Aiming for factor4 of molding factories

Proposing countermeasures against gas, the great enemy of molding, and new mold cleaning methods.

2022.05.16

Trouble caused by gas

In plastic injection molding, the gas generated from resin is extremely troublesome.

Gas is generated not only when the resin is injected into the mold, but also when it dries or melts in the cylinder, causing various troubles. The true nature of this gas is the additive contained mainly in the resin. Additive components such as stabilizers, antioxidants, lubricants, flame retardants, plasticizers, and antistatic agents vaporize when the resin is Overheat to generate gas.

What kind of effect does the gas generated in this way have on molded products and equipment? Let's look at an example of trouble caused by gas.

Molding defects

The most urgent need to deal with gas problems is molding defects. Gas burning, which causes a part of the molded product to carbonize and turn black, and short shots (poor filling) are especially big problems.

In addition, silver streak (silver streaks), which causes a glittering streak pattern on the surface of the molded product, is also one of the molding defects caused by gas.

Problems caused by gas often occur when the molding conditions are stable and production is on track, so it can be said to be a great enemy in mass production processes that require long-term continuous molding.

Equipment trouble

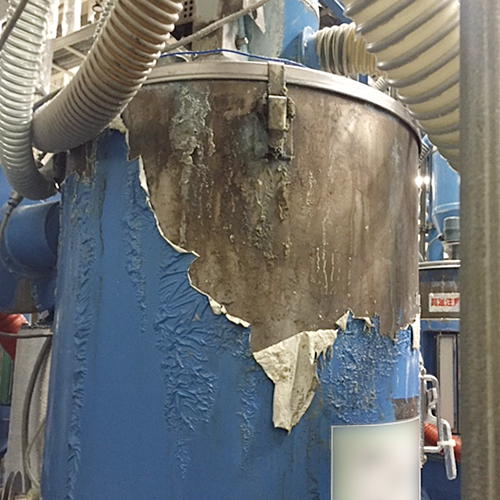

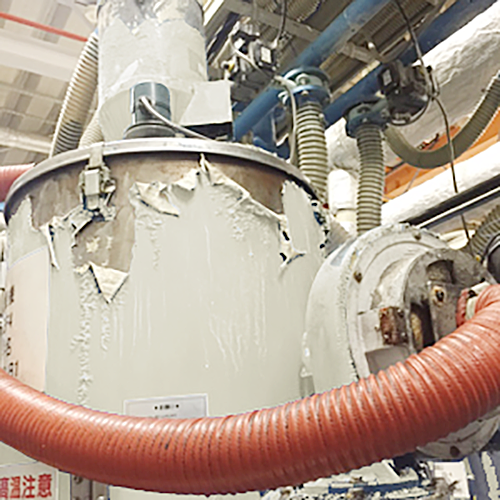

Gas is also generated when the resin is dried. Vaporized gas exits the dryer exhaust and adheres to the walls, ceilings and equipment of the molding factory, where it crystallizes or solidifies.

In addition, the mold release agent may volatilize and adhere to the surface of the device, causing the paint to peel off.

These lead to the deterioration of the molding factory environment and the contamination of foreign matter.

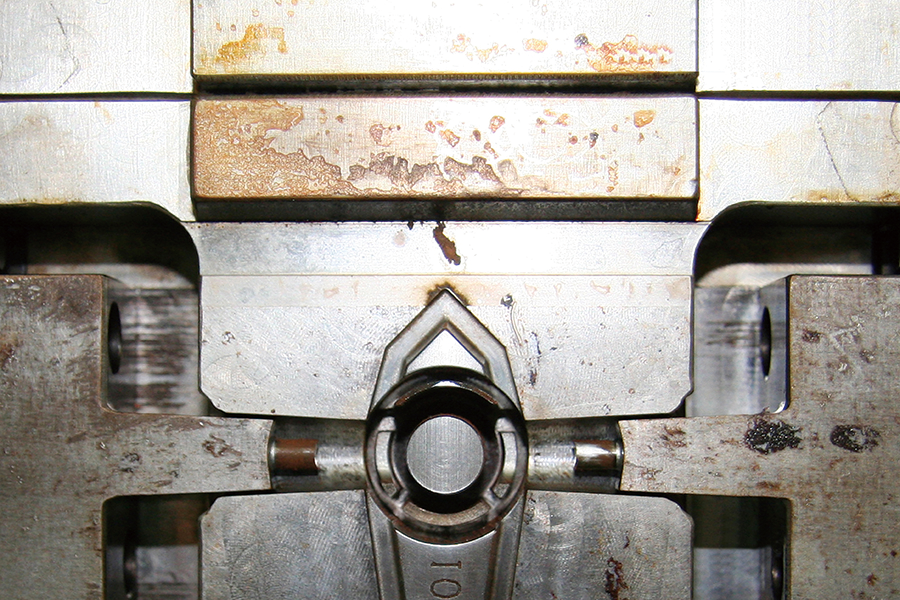

mold trouble

The solidification of the gas adhering to the mold may clog the gas vent and cause a short shot, or the surface of the molded product may become cloudy or foreign matter may adhere to it.

There is also a risk of damaging the mold if the gas is left unattended. To prevent this, the mold must be cleaned, but it takes Emergency lot of time and effort to remove the mold from the molding machine, disassemble and clean it, which is a major factor in reducing productivity. increase.

Approach to gas measures

Since the additive, which is one of the causes of gas generation, is contained in the resin itself, it is not possible to take fundamental measures at the molding factory. Therefore, it is common to take measures by adjusting the molding conditions, such as installing a vent in the mold that allows gas to escape easily, adjusting the gate position, or lowering the injection speed. However, once mass production begins, it is difficult to change the conditions, and there are limits to the countermeasures.

Therefore, MATSUI proposes solutions from the three perspectives of "suppressing gas generation," "collecting gas," and "removing gas adhering to molds."

Suppresses gas generation

The first thing to consider as a gas countermeasure is to suppress the generation of gas itself. For that purpose, proper material drying is important.

Thermal Fin Vacuum Dryer DPD3.1The can dry the resin at a low temperature by putting it in a vacuum state, so it is possible to suppress the generation of gas due to overheating. Furthermore, by combining the small Thermal Conduction Dryer PMD and the nitrogen (N2) generator, not only the water in the resin that causes gas during drying is removed, but also oxygen is replaced with nitrogen for stable molding. Make it possible.

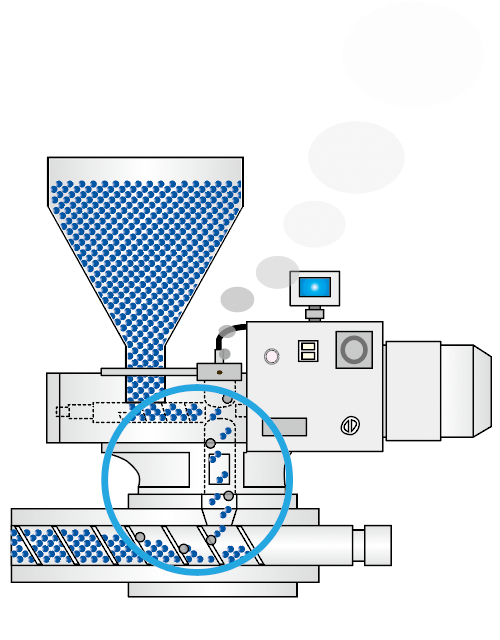

Gas is also generated when the resin is melted in the screw. Since the resin put in the hopper is supplied into the cylinder by its own weight, the inside of the screw is usually filled with resin, and the heat generated when kneading with the screw (shear heat generation). ) Generates gas. In addition, there is no escape for the generated gas, which leads to trouble.

The raw material fixed quantity supply device (Starved feeding device) reduces the density by supplying a fixed amount of resin into the cylinder and suppresses the generation of gas. Since there is room in the cylinder, it promotes the release of water and gas. By forcibly sucking the gas that has become easy to escape in this way, it is possible to efficiently eliminate it.

recover gas

Even if all the measures mentioned above are taken, the generation of gas cannot be completely prevented. Therefore, the next effective measure is to "recover the generated gas."

Generally speaking, gas recovery is a method of adding a gas vent to the runner part or mold of the molded product to let the gas escape. However, if this gas vent is clogged with gas, it may cause troubles such as molding defects.

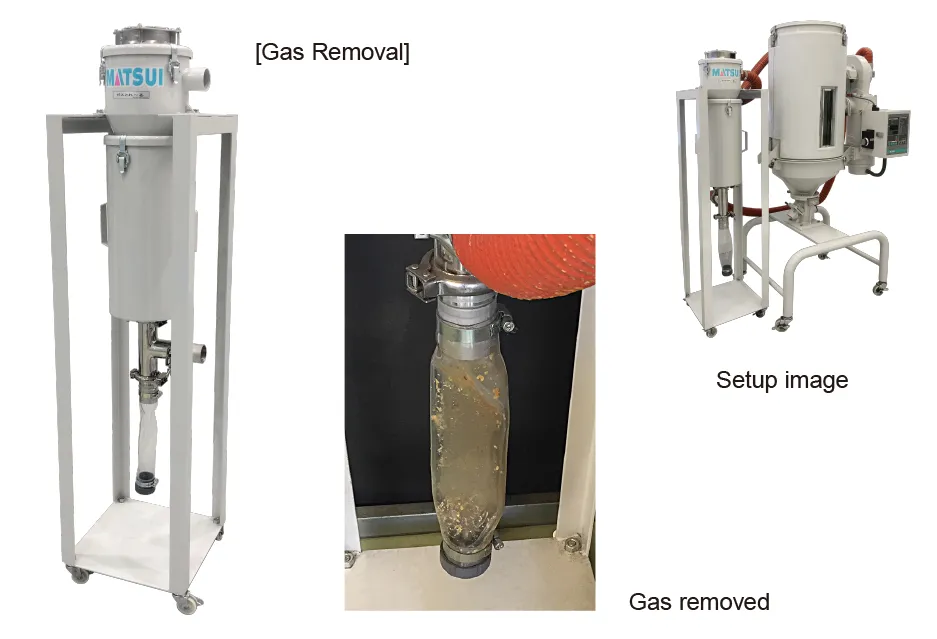

Indirect cooling gas recovery equipment is useful there. By attaching this device to the exhaust line of the dryer, it is possible to cool, solidify, and recover the gas generated from the resin. This prevents the generation of gas in the molding process and prevents the crystals of gas components from adhering to the periphery of the dryer.

There is also a mold gas suction device that prevents gas from adhering to the mold.

This is a device that is connected to the gas vent of the mold and sucks out the gas inside the mold by applying suction when the mold is closed. This action reduces the clogging of the gas vent and the adhesion of gas to the mold, and eliminates the need for frequent mold maintenance, which extends the interval between maintenance and is expected to improve productivity.

⇒ MAG

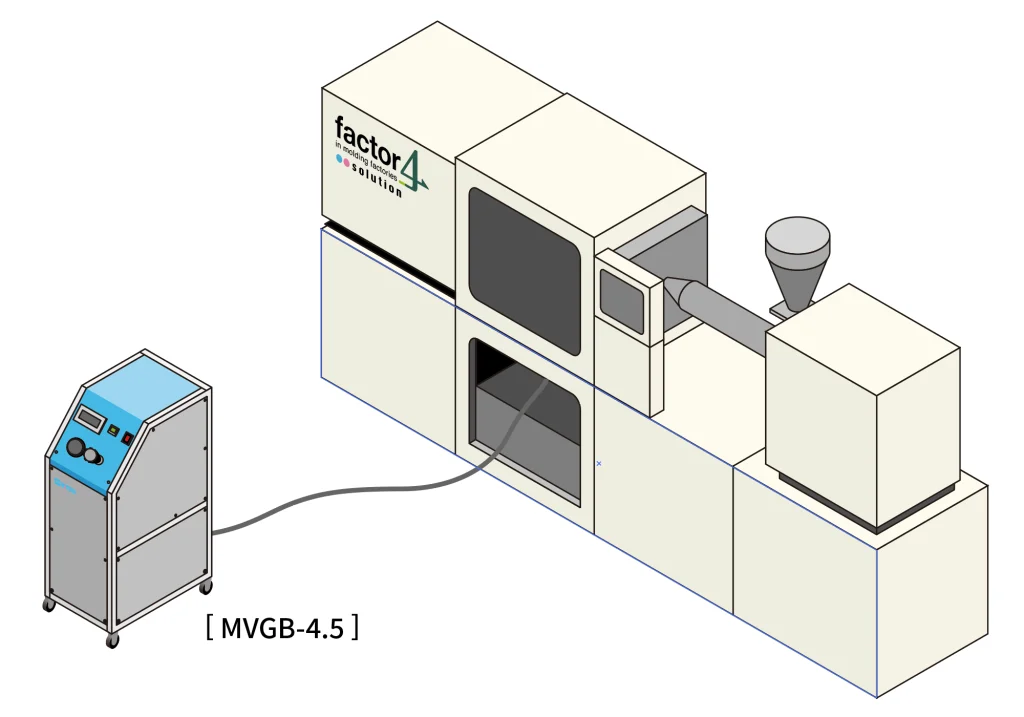

Furthermore, the gas booster with a vacuum pulling function not only Suction gas by vacuum, but also boosts the pressure up to 4.5MPa when pressurizing, and backwashes the gas vent and porous part to prevent clogging of the gas vent. It is also possible to reduce the number of extrusion pins by using pressurized air to assist mold release.

Removal of mold adhesion gas

Even after suppressing and recovering gas generation, unprevented gas may adhere to the mold. Next, we will introduce a solution that allows easy, quick, and safe maintenance for this "removal of gas adhering to molds".

mold cleaning

When gas components adhere to the mold, the first thing that is done is hand cleaning. The flow is to open the mold while it is still on the molding machine and wipe it off with a parts cleaner (organic solvent) and a waste cloth.

For medium to heavy adhesion that cannot be helped by manual cleaning, remove the mold from the molding machine, disassemble it, and then perform ultrasonic cleaning, bead blast cleaning, and sand blast cleaning.

Ultrasonic cleaning is a method in which molds and pieces are placed in an alkaline cleaning solution, and dirt is lifted by ultrasonic vibrations and pressure changes. Dirt can be removed even in complex shapes that cannot be reached by hands or brushes.

Bead blast cleaning and sand blast cleaning are cleaning methods that remove dirt from the mold by blowing media containing abrasives with compressed air inside the chamber (booth). Various effects can be expected by selecting the size and material of the particles without using chemicals such as solvents.

Problems with conventional mold cleaning

In fact, there are problems with the conventional cleaning methods.

hand wash

You cannot work until the mold has cooled. Also, be careful as it will damage the mold if you do not use the proper tools. Since it uses an organic solvent, it may affect the human body.

Ultrasonic cleaning

A large amount of cleaning liquid is required, and it takes time and effort to replace the cleaning liquid. You also need a cleaning tank that is sized to fit the required area. Since the cleaning solution is alkaline, it not only puts a burden on the human body and the environment, but can also affect parts.

Sandblast / bead blast cleaning

The beads used for cleaning become industrial waste, and since it is a physical processing method, the surface of the mold is worn. In addition, it is necessary to install a chamber necessary for cleaning, and management such as securing work space and cleaning is necessary.

■ Comparison of issues with each cleaning method

| Cleaning method | Abrasiveness | Secondary waste | Workload |

| sand blast | can be | can be | big |

| Bead blast | can be | can be | big |

| Ultrasonic cleaning | none | can be | big |

| Hand wash | none | none | big |

All of these not only have issues, but also involve the process of removing the mold from the molding machine, disassembling it, cleaning it, reassembling it, and putting it back on the molding machine. This is a huge waste of time and greatly impacts productivity.

New mold maintenance

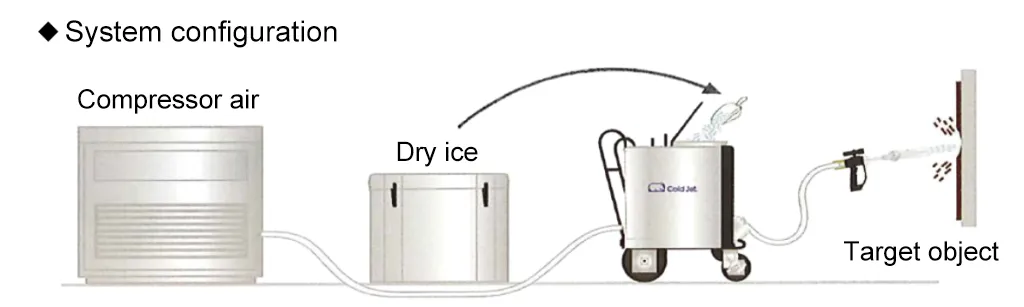

The solution proposed by MATSUI is dry ice blast cleaning, which has high detergency while overcoming the above issues.

dry ice blast cleaning

In this method, dry ice is sprayed onto the object to be cleaned, and its explosive force is used to clean the object.

With this cleaning method, it is possible to work while the mold is still attached to the molding machine, which greatly reduces wasted time required for cleaning.

In addition, since dry ice is carbon dioxide itself, it is friendly to the human body and the environment and does not generate waste. Furthermore, it has no abrasiveness and can be cleaned without damaging the mold.

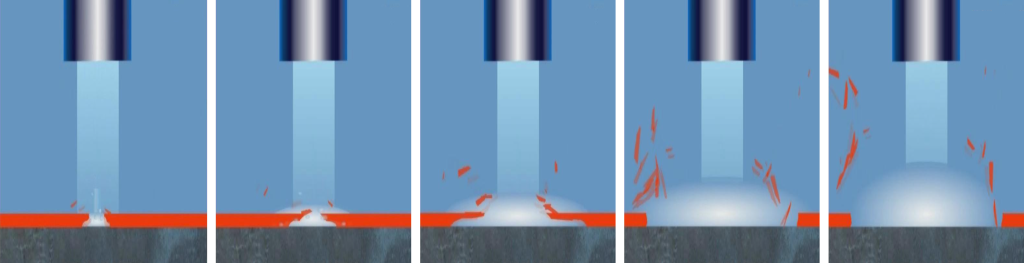

Washing principle

The principle of dry ice blast cleaning consists of three elements: impact, temperature difference, and small explosion.

First, dry ice is hit against the object at supersonic speed to give a shock. Next, because dry ice has a low temperature of about -80 degrees Celsius, the temperature difference causes a difference in shrinkage rate, and foreign matter floats up.

Finally, when dry ice sublimates and turns into a gas, its volume expands about 800 times, and its small explosion removes foreign matter.

Since no chemicals that attack the mold are used, it can be used with molds made of any material.

⇒Dry ice blasting

Further effects can be achieved by using dry ice with different shapes and sizes depending on the application, such as shaving powder-like dry ice for finely processed surfaces and pellet-like for stubborn stains. We also have a wide variety of nozzles.

It's a waste just to clean the mold!

Dry ice blast cleaning can be used not only for molds, but also for cleaning screws, Mixing blade, and painting lines. In addition, deburring of molded products and Interlock with automatic machines can be used for unmanned degreasing, which has a wide range of uses.

Summary

There is more than one way Resolve problems caused by gas. Depending on each problem, it is necessary to select the appropriate method according to the situation, such as suppressing gas generation, removing generated gas, and removing gas that has adhered.

MATSUI proposes various solutions to increase the productivity of the injection molding process. Please feel free to contact us.

CX Design Department Yasuhiko Iijima