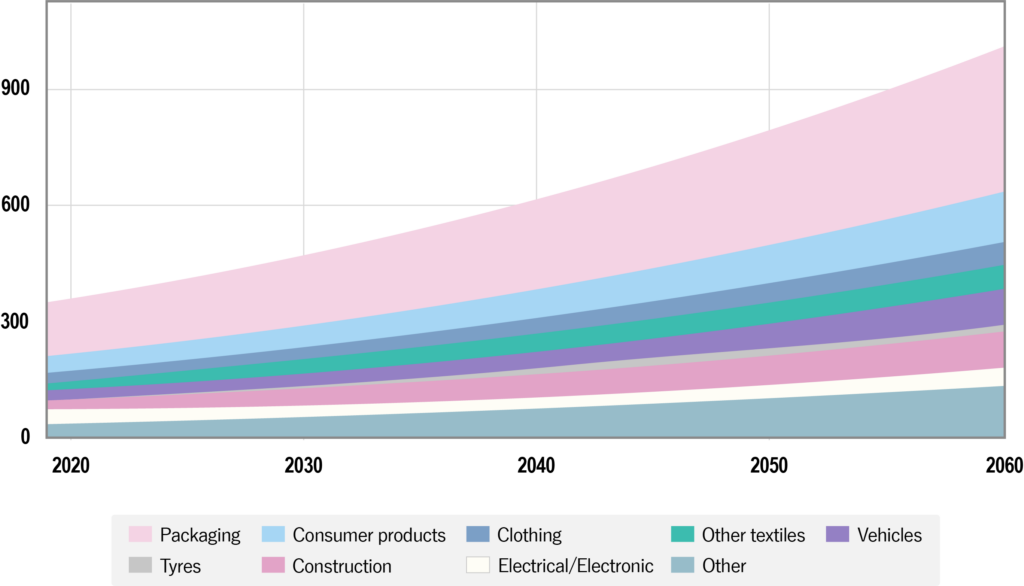

In recent years, the social environment surrounding plastics has undergone major changes. In addition to growing interest in the issue of plastic waste, there is a global trend toward a "circular economy" that relies on the use of recycled plastics.

According to an OECD report, the amount of plastic waste worldwide is expected to triple by 2060, while the recycling rate remains at less than 20%. To address this issue, there is a strong demand for countries and industries to shift to "manufacturing that does not assume waste."

Total amount of plastic waste by use (million tons)

Against this backdrop of global trends, the recycled plastics market is steadily expanding in Japan as well. According to a survey by the IMARC Group, the size of Japan's recycled plastics market is estimated to be approximately 9 million tons in 2024, and is predicted to reach 11.2 million tons in 2033. Behind this growth are increasing demand for environmentally friendly products, government policies promoting the use of recycled materials, and advances in recycling technology. In the manufacturing industry, too, the use of recycled materials is changing from an "option" to a "prerequisite."

Treat sprues and runners as valuable resources

In this context, sprues, runners, and defective products that are generated on a daily basis during the molding process are being reexamined. Traditionally, these have often been treated as "by-products that cannot be made into products," and the general practice has been to collect, discard, or outsource their processing. However, if we change our perspective, these are valuable raw materials with clear quality and controlled sources.

In-process recycling involves crushing sprues and runners on-site and reusing them as Regrind material.

・Reducing material waste

・Reduction of raw material costs

- Reduction of man-hours related to storage, transportation and disposal

・Reducing environmental impact

It achieves multiple effects at the same time.

In particular, closed recycling systems that complete the entire process from collection to reuse within factory are attracting attention because they make it easier to reduce quality variations and maintain stable molding conditions.As the use of recycled plastics expands today, the questions of "how to reuse" and "at which process to ensure quality" are directly linked to both product quality and corporate value.

