プラスチック成形現場で変わり始めたリサイクルの考え方

リサイクルが前提となりつつあるプラスチック業界の現状

近年、環境負荷の低減や資源循環の観点から、プラスチックリサイクルへの取り組みが世界的に加速しています。大量生産・大量廃棄による環境問題への懸念が高まる中、プラスチック製品を製造するメーカーにおいても、原材料の選定から成形、使用後の再利用までを含めたライフサイクル全体での対応が求めれられるようになっています。3R(リデュース、リユース、リサイクル)の推進や再生材の活用を通じて、サーキュラーエコノミーへの転換が進められています。

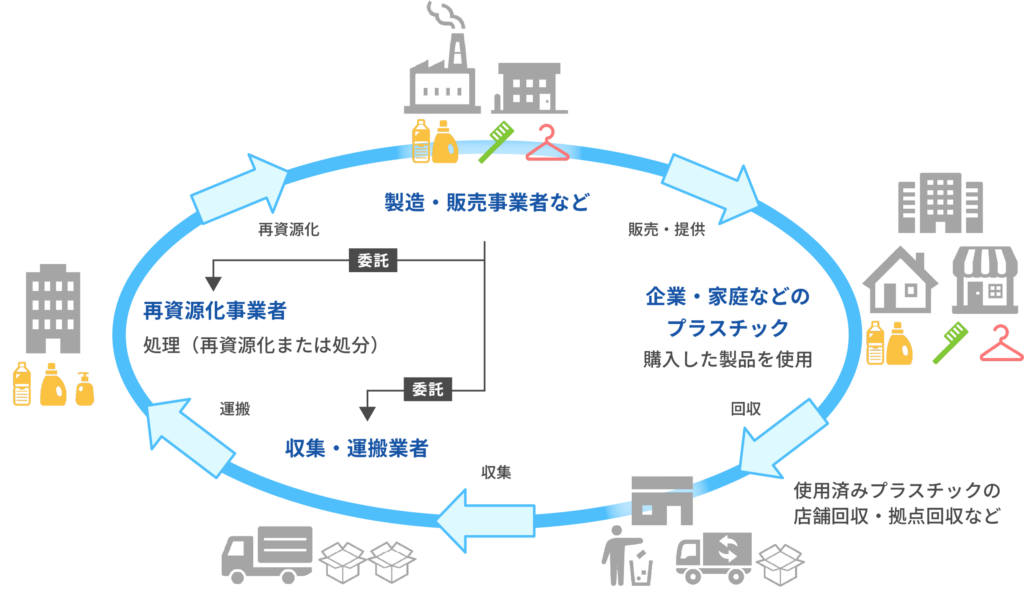

日本においては、2022年4月1日から「プラスチックに係る資源循環の促進等に関する法律(プラスチック資源循環促進法)」が施行され、製品設計から製造、使用、廃棄に至る各段階での資源循環の取り組みが、製造事業者にとっても重要な指針として位置づけられました。これにより、プラスチック製品を製造するメーカーには、再資源化を見据えた材料選択や、成形工程における廃プラスチックの排出抑制など、現場レベルでの対応が求められています。

このように、単なる廃棄物削減にとどまらず、成形現場で発生するプラスチックをいかに資源として活用していくかが、プラスチック製品製造メーカーにとって重要なテーマとなっています。

自動車業界から始まるプラスチック資源循環の新しい基準

ELV規則による廃車までを見据えたものづくりへ

自動車業界では、車両の製造から使用、廃棄に至るまでを一つの循環として捉える動きが促進されています。背景にあるのが、資源循環や環境負荷低減に対する会社的要請の高まりです。

こうした流れの中で注目されるのが、EUを中心に整備が進められているELV(End-of-Life Vehicles)規則です。ELV規則では、自動車の設計・材料選定の段階から、廃車のリサイクル性を高めることが求められており、特にプラスチック材料については、再生材の活用を前提とした考え方が明確に示されています。

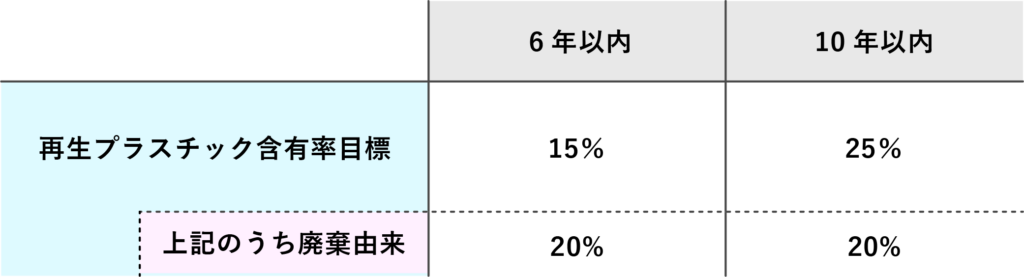

具体的には、規則の施行から6年以内に、自動車に使用されているプラスチックのうち最低15%を再生プラスチックにすること、さらに10年以内には25%まで引き上げることが求められています。加えて、その再生プラスチックの20%は、使用済み自動車や使用段階で取り外された部品など、廃車由来のリサイクル材を使用することが示されています。

このように、自動車業界では「どの材料を使うか」だけでなく、「使われた後にどう循環させるか」までを含めた材料運用が重要となりつつあります。これは自動車メーカーだけの課題ではなく、プラスチック製品を成形・供給するメーカーにとっても、今後のものづくりを考える上で無視できない動向です。

成形できるかどうかにとどまらず、成形工程で発生するプラスチックをどのように管理し、再利用につなげていくのか。その姿勢そのものが、材料選定や成形プロセスの評価につながる時代に入り始めています。

成形現場から始まるリサイクル

こうした資源循環の流れを受け、プラスチック製品を扱うメーカーにとっても、「自社で何ができるのか」を考えることが重要になっています。一方で、成形品そのものを粉砕・再生する工程については、専門業者に委託しているケースが大半です。

そこで改めて注目したいのか、成形工程で日常的に発生するスプル―やランナーです。これらは最終製品にはならないものの、材質は成形品と同一であり、適切に粉砕・管理することで、再び材料として活用することが可能です。

成形品のリサイクルは外部に委ねる一方で、スプルー・ランナーであれば成形現場の判断と運用によって、無理なく社内リサイクルを始めることができます。スプル―・ランナーを「廃棄物」として処理するのではなく、「再利用できる資源」として捉うことで、材料ロスの削減やコスト低減、さらには環境負荷の低減にもつながります。

このように、成形工程に目を向けることは、資源循環への取り組みを現場レベルで具体化していくうえで、有効な手段といえます。

ランナーのリサイクルを支える粉砕工程の重要性

スプルー・ランナーを再利用するためには、単に粉砕すればよいというわけではありません。粒度のばらつきや粉塵の発生、異物混入などがあると、成形品質の低下や設備トラブルにつながる恐れがあります。

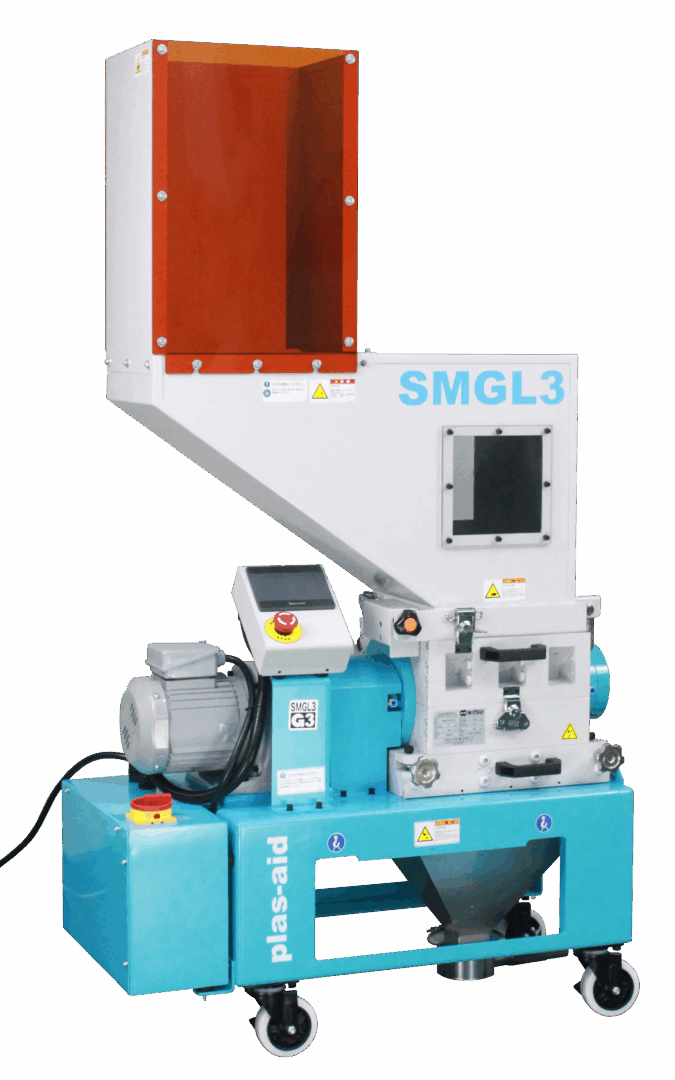

そのため、成形工程で発生するスプルー・ランナーを安定した再生材料として活用するには、適した粉砕条件で、均一に処理することが重要です。こうした課題に対応するために設計されたのが、弊社の低速粉砕機「SMGL3」です。

特長

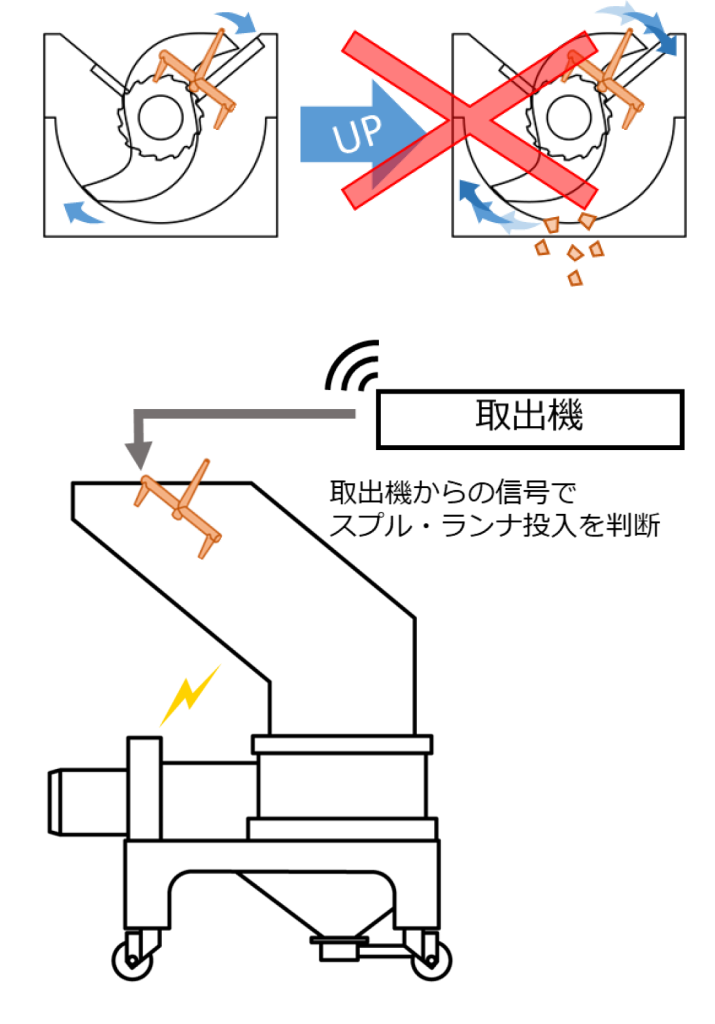

1.切れ味を追求した新設計カッターで粉砕精度UP!

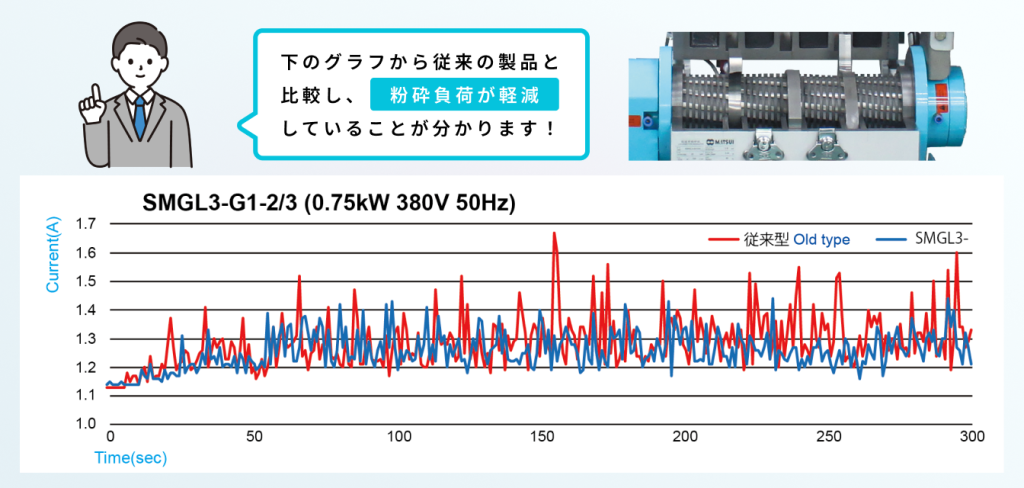

刃の構造を改めた新設計カッターの採用により、安定粉砕と粉砕負荷の緩和を実現しました。

また、刃物(固定刃、固定荒砕刃、ガイドブレード)は、両面使用が可能です。

2.清掃性を向上させる3つのポイント

💡一方向アクセス構造

粉砕機を成形機に沿わせたレイアウトであっても、粉砕機全体の清掃を行うことが可能です。従来は粉砕機を手前に移動しなければ清掃できませんでしたが、SMGL3は一方向から清掃部が全て開く構造のため、日々のメンテナンスが行いやすくなっています。

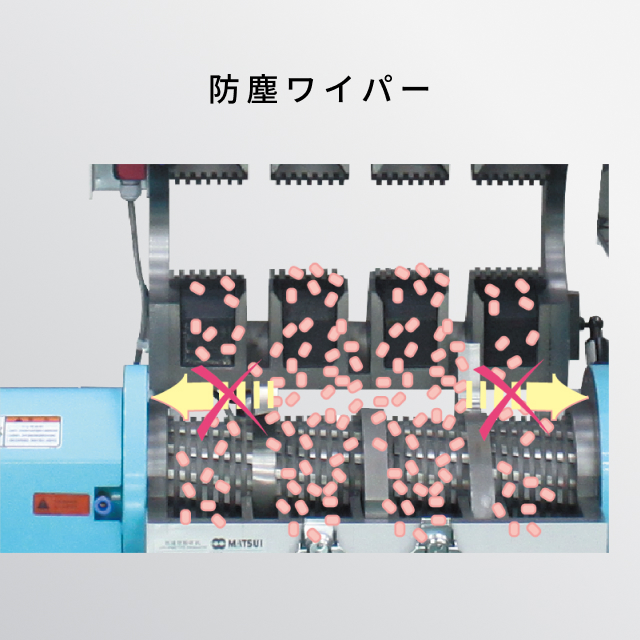

💡防塵ワイパー

チャンバーの左右には防塵ワイパーを装備し、チャンバー外への塵の侵入を防ぎます。そのため、粉砕によって発生した粉が除去しにくい場所に入り込むことがありません。

💡両面カッター

両面使用することのできる刃で切れ味を保ち、粉発生を抑制します。

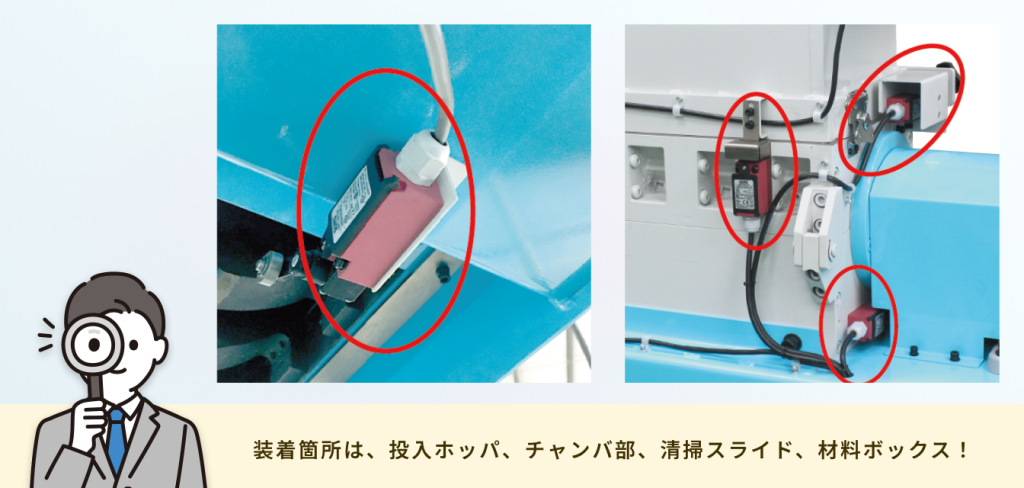

3.安全性は抜群です!

安全リミットスイッチを4カ所に装備しました。

4.使い勝手が向上しました!

輸送先へ360度どこからでも接続することが可能です。限られたスペースでもご安心ください。機体下部にある吸引ボックス(ロック付)は、簡単に脱着することができます。

高付加価値モデルSMGL3-G3のここがすごい!

こんなお困りごとありませんか?

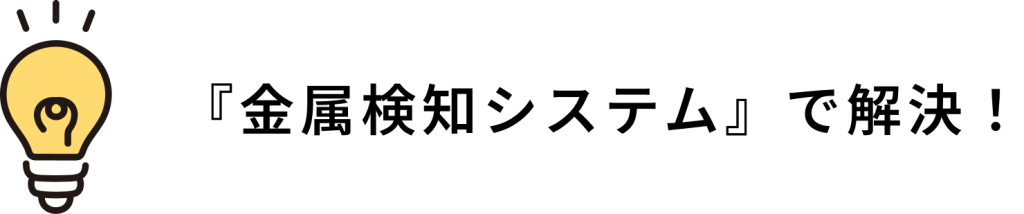

SMGL3は取り出し機と連動させることで、材料の投入状況を検出することが可能です。

スプル・ランナの投入後、機器内のブリッジ発生やアイドル状態の継続などにより、粉砕刃の回転数が低いままの場合は、未粉砕であることを検知し警報でお知らせします。

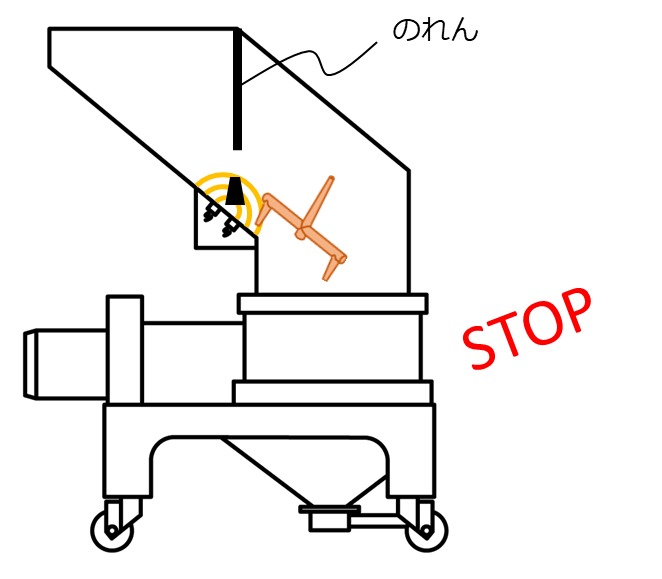

金属検出用の静電容量式センサで通過する金属異物を検出し、停止かつ報知機器を保護します。また、スプル・ランナが投入ホッパ内を移動することにより、検出範囲に入らないといった心配も、飛散防止用ののれんに当り、投入ホッパを滑るように落下するため問題ありません。多くのスプル・ランナは、検出範囲を通過し、金属異物を検出します。(受注対応)

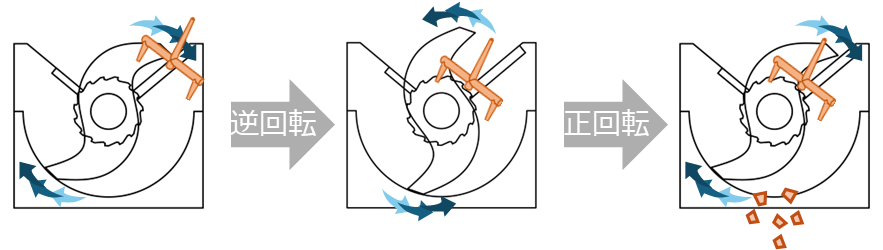

消費電力から過負荷を検知したとき、スプル・ランナが噛み込んだと判断し、粉砕刃を逆回転させ、再び正回転させて粉砕にリトライします。噛み込みが解消されると、通常の粉砕を継続する仕組みです。

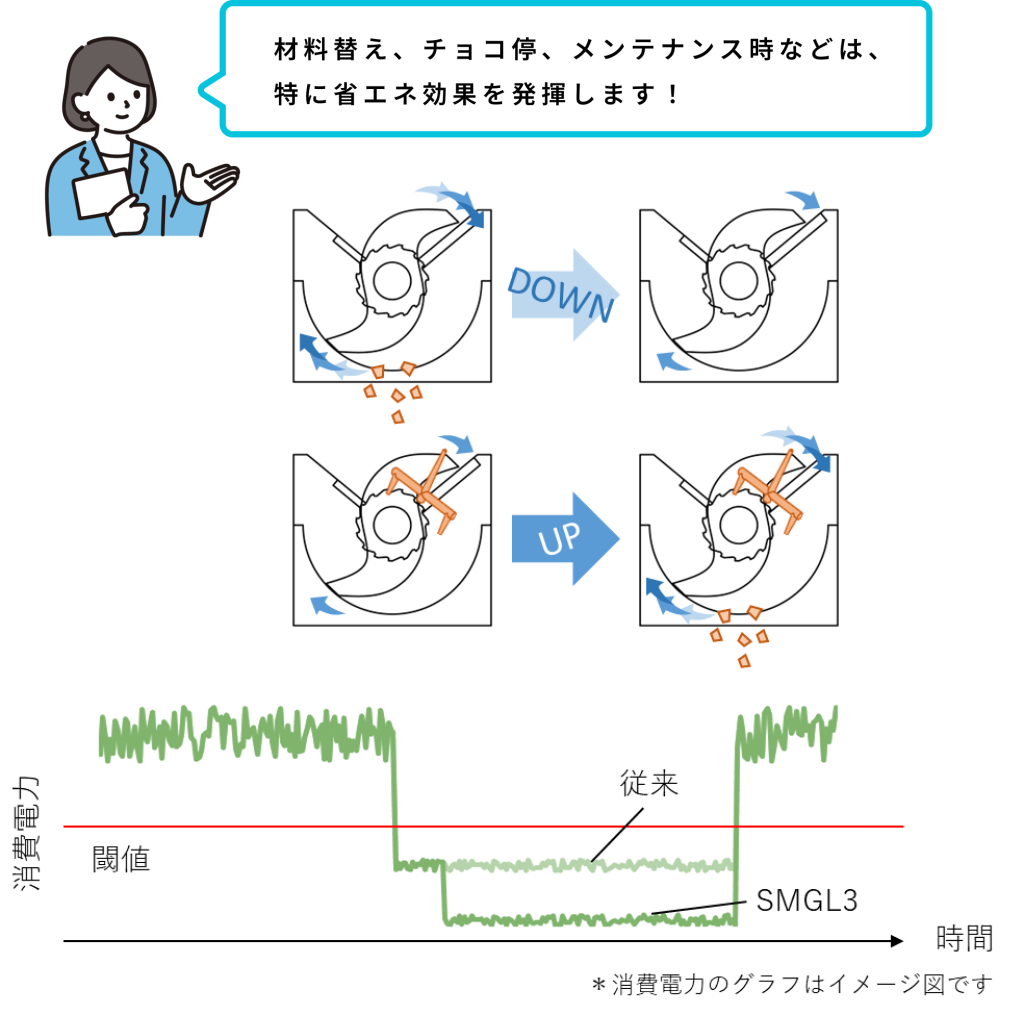

消費電力から無負荷を検知した際は、スプル・ランナがないと判断し、粉砕刃の回転数を下げます。そして、消費電力から再び負荷を検知した際は、スプル・ランナが投入されたとみなし、粉砕刃の回転数を上げます。