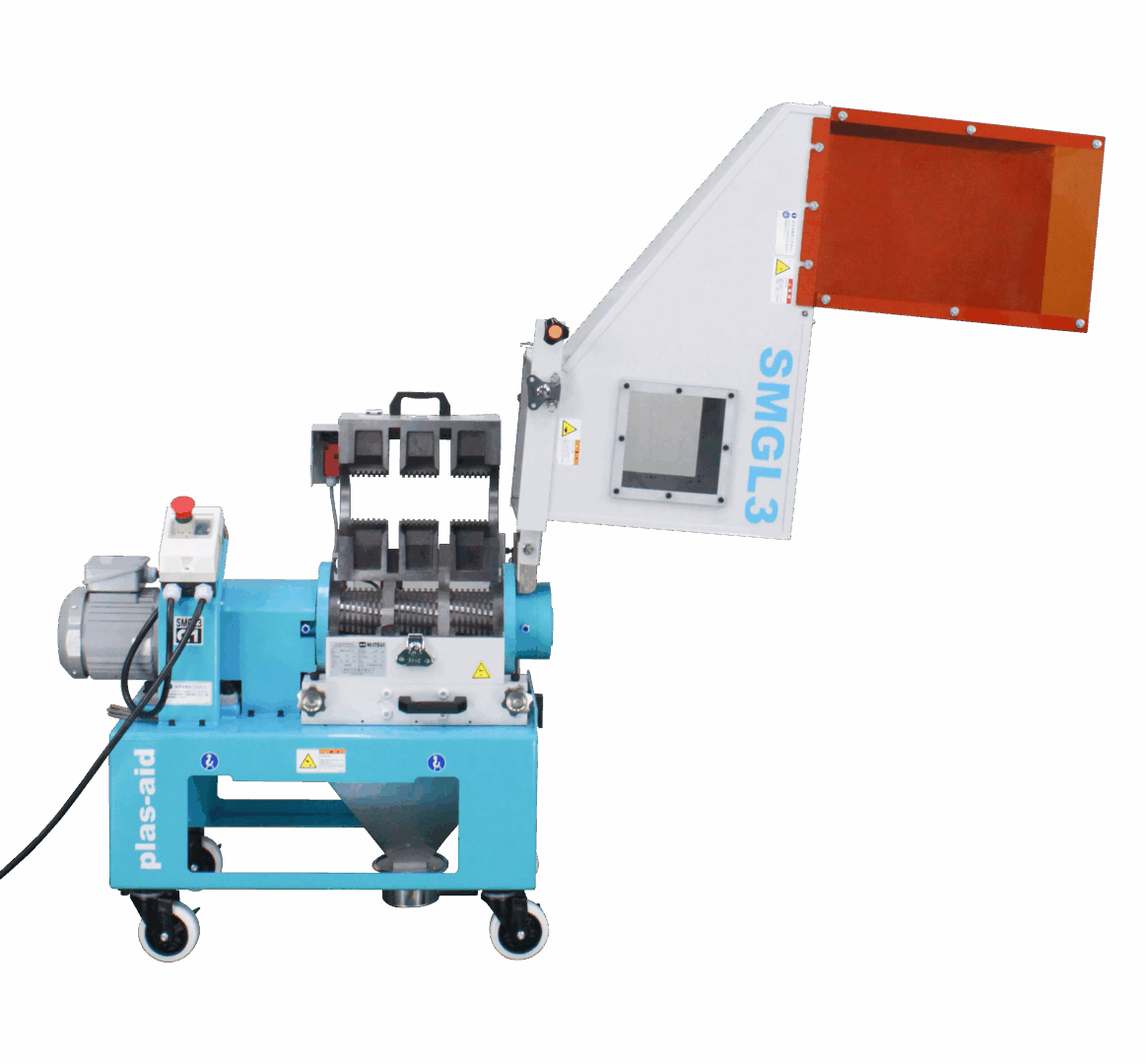

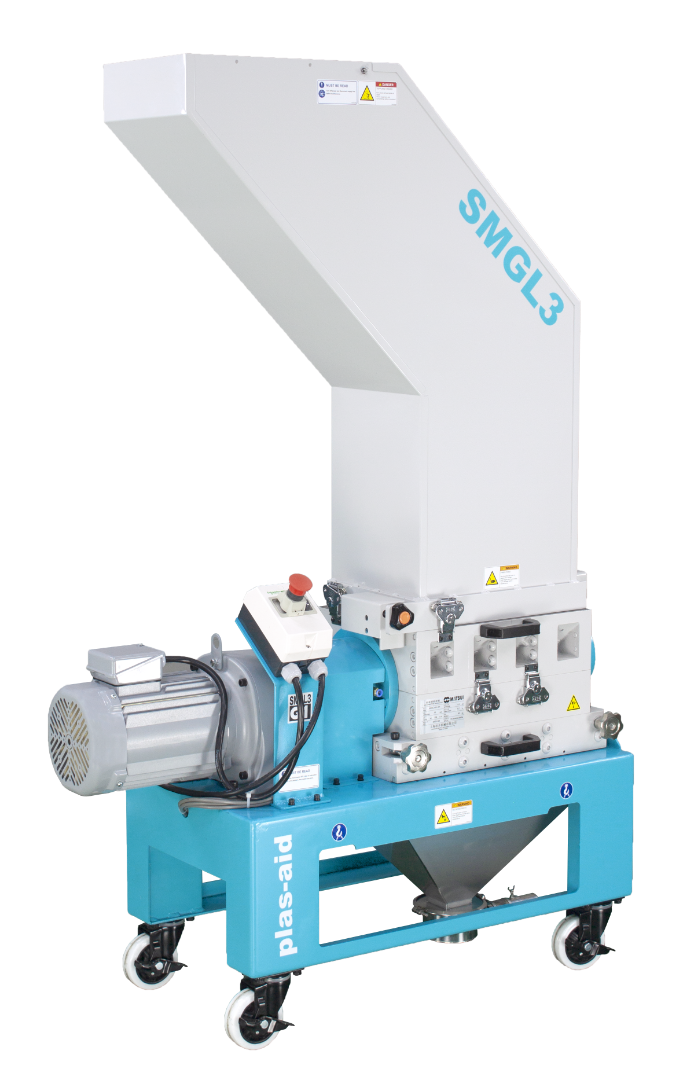

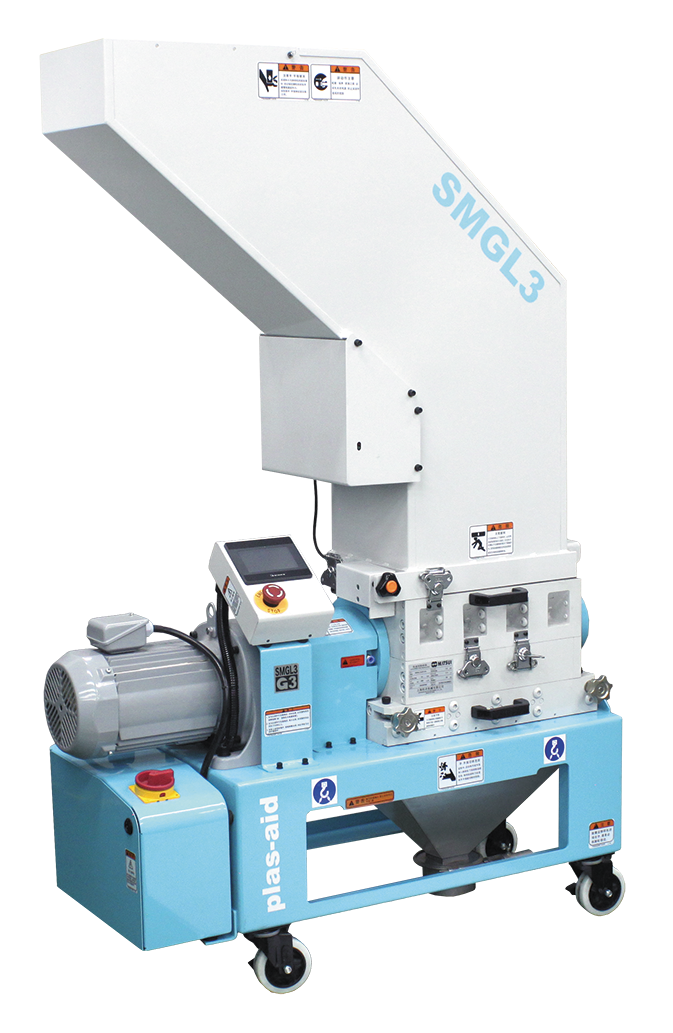

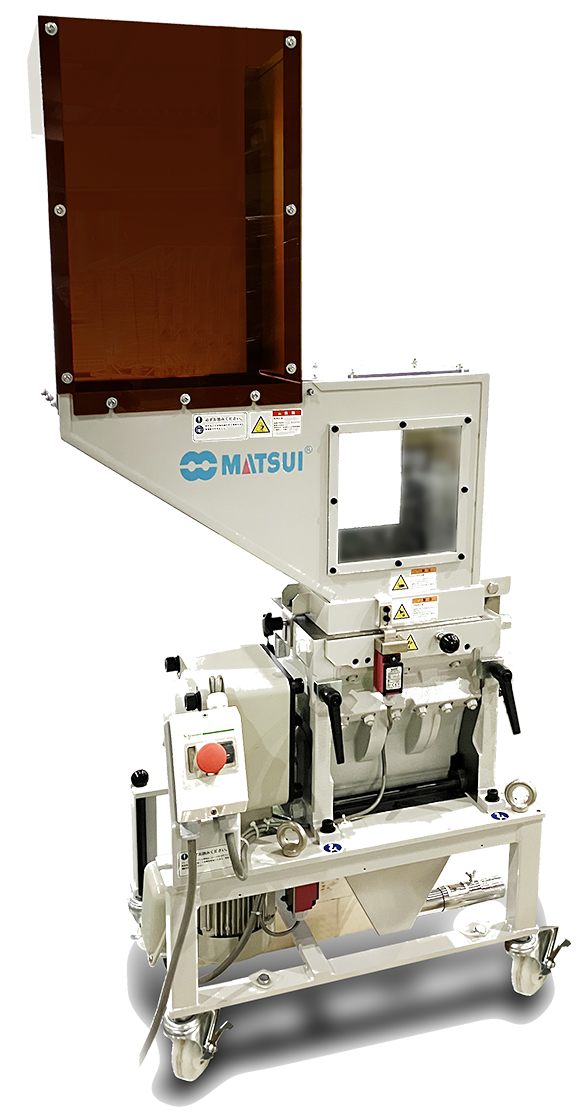

Plastic Granulators is the starting point for in-process recycling

Granulators are the starting point for this in-process recycling. They are not just a device for pulverizing materials, but are playing an increasingly important role as core equipment that supports resource circulation, stable quality, and improved production efficiency.

Granulators we will introduce below emphasize ease of use, safety, and maintainability on-site, and will help you create a workplace where sprues and runners are utilized as valuable resources.

[References] For more information, please see here

OECD: Global Plastics Outlook: Policy Scenarios to 2060

IMARC Group: Japan Recycled Plastics Market Report

Ministry of the Environment: Act on Promotion of Resource Recycling of Plastics

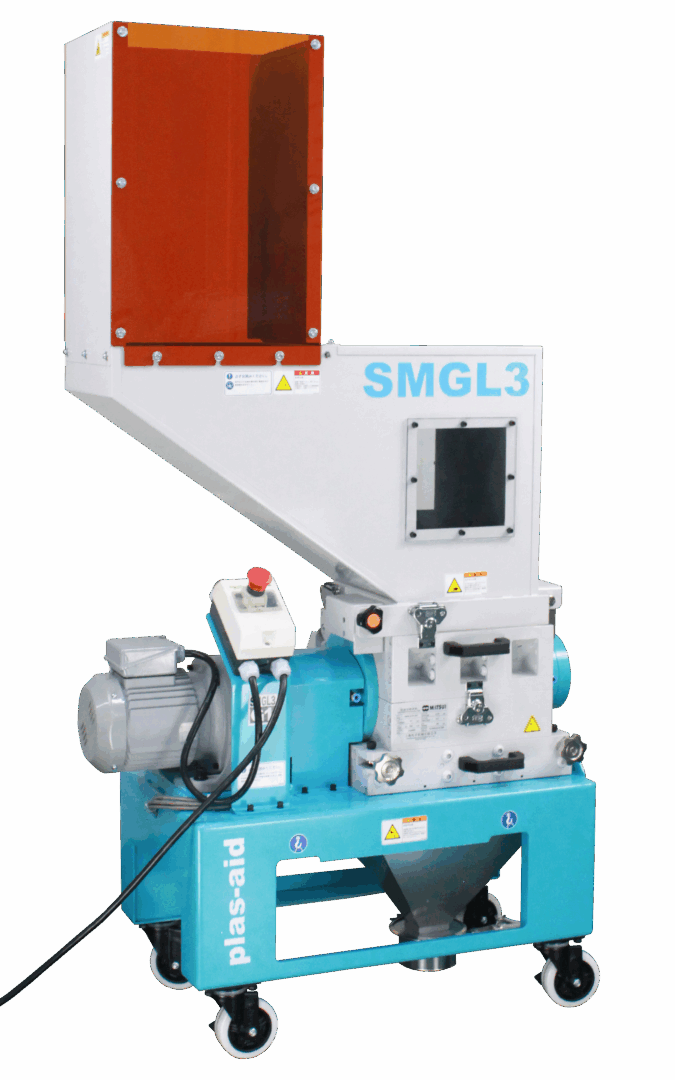

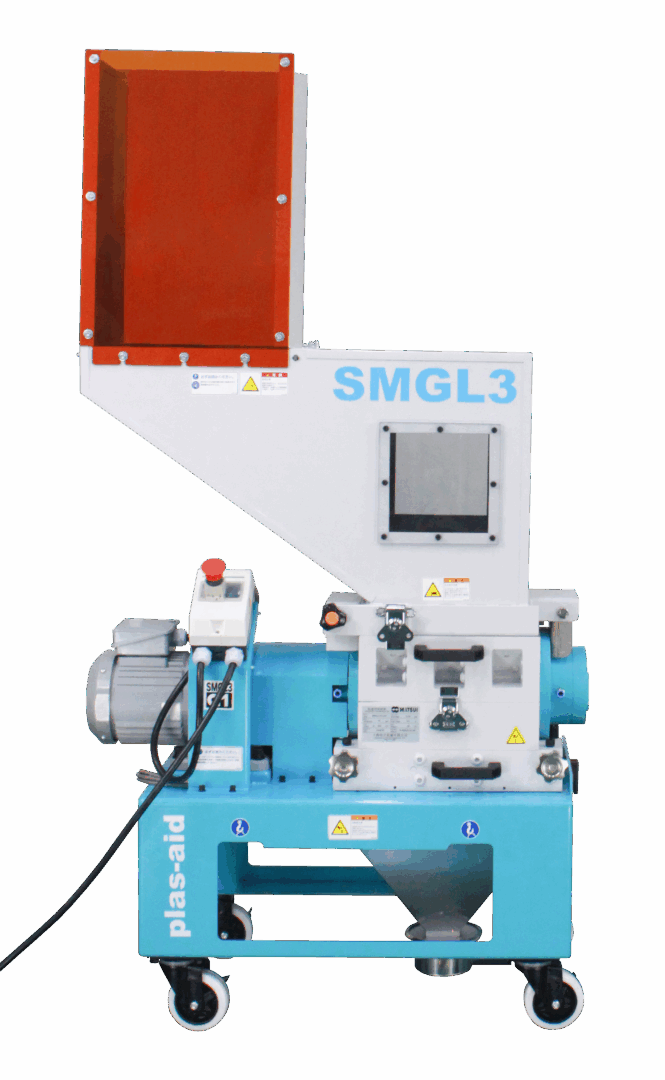

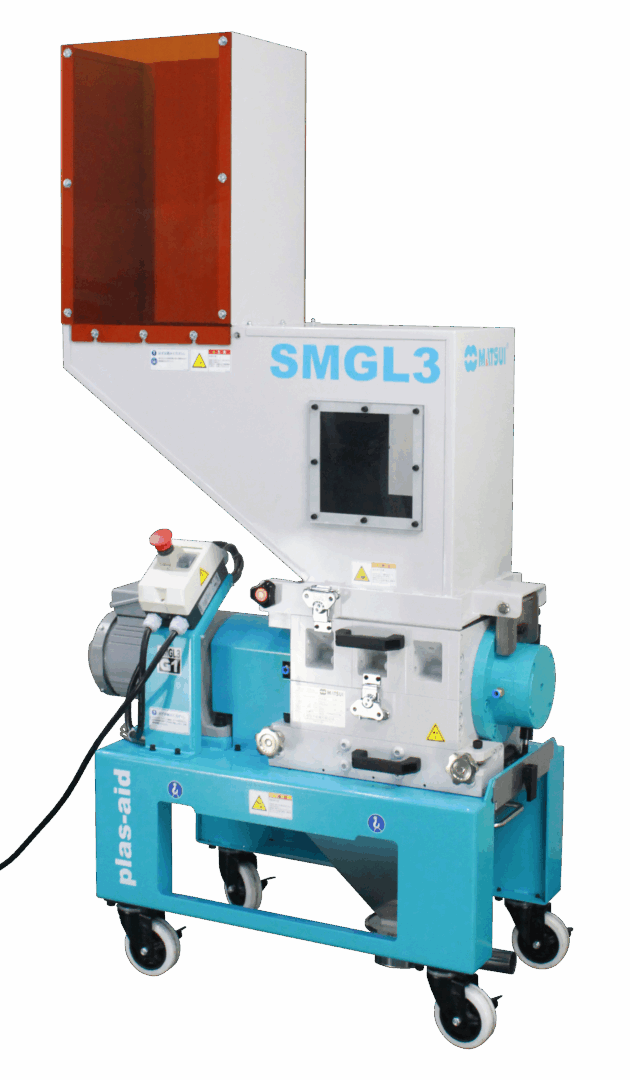

Features

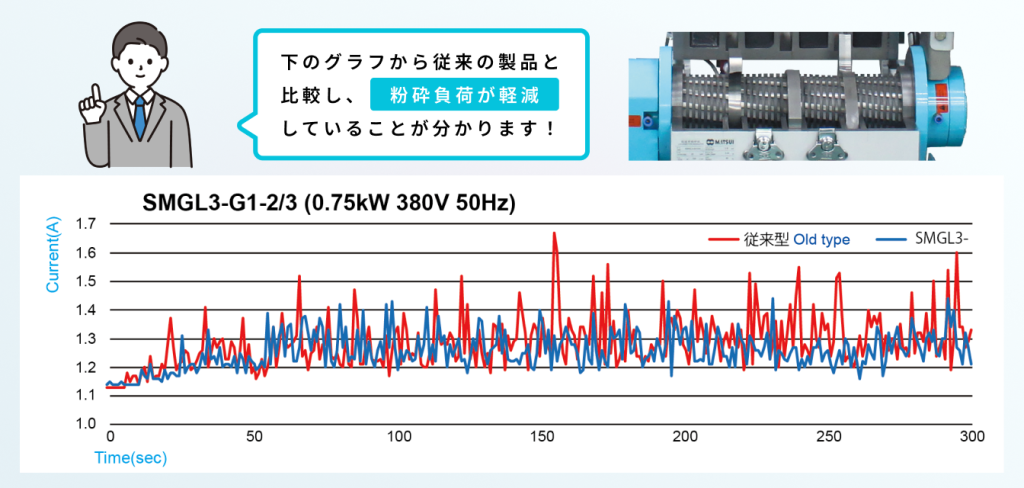

1. Newly designed cutter with sharp cutting edge for improved grinding accuracy

By adopting a newly designed cutter with a revised blade structure, we have achieved stable crushing and reduced crushing load.

In addition, the blades (fixed blade, fixed crushing blade, guide blade) can be used on both sides.

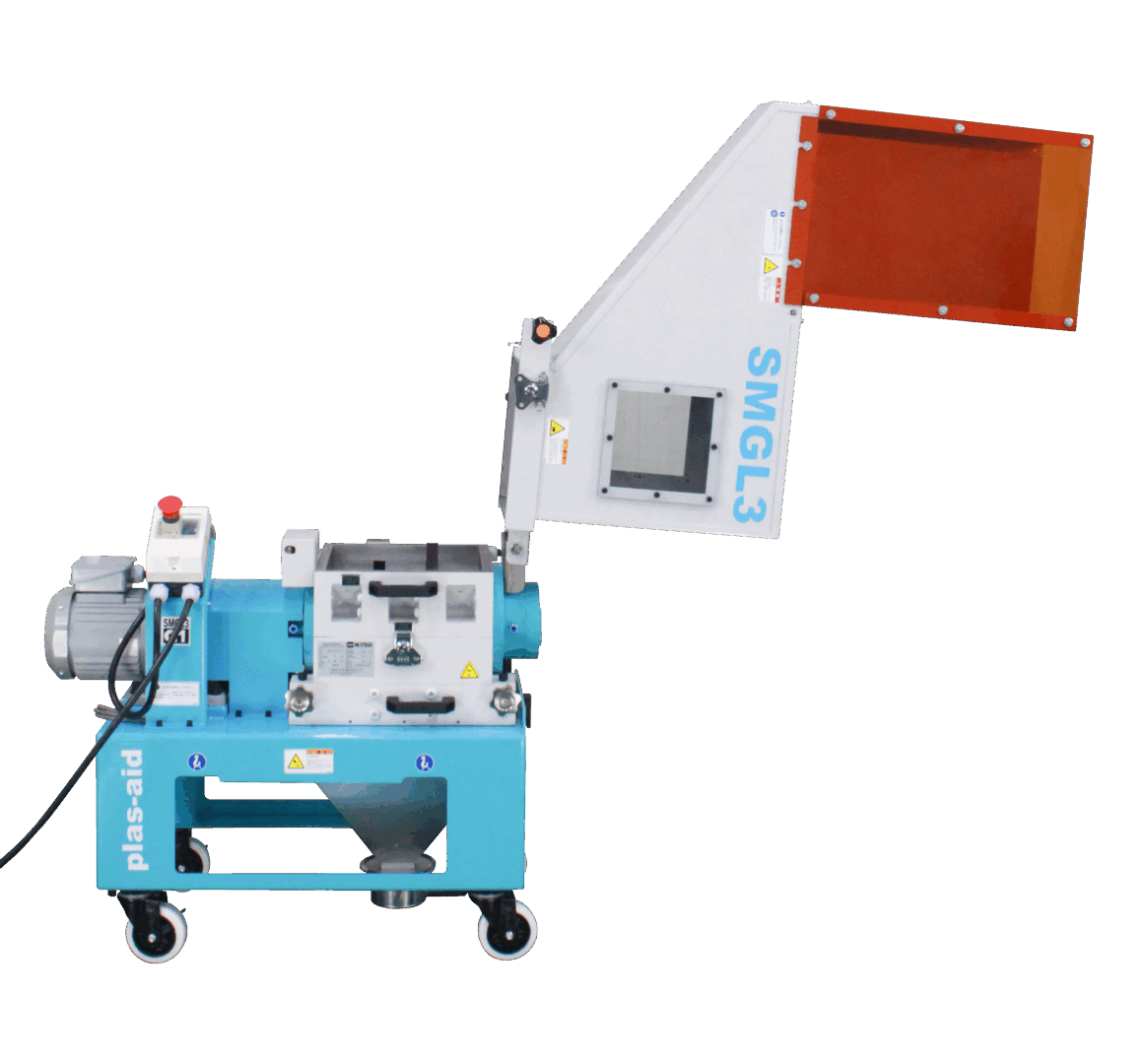

2. Three points to improve cleaning

💡One-way access structure

Even if Granulators is arranged next to the molding machine, it is possible to clean the entire Granulators. Conventionally, Granulators had to be moved forward in order to be cleaned, but the SMGL3 has a structure where the cleaning section can be opened completely from one side, making daily maintenance easier.

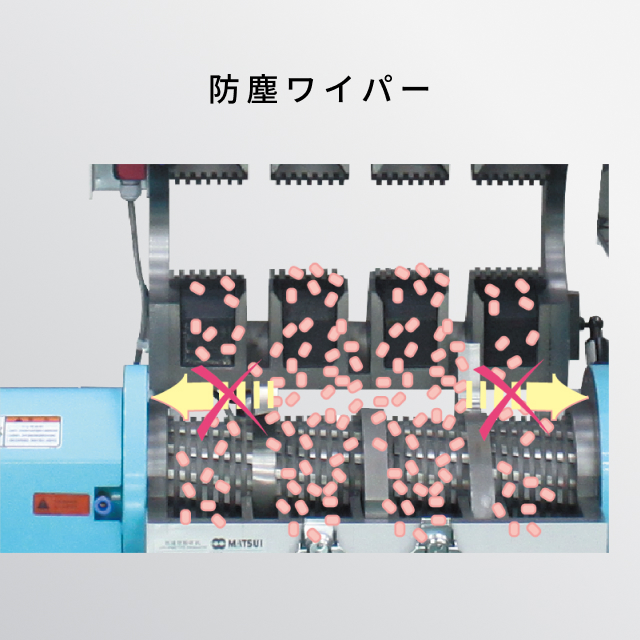

💡Dustproof wiper

Dustproof wipers are installed on the left and right sides of the chamber to prevent dust from entering the chamber. This prevents powder generated by grinding from getting into places where it is difficult to remove.

💡Double-sided cutter

The blade can be used on both sides to maintain sharpness and reduce dust generation.

3. Uncompromising Safety: Engineered for Peace of Mind

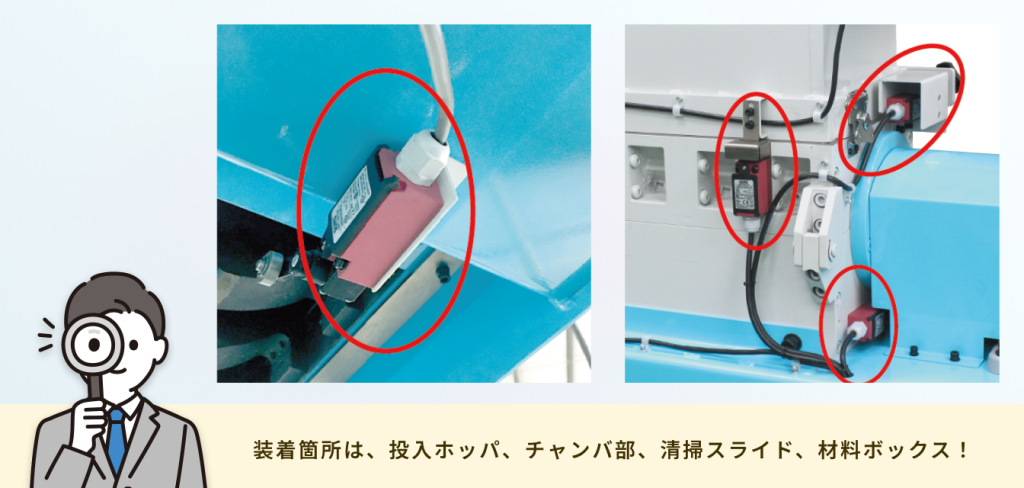

Equipped with safety limit switches in four locations.

4. More User-Friendly Operation

360-degree connectivity allows for seamless integration into any production layout, even in confined spaces. The suction box at the base features a secure locking mechanism and can be easily detached for quick maintenance